Electric

VLSI Design

System

Tutorials

from CMOSedu.com (Return)

Tutorial

6 Ė Placing circuit layouts in a padframe

for

fabrication

In this tutorial

weíll take the circuits we designed in the previous tutorials and place

them on

a simple padframe for

fabrication.

To begin this tutorial, use Electric to open the jelib we created in tutorial 5, tutorial_5.jelib (right click to save to C:\Electric).

Save this library

as tutorial_6.jelib, again in C:\Electric.

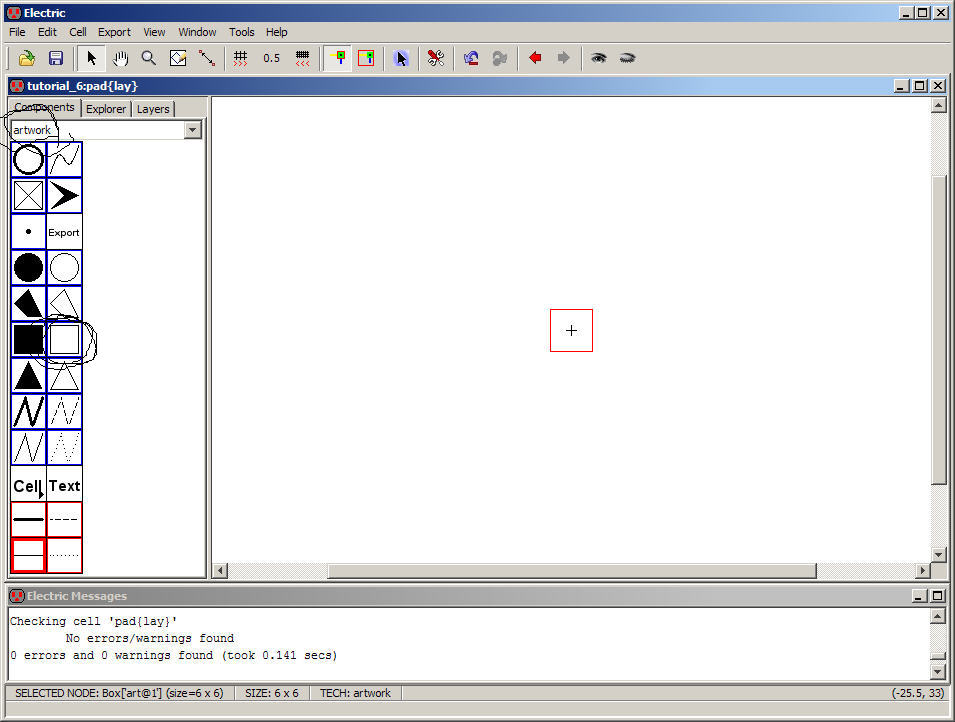

Create

the layout view of a cell called ďpad.Ē

Go

to the artwork menu and select/place a Box as seen below.

Our

setups were created in Tutorial

1 using in On Semiconductorís C5

process and

fabrication through MOSIS.

Further,

this process uses the MOSIS scalable CMOS (SCMOS) submicron design rules.

A

tiny chip fabricated in this process via the MOSIS Educational Program

(MEP)

measures 1.5 mm by 1.5 mm.

Information

about the MOSIS Educational Program (MEP) is found here.

We

need to determine the size of the Pad cell above.

The

scale factor (lambda) used in these setups is 300 nm so a layout that

measure

5000 by 5000 is 1500 um by 1500 um (1.5 mm = 1500 um)

If

we have 12 cells on a side (10 plus two corners) then each cell must be

5000/12

or 416.66.

Weíll

round this down to 400 to ensure our chip is a little smaller than the

maximum

size of 1.5 mm square.

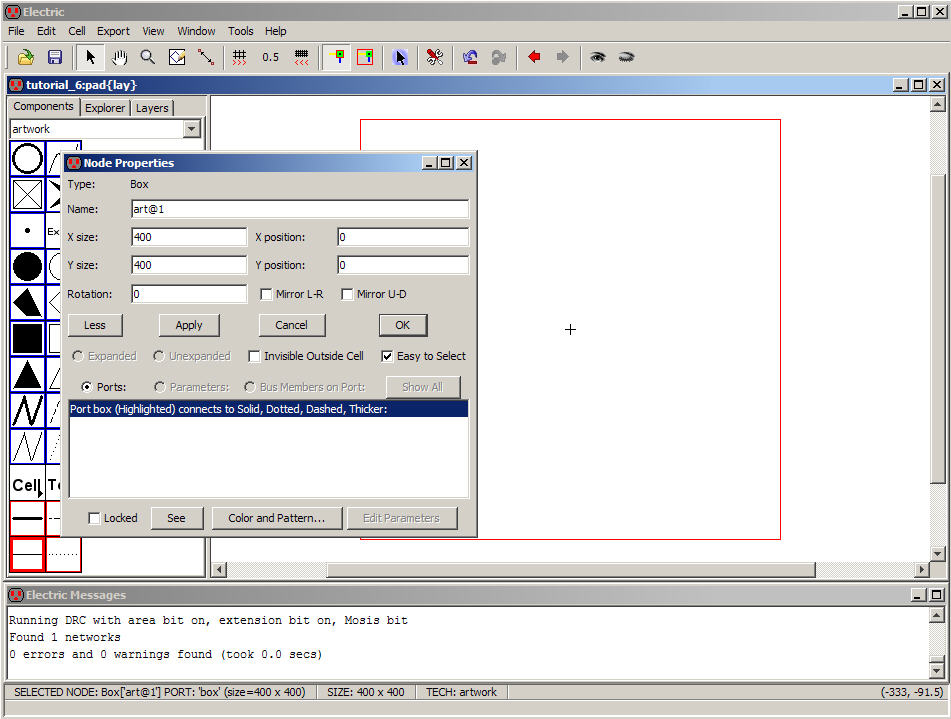

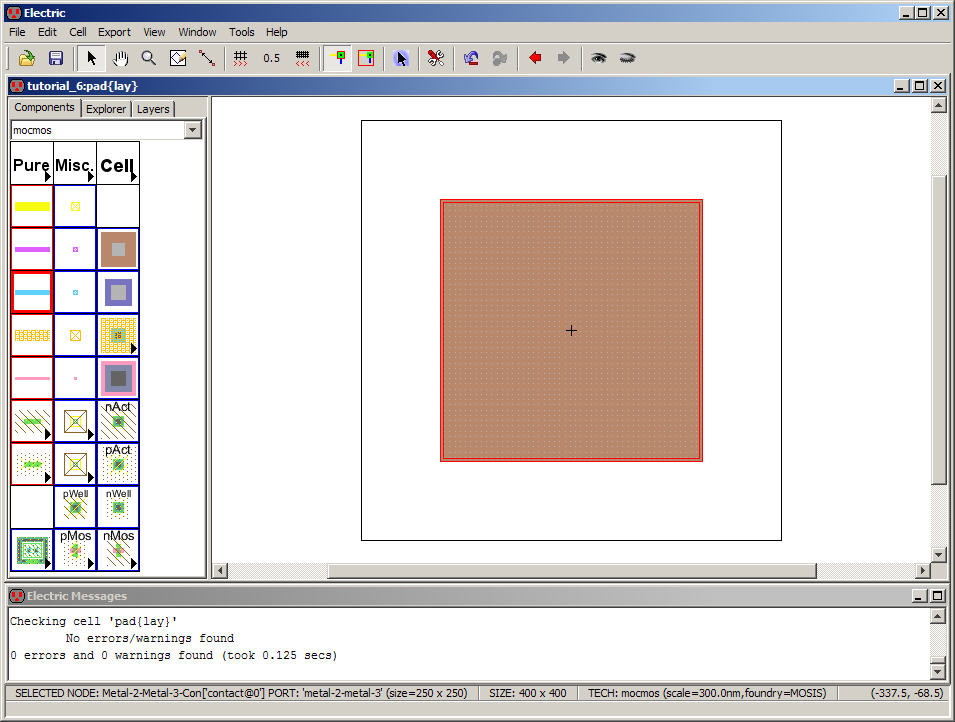

Change

the size of the Box above to 400 square and center it on 0,0 as seen

below.

