Lab 3 - ECE 421L

Authored

by Byron Gorsuch,

gorsuch@unlv.nevada.edu,

September 19, 2017

Lab Description

This

lab will continue the development of the 10-bit DAC from lab 2. In this

lab, the layout of the DAC will be created by using n-well resistors

and metal 1 for connections.

Prelab

Tutorial 1 was completed in order to layout a 10K Ohm n-well resistor which will be used to create a layout for the DAC schematic created in lab 2.

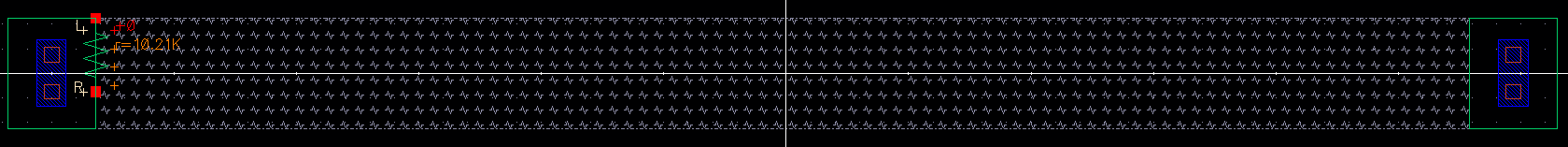

Figure

1: 10k n-well resistor layout

In

order to determine the length and width of the n-well to create a 10k

resistor, the considerations of the C5 process from MOSIS were used.

- n-well material is about 800 Ohms/square

- Minimum width of the n-well is 12λ

- λ for the C5 process is 0.3Ám

Using

this information the minimum width for the resistor is 3.6 microns. At

800 Ohms a square, in order to achieve a resistance of 10k Ohms it can

be calculted that 12.5 squares are needed.

By choosing the width to

be 4.5 microns as in tutorial 1, it can then be calculated that the

length must be about 4.5 * 12.5 microns or about 56 microns, however in

order for the resistor to fit the

edges on the grid a length of 56.1 microns was used.

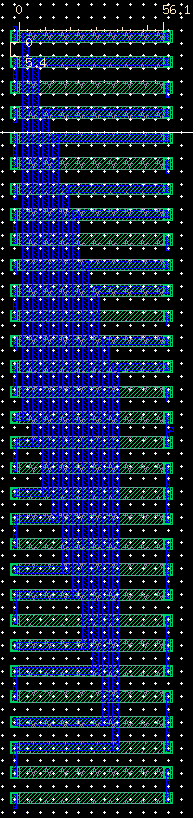

Figure 2: 10k

n-well extracted view

Lab

The

n-well resistor created in the prelab was used in order to layout a

10-bit DAC using the R-2R structure. By using the ruler tool, accessed

by pressing 'K' in Virtouso, the exact dimensions of the n-well

resistor could be calculated as well as the minimum distance between n-wells (18λ = 5.4 microns).

Figure

3: DAC Layout

Figure 4: DAC Layout

Close-up

Figure 5: Extracted View of

DAC Layout

Once the layout was complete, the

validity of the layout could be checked using the Design Rule

Checking(DRC) tool. If the DRC is successful, the command interpreter

window will display the tests run and report zero errors found.

With a DRC the extracted view of the layout can be created. A close-up

of the ectracted view of the layout can be seen in Figure 5 above.

The extracted view will display the value of each n-well resistor as

well as any pins connected to the node being observed.

To ensure that the DAC layout is in fact the correct layout of the

schematic from lab 2, the extracted view can be compared to the

schematic

for verification using the Layout-Versus-Schematic (LVS) tool.

