Cadence

Design System

Tutorials

from CMOSedu.com (Return)

Tutorial

6 – Placing circuit layouts

in a padframe for

fabrication

In

this tutorial

we’ll place the R_div,

NMOS_IV, PMOS_IV, inverter,

nand2, and ring oscillator that we laid out

in

the earlier tutorials in a padframe

for fabrication through MOSIS.

Note

that we won’t include a buffer to drive the large,

around 30 pF, off-chip load capacitance

from

the scope probes, packaging, and test board needed to

test the chips.

What

this means is that if the chip we lay out here is

fabricated it’s likely that attempting to measure the

oscillation

frequency, or the gate delay, with a scope probe

will result in drastically different results than the

simulations.

It’s likely that measuring the ring oscillator

frequency will actually result in killing the oscillations

(see

the CMOS

book for details on the use of output

buffers to drive off-chip loads).

Okay,

let’s begin by copying the library, Tutorial_5, into a new library

called

Tutorial_6.

Ensure,

when you copy, that “update instances” is selected so that the new

library

doesn’t reference cells in the other libraries.

As

always, put the new library in $HOME/CMOSedu

We

are using

On

Semiconductor’s C5

process for fabrication through MOSIS.

Further,

this process uses the MOSIS scalable CMOS (SCMOS) submicron design rules with lambda

of 300 nm (technology

code SCN3ME_SUBM at 0.3).

A

“tiny chip” fabricated in this process via the MOSIS Educational

Program (MEP)

measures, at most, 1.5 mm by 1.5 mm.

Information

about the MOSIS Educational Program (MEP) is found here.

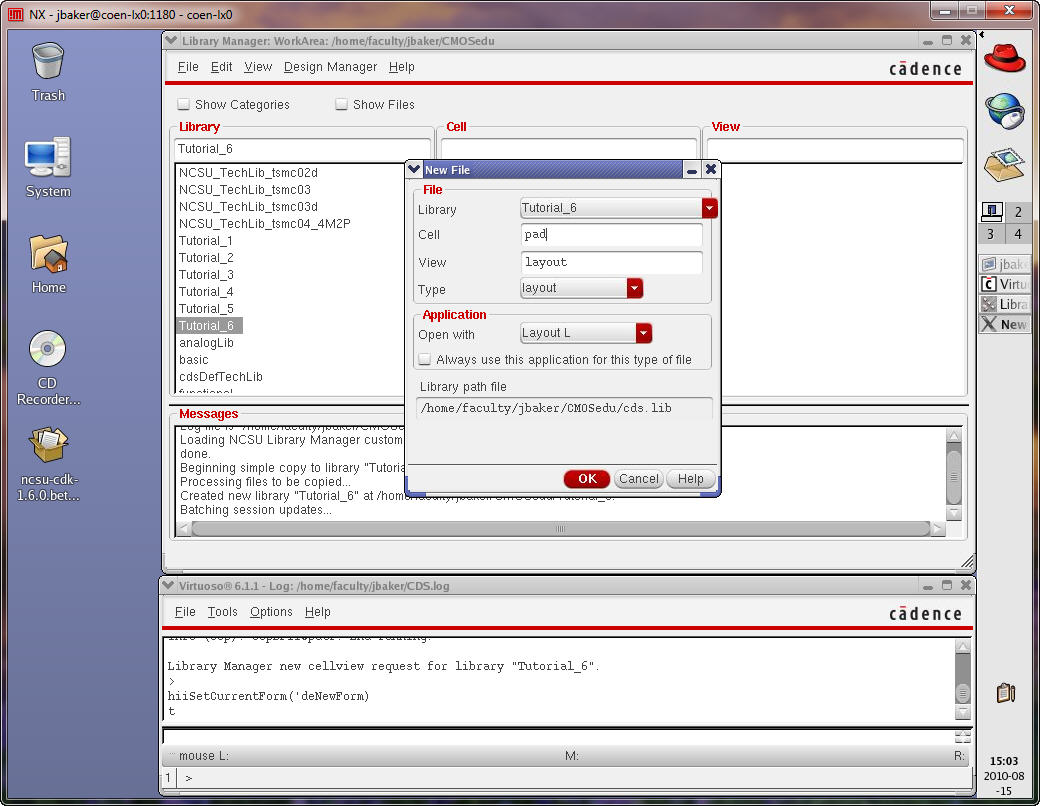

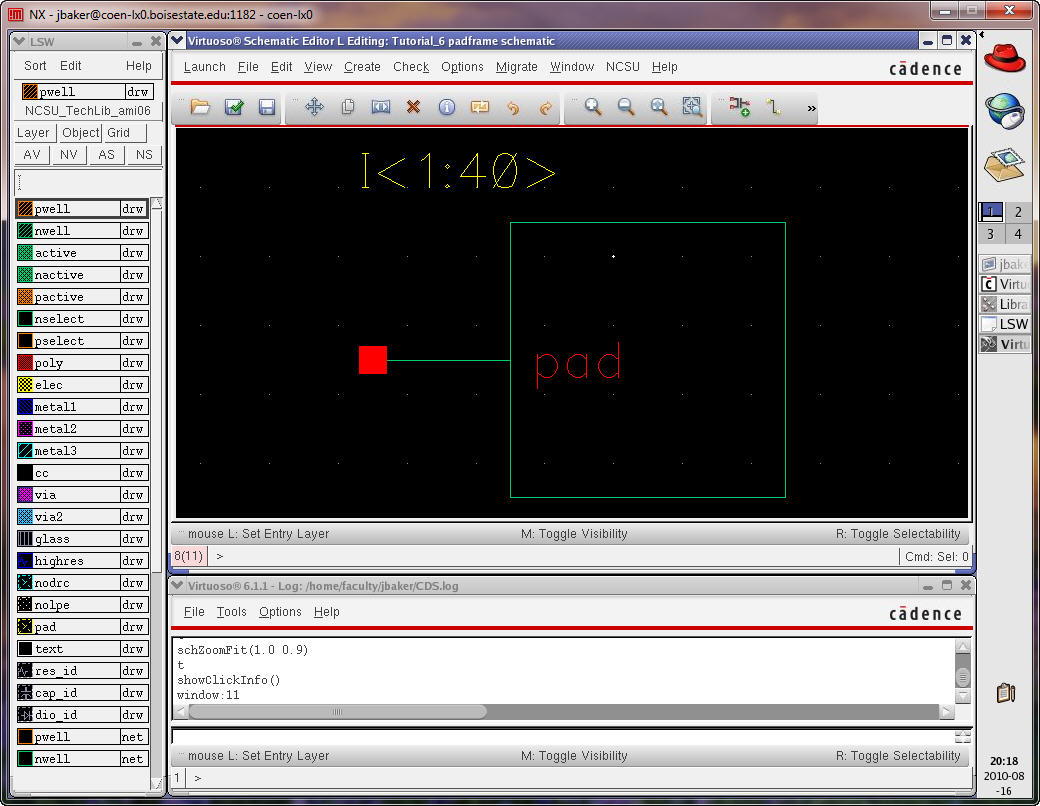

Create

a new layout cellview

called

pad.

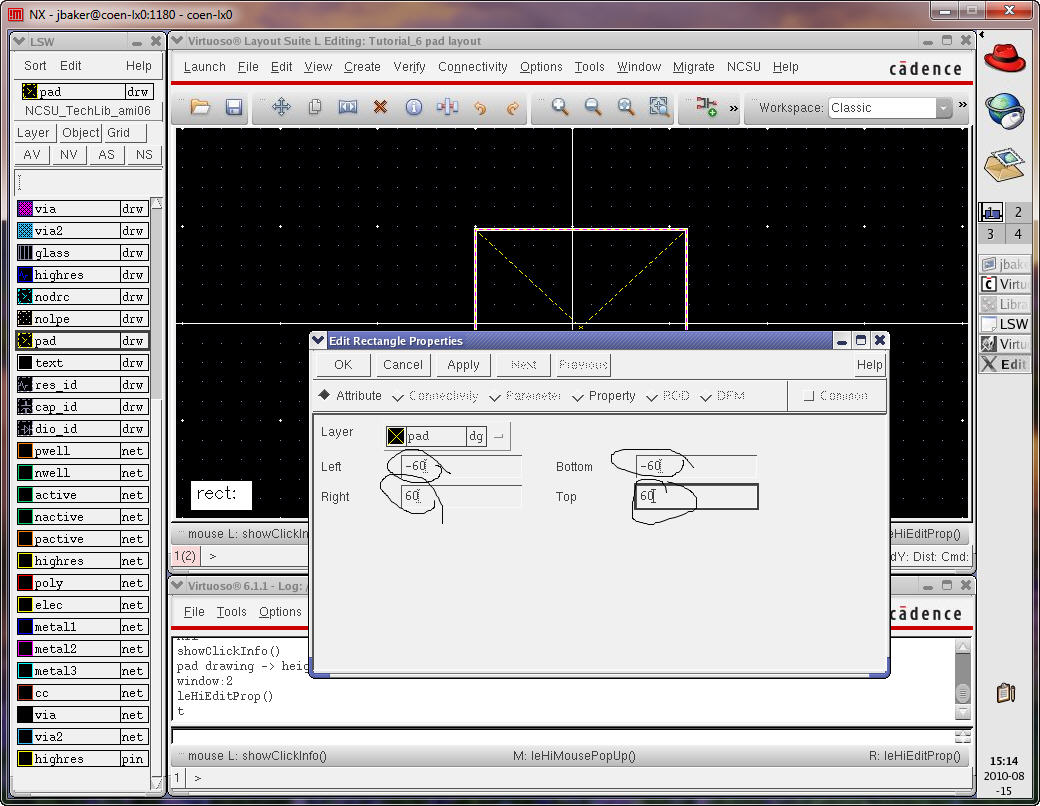

If we have 12 pad

cells on a side (10 plus two corners) then each cell must be 1.5mm/12

or 125

um.

In order to ensure

this pad falls on the 0.15 um grid let’s reduce the pad cell size to

120 um.

This also ensures

that the final chip size is smaller than the 1.5 mm square size we are

allowed.

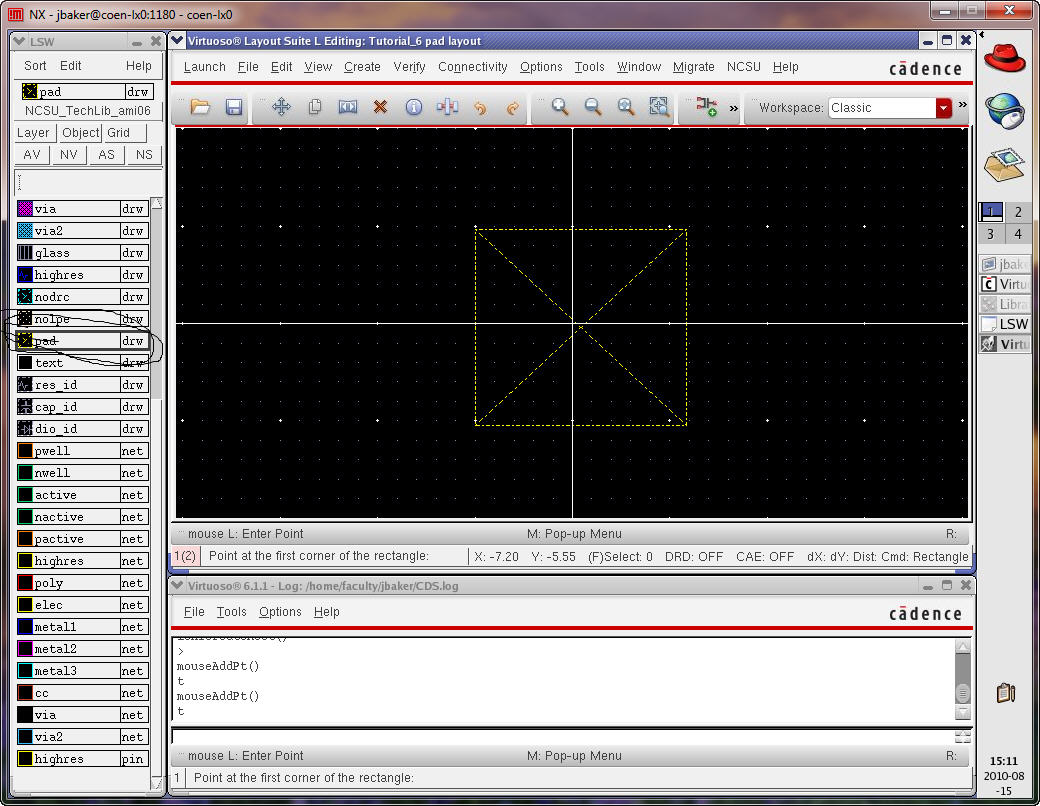

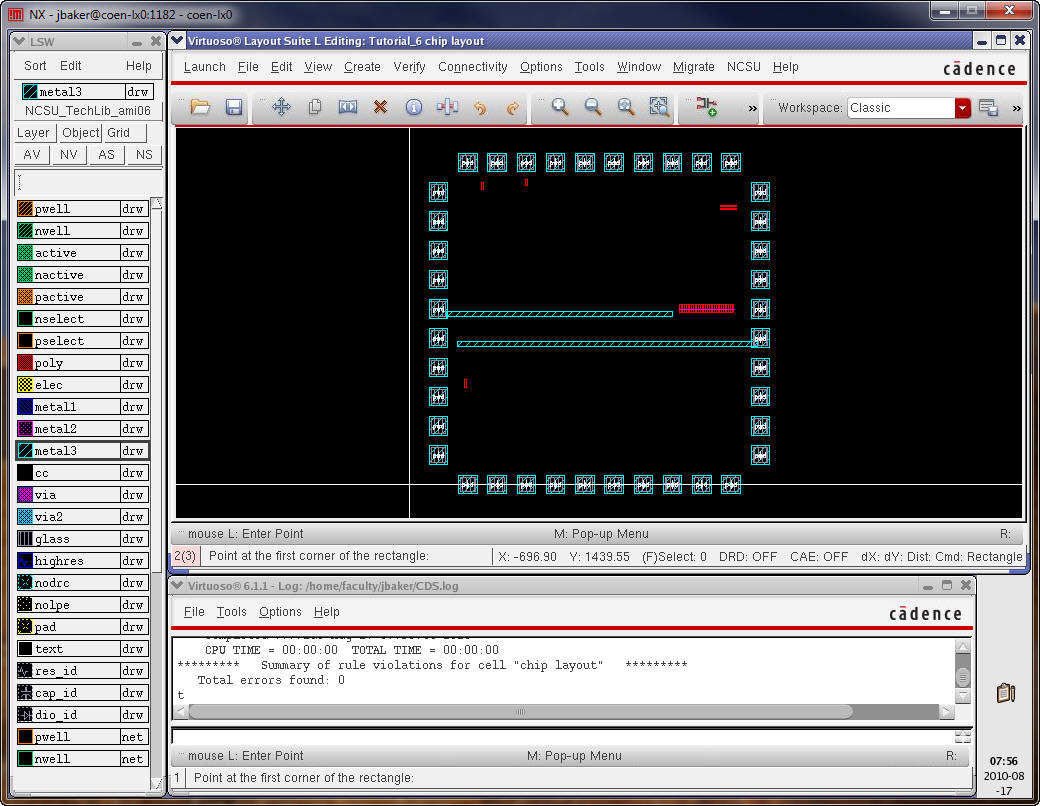

Select the pad

layer and add an arbitrary size rectangle as seen below.

The pad layer has

no fabrication significance (so you really don’t need it).

The pad layer was

used by MOSIS to indicate the location of the pads (now the location of

the

glass layer, that is cuts in the passivation,

is

used).

We’ll use the pad

layer as an outline for the cell. We could also use the text layer for

a cell

outline.

Next edit the

rectangle’s properties so that it is 120 um square centered upon the

origin.