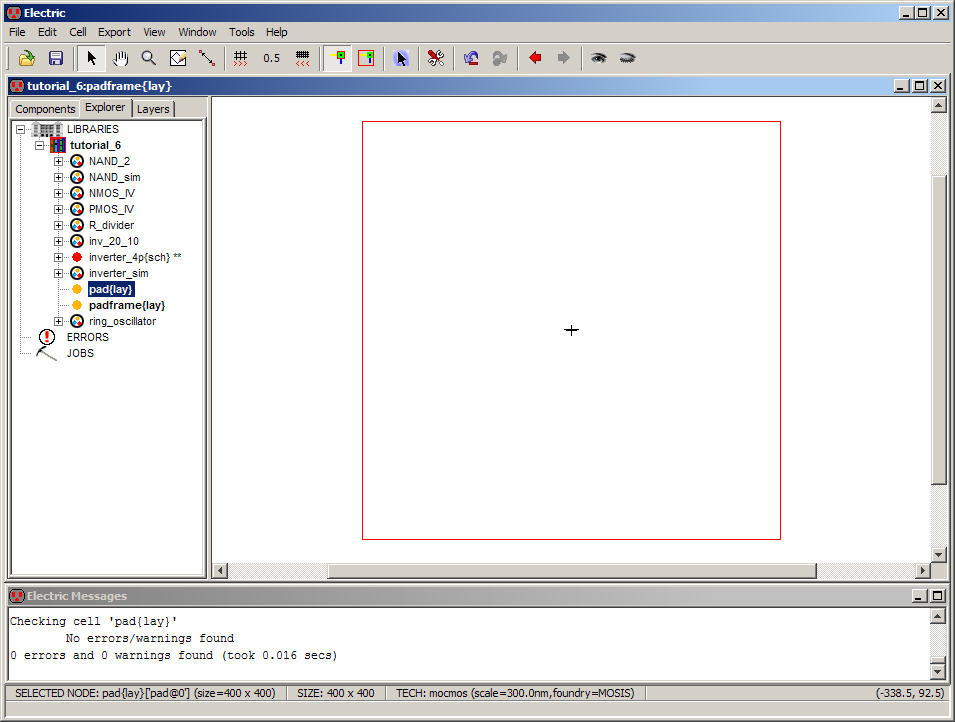

Before

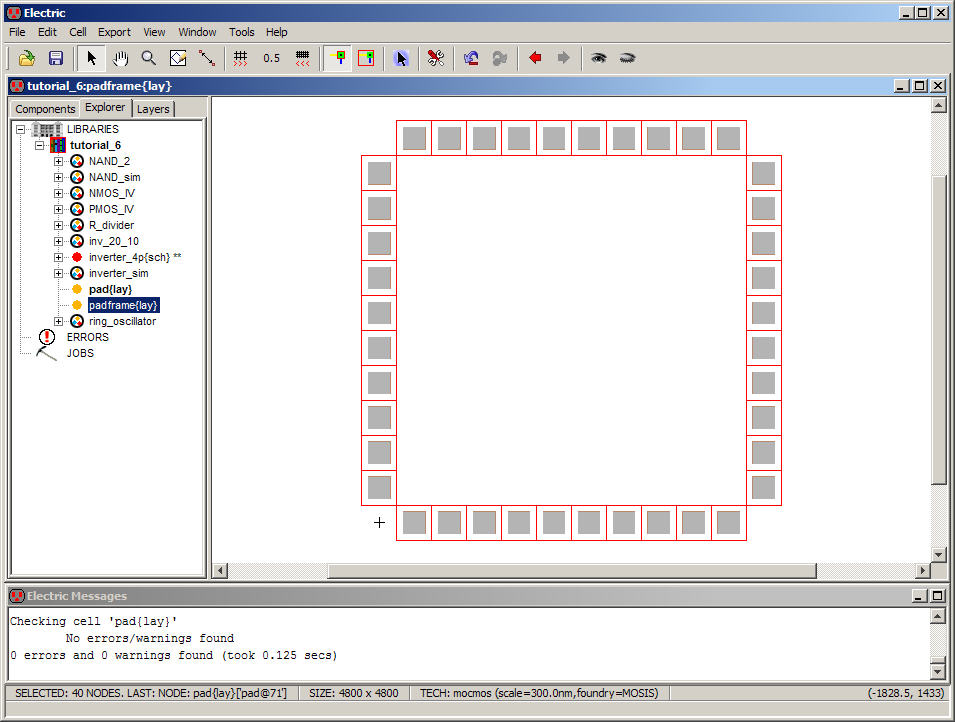

we add anything to our pad cell letís create a layout view of a padframe cell (do this now).

Place

the pad cell into this padframe

cell as seen below.

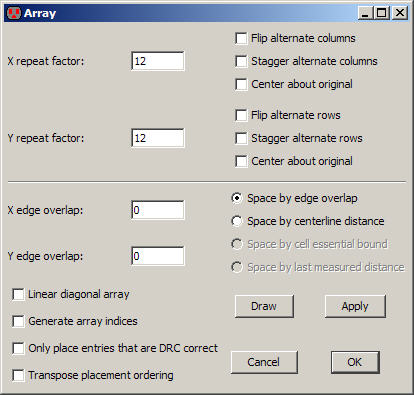

Next

letís use the Array command (Edit -> Array or simply F6) with

the pad cell

selected.

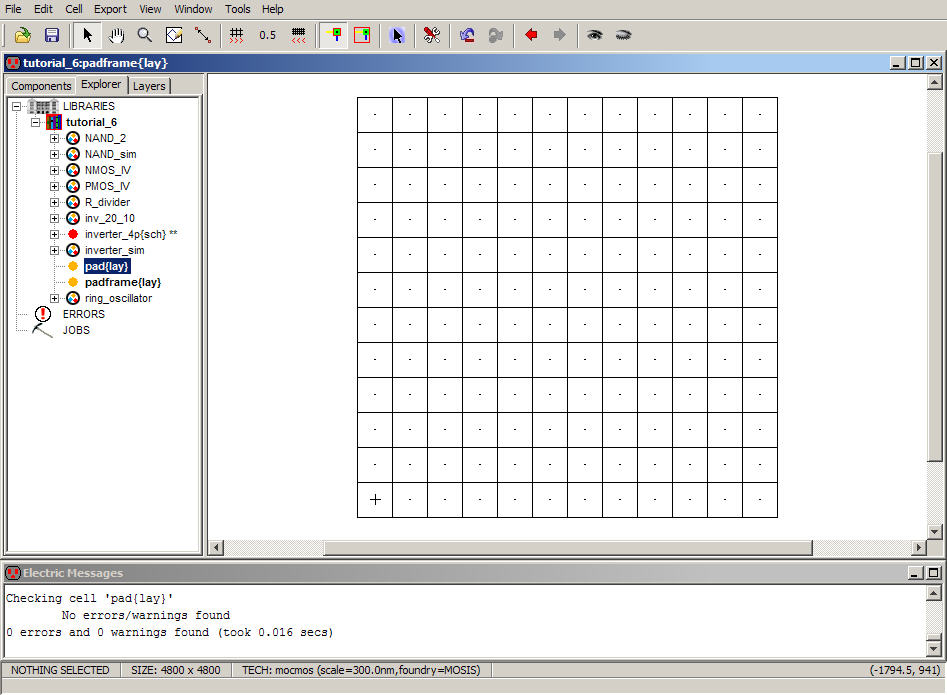

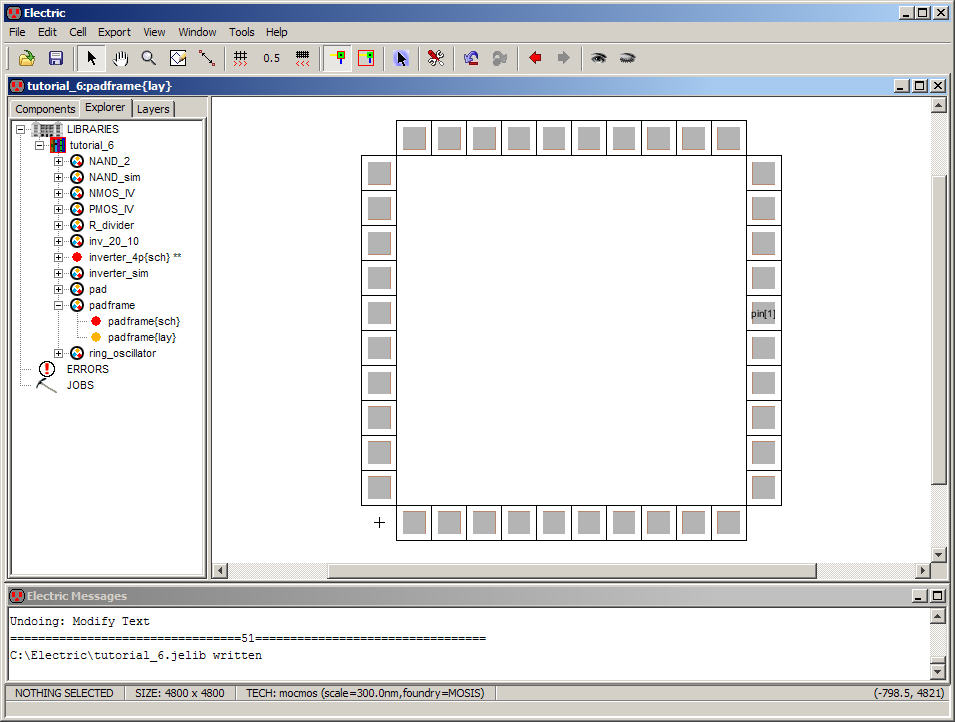

After

filling the window we get the following.

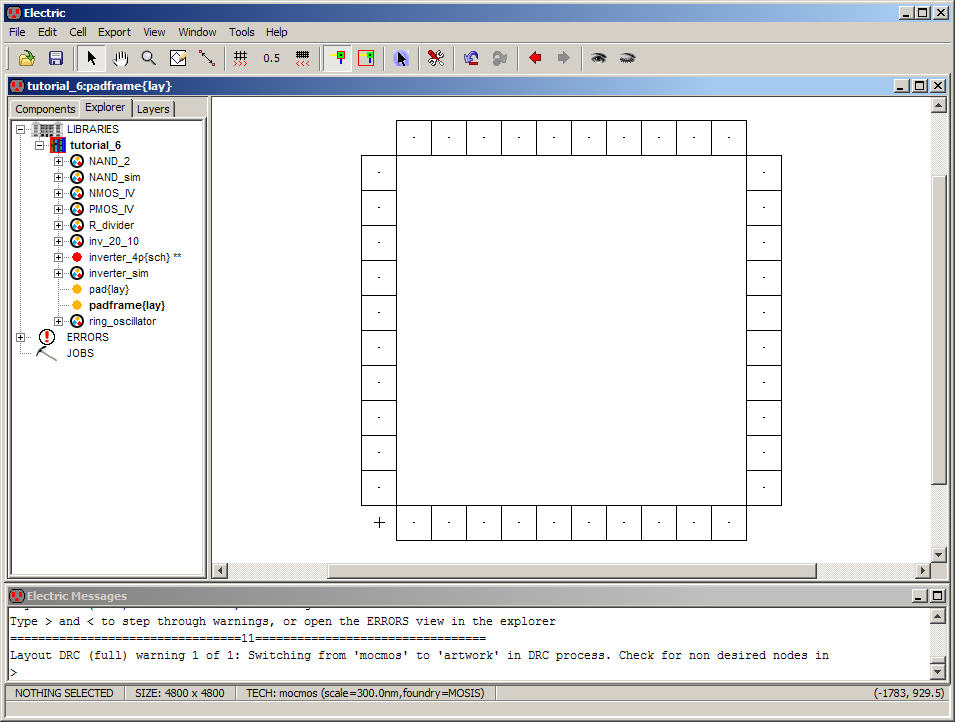

Next

delete the corner and interior pad cells.

