Lab 4 - ECE 421L

Authored

by Martin Mercado mercam13@unlv.nevada.edu,

09/26/2023

IV characteristics and layout of NMOS and PMOS devices in ON's C5 process

Pre-Lab:

- Back-up all of my from the lab and the course.

- Read through this lab before starting it.

- Go through Tutorial 2 seen here.

- In

the simulations in this lab the body of all NMOS devices (the

substrate) should be at ground (gnd!) and the body of all PMOS devices

(the n-well) should be at a vdd! of 5V.

For

Tutorial 2, I'm going to be laying out and simulating the operation of

NMOS and PMOS transistors using the C5 process form Tutorial 1.

First, I made a new library for Tutorial 2.

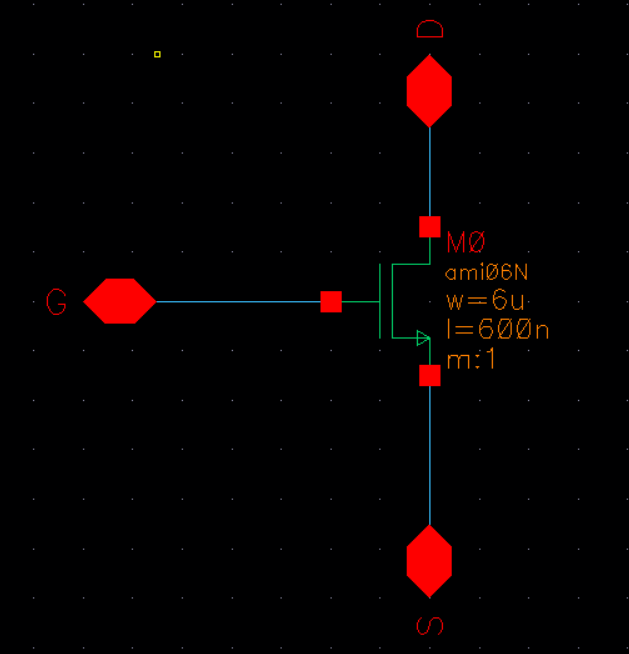

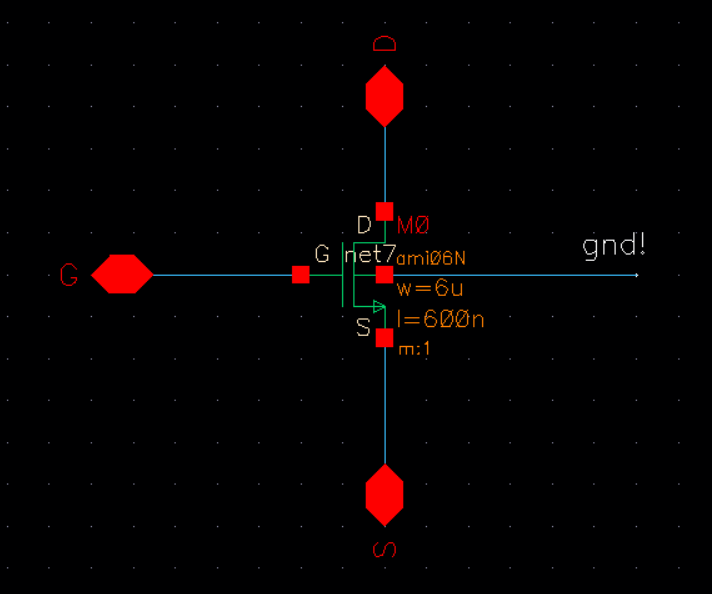