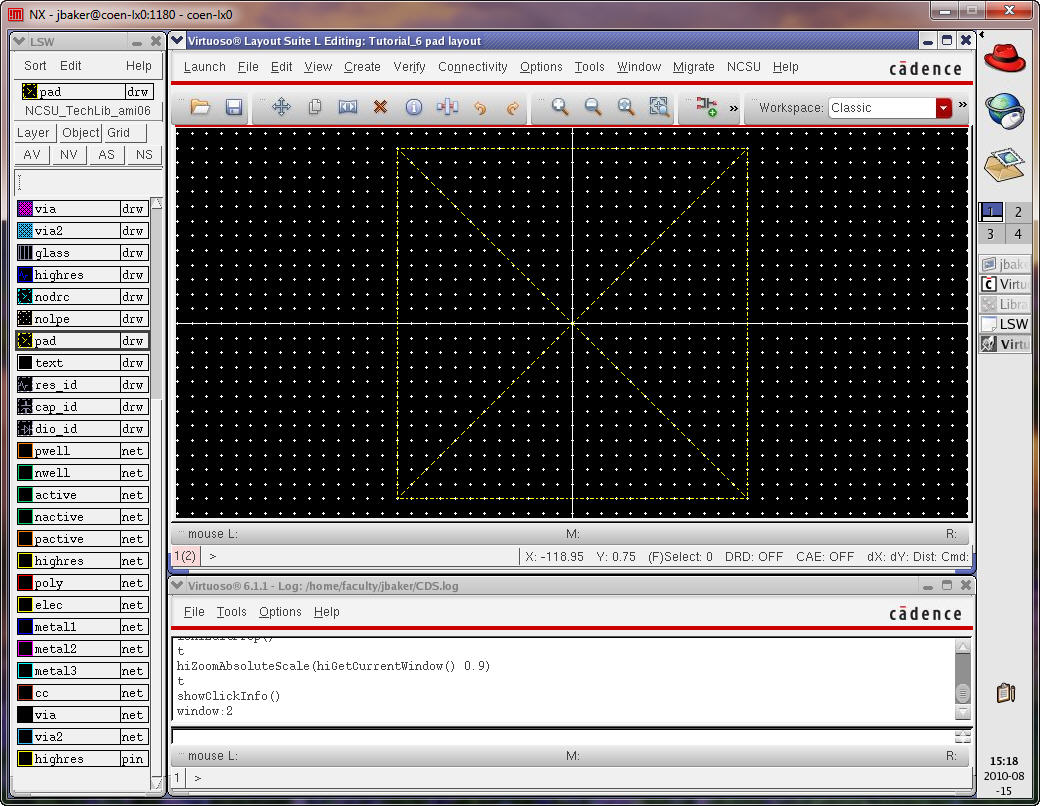

After fitting the

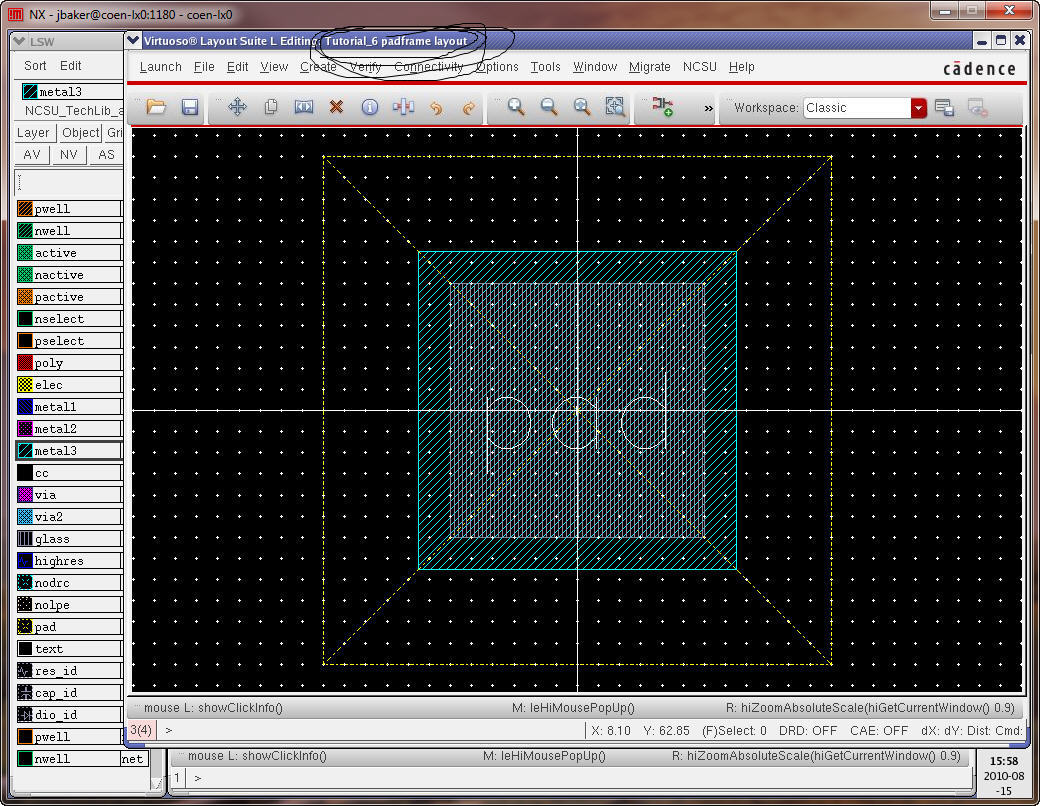

layout we get the following.

The

pad size (metal3) is 75 um square with overglass

(called glass, the opening in the top layer passivation)

6 um

smaller or a rectangle of 63 um.

Note

that both of these sizes, 75 and 63, are divisible by

0.15 (to avoid DRC errors by drawing layout off grid).

Add

two rectangles on these layers, centered around 0,0 to

get the layout of a pad.

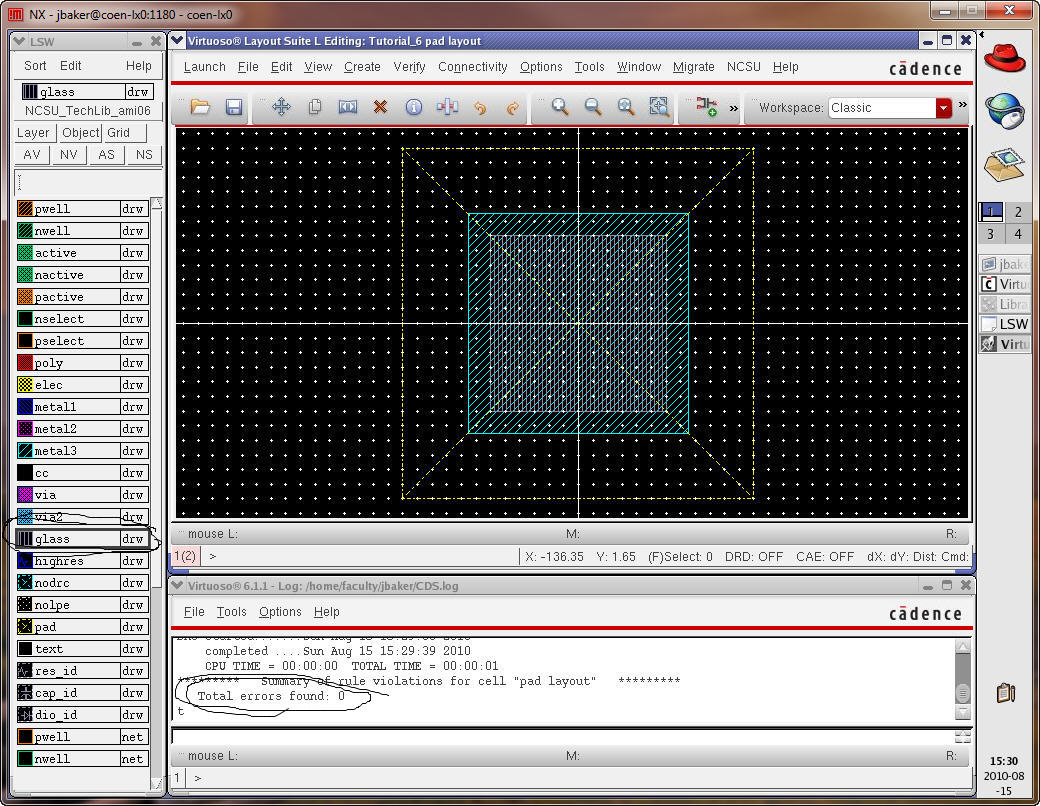

DRC

the layout to ensure no errors. Save the cell.

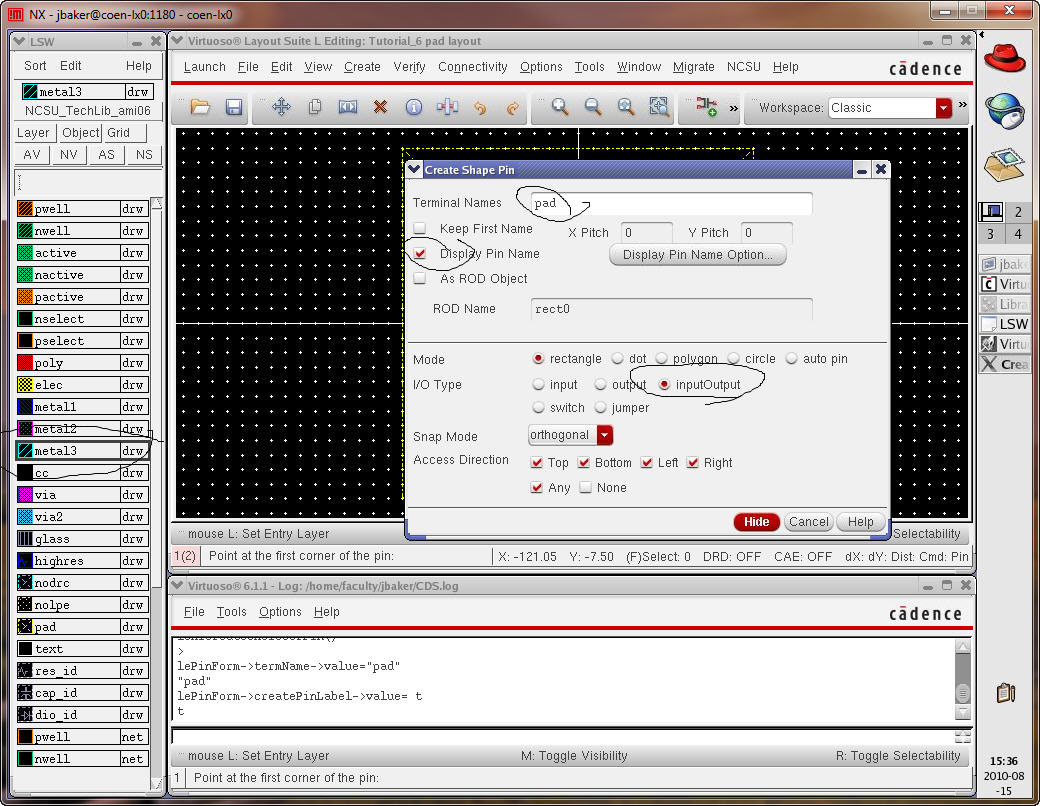

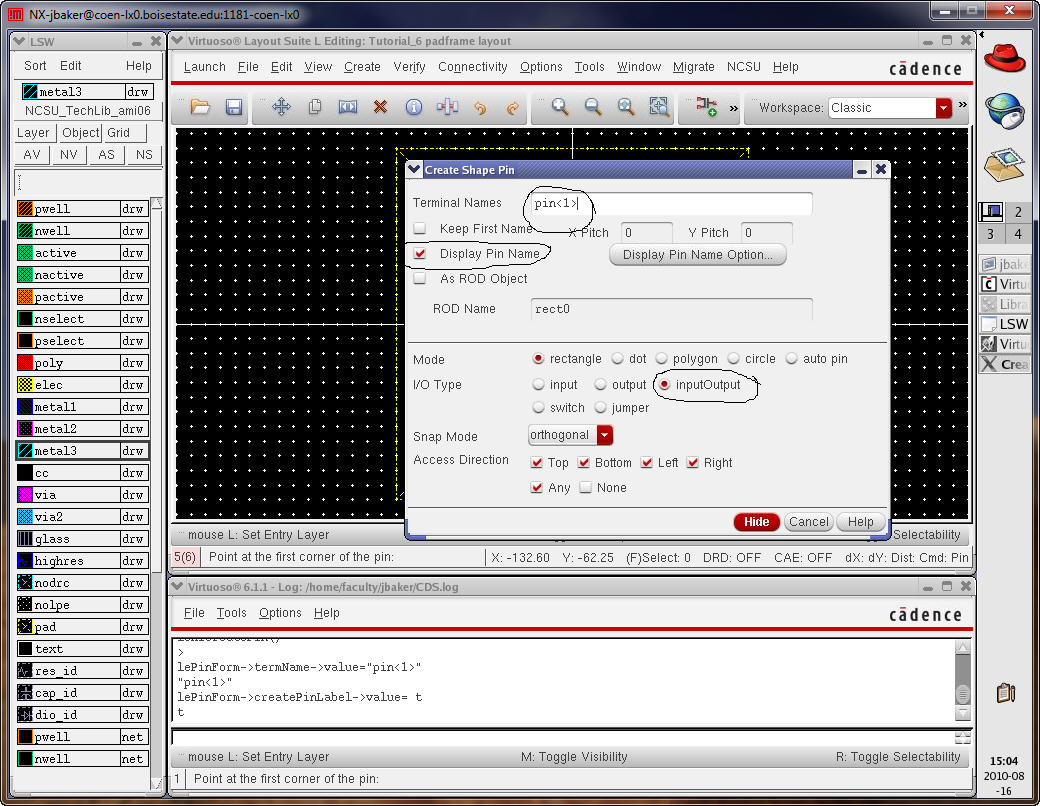

Next

instantiate a pin called “pad” with a direction inputOutput.

Use

the metal3 layer and place the pin over the entire metal3

rectangle (so the size is 75 um square).

Also

ensure Display Pin Name is selected.

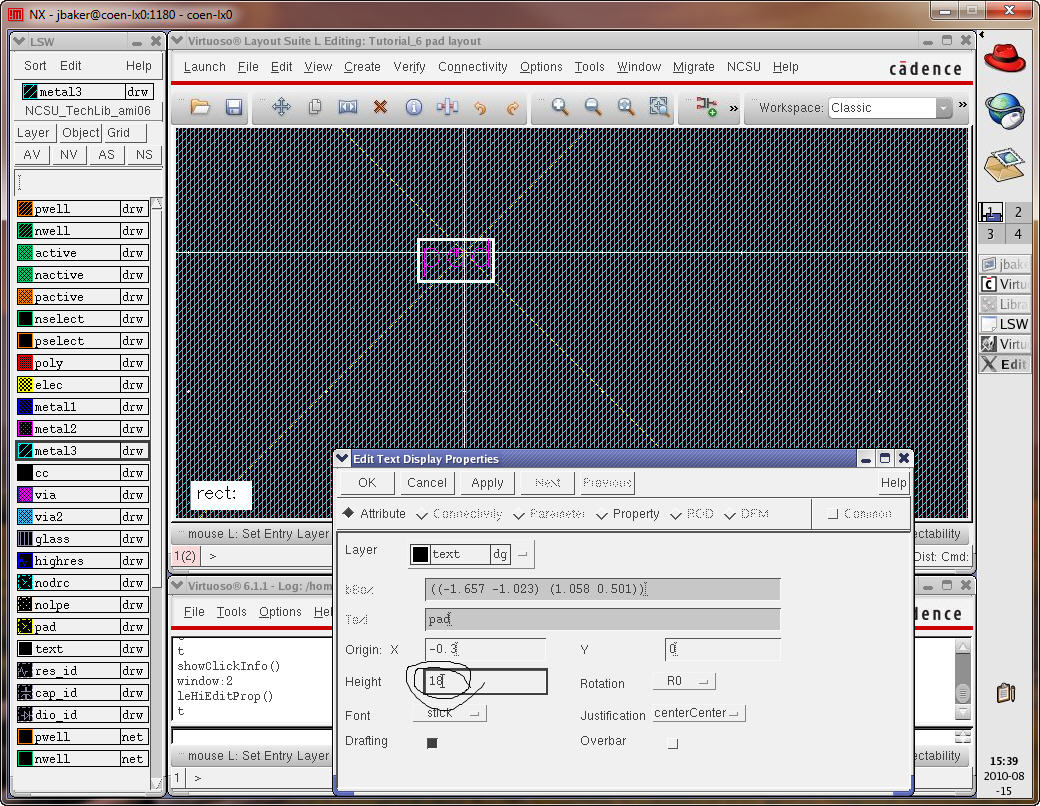

Zoom in and select the pin name and set it’s size to 18 um.