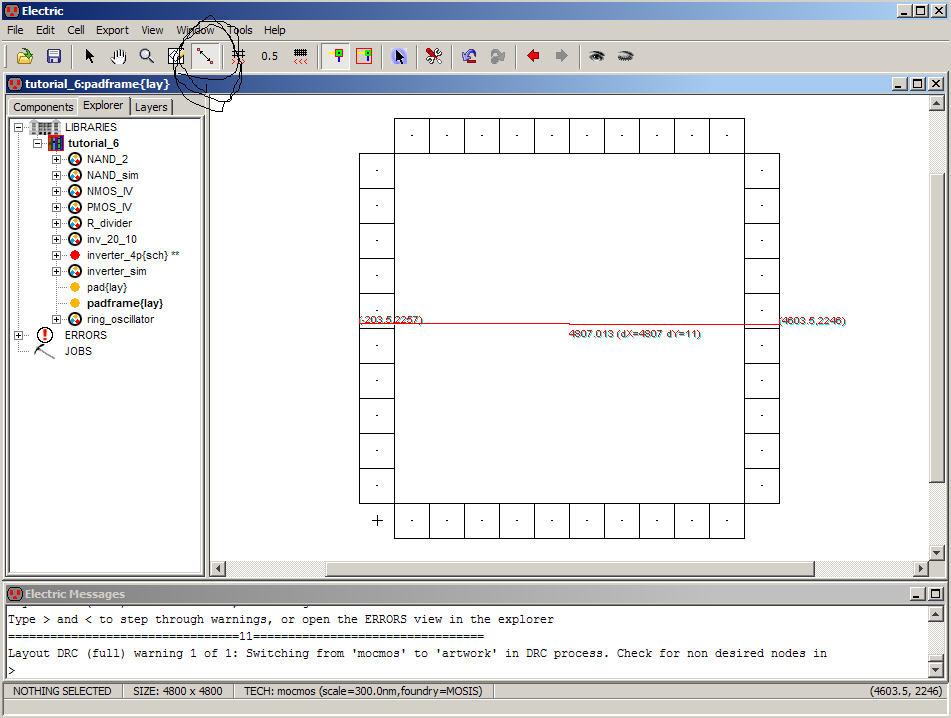

Letís

measure the size of the cell using Windows ->

Measurement -> Toggle Measurement Mode (or press M or use the

circled icon

seen below)

Pressing

M toggles back and forth between making measurements

and the normal click/zoom/wire cursor.

Pressing

Esc (or Windows -> Measurement -> Clear

Measurements) while in the measurement mode clears the measurements.

Note

that the exact size of the cell, 4800 by 4800, is seen

at the bottom of the display.

Letís

go back to the pad cell and add metal to make the pad.

Weíll

using 75 um square bonding pads so, since the scale

factor is 300 nm, a 250 lambda square piece of metal is used.

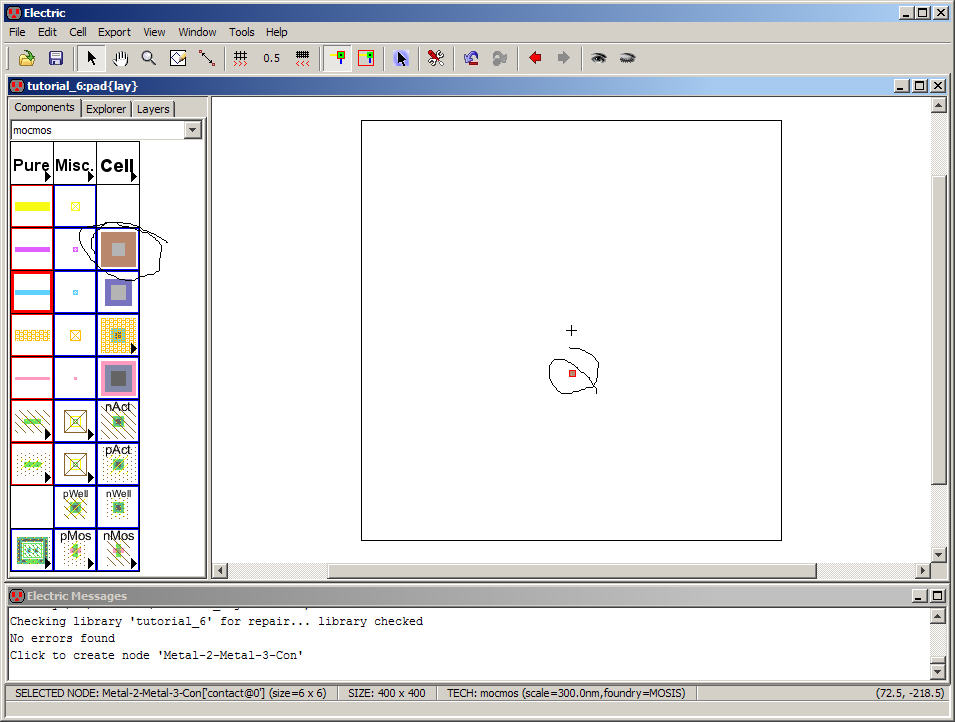

Add

a metal2-metal3 contact Node to the pad layout as seen

below.

Change

the size of this Node to 250 by 250 and center it on

0,0 as seen below.

Our

padframe now looks like

the

following (after selecting the cells and using the open-eye on the menu

to show

the cellsí contents).

Letís

go back to the pad cell.

We

need to do two things to this cell, add an Export so that

we can connect to it, and

add

the Passivation layer

(sometimes called overglass)

so that the top layer of

passivation (glass) is

removed

and get access to the metal3 (else we canít get the

signals off chip!).

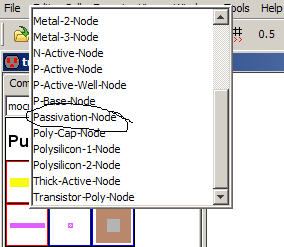

According

to the design rules the minimum overglass

opening is 60 microns (200 with our 300 nm scale factor).

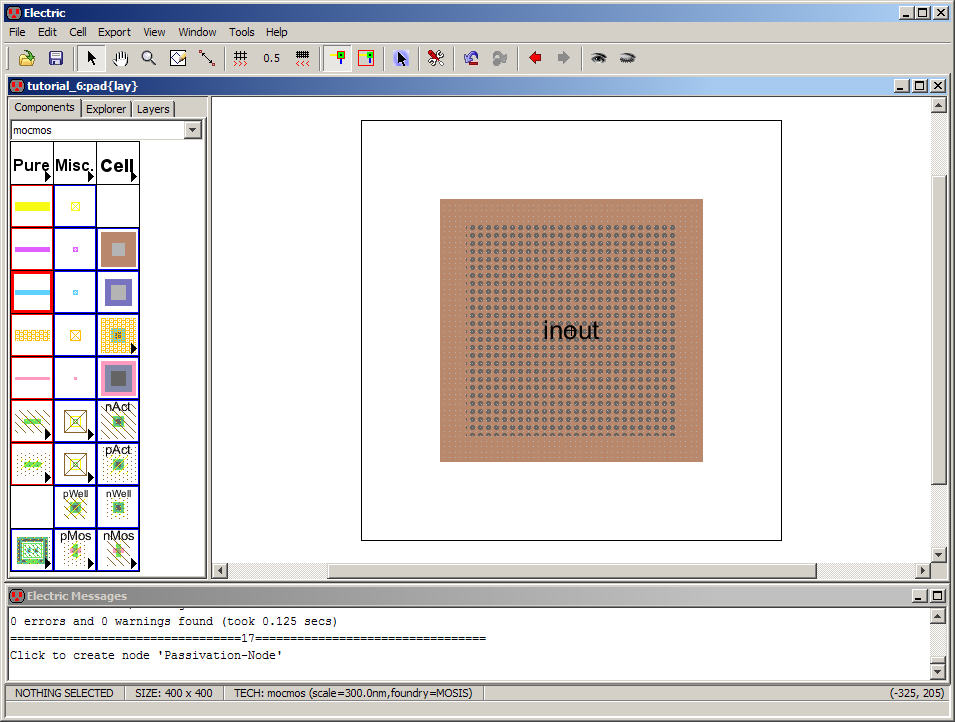

Add

a Pure layer of Passivation

to

the pad cell.

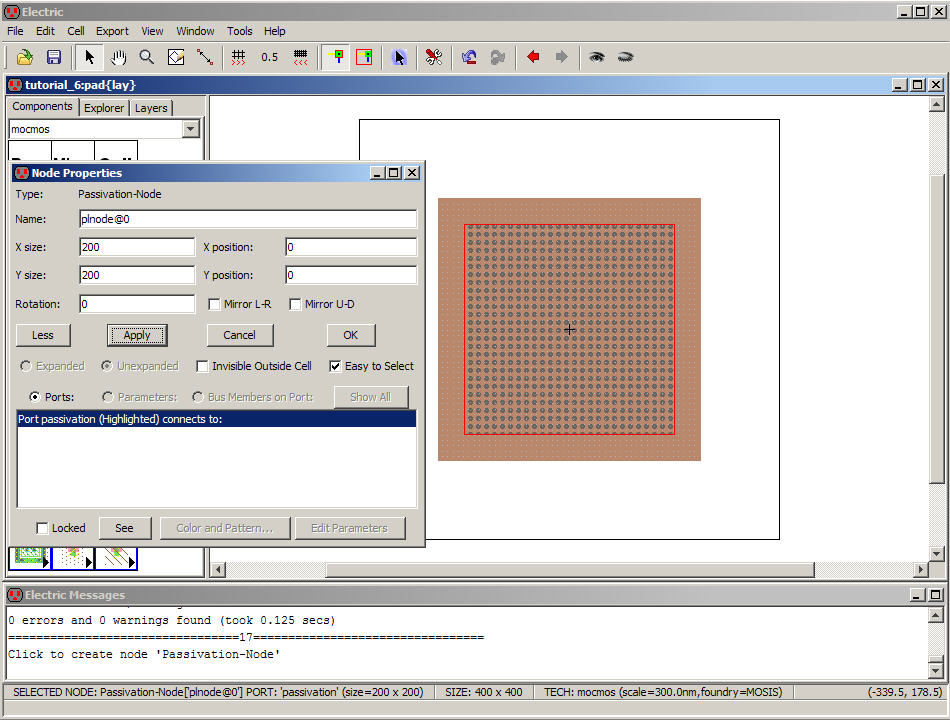

Next

change the size of this Pure-Node to 200 by 200 and

center it on 0,0 as seen below.

Next

select the metal3-metal2 Node and Export it as inout.

Change

the size of the Export text to 25 as seen below.

DRC

your design to ensure no errors.

The

layout of our pad is complete.