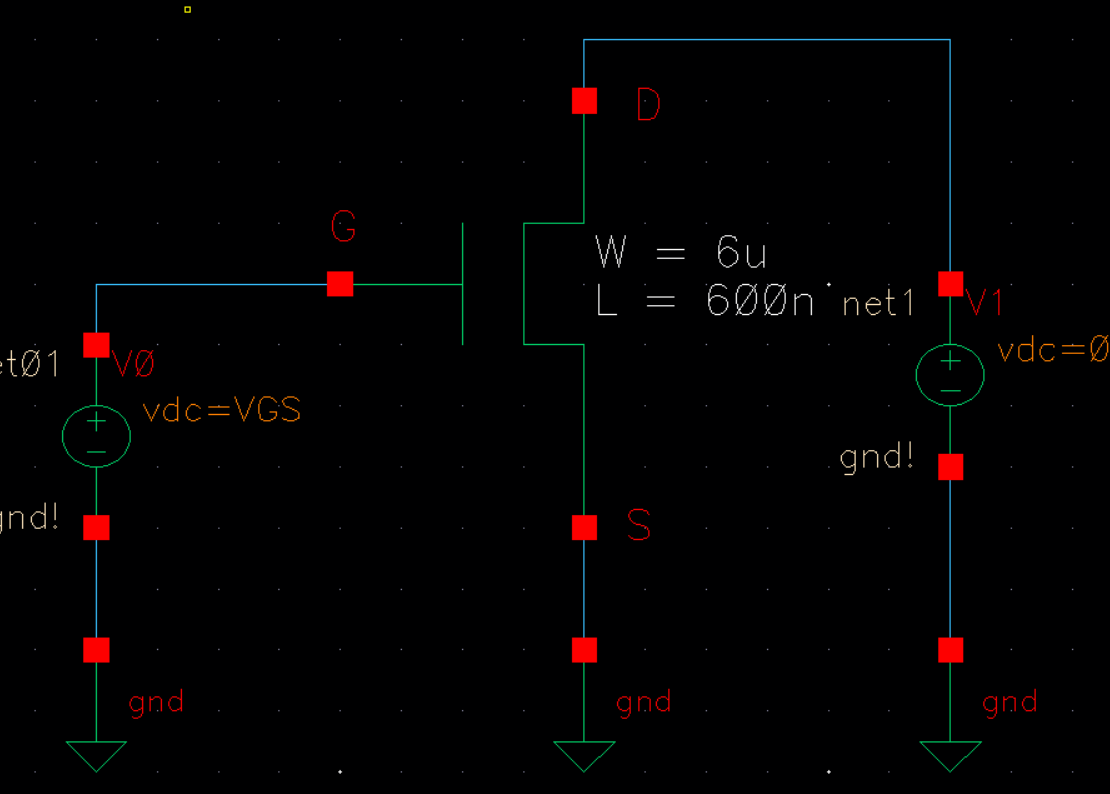

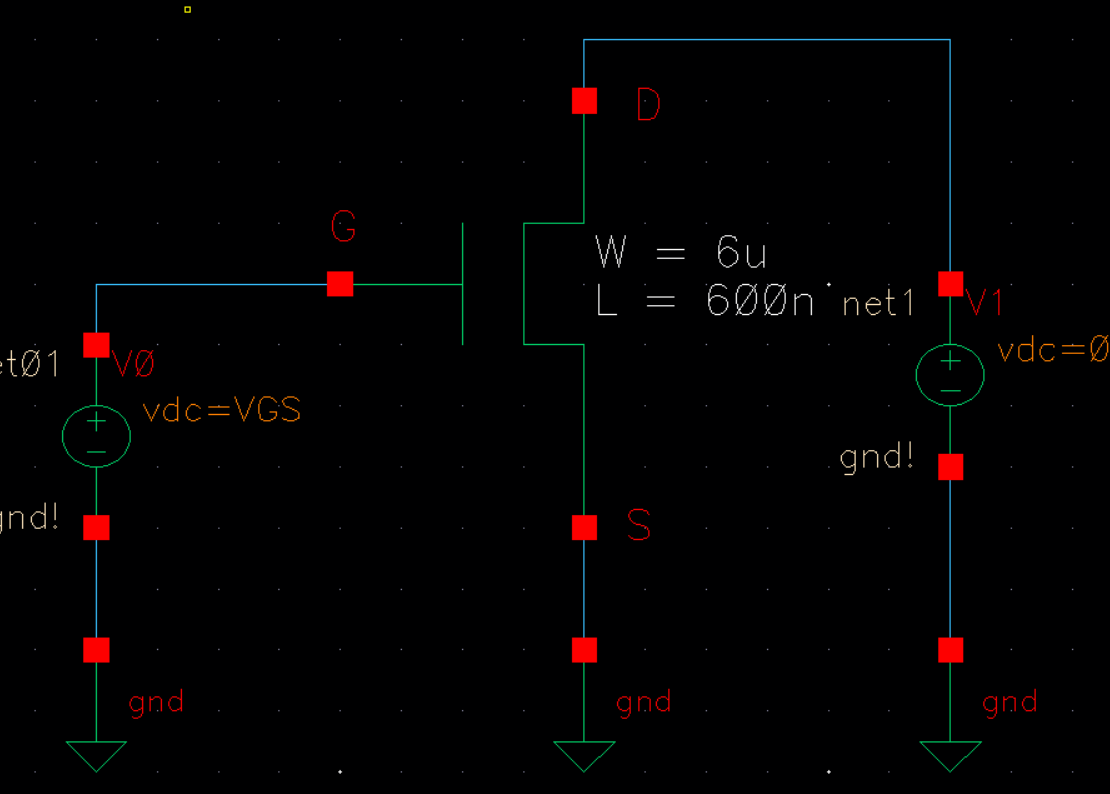

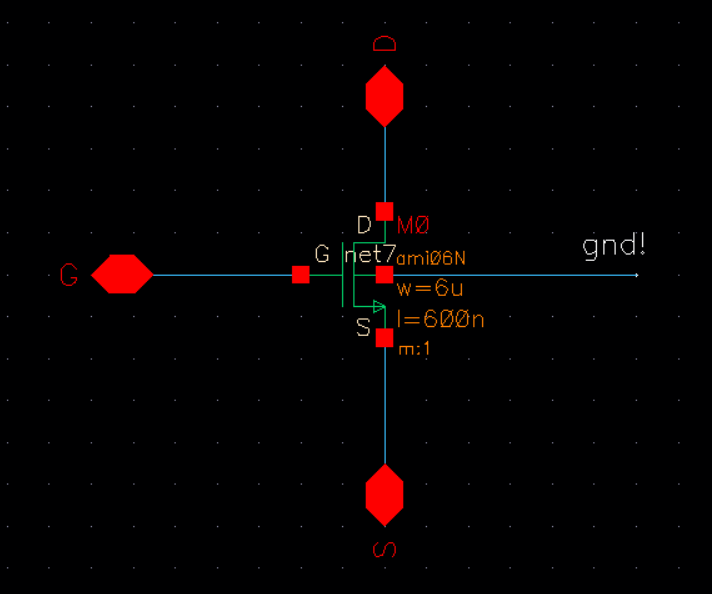

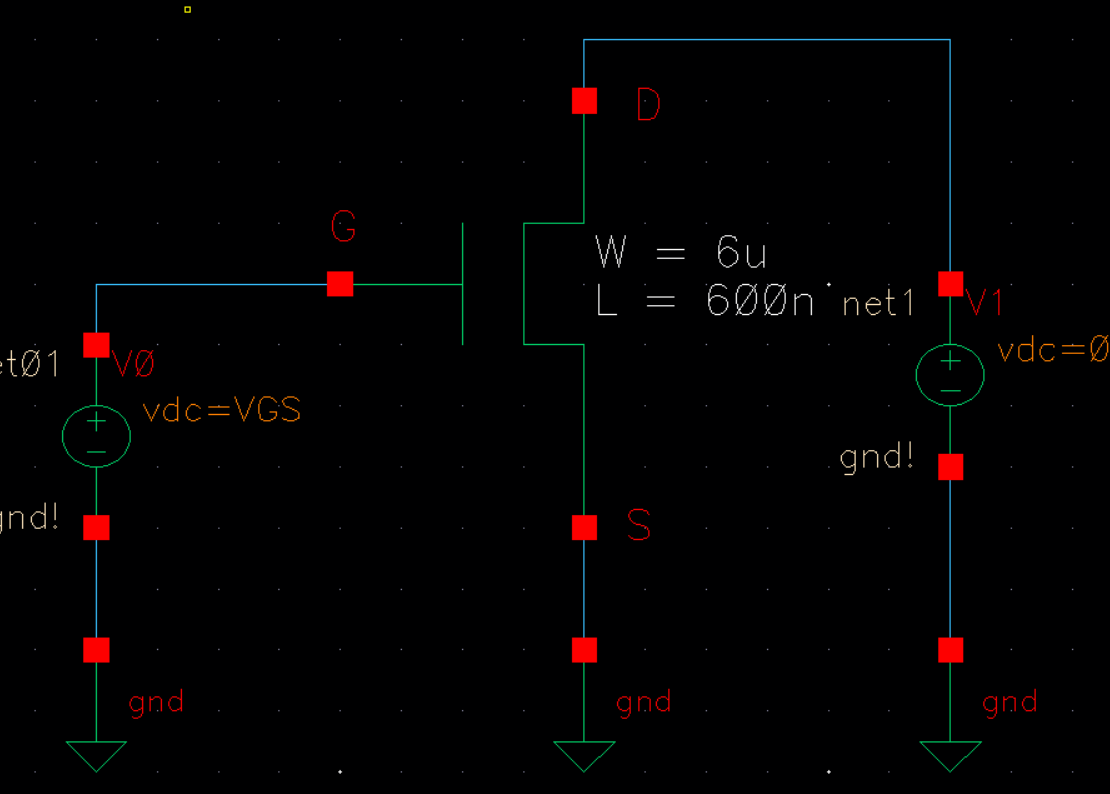

Now, the Tutorial will instruct me to make an NMOS schematic.

Then, I will create a symbol for the schematic.

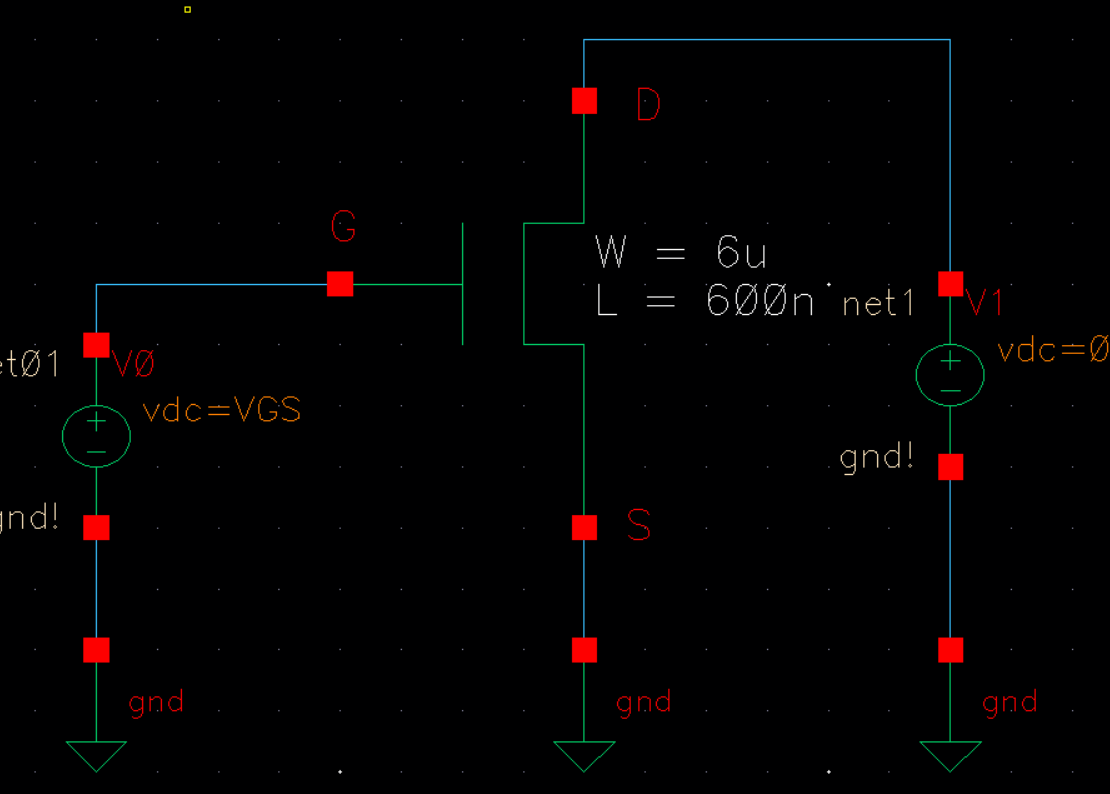

Using the symbol, I will make a new schematic.

