EE 421L Digital Integrated Circuit Design Laboratory - Lab

5

10/5/16

Pre-lab

work

o Back-up all of your work from

the lab and the course.

o Go through Tutorial

3

Experiment

Draft

schematics, layouts, and symbols for two inverters having sizes of:

o 12u/6u (= width of the PMOS /

width of the NMOS with both devices having minimum lengths of 0.6u)

o 48u/24u where the devices use

a multiplier, M = 4 (set along with the width and length of the MOSFET

The

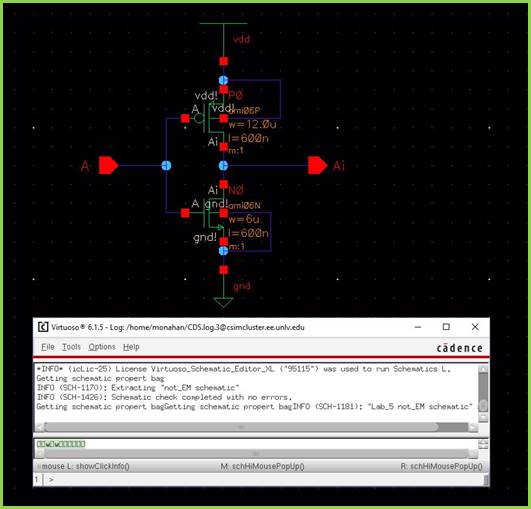

first inverter designed was the 12u/6u inverter with minimum length of 600n.

The associated file is titled not_EM. The designs were drafted using the NCSU Tech Library

and instantiated pmos and nmos

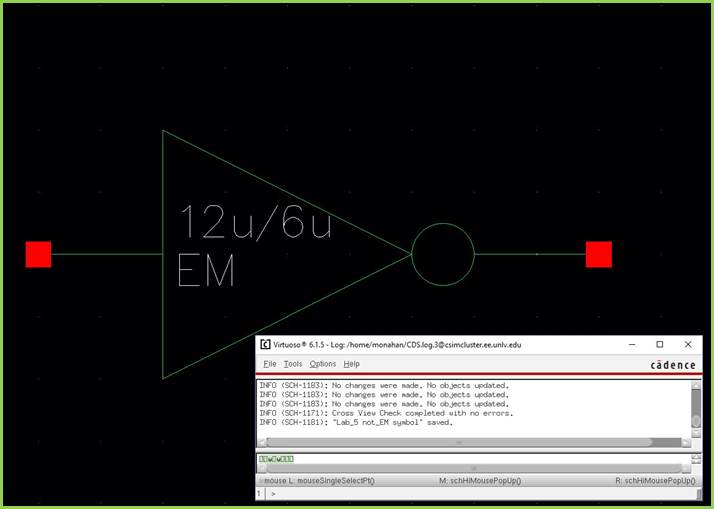

devices. The inverter schematic with DRC verification is displayed to the left

below. The inverter symbol with DRC verification is displayed to the right

below. Note, the schematic displays two pins, input A, and output Ai. The

symbol view reflects the widths of the PMOS and NMOS for ease of reference.

Next,

the 12u/6u inverter layout and extracted layout were created. The layout with

DRC verification is displayed to the left below and the extracted layout with

LVS verification is displayed to the right below. Note the power in the layout

is connected to the n-well via the ntap cell and

there are four pins, input A, output Ai, input-output vdd!, and input-output gnd!.

After

finishing the first inverter, the 48u/24u inverter with multiplier M=4 was

created following the same basic procedure. The associated file is titled not_4_EM. The schematic, below left with

DRC verification, and the symbol, below right with DRC verification, were

created first. Note the multiplier, m=4, is visible on the schematic view.

Following

format, the 48u/24u layout and extracted layout were designed with successful

DRC and LVS verifications. The layout is displayed directly below.

Next,

the extracted view with successful LVS verification is displayed below.