Note

that if you want to change the pin's name (grayed out below) you have

to select the rectangle on metal3 and *not* the pin name (text).

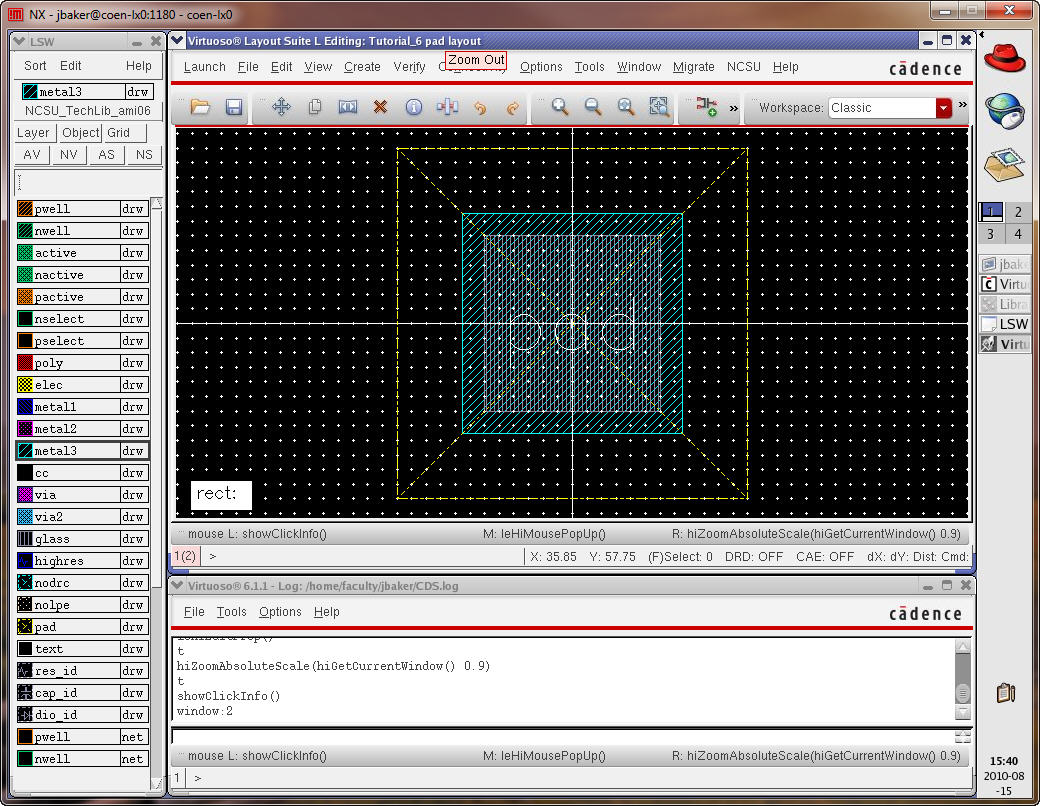

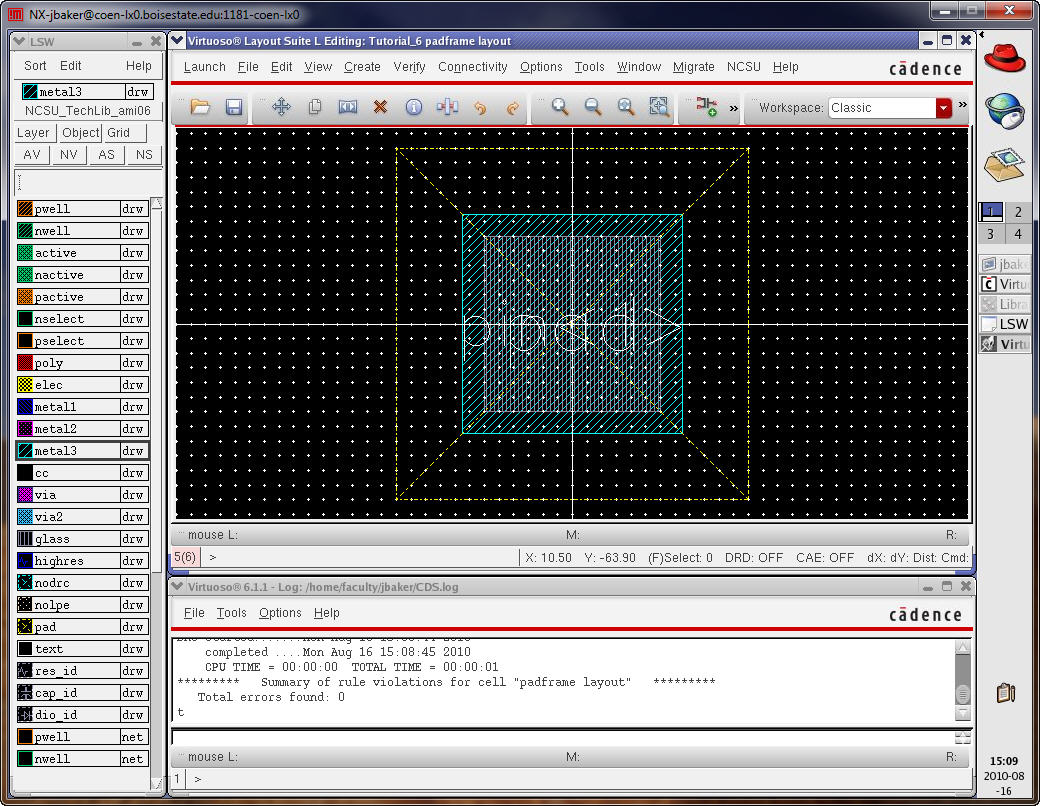

After

fitting the layout we get the following

Save

and DRC the layout.

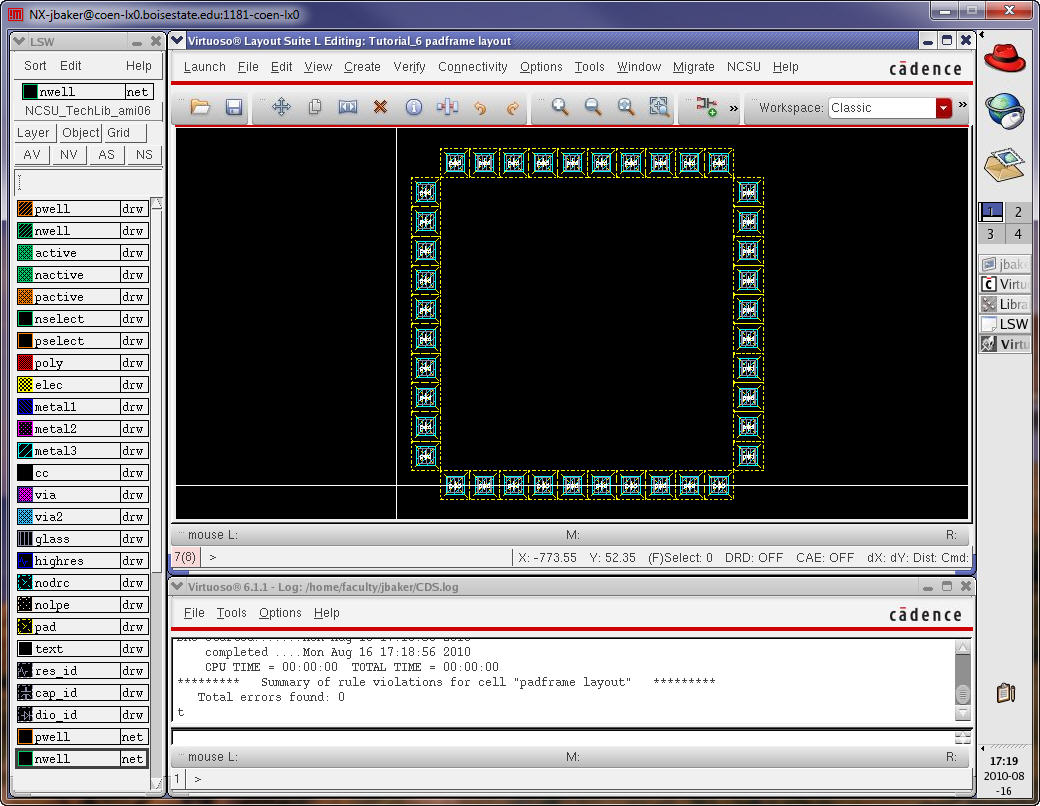

Next

create a layout cellview

called padframe and

instantiate the pad cell into

this new cell as seen below.

Add

a pin on the metal3 layer called pin<1> with a

direction of inputOutput.

Ensure

that Display Pin Name is selected.

After

setting the pin<1> text size to 15 um we get

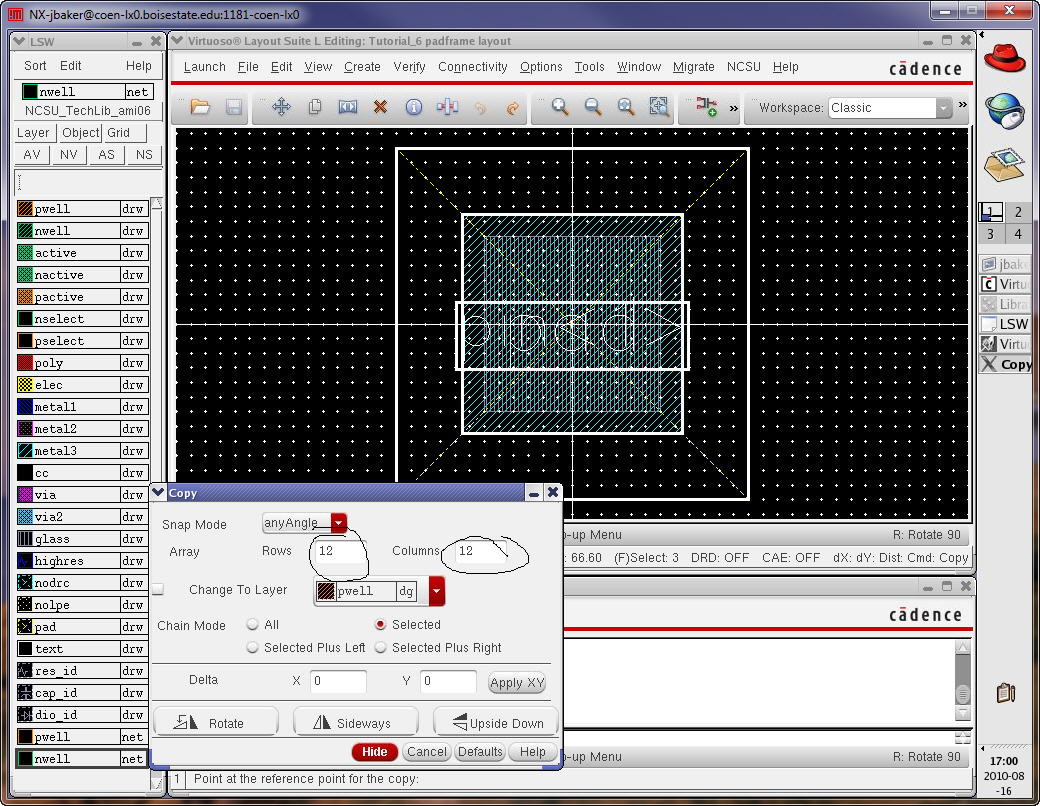

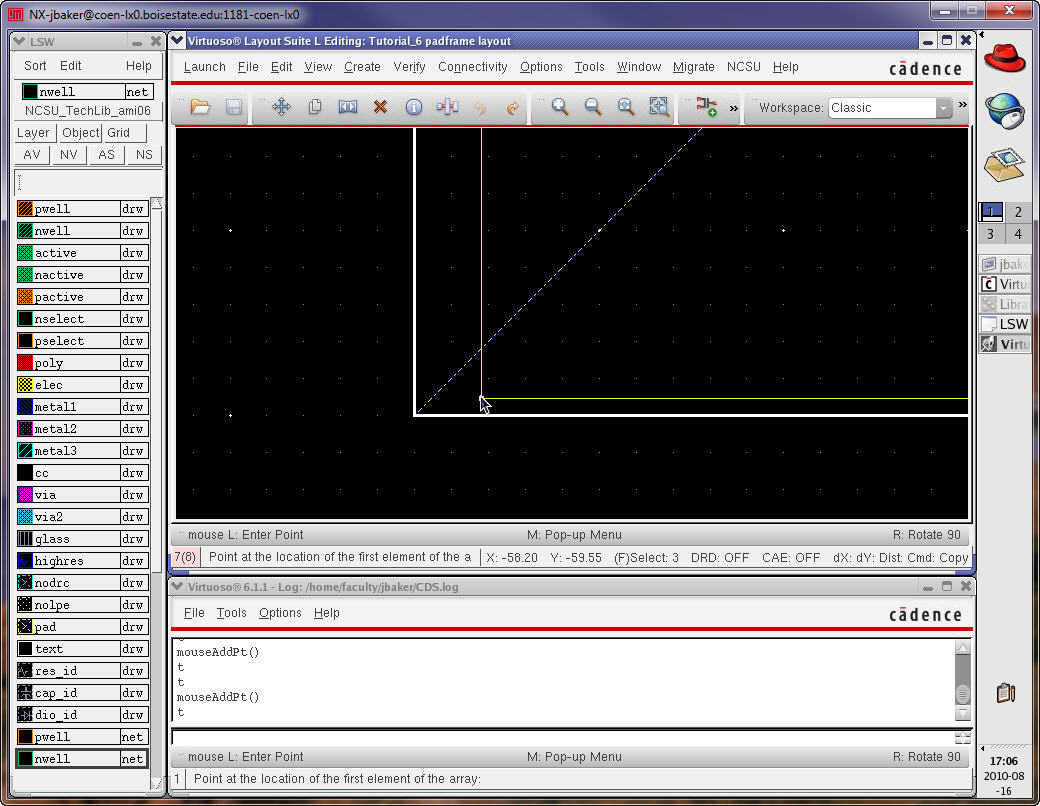

Next

copy, c, the pad cell and pin then use F3 and set

the number of rows and columns to 12.

Select

the lower left corner of the layout.