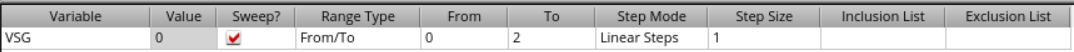

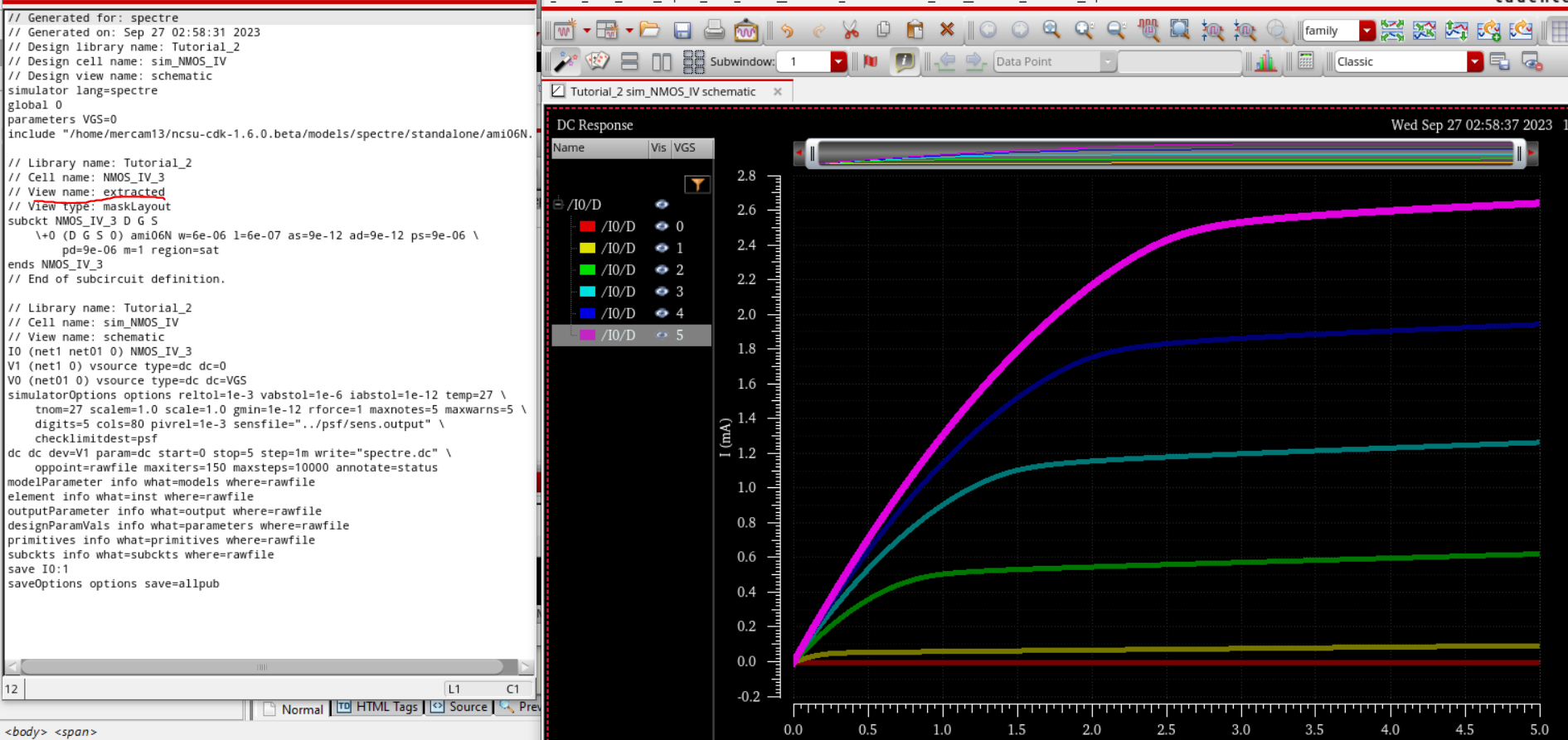

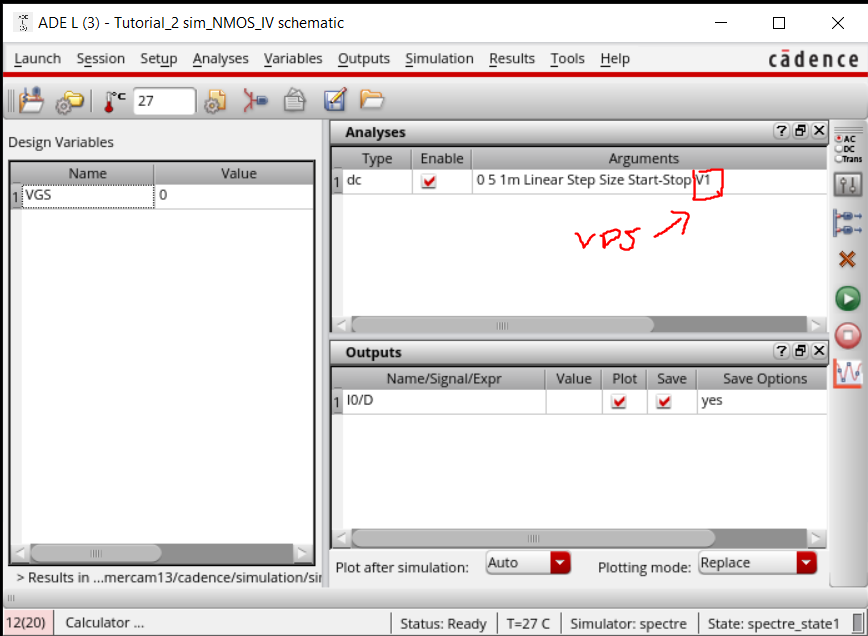