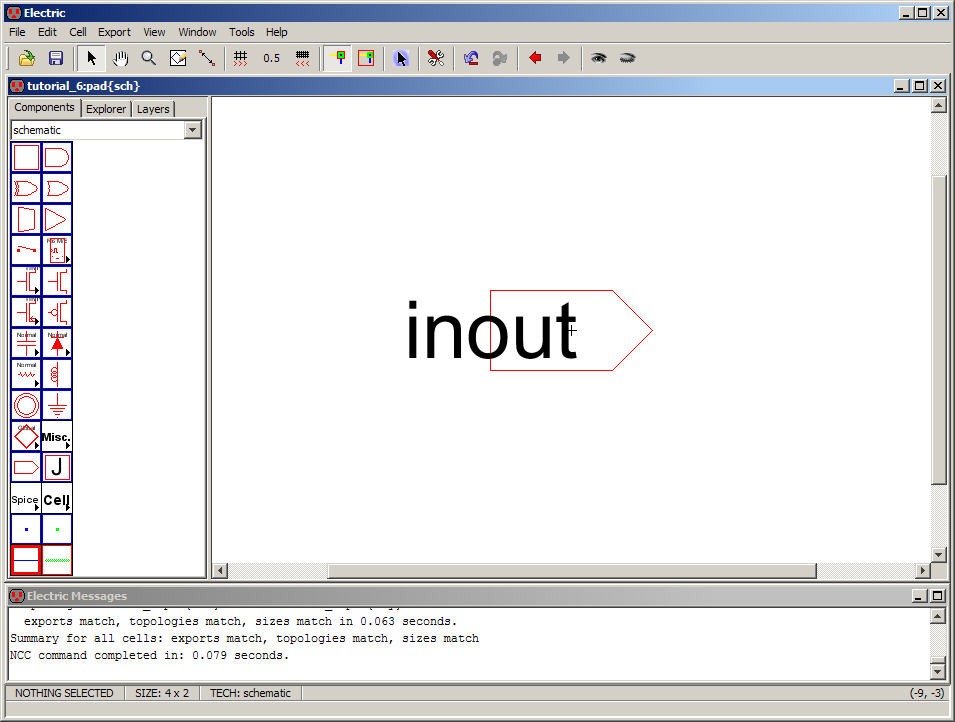

Letís

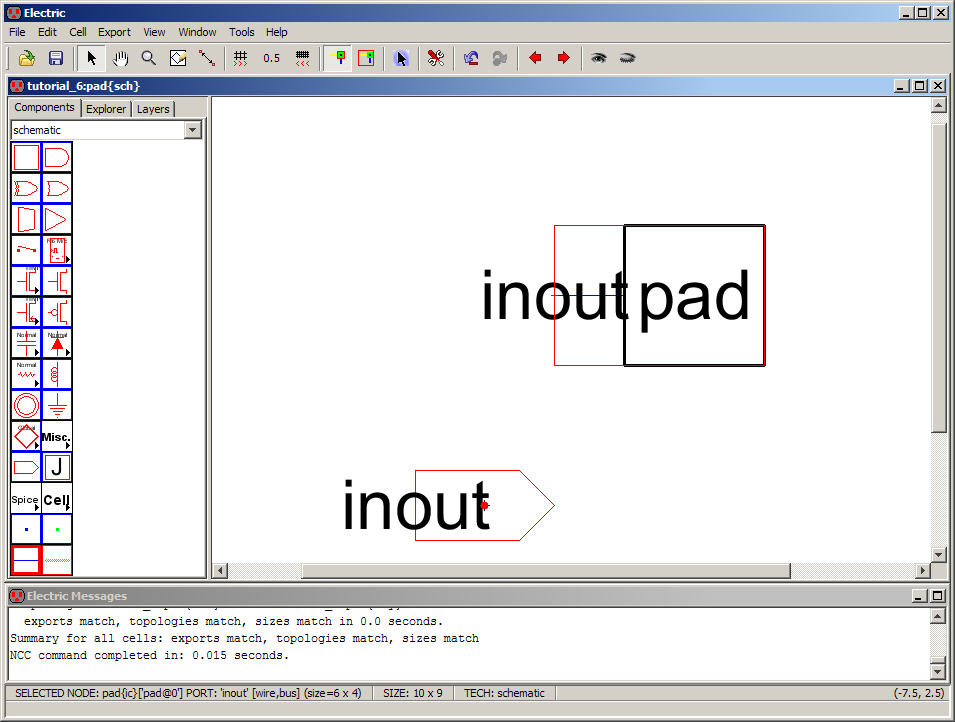

now make a schematic representation for this layout.

Create

a schematic view of the pad cell.

Add

the off-page Node and Export inout

as seen below.

Check

the schematic (F5) and NCC the layout and schematic

views.

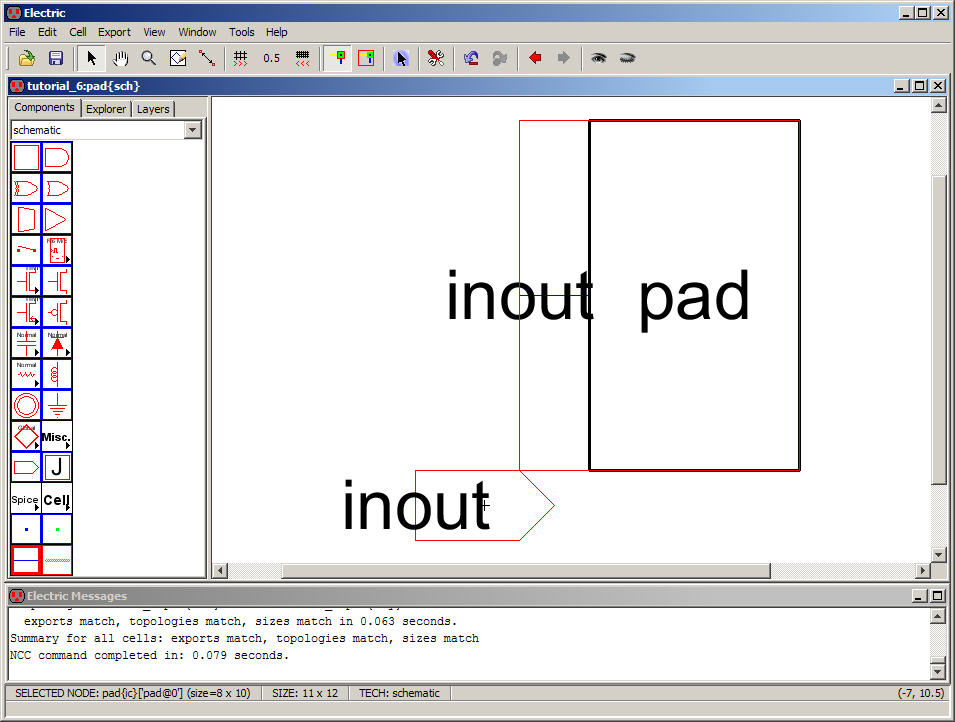

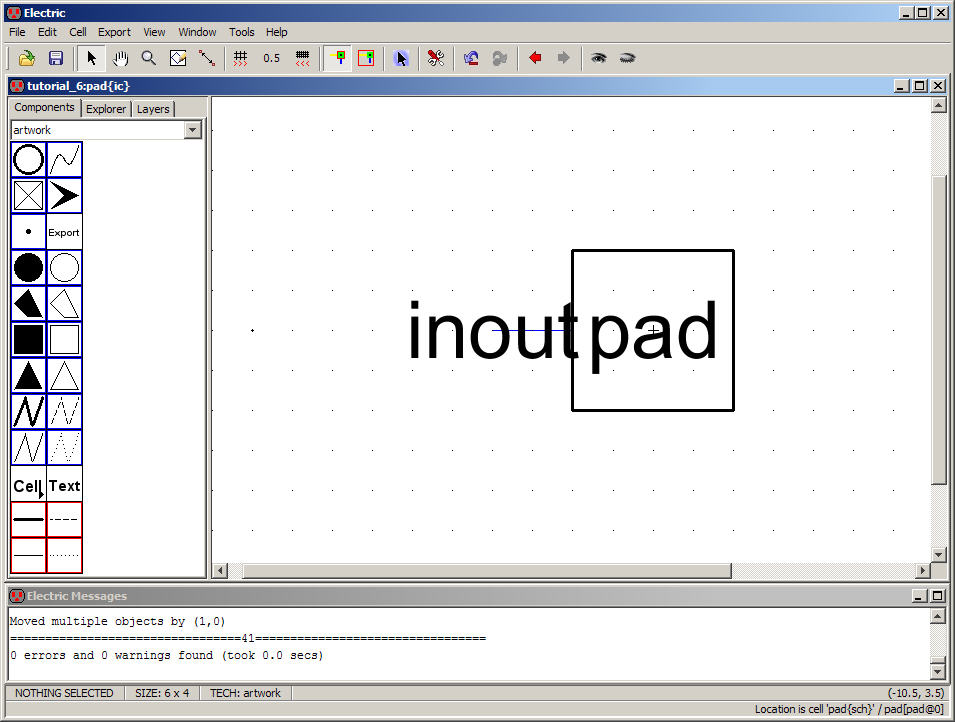

Next,

go to View -> Make Icon View

Descend

into the icon.

Select

the box and use Edit -> Modes -> Edit ->

Toggle Outline Edit (or just press Y) to adjust the size of the box.

When

finished adjusting the size press Y to get out of this

mode.

Adjust

the sizes until you get something that looks like the

following.

The

schematic view of the pad now looks like the following.