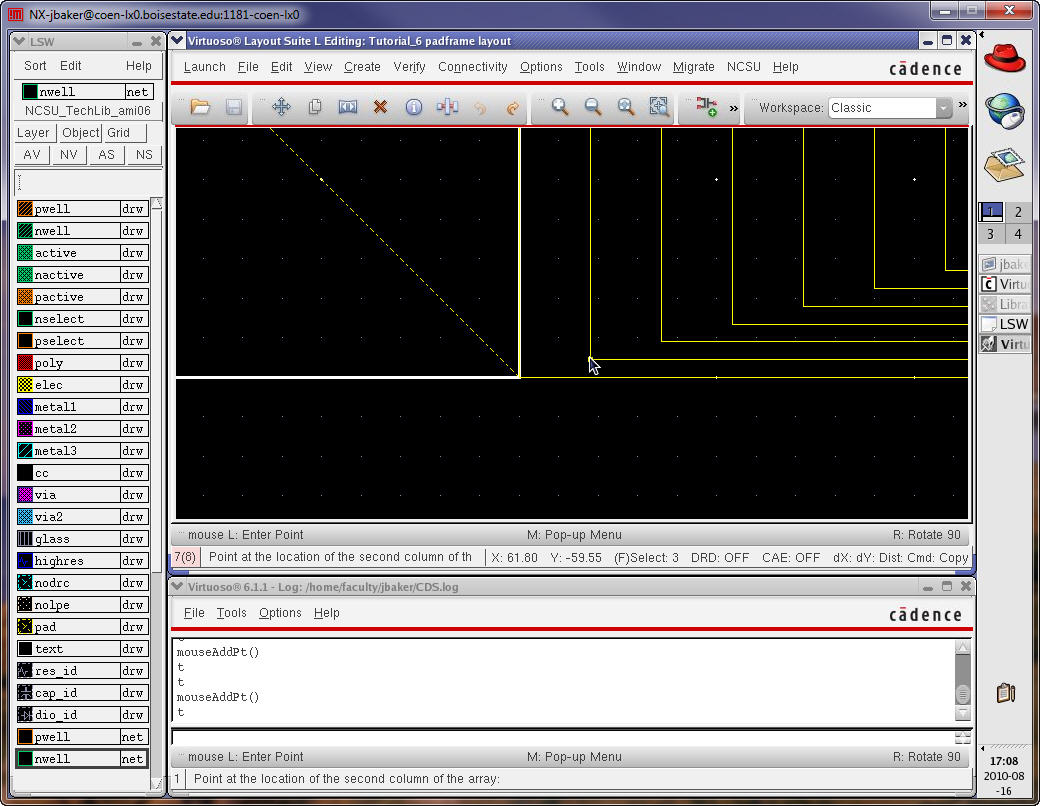

Next

click on the lower right corner of the layout.

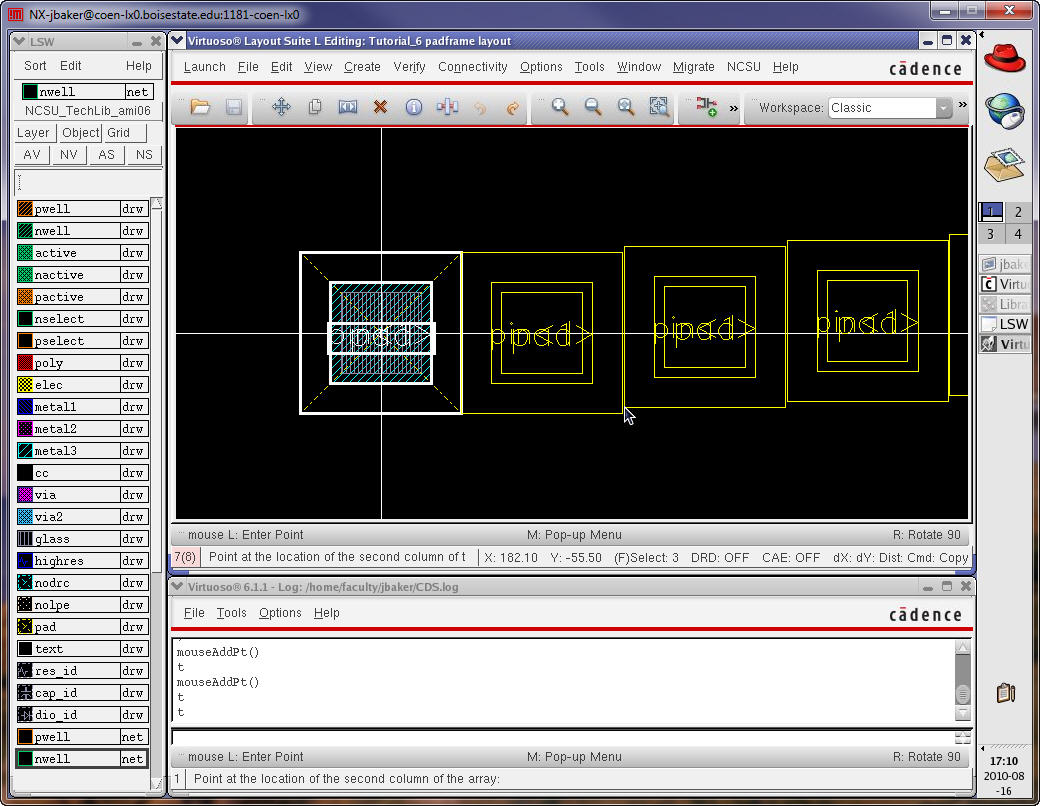

Following

this click in the lower right corner of the first

copied cell as seen below (zoom in to ensure that the cells are aligned

properly).

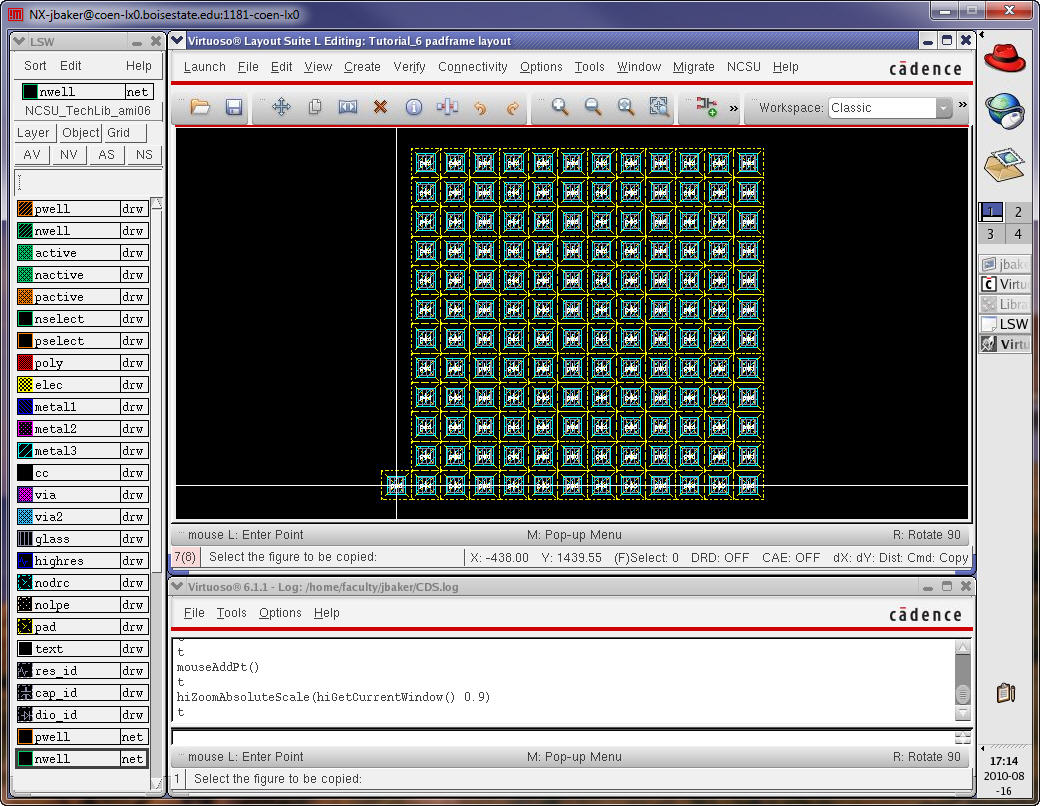

Finally,

click in the top, right, of the first copied cell to

get the layout seen below.

It’s

okay to make mistakes and try again (hit u to

undo and start over).

Delete

the middle, corner, and extra pads/pins to get the

basic padframe seen

below.

DRC

and save the layout of the padframe.

The

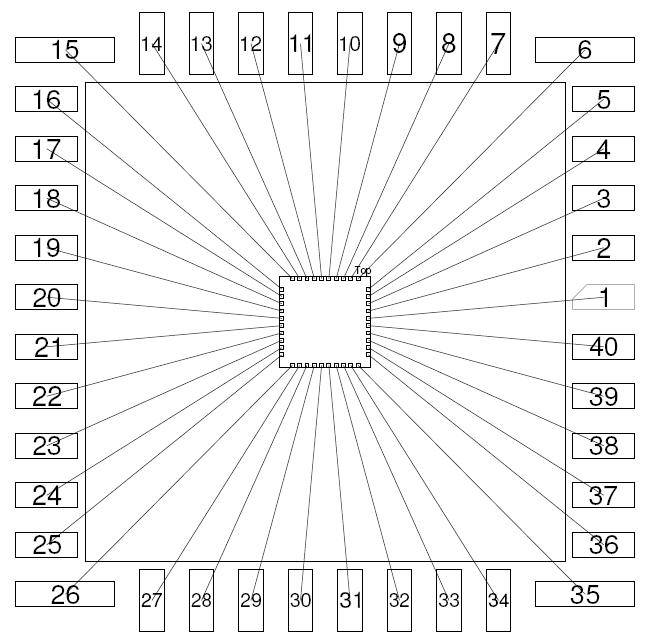

padframe is likely

bonded to

the package with the configuration seen below (the bonding diagram).

All

of the pins in the above layout are labeled pin<1>.

Change

the labels so that they match the bonding diagram seen

below.

For

example, pin 1 of the package corresponds to the 5th

bonding pad from the top on the right side of the die.

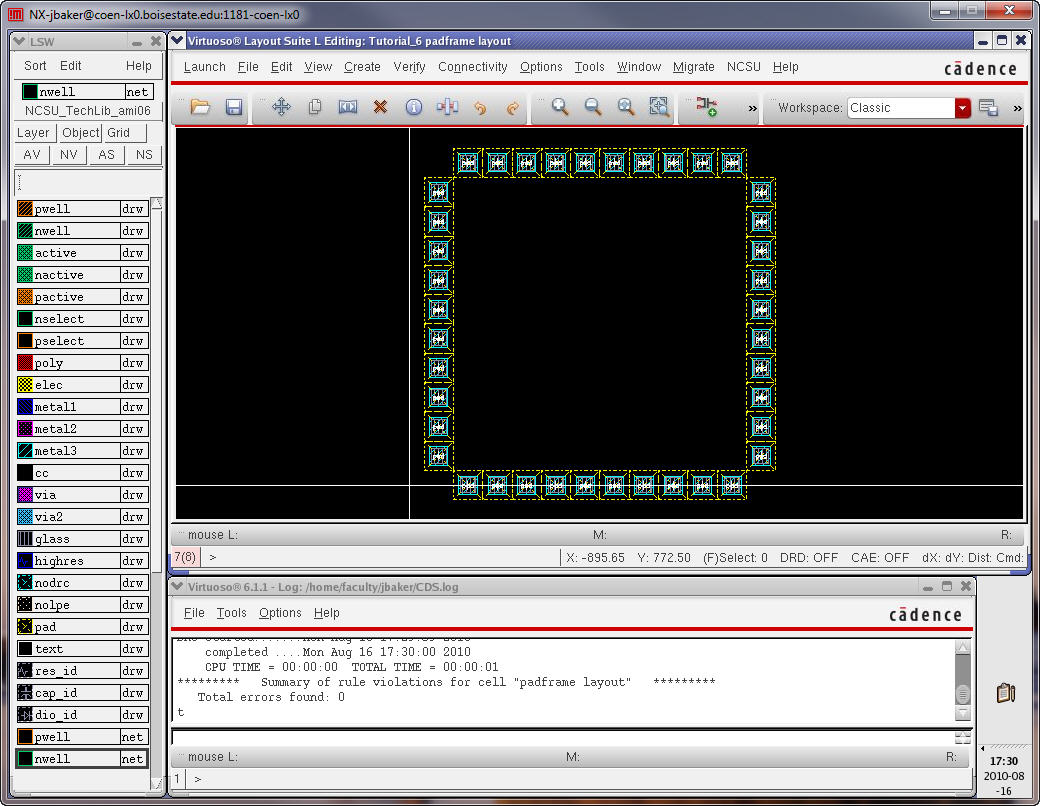

Remove

the pad layer from the pad cell.

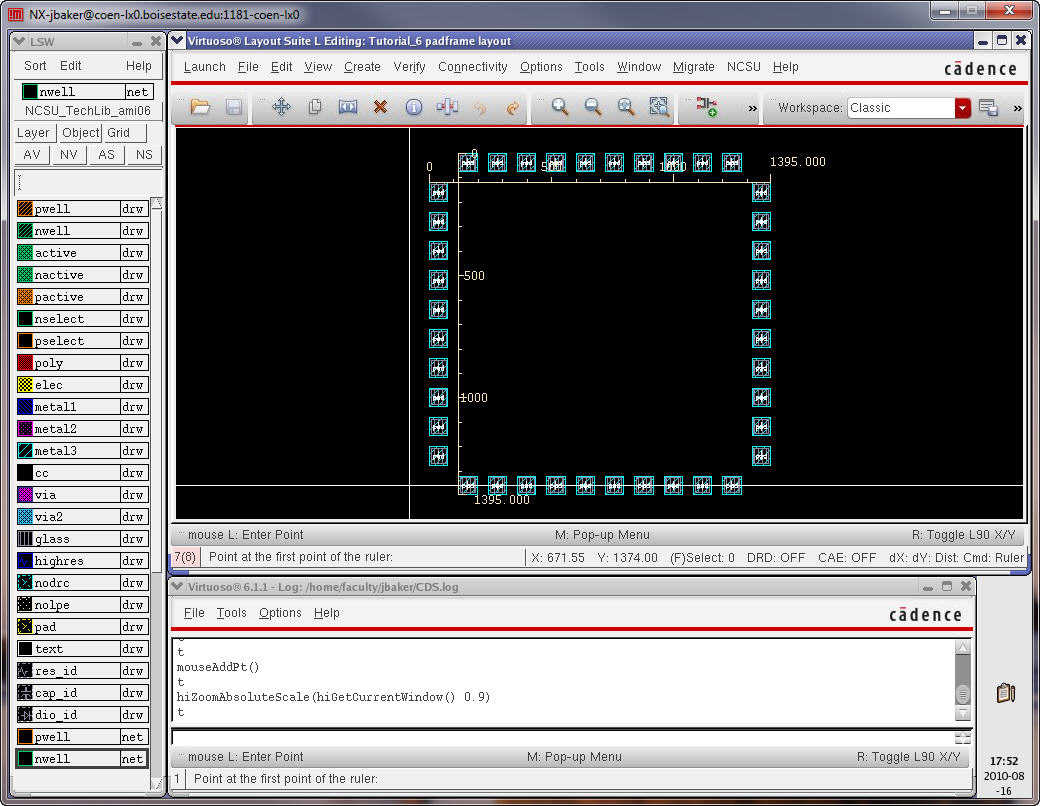

Let’s

measure the size of the padframe

(our chip) since we’ll need this information when we submit to MOSIS.

Using

the ruler we get the following sizes (1.395 mm square).