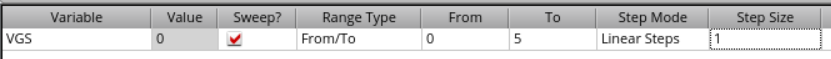

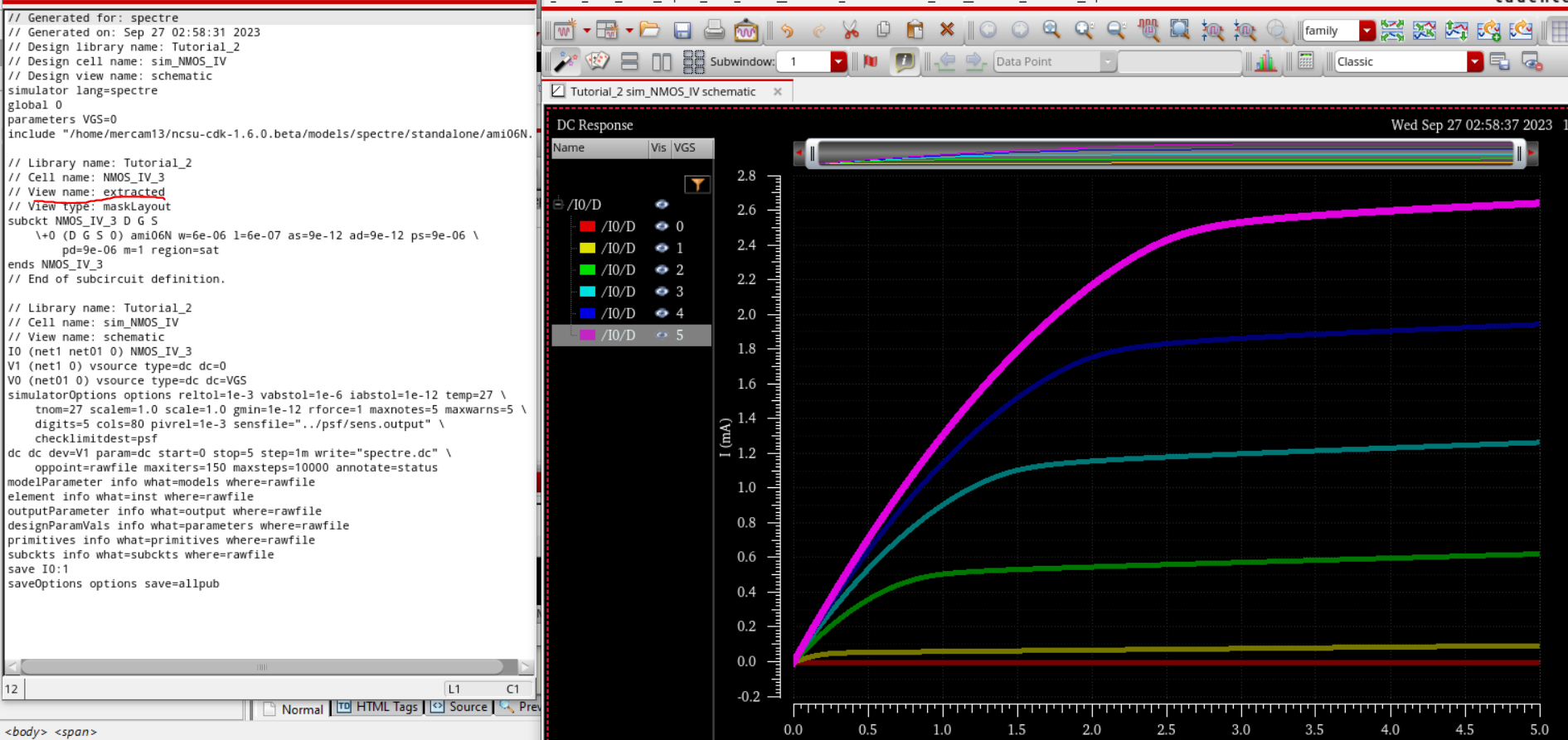

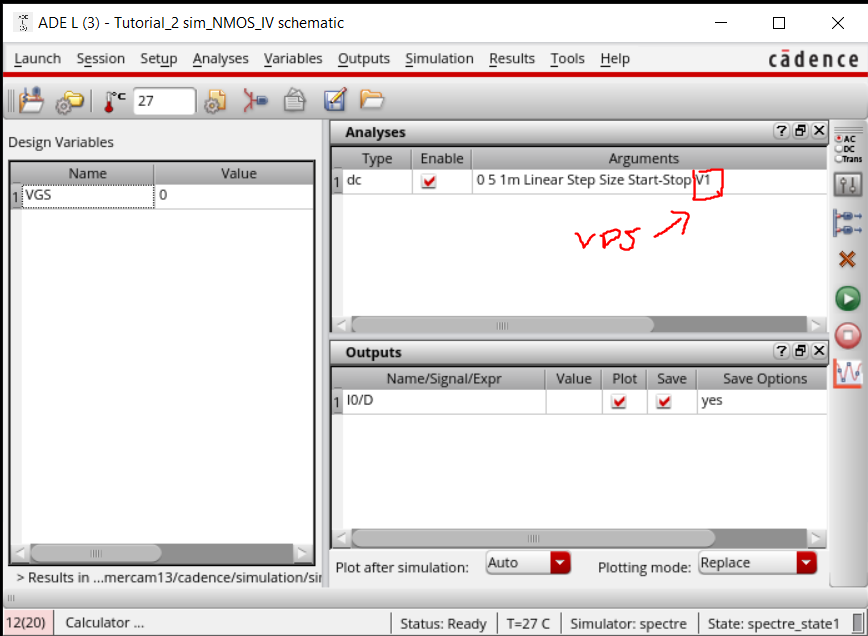

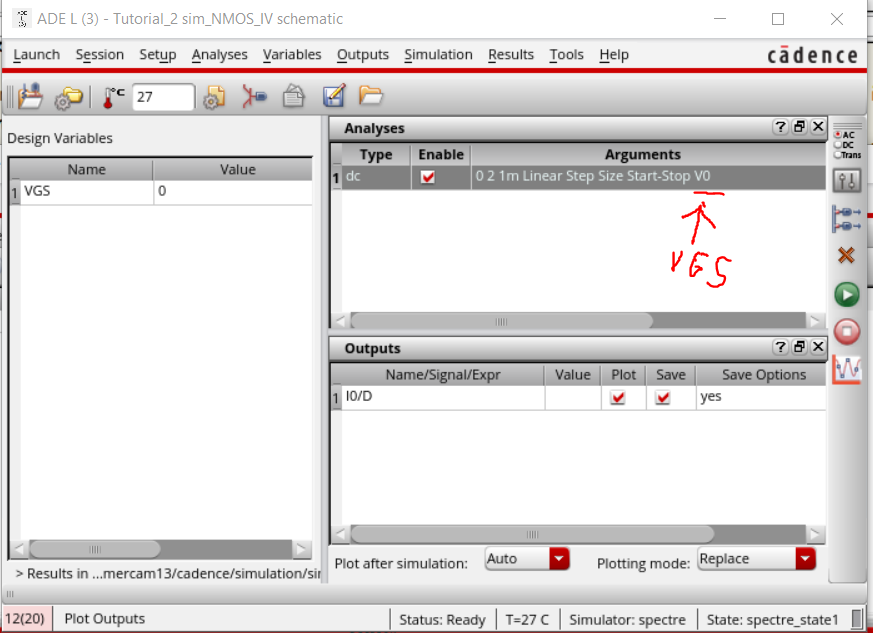