With matching netlists, the extracted view can faithfully be used in

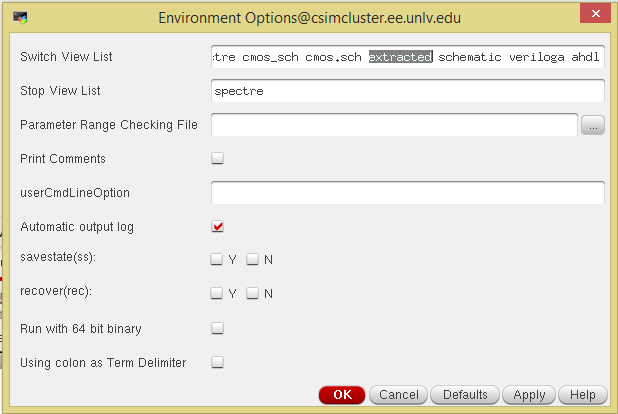

order to simulate the layout. This can be done by opening the Spectre

simulation tool and selecting Setup -> Environment. From this

window, simply enter the word "extracted" before the word "schematic"

as shown

in figure 8 below. Once this is done the simulation can be performed as usual.

Figure 6: DRC Success

Figure 7: LVS Success

Figure 8: How to Sim Extracted View

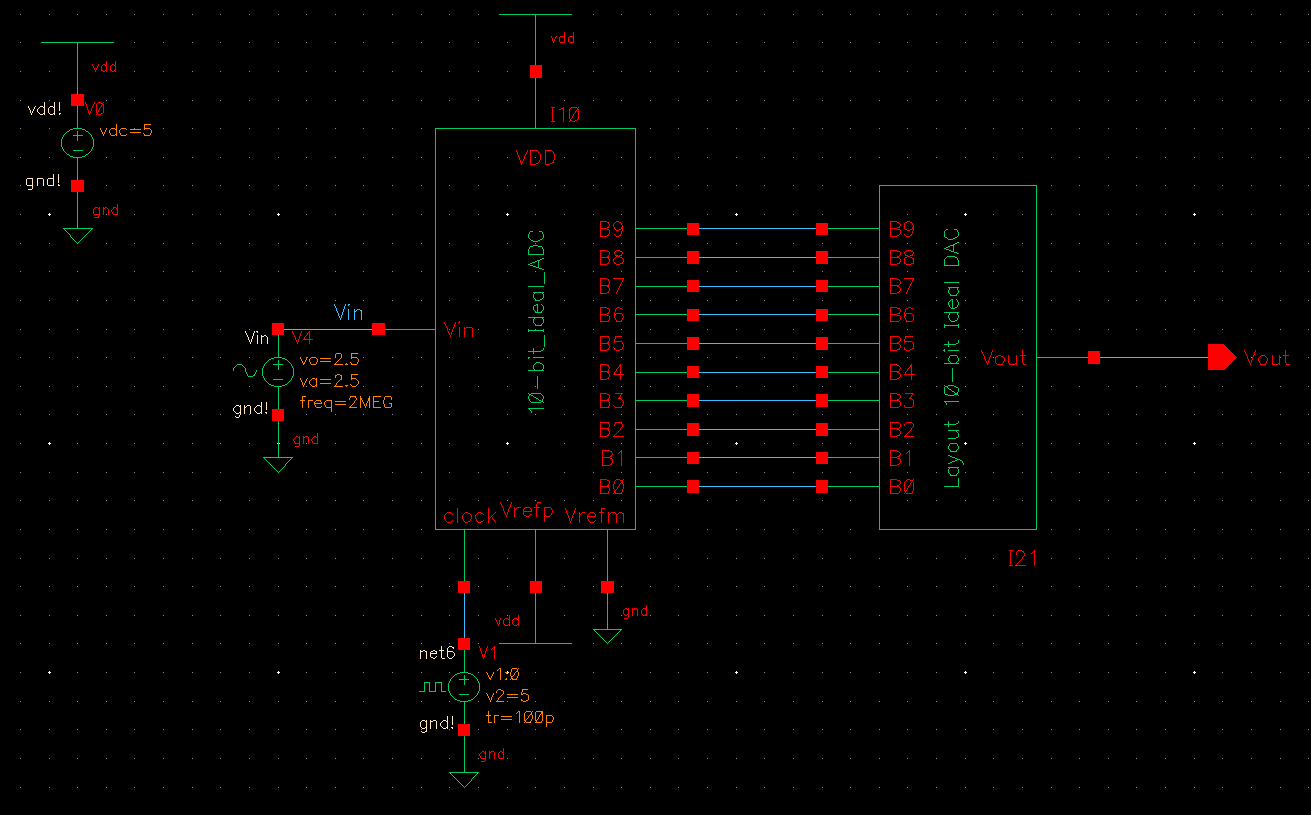

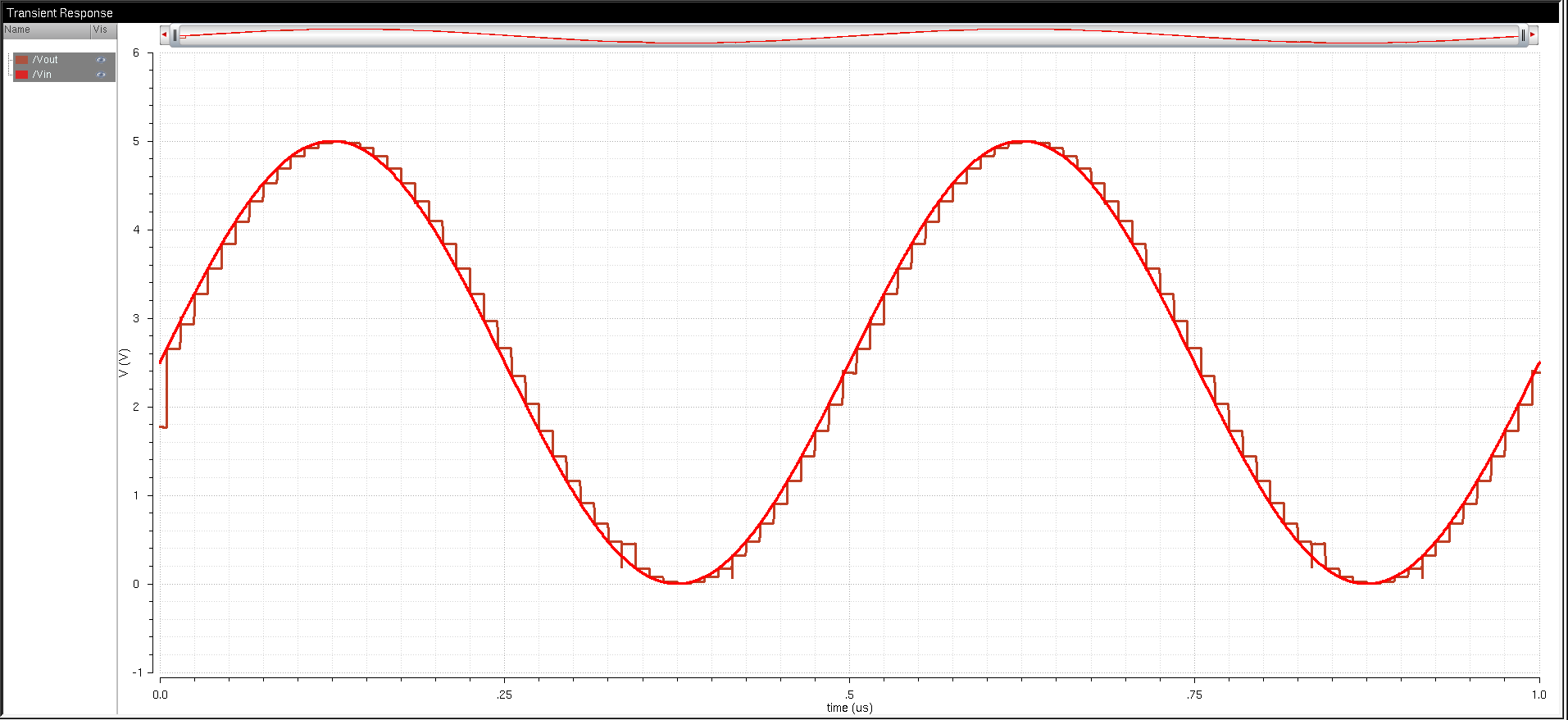

Figure

9: Test Schematic

Figure 10:

Simulation Results

The schematic used to test

the DAC created with the layout is the same as in lab 2. As can be seen

in figure 10 above, the behavior of the DAC is as expected based on the

simulations from lab 2.

The files used for this lab can be found here

Return to my lab directory

Return to CMOSedu.com