The

only experienced difficulty in this portion of the lab was laying out the

metal1 connections for the 48u/24u inverter design. Specifically, connecting

the devices properly the first attempt required referencing the CMOS textbook

and then the supplied Lab 5 design files to validate the proper technique for

the metal 1 connections was followed. After

referencing these resources, the 12u/6u and 48u/24u inverter schematics,

symbols and layouts were finished, thus concluding the first requirement for

Laboratory 5.

Using

SPICE simulate the operation of both of your inverters showing each driving a

100 fF, 1 pF, 10 pF, and 100 pF capacitive load

o Comment, in

your report, on the results

Use UltraSim

(Cadence's fast SPICE simulator for larger circuits at the cost of accuracy)

and repeat the above simulations

o Use Setup

-> Simulator/Directory/Host and select UltraSim as

seen below

o You'll also

have to point to the MOSFET models again as seen below

o Note that UltraSim only performs transient simulations (not AC,

Noise, DC, operating point, etc.)

o

Not

knowing this last item will lead to wasted time if trying to use UltraSim exclusively for simulations

Following the design of the

inverters, each inverter was simulated driving the specified 100fF, 1pF, 10pF

and 100pF capacitive loads. The associated file is titled sim_not_EM. The first step

required drafting a schematic to simulate using the inverter designs. To start,

the 12u/6u inverter was simulated. Notice the schematic view displayed below

shows 'Cload' for the capacitor value. This was done

to demonstrate the creation of a single schematic where the capacitive load was

varied as required for each successive simulation. Also, notice the inclusion

of a global vdd source as necessary due to the PMOS

source connection to vdd in the inverter. The voltage

to the inverter is a pulse from 0V to 5V.

The simulations were first performed

following the same procedures as performed in previous laboratory experiments

using Cadence. These steps include launching the Analog Design Environment (ADE

L), including the model libraries for the NMOS and PMOS devices as done in Tutorial2

, and performing a transient simulation. Next, the simulations were repeated

using UltraSim. Ultra Sim is activated via the ADE

Setup > Simulator/Directory/Host and selecting UltraSim

from the Simulator dropdown. These steps are displayed in the two images below.

The simulation results are displayed

below for comparison. The capacitive load for each simulation is labeled on

each plot with the Spectre simulation results (blue

and red traces) on the left and the UltraSim results

(red and green traces) displayed on the right. Notice for the 100fF load plots

directly below, the output is inverted, as the design intended.

The

simulation results demonstrate that a larger capacitive load results in a

larger time constant, RC, and consequently, a longer time for the capacitor to

charge and discharge. Thus, the inverter characteristics disappear as the

capacitive load increases. The simulations above verify that a 12u/6u inverter

in On's C5 process loses the

ability to invert with loads larger than 1pF. The 10pF load shows the output

starts to resemble a triangle wave rather than an inverter. Also, note the UltraSim and Spectre results

appear identical.

The

next step was to repeat the same simulations performed above using the 48u/24u

inverter. The associated file is titled sim_not_4_EM.

The schematic view with successful DRC verification is displayed below.

Once

again the simulations were performed using both Spectre

and UltraSim with the required capacitive loads. The

results are displayed below with Spectre results

(blue and red traces) displayed to the left and UltraSim

results (red and green traces) displayed to the right.

Initially,

the larger inverter operates similarly to the smaller inverter. However, due to

the increased width the 48u/24u inverter can supply more current and drive

larger loads than the 12u/6u inverter. This can be seen in a comparison of the

10pF loads for each inverter. The 12u/6u inverter is displayed to the left

below and the 48u/24u inverter is displayed to the right. Clearly, the 48u/24u

inverter drives the larger load easier. For simplicity, only the Spectre

results are included in the comparison.

Conclusion

Laboratory

5 included drafting schematics, layouts, and symbols for both a 12u/6u inverter

and a 48u/24u inverter, both with a minimum length of 600n. All design specifications

were met with successful DRC and LVS verifications performed and recorded.

Additionally, both inverters were simulated driving varying capacitive loads

using both Spectre and UltraSim.

The results of the simulation demonstrate the wider 48u/24u inverter is capable

of driving larger capacitive loads than the 12u/6u inverter.

Return to

Monahan Lab Report Directory

Return to EE 421L

Fall 2016 Student Directory