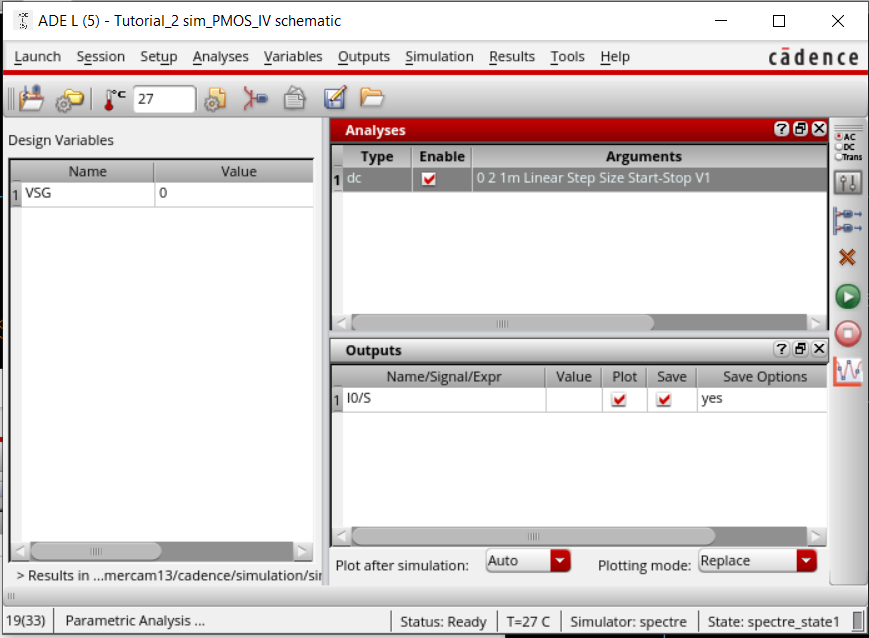

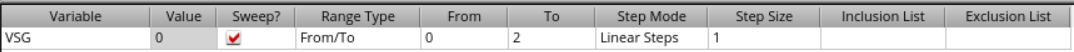

I will now simulate the schematic using parametric analysis.