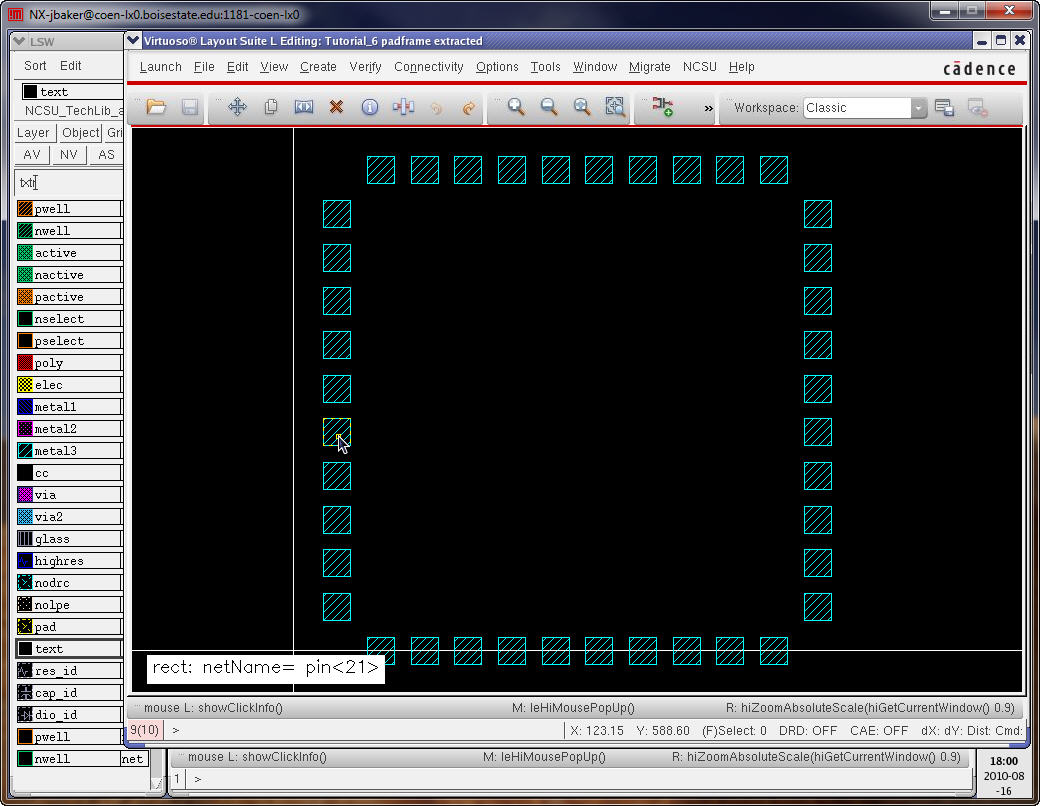

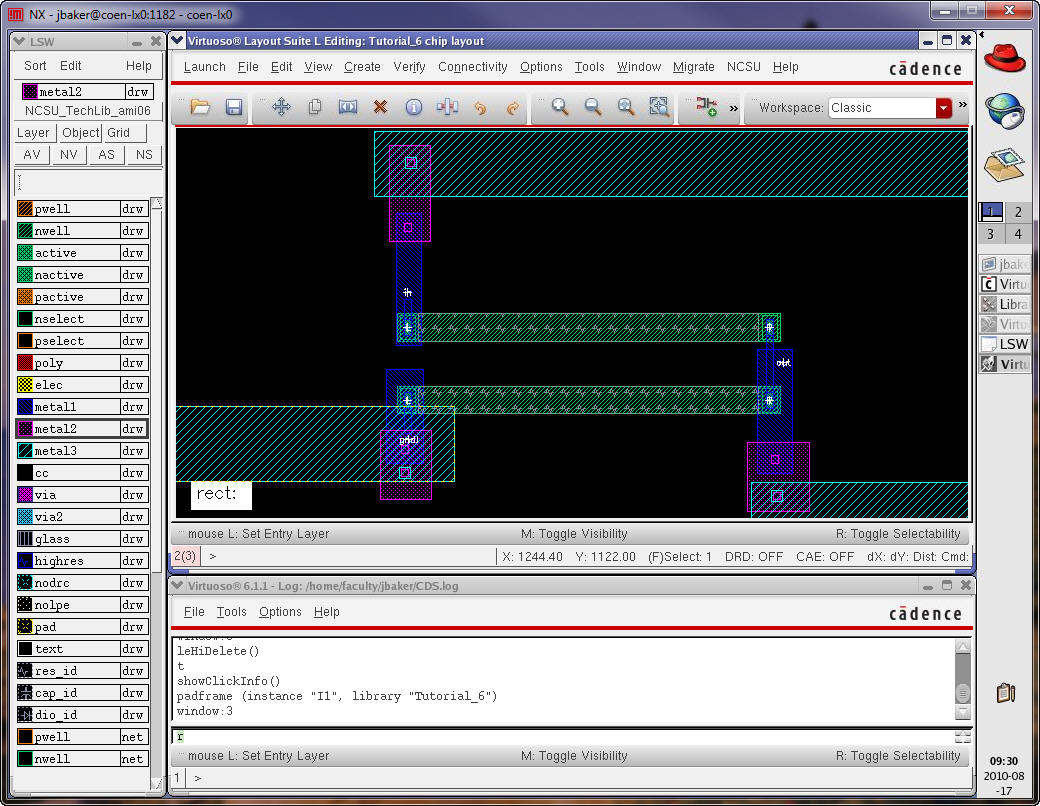

Before

leaving the layout view of the padframe

let’s generate the extracted view.

The

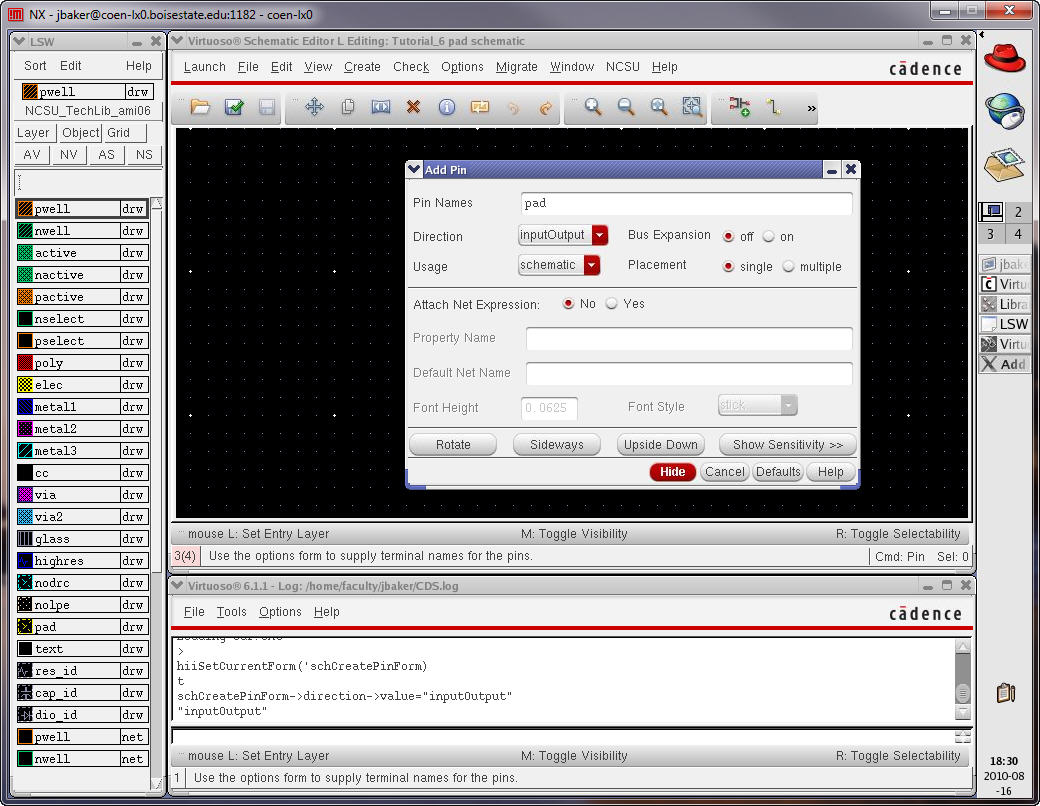

next thing we need to do is generate schematics for the

pad and padframe

layouts.

Generate

a schematic cell view for the pad cell and add a

pin, called pad, with a direction of inputOutput.

Check

and Save the schematic.

Use

Check -> find marker to ignore the warning that the

pin is floating.

Check and Save the schematic again.

Note

that an LVS can't be performed between the pad schematic and layout

since there are no devices (resistors, capacitors, transistors) in the

circuit.

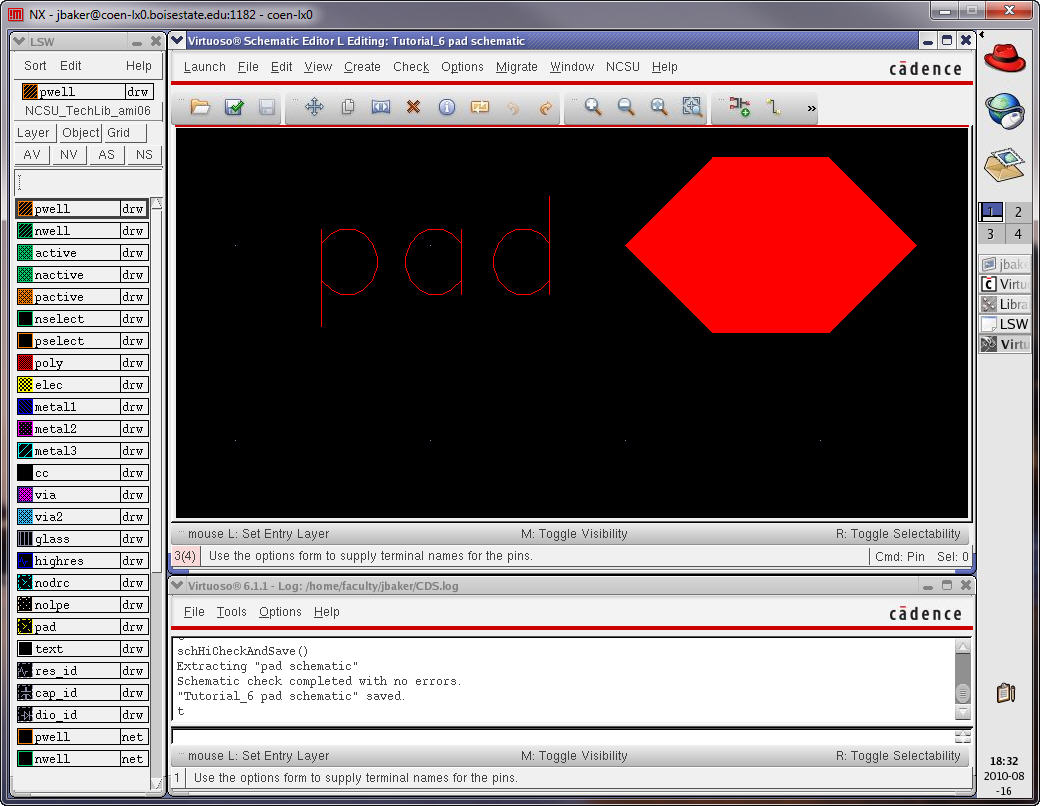

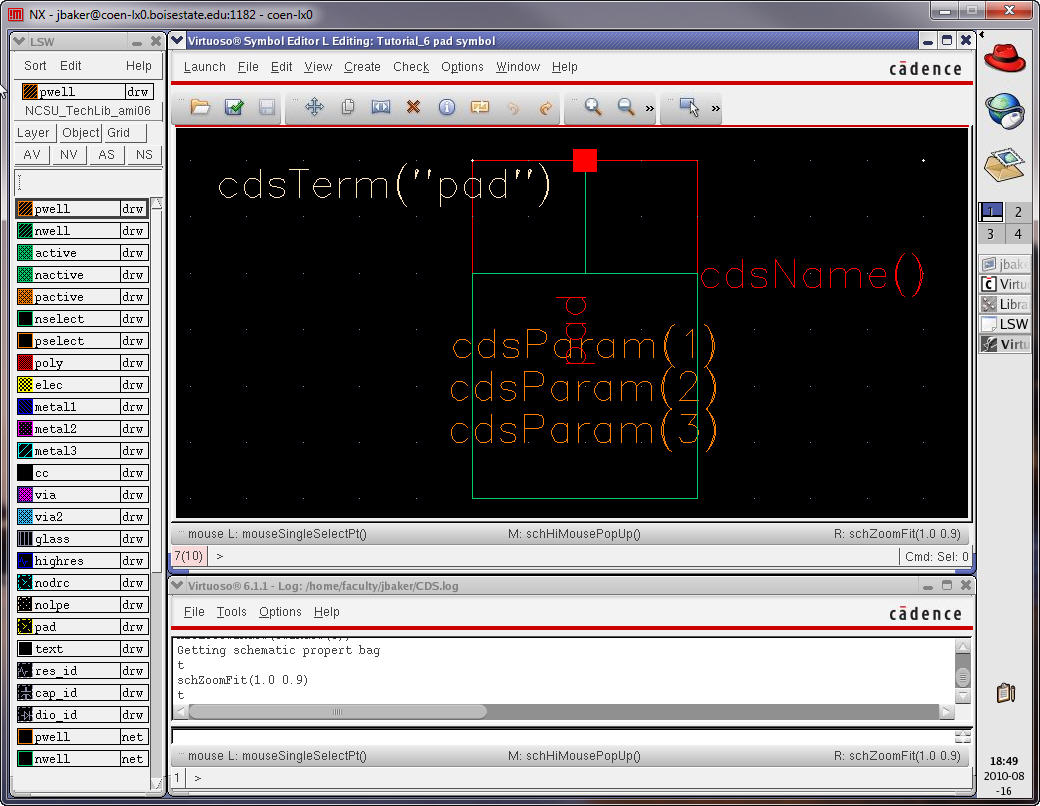

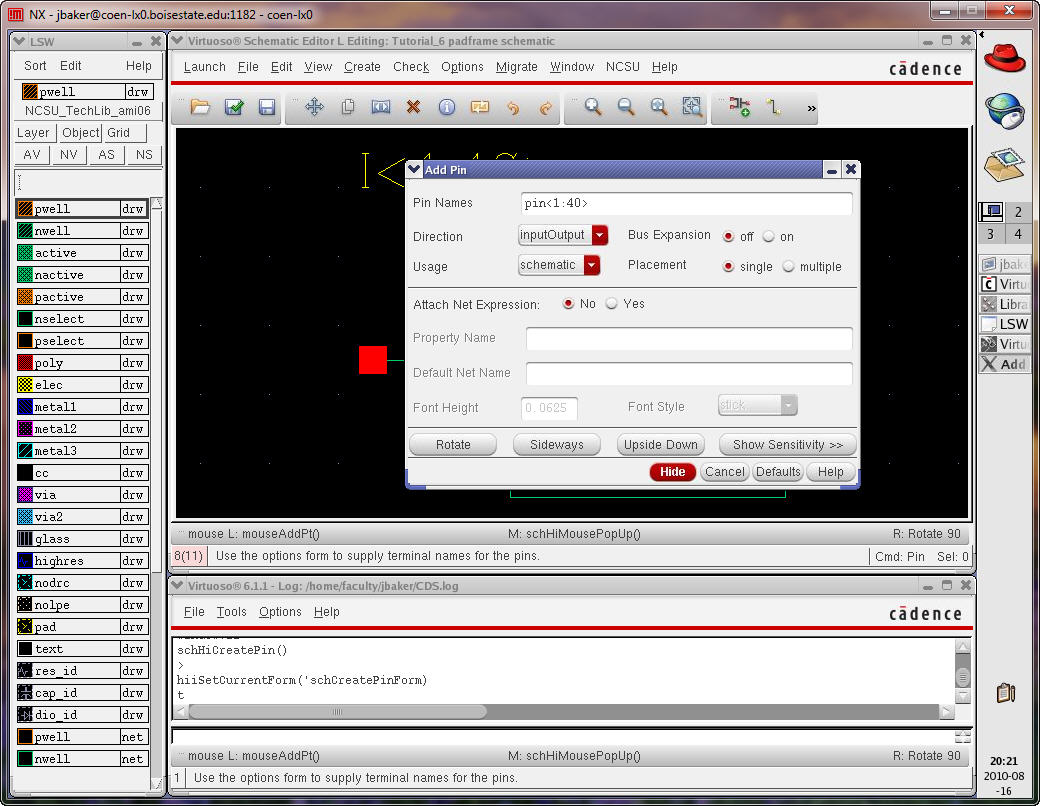

Next

use Create -> Cellview

-> From Cellview

to create a symbol for the pad.