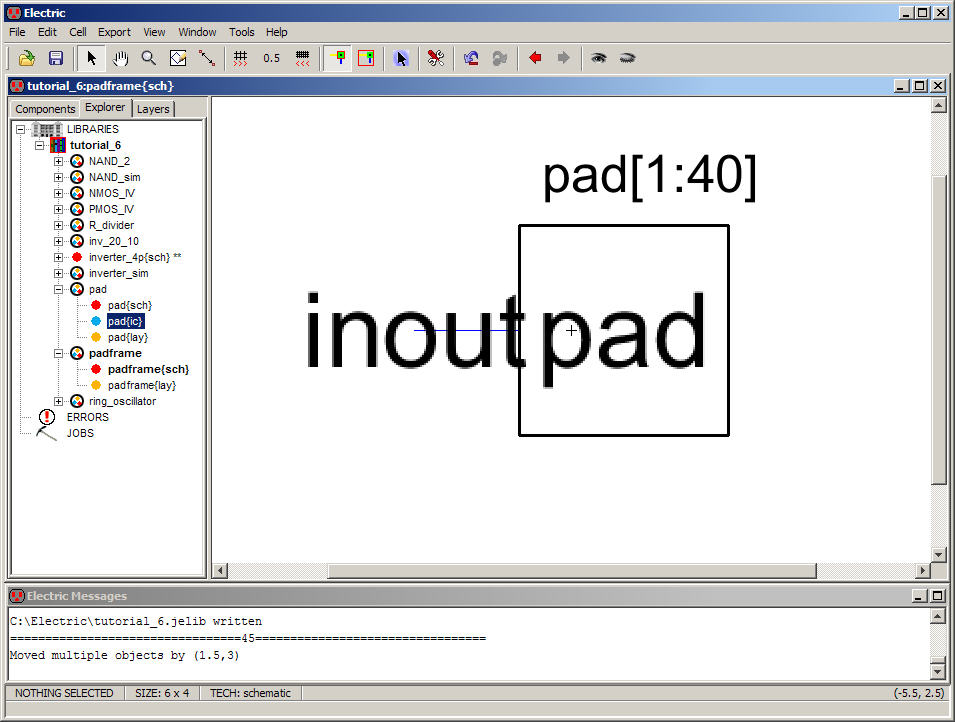

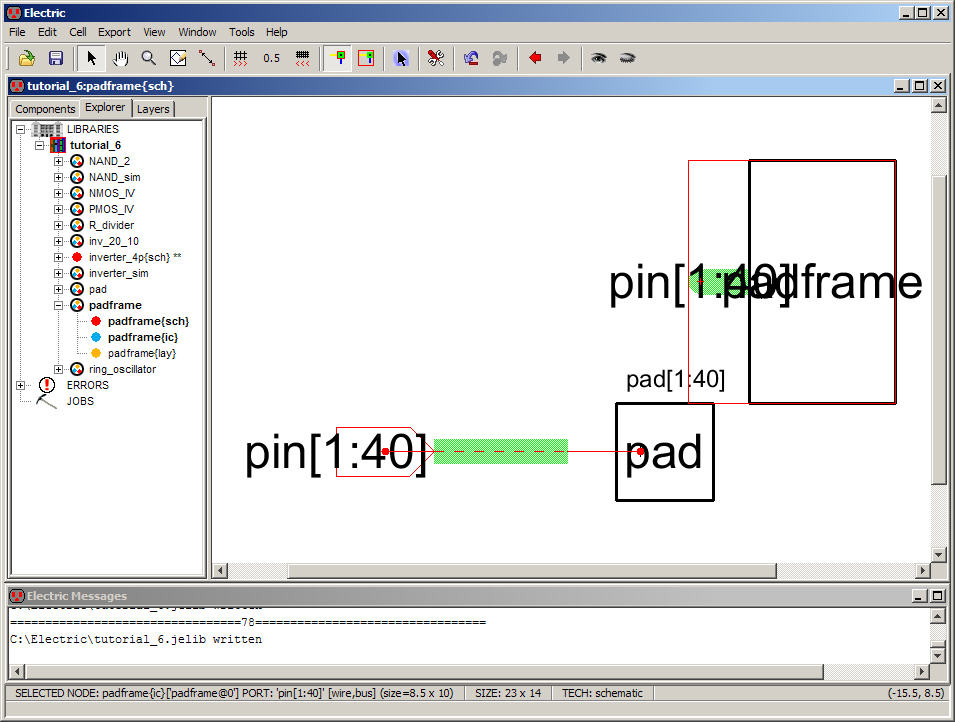

Letís

create a schematic view for the padframe

(do this now).

Place

the icon of the pad into the schematic view of the padframe cell and

change

its name to pad[1:40] (and move the name) as seen

below.

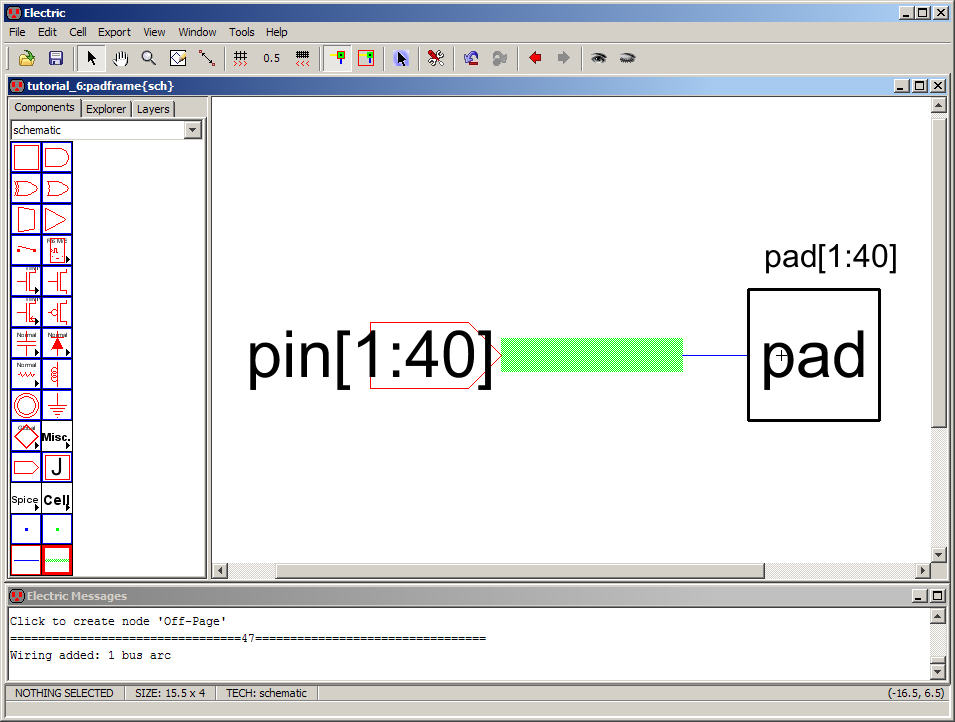

Next

add an off-page Node and connect a bus between the pad

icon and the off-page Node.

Export

the port of the off-page node as seen below using the

name pin[1:40].

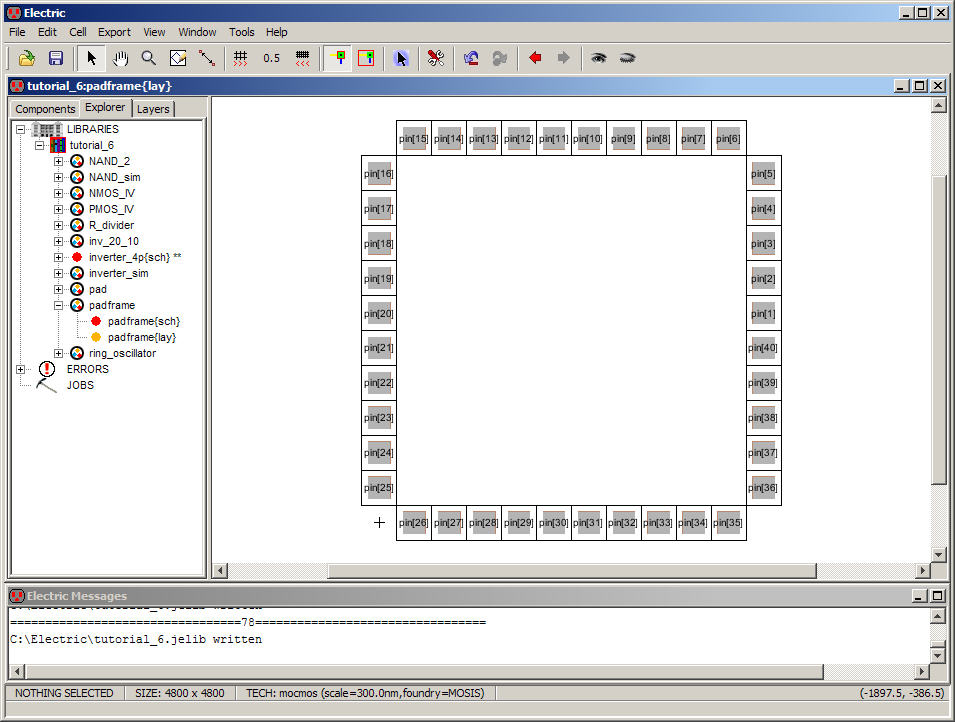

We

havenít exported anything in the padframe

layout so we need to go back and do that.

However,

it would be nice if pin[1] corresponds to pin1 of

the package.

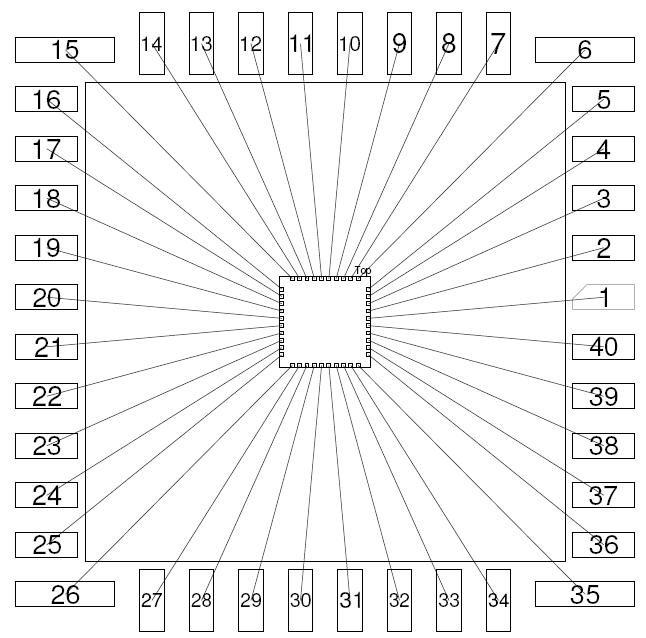

MOSIS

uses a 40 pin DIP package for the educational program

with a bonding diagram seen

below

(our padframe, that is,

chip

is in the middle of the figure).

Pin1

of the package is connected to the fifth pad from the

top and the right side.

Letís

export this pin on the padframe

layout now (and change the export text size to 125).

We

need to do this for the other pins.

One

trick, after youíve exported all the pins is to select

the entire layout, then Ctrl+I

it

and removing everything but the text. Then change the text

unit size to 125.

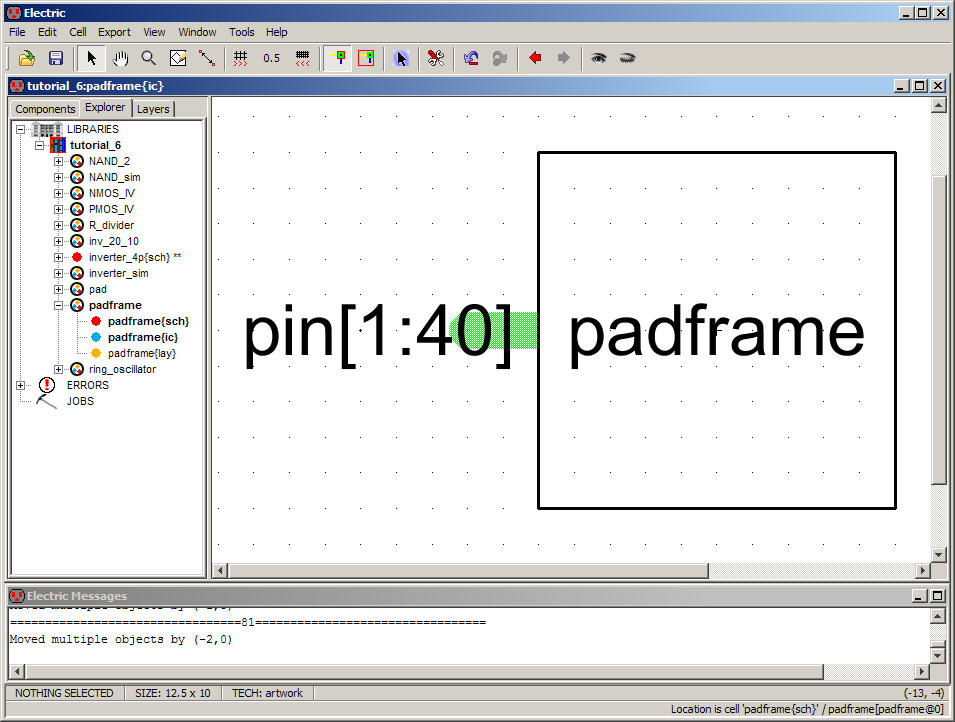

Next

letís create an icon view for the padframe.