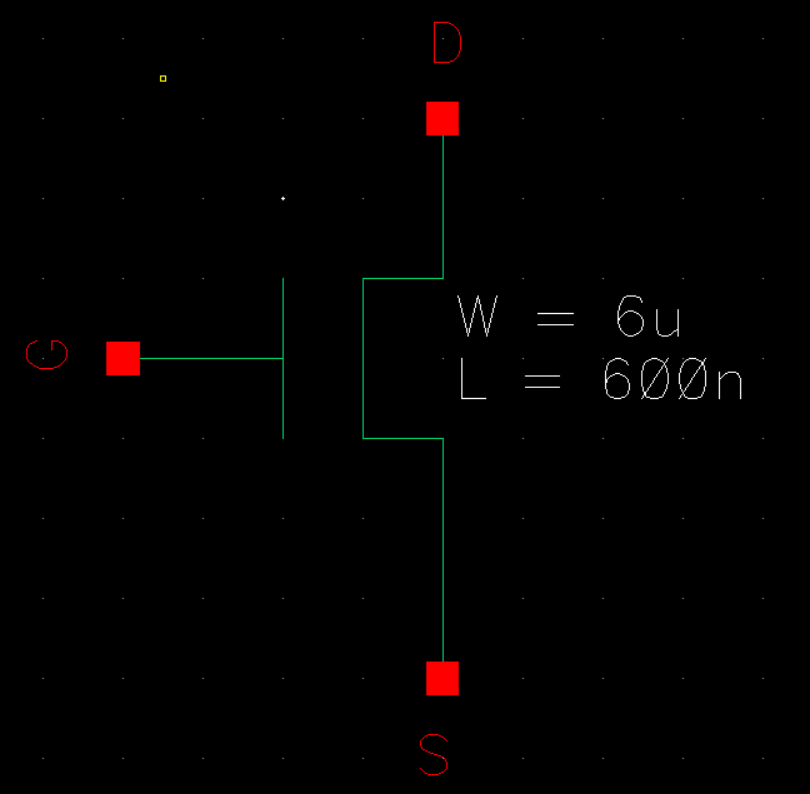

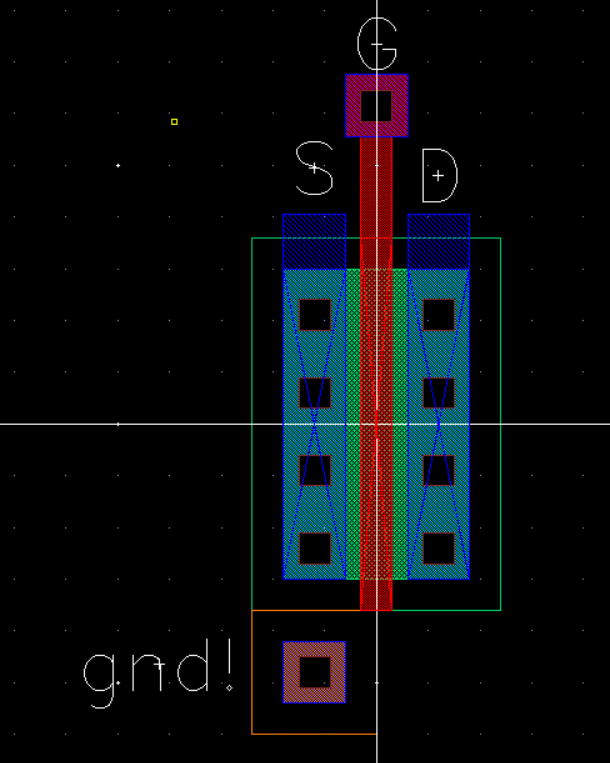

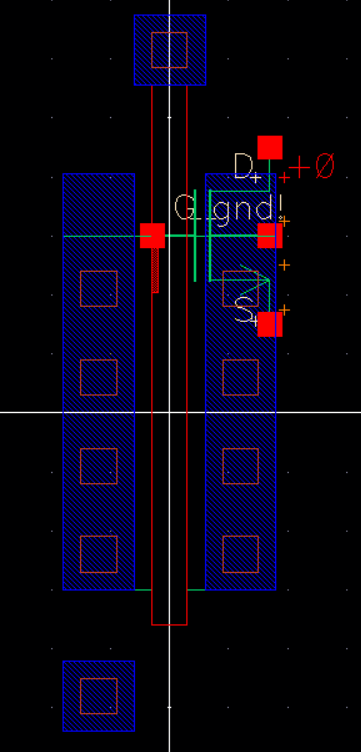

I will now create a layout of the NMOS.

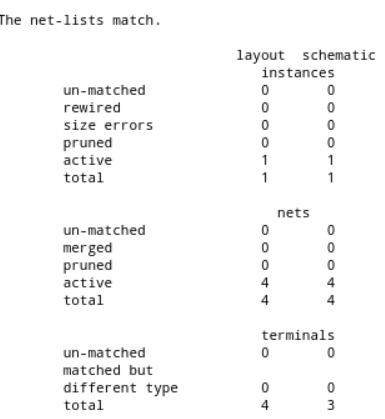

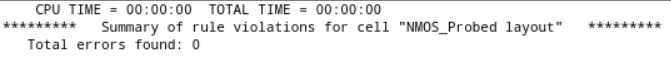

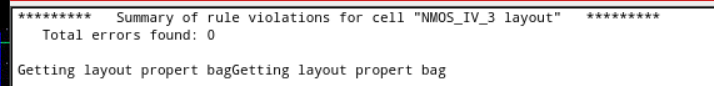

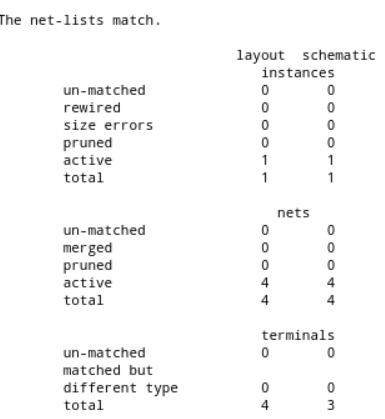

DRC and Extract.

LVS will fail due to not have a 4-terminal transistor in the schematics.

Need to change schematic and LVS again.