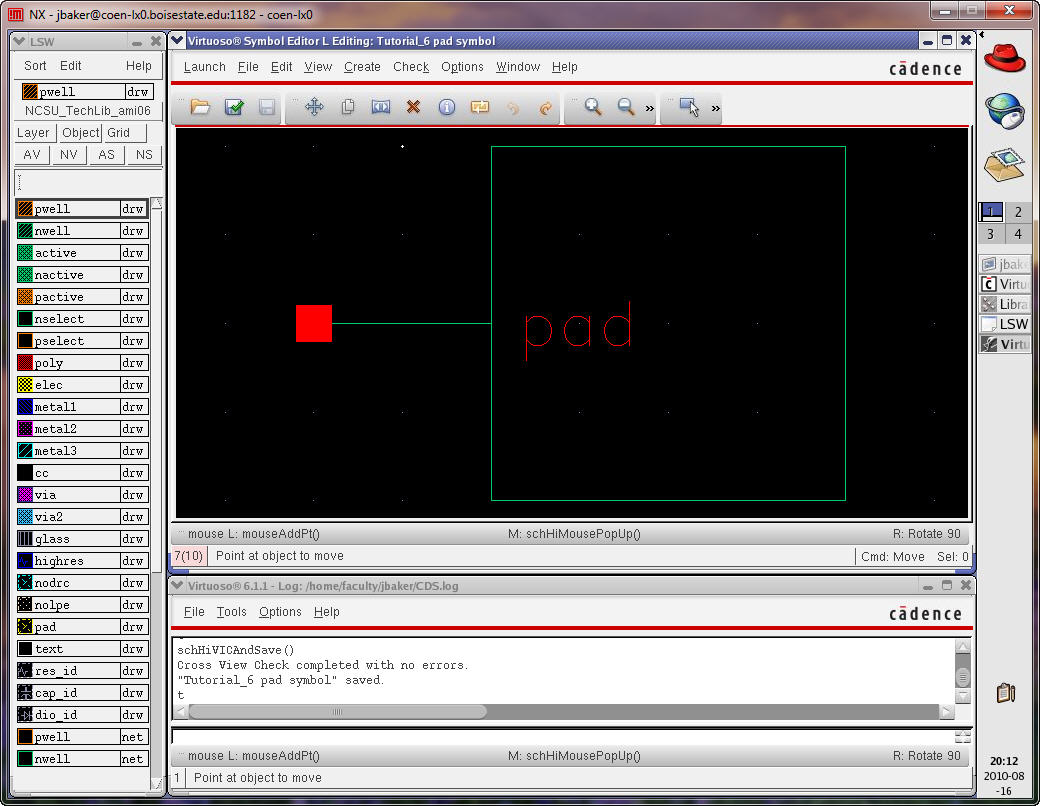

Delete

most items and rotate to get the following.

Save

the pad symbol cellview

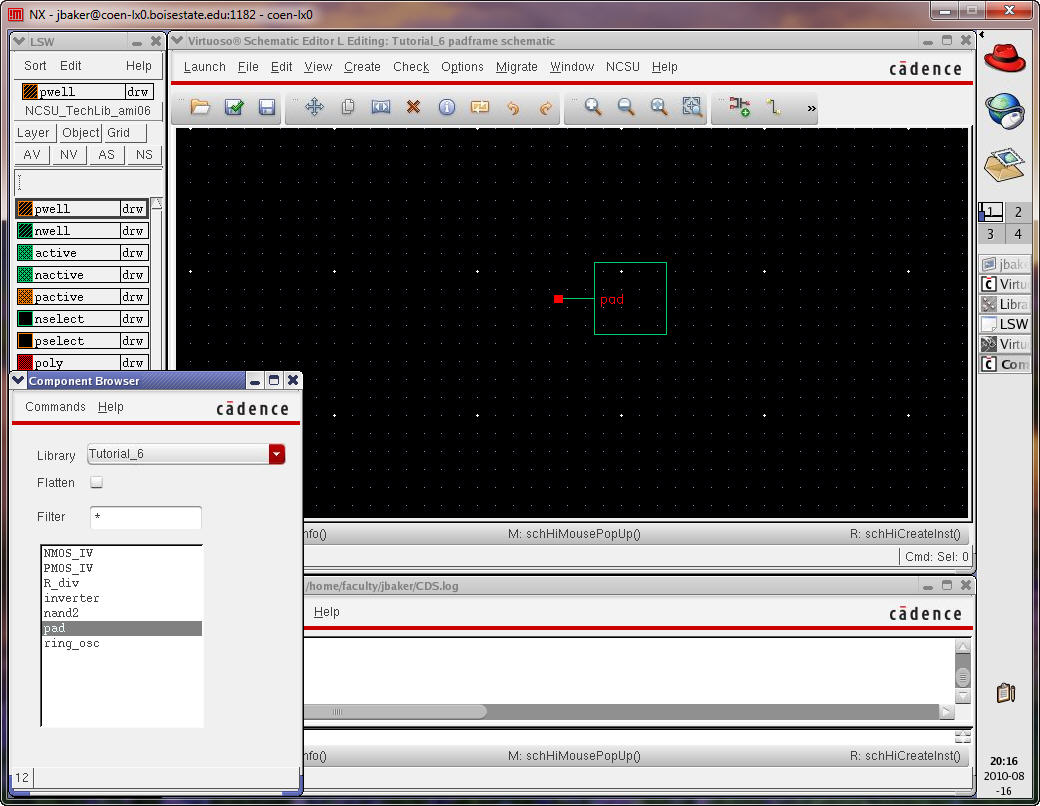

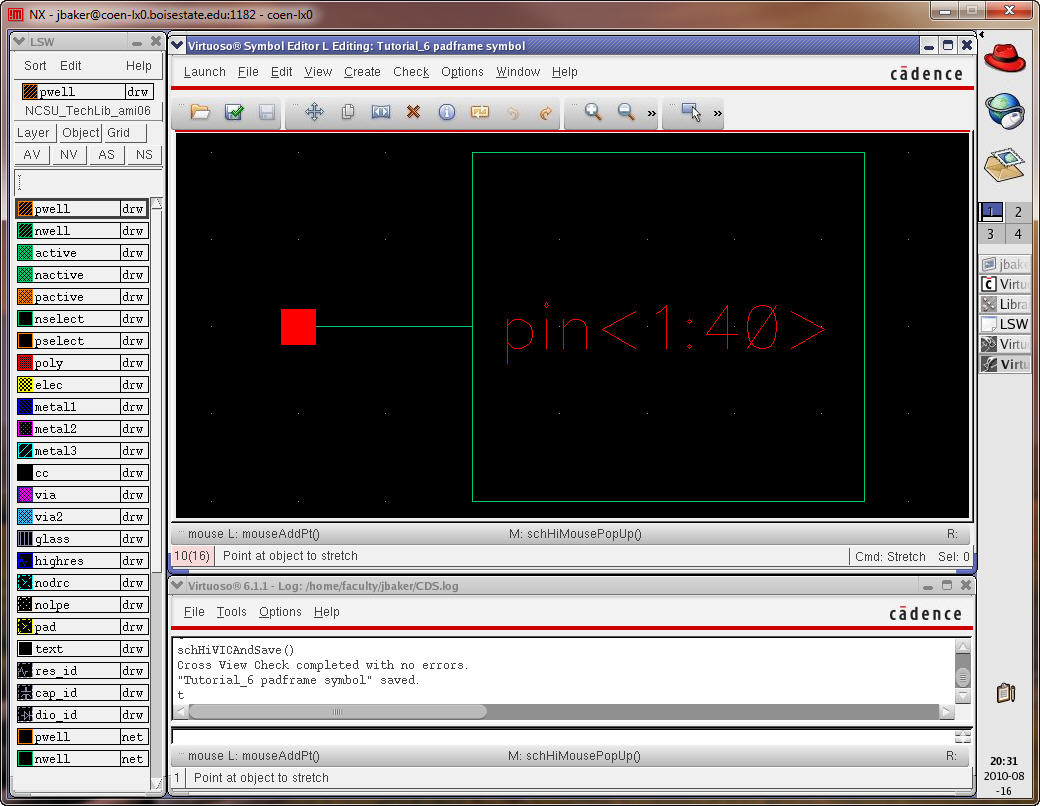

Create

a schematic cellview

for the

padframe and instantiate

the pad cell.

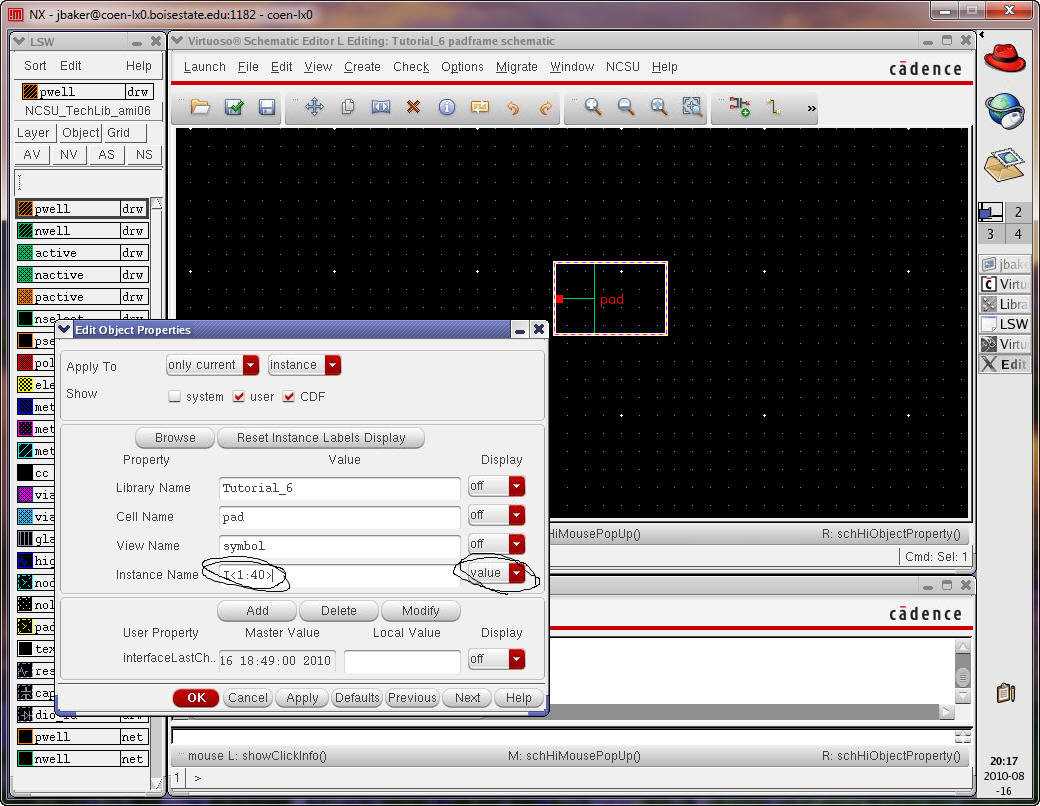

Array

the instance name and ensure the Display is set to

value as seen below.

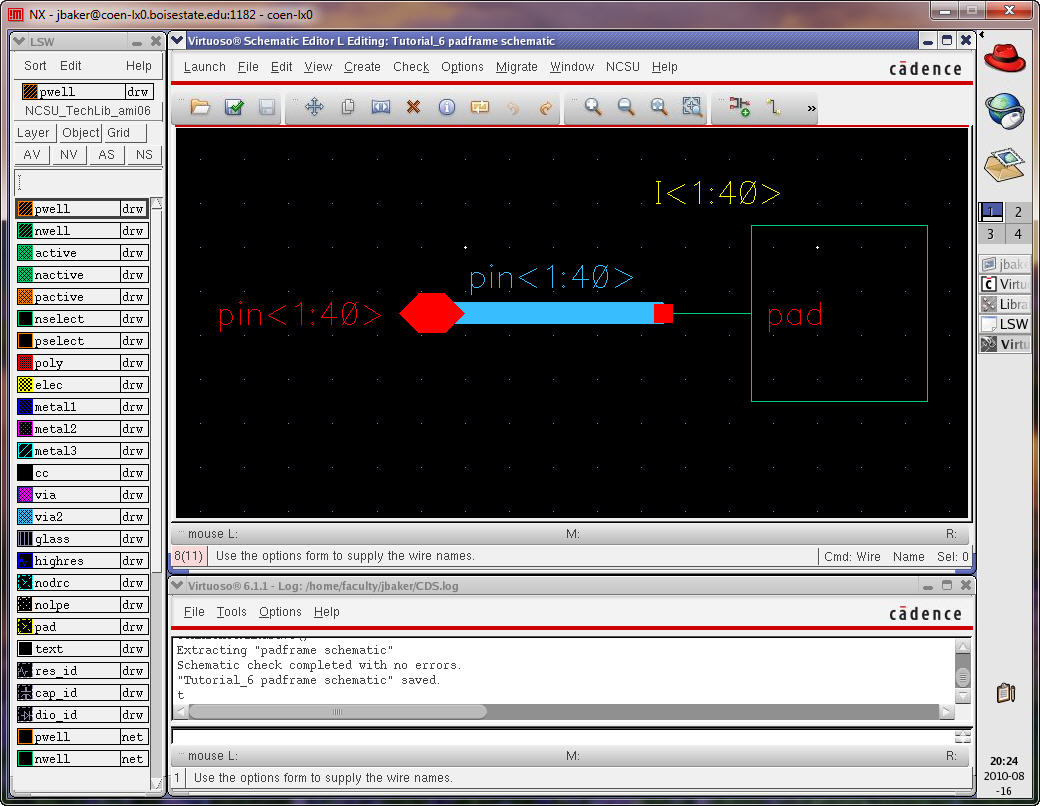

Add

a pin with a name of pin<1:40> and a direction of inputOutput to match the layout

of the padframe.

Add

a wide wire with a label pin<1:40>

Check and Save the schematic view of the padframe.

Note that an LVS can't

be performed between the padframe schematic and

layout since there are no devices

in the circuit.

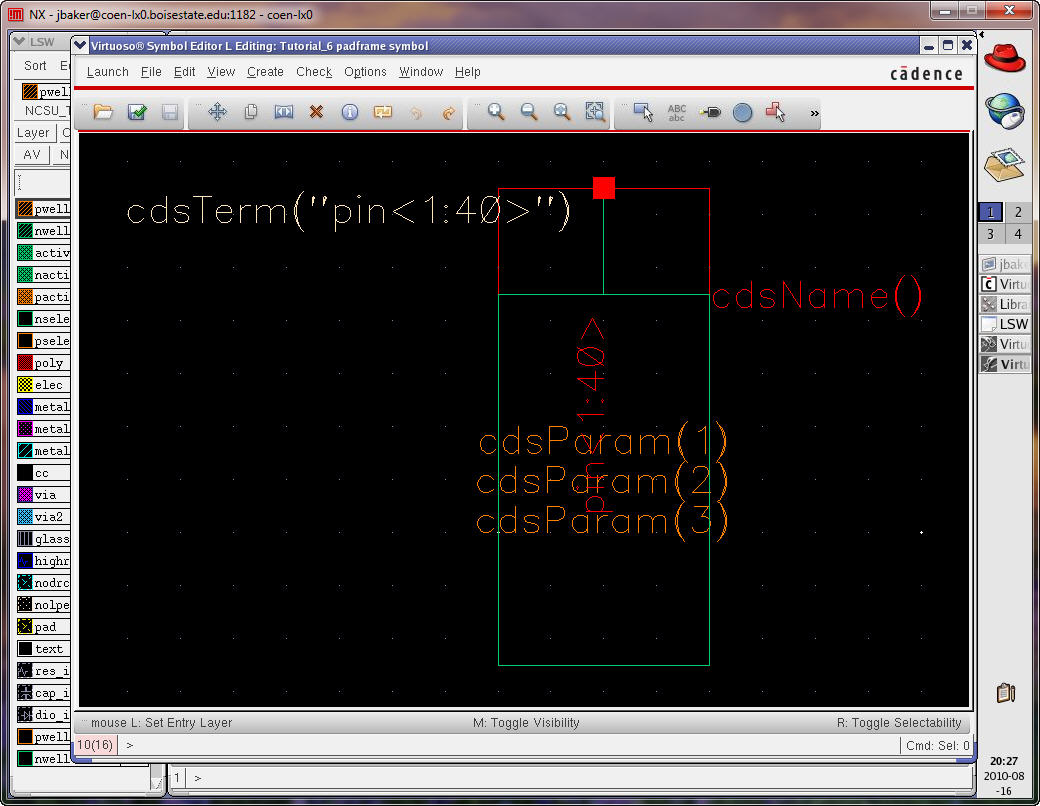

Next

let’s create a symbol for the padframe

using Create -> Cellview

-> From Cellview

Again,

delete most items, stretch, and rotate to get the

following.