Go

back to the schematic of the padframe

and use View -> Make Icon View

Descend

into the icon view of the padframe

and use Edit -> Modes -> Edit -> Toggle Outline

Edit (or just press Y)

again to adjust the size of the box.

Move

the Export text to the left until you get something that

looks like the following.

Save

your library.

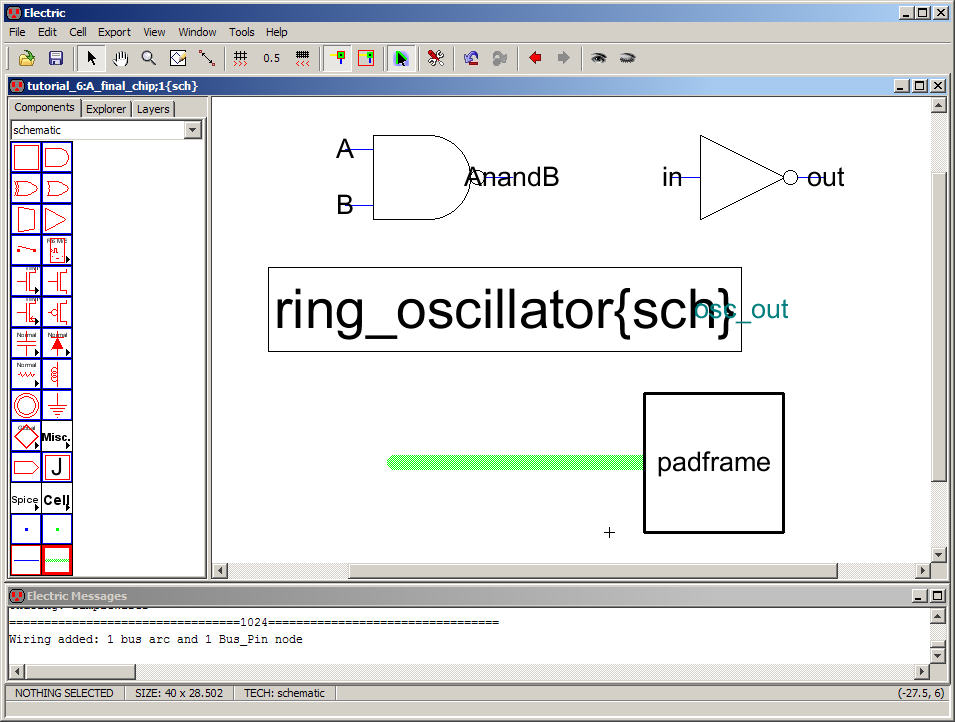

We

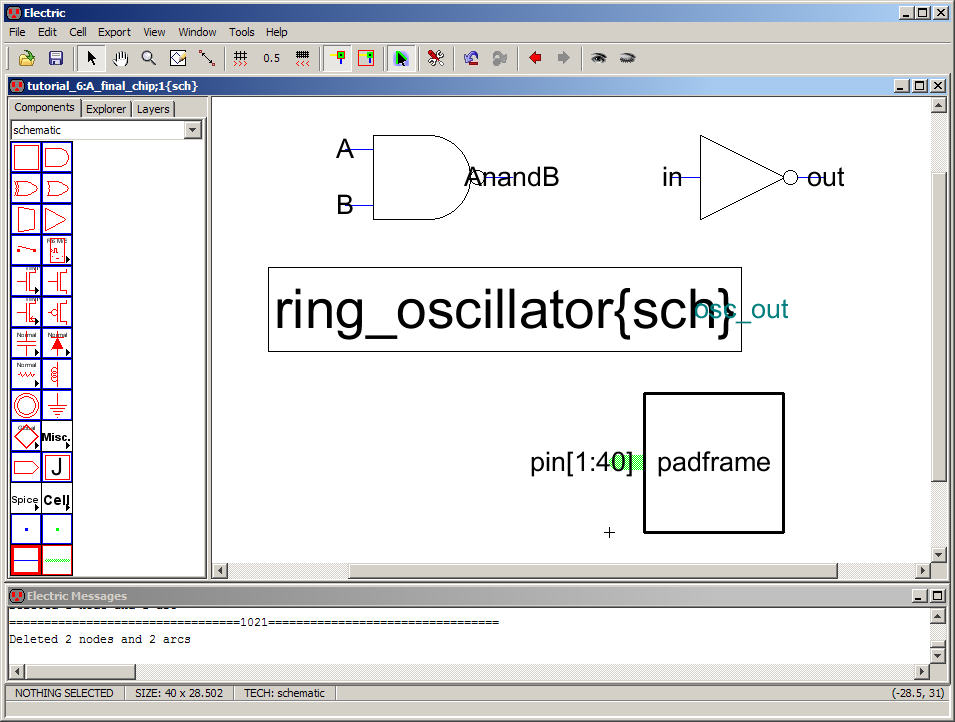

are now ready to make a cell for our final chip (the chip

we want to send out for fabrication).

Make

a schematic view for a cell called A_final_chip.

This

name was selected so that the cell would be at the top

of the Explorer.

On

this chip weíll place the NAND_2, inv_20_10, and the ring

oscillator.

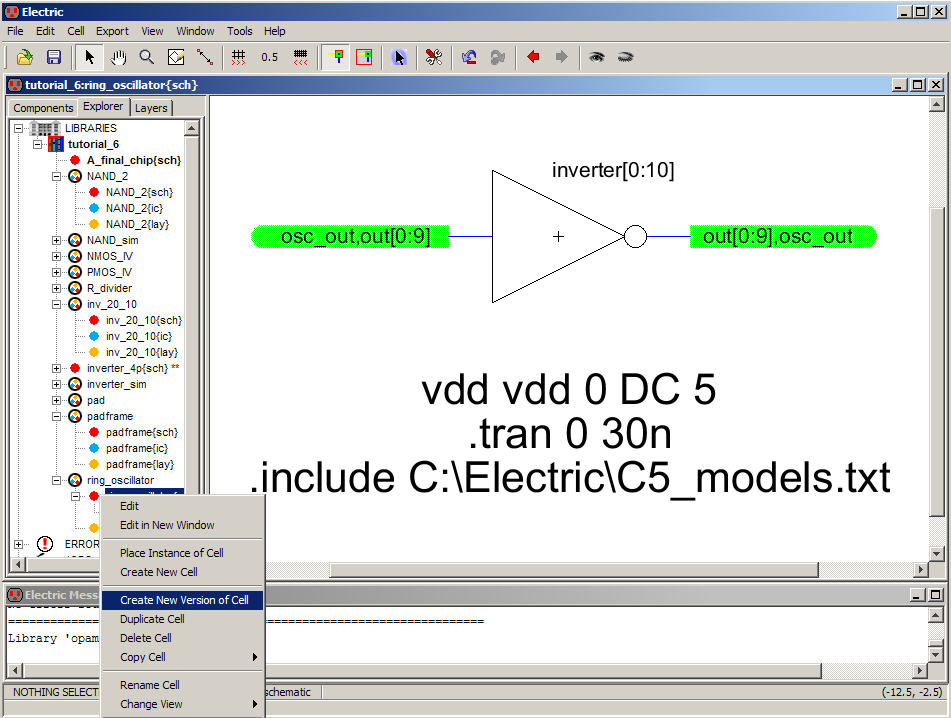

Since

the two schematic views of the ring oscillator have

Spice Code in them letís create a third version and remove the Spice

Code.

Since

the NAND_2 and inv_20_10 cells have icon views letís

place the ring oscillator without an icon view.

Note

that we can easily make an icon (View -> Make Icon

View) but we arenít just to be different.

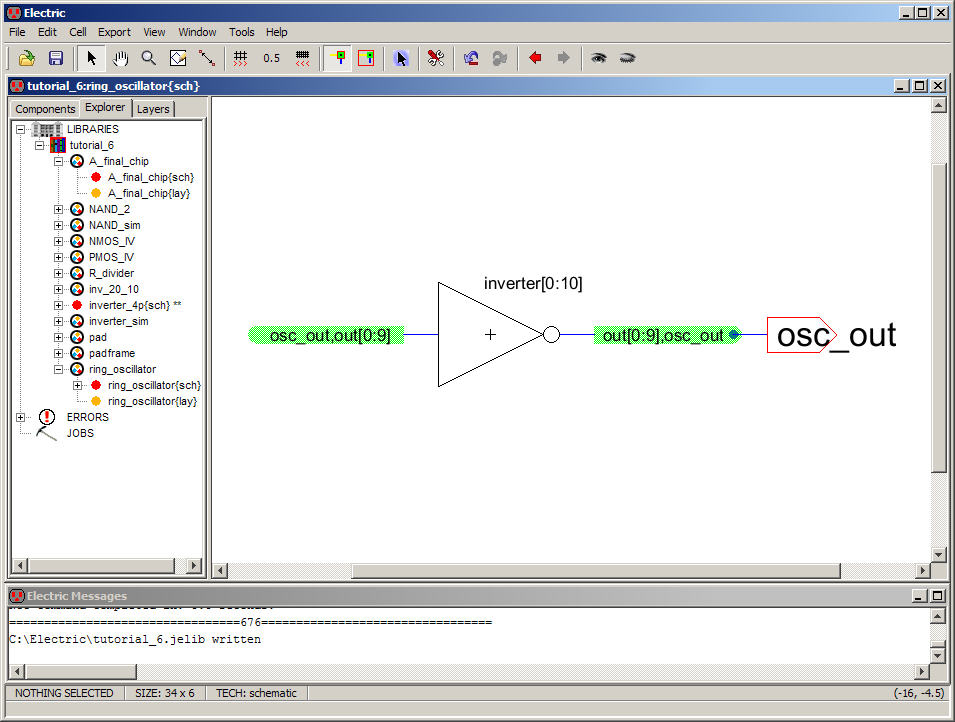

Letís

Export osc_out as seen

below.