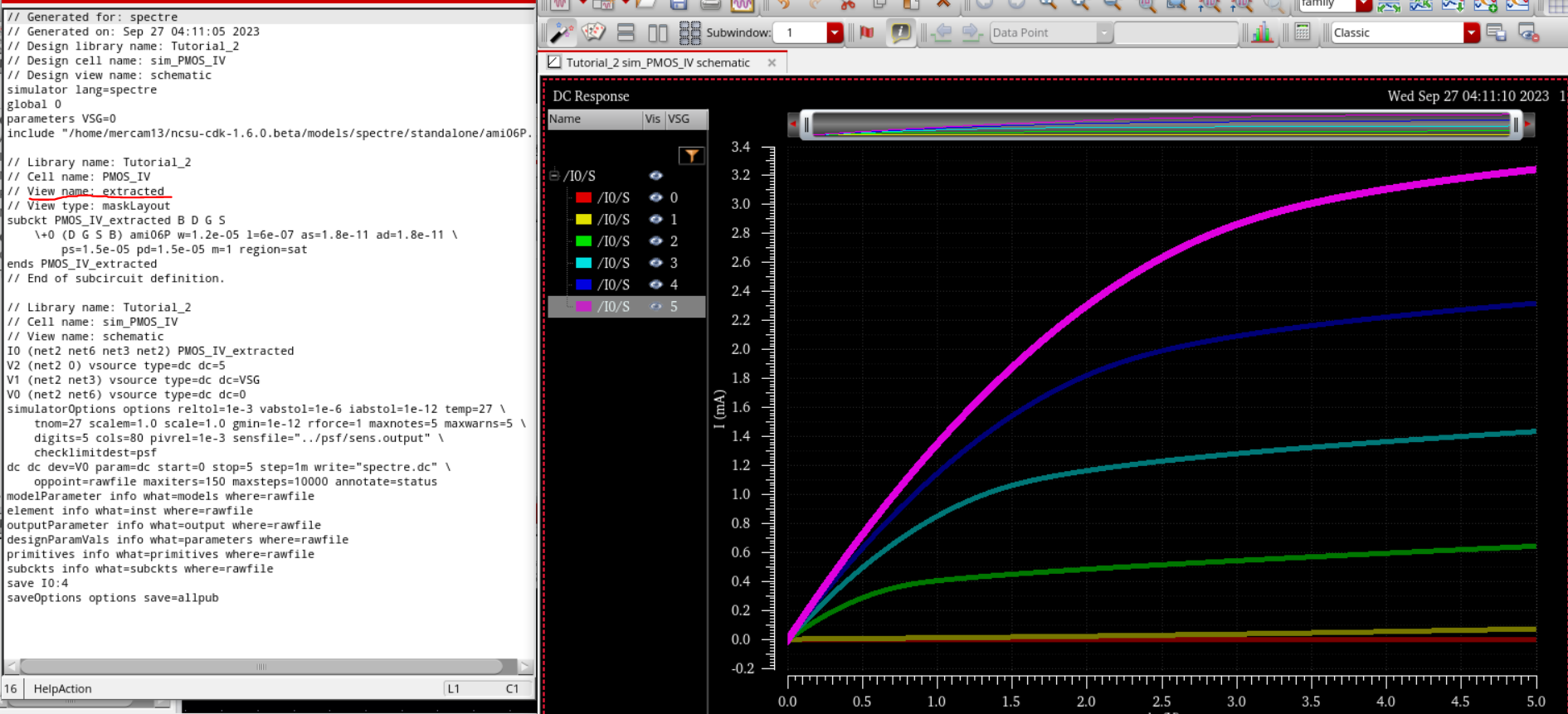

Now we simulate the extracted layout.

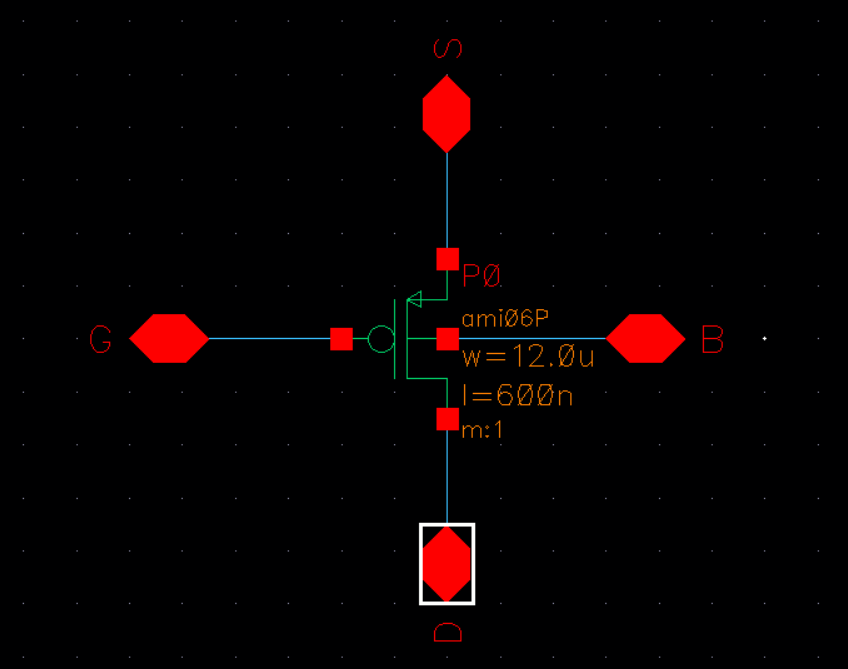