Check

and Save the symbol view.

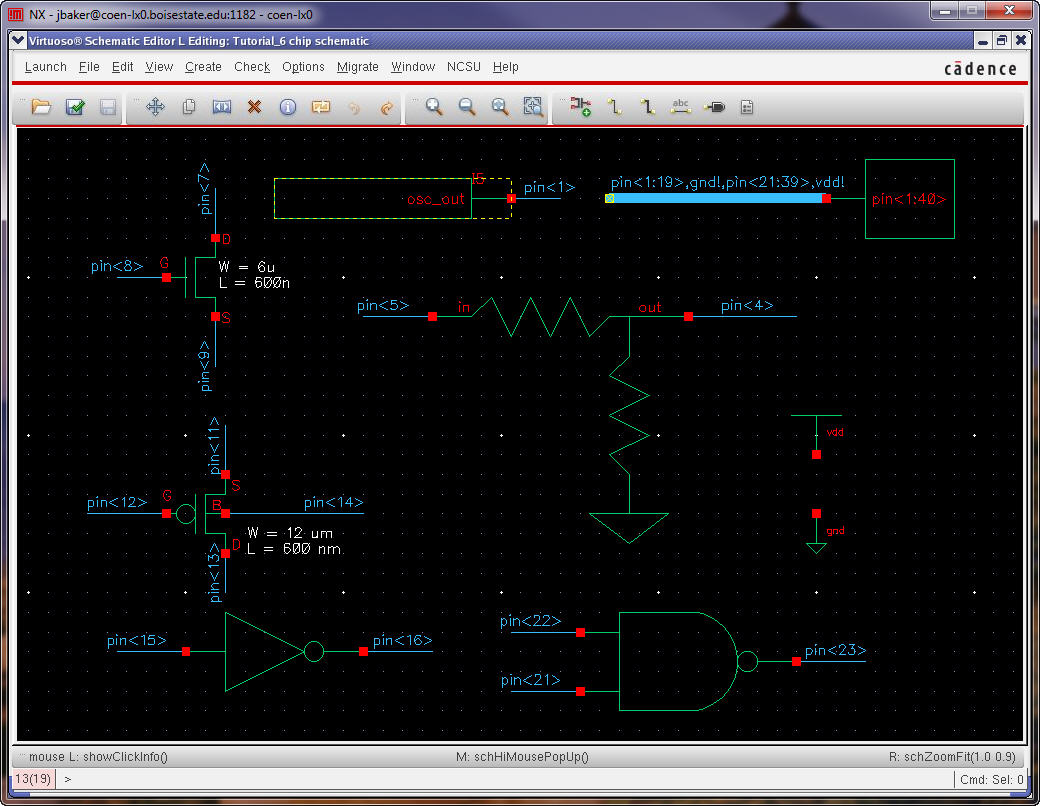

Okay,

we are ready to create our chip layout.

Create

a schematic view of a cell called “chip” and add the cells we’ve

created in the

tutorial.

Wire

the cells up as seen (an arbitrary connection).

Note

how we’ve used pin<20> for ground and

pin<40> for power.

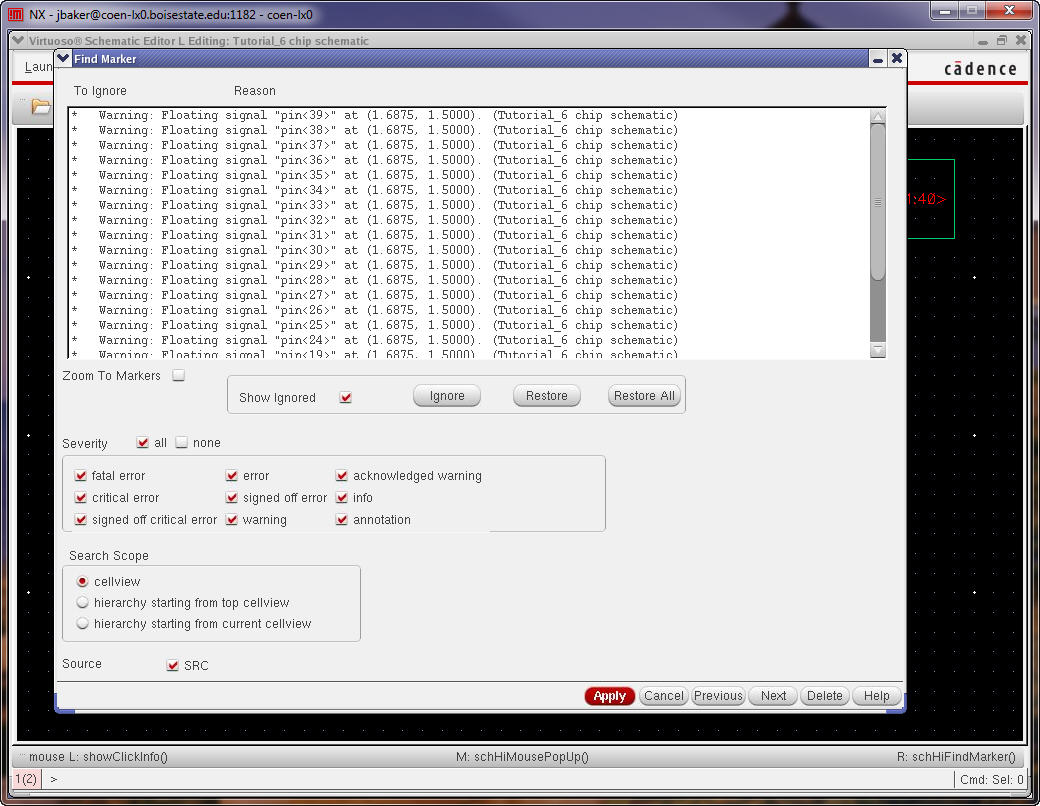

Check

and Save the chip schematic.

Notice

that all of the unused pins on the padframe

are

floating.

Ignore

these warnings and then Check and Save again.

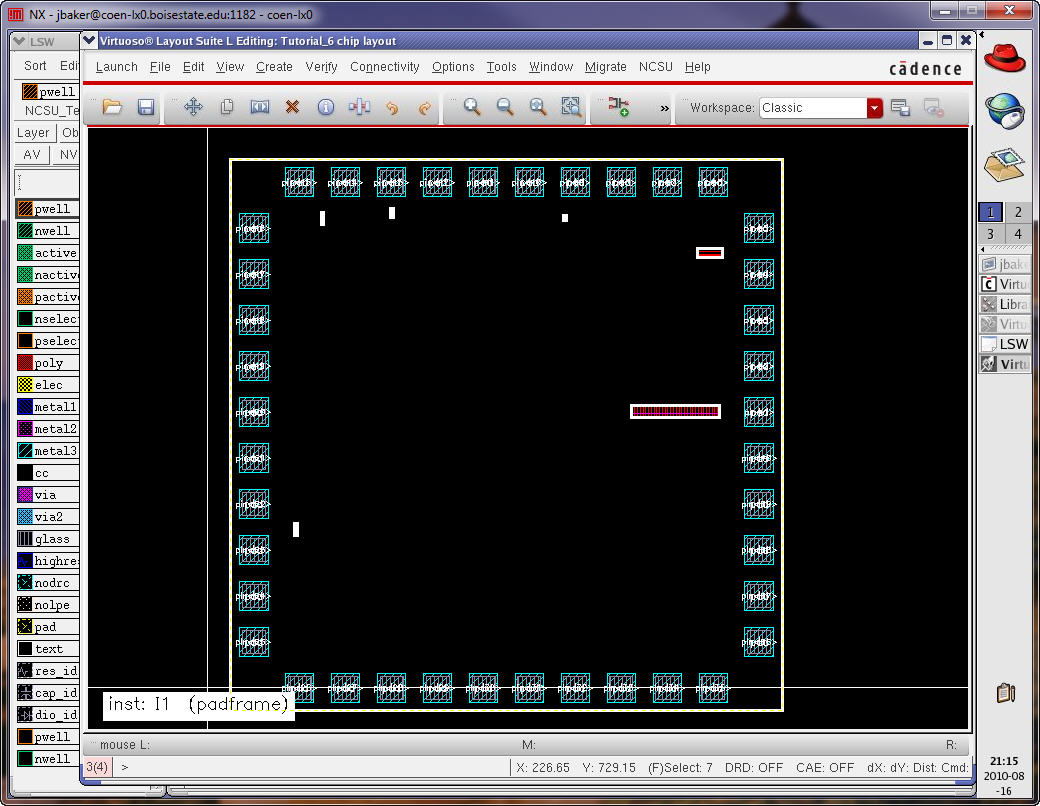

We

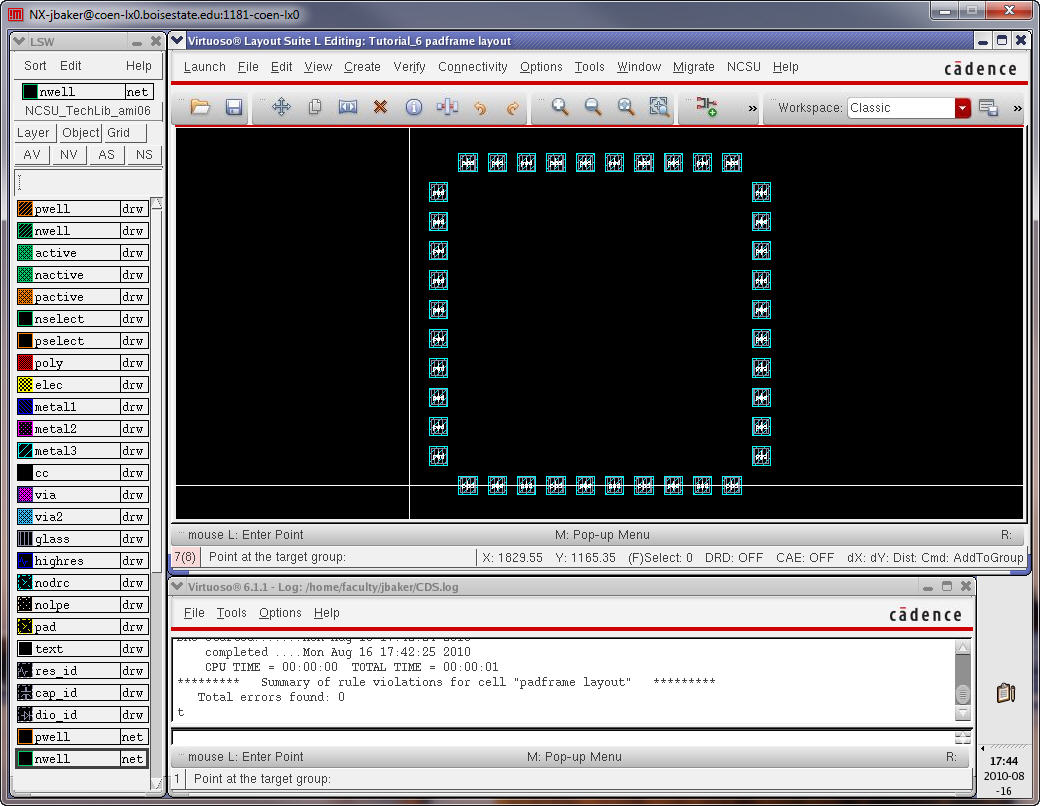

are ready to connect the cells up to the padframe

in

the layout.

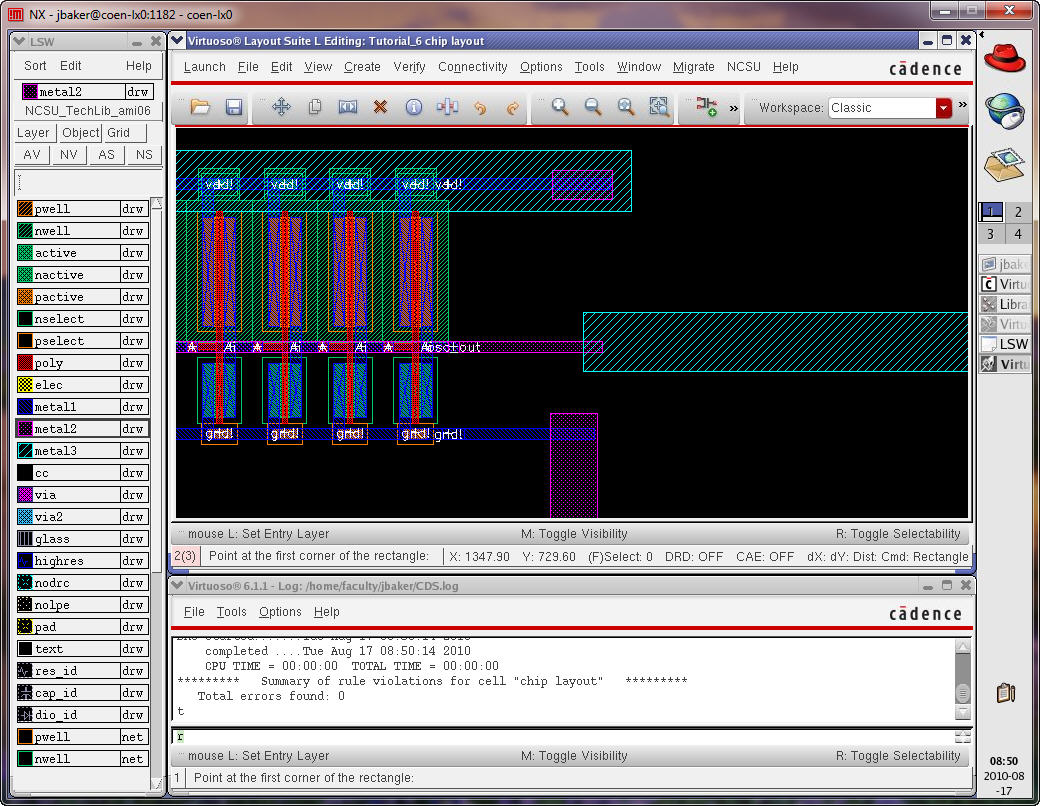

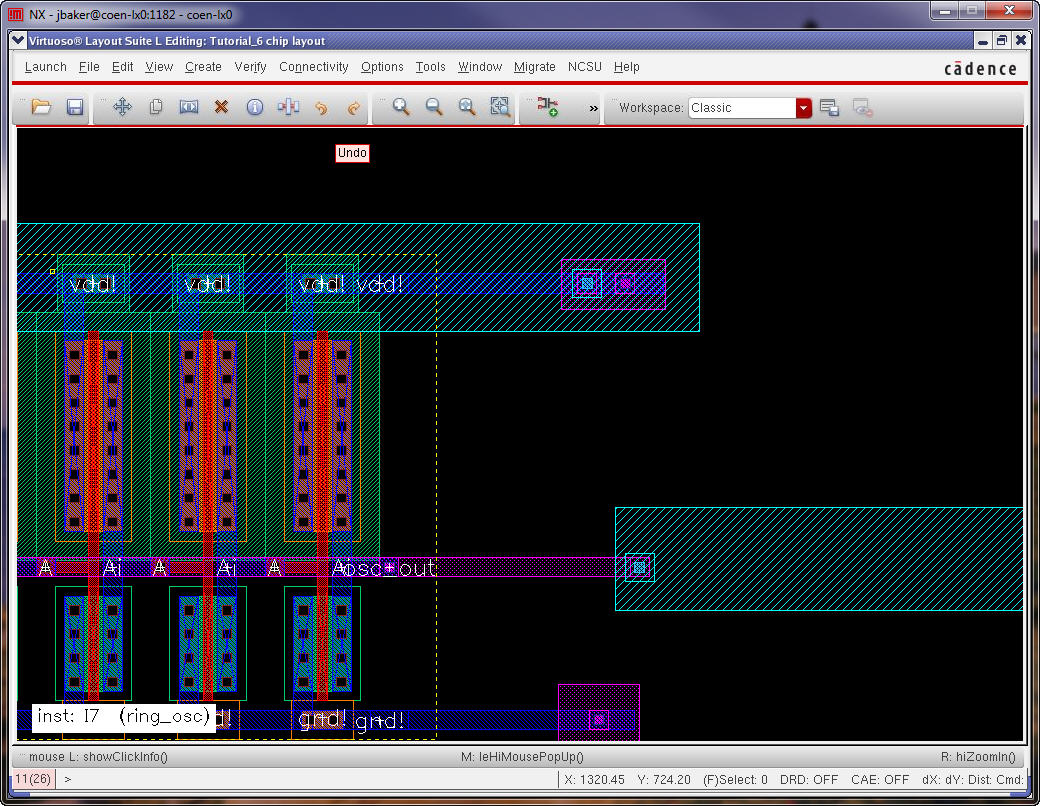

Create

of layout view of the “chip” cell.