We

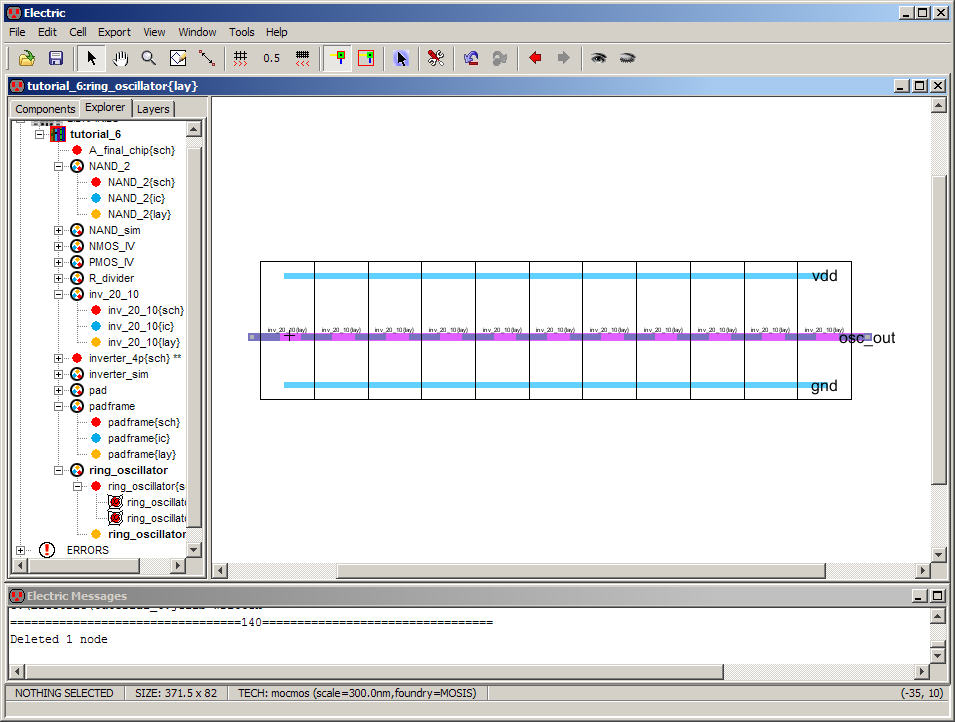

need to go to the layout and Export a Pin as osc_out.

We

also need to remove the Spice Code as seen below (feel

free to make a new version of the cell so you can go back and simulate

if

desired).

Verify

the resulting layout NCCs, DRCs, and Well Checks

without errors.

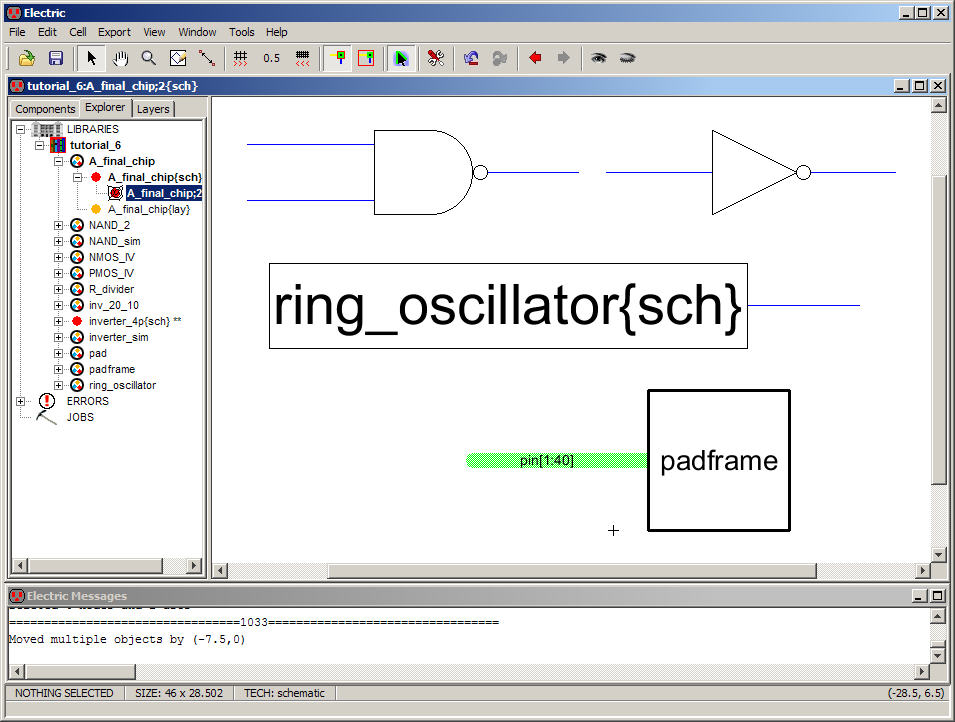

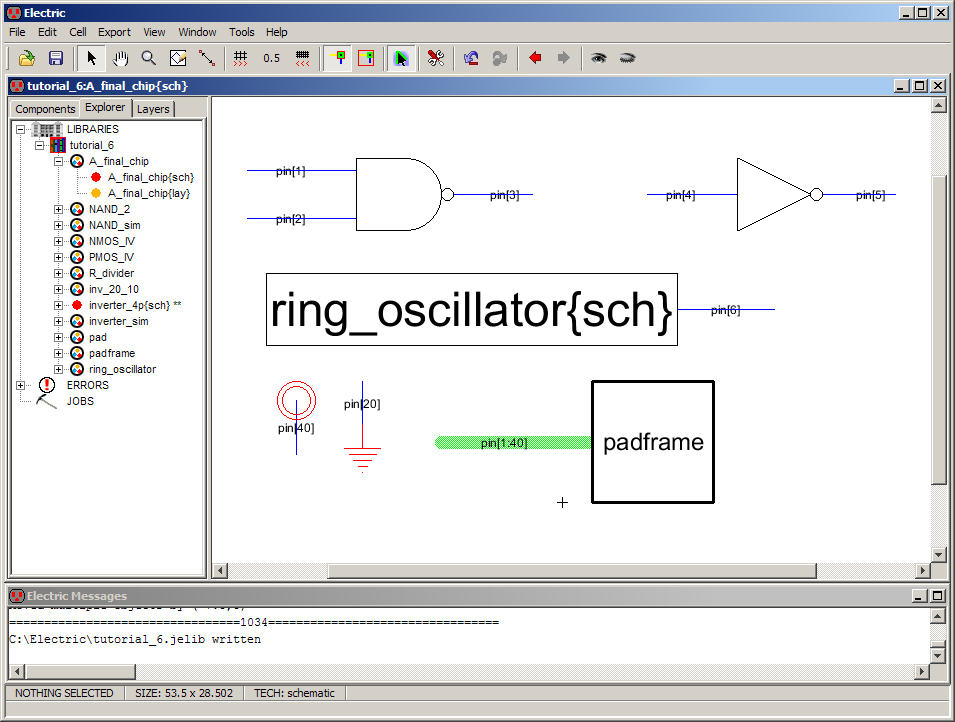

Open

the schematic view of A_final_chip.

In

this cell add the icon views for NAND_2, inv_20_10, the padframe and the schematic view

of the ring oscillator.

First

letís connect a bus to the padframe

icon.

Next

letís add wire Arcs to the icons and ring oscillator

then label the bus connected to the padframe.

Letís

connect the gnd and vdd to pins 20 and 40

respectively

Lets

connect A, B, and AnandB

to

pins 1, 2, and 3 respectively.

Inverter

in and out will be connected to pins 4 and 5

respectively.

Finally

letís connect osc_out

to

pin 6

The

results are seen below.

Check

your schematic for errors (F5).