Place

the R_div,

NMOS_IV, PMOS_IV, inverter, nand2, and ring oscillator

cells near the pads that they will connect to, below.

We

can adjust the cells’ positions as needed in a moment.

We

won’t try to make the layouts pretty but rather we’ll focus on wiring

the

circuits to the padframe

quickly.

Let’s

begin by drawing rectangles on metal3 for connections to vdd!

and gnd!

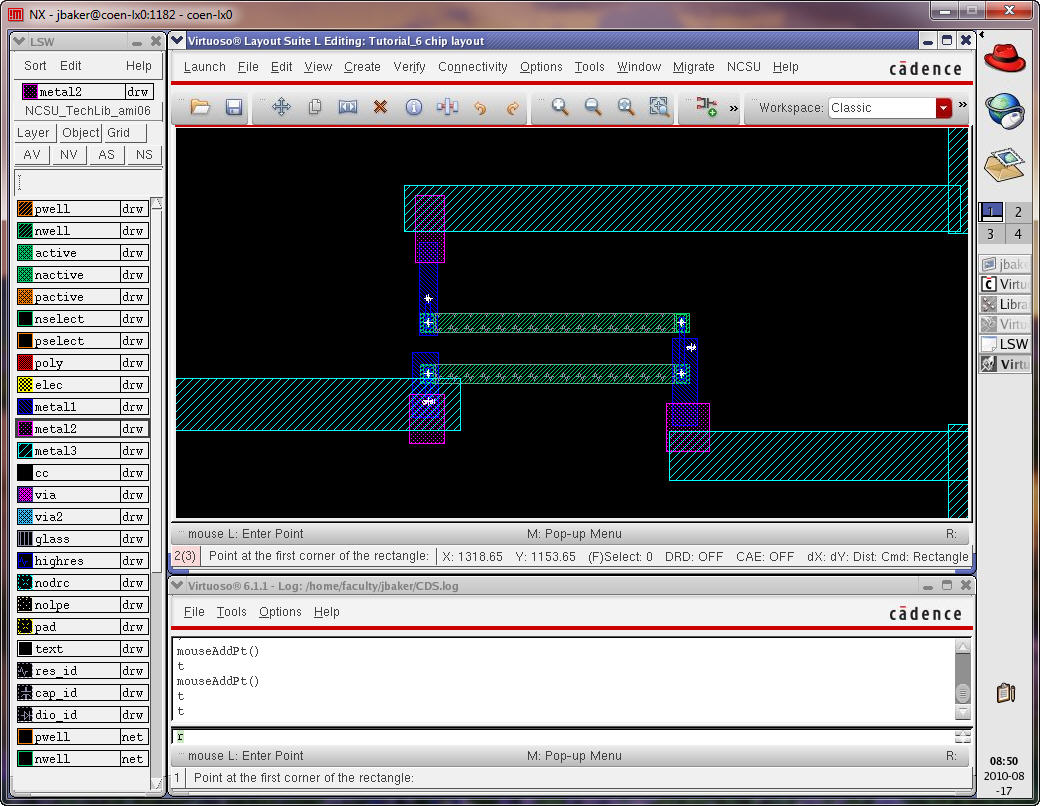

Next

let’s add rectangles on the metal layers to move towards connecting the

cells

up to the padframe.

Below

are examples zoomed in around the ring oscillator and resistive divider.

Again,

we are not trying to make a “pretty” layout (or a good one for that

matter) but

rather just connect the circuitry up.

It’s

useful to DRC the layout as you go to fix the errors that will occur.

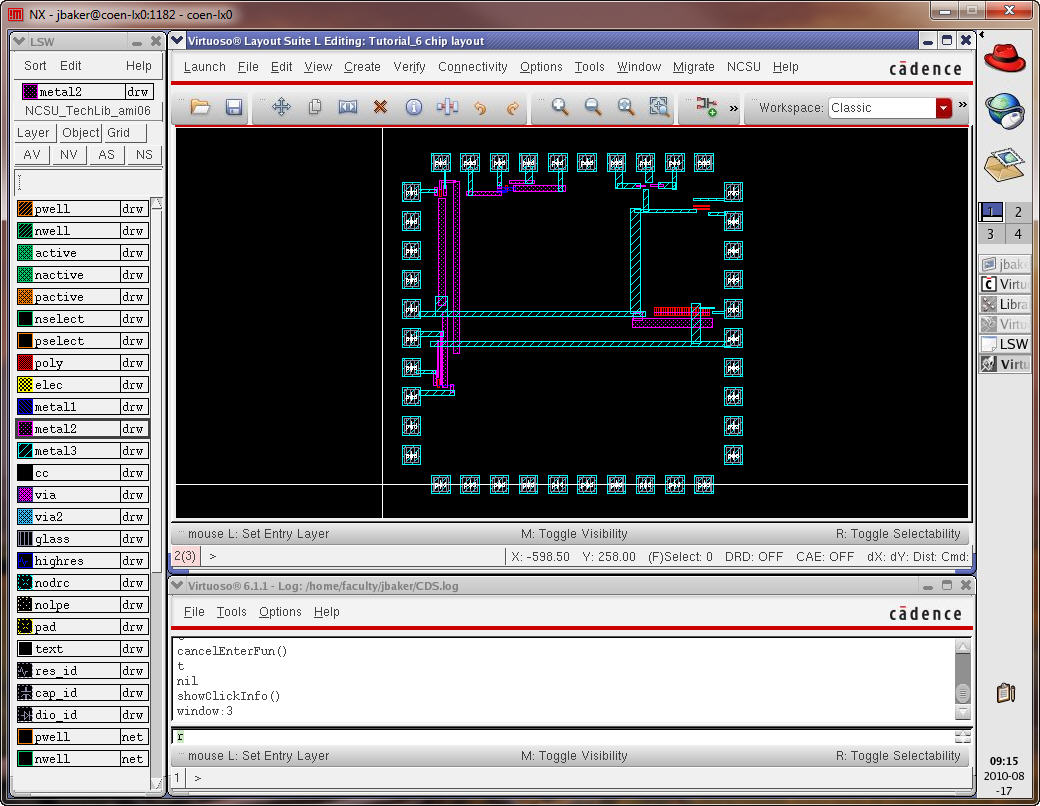

After

adding all rectangles our chip layout may look like the following.

Next

let’s add vias.

Below

are examples (again, these are not examples of good layouts but rather

simply

to illustrate the operation of the tools).

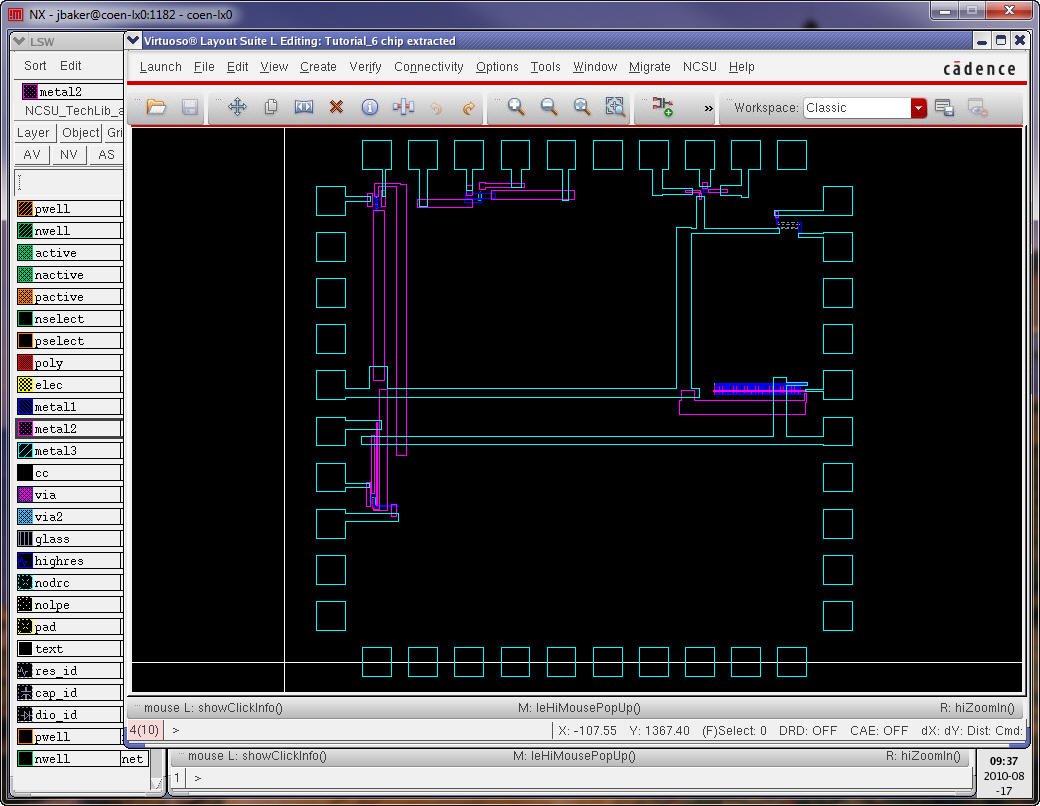

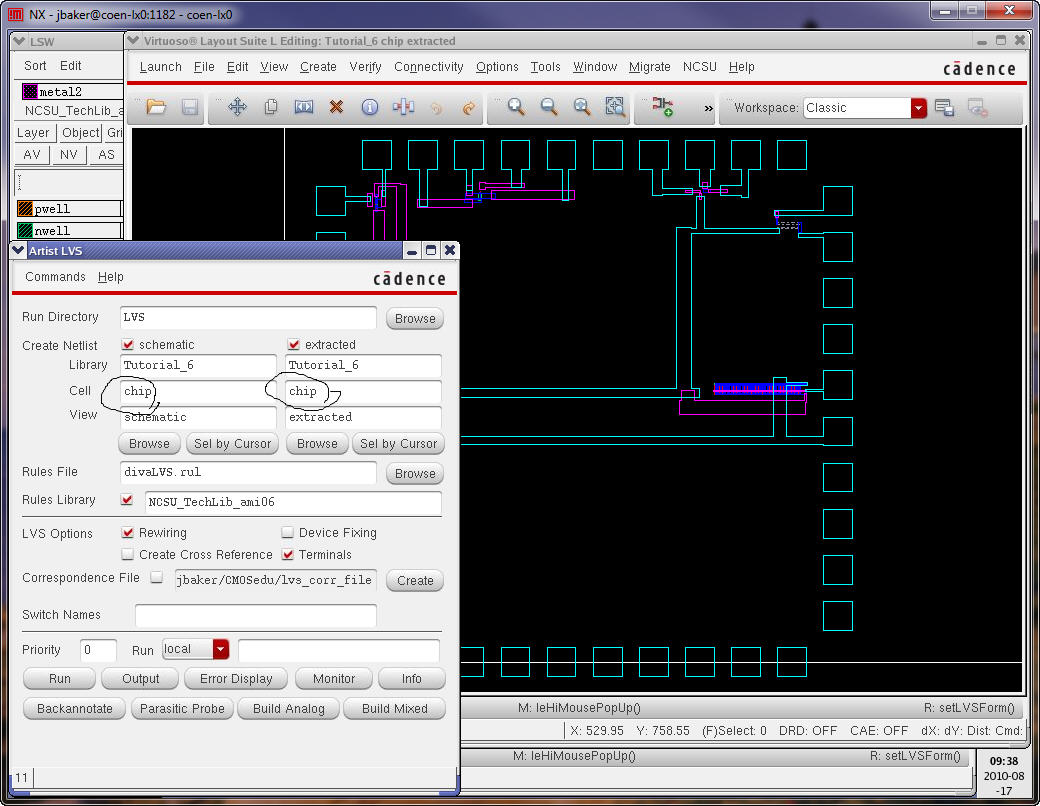

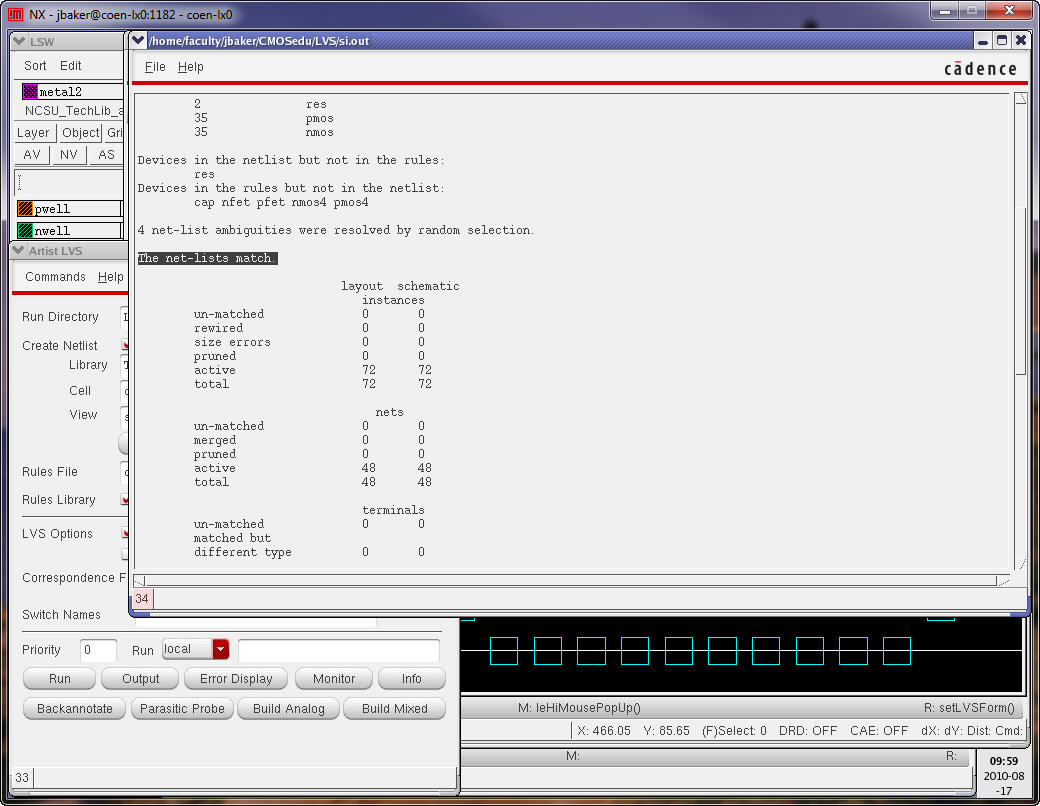

After

adding the vias let’s

extract the layout.

And

then perform an LVS.

This

concludes Tutorial 6.

For

your reference the Tutorial_6 directory is available in Tutorial_6.zip.