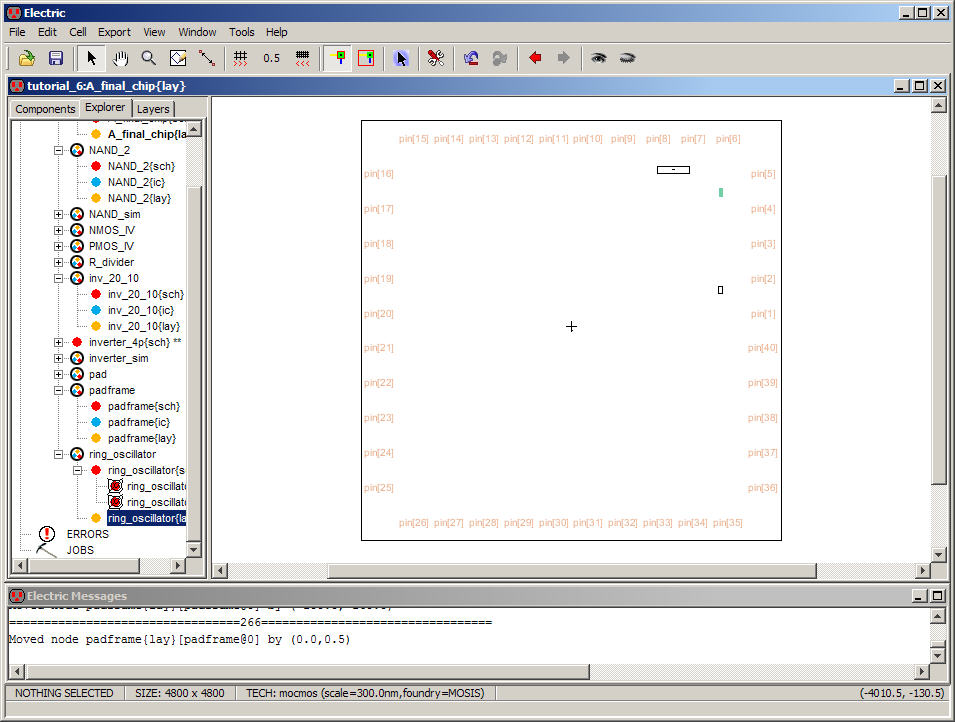

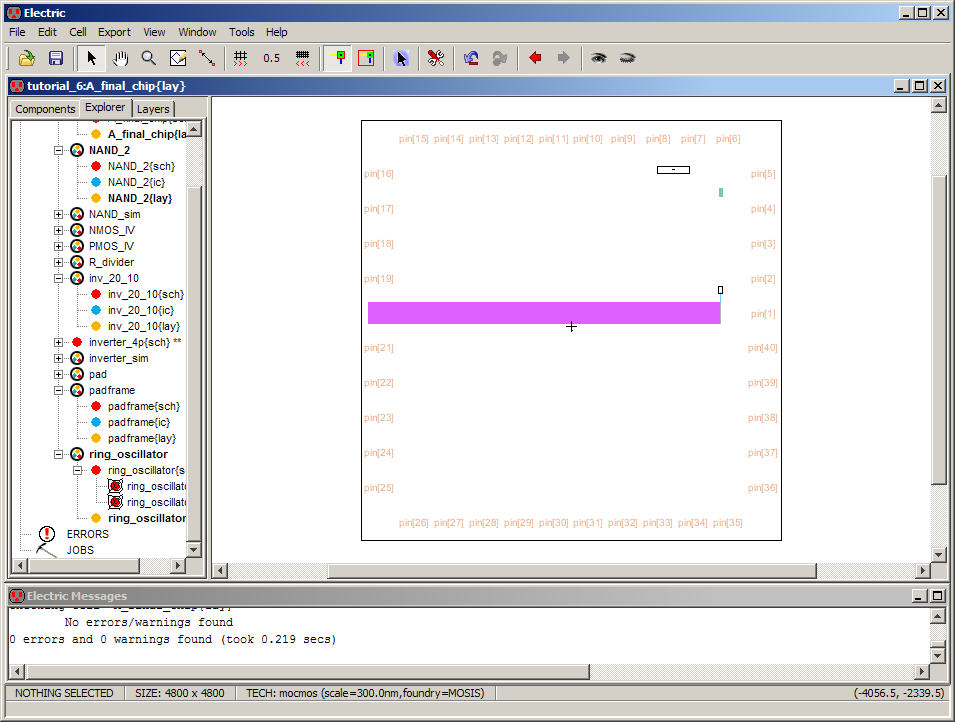

Next

make a layout view of A_final_chip

and place the NAND_2, inv_20_10, and ring_oscillator

layouts in the cell.

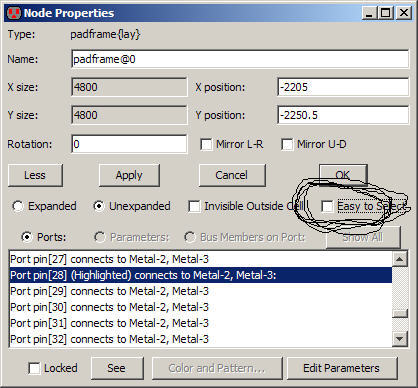

Letís

next select the padframe

layout and set its properties so that it isnít easy to select.

If

we donít make the padframe

hard

to select then it will be difficult to select the other cells that are

occupying the same area.

Remember

this feature since it could lead to frustration (why

canít I select this!!!)

The

issue is that we still need to be able to select parts of

the padframe (the

Exports labeled pin[1:40]).

This

is where the special select comes in handy (icon in the

middle of the menu).

Use

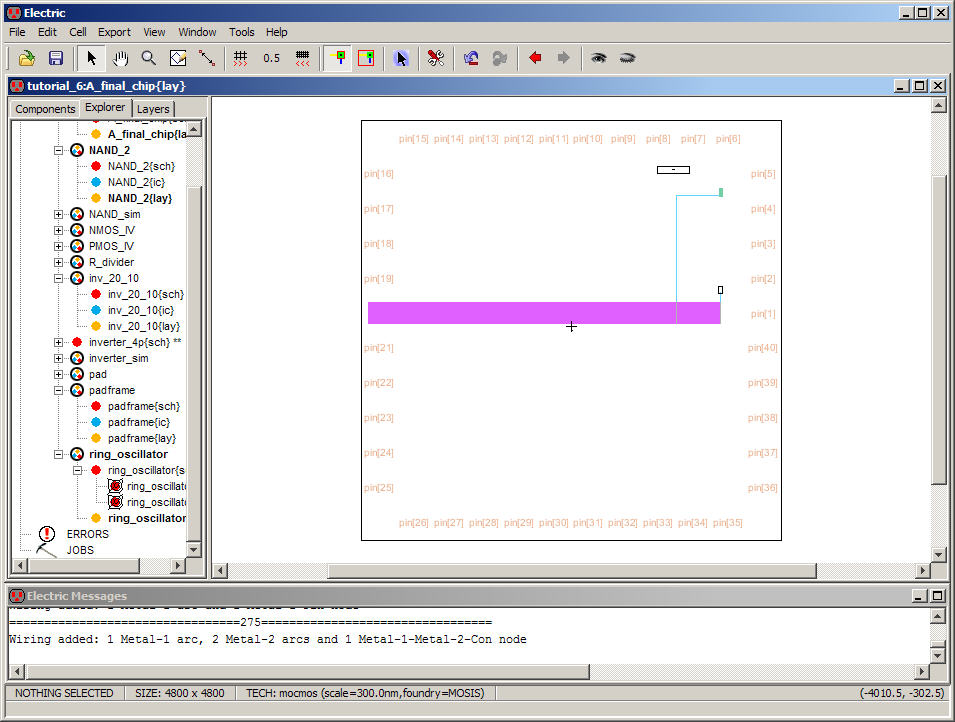

the Toggle Special Select so we can select pin[20]

(ground).

After

selecting pin[20] Toggle Special Select again and then

right click on the ground connection of the NAND gate (zoom in so itís

easier).

Below

is the result.

Connect

the ground up of the inverter next.

Note

that an important concern, that we arenít covering here,

is the sizing of the conductors.

Here

we arenít being practical but rather simply wiring the

chip up so that it matches the schematic.

Add

the other wire connections then DRC, NCC, and (after

Exporting gnd and vdd and

changing the text size to 125) Well Check.

The

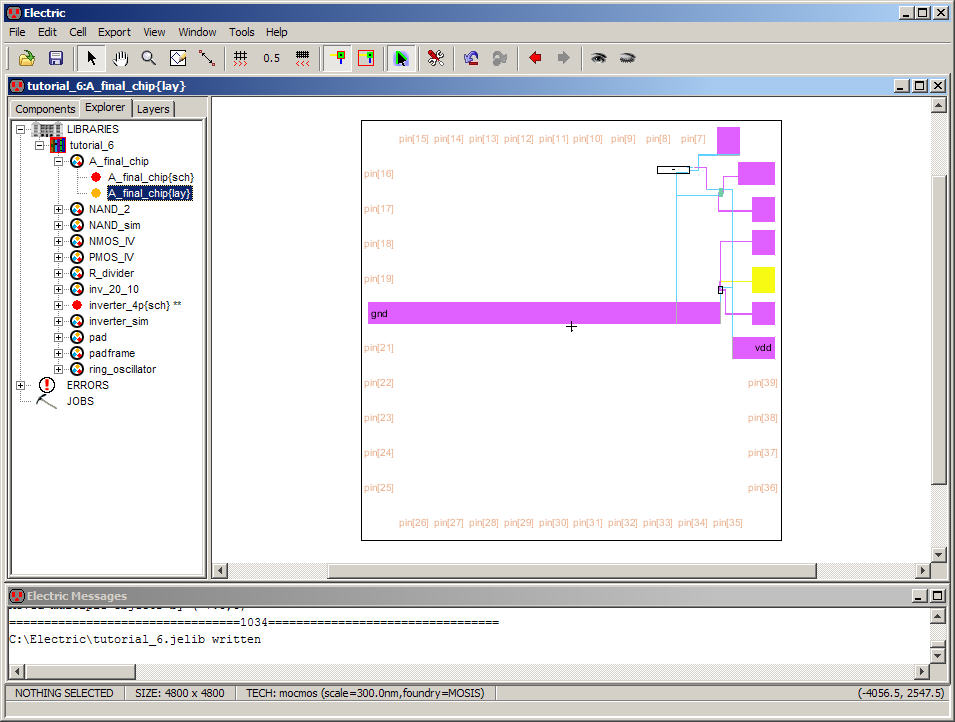

final layout (yours will likely look different) is seen

below.

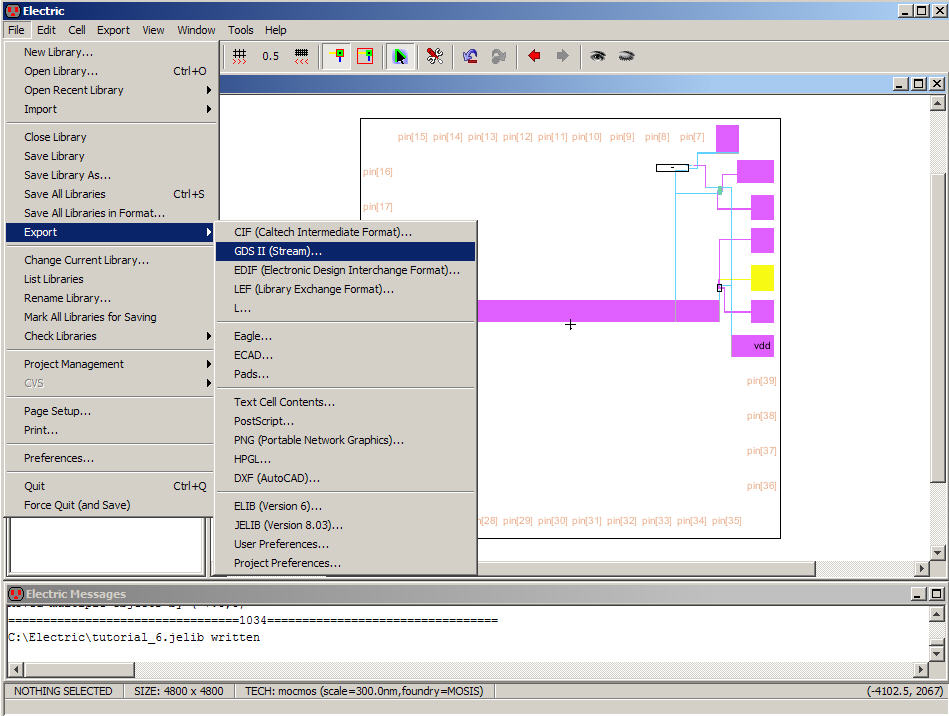

The

GDS (stream) file for this chip can be generated using

the menu commands seen below.

Once

we have GDS we can send it to MOSIS for fabrication

following the instructions seen here.

Save

the library.

This

is the end of the written Electric tutorials from CMOSedu.com

For

your reference the final jelib

used in this tutorial

is located in tutorial_6.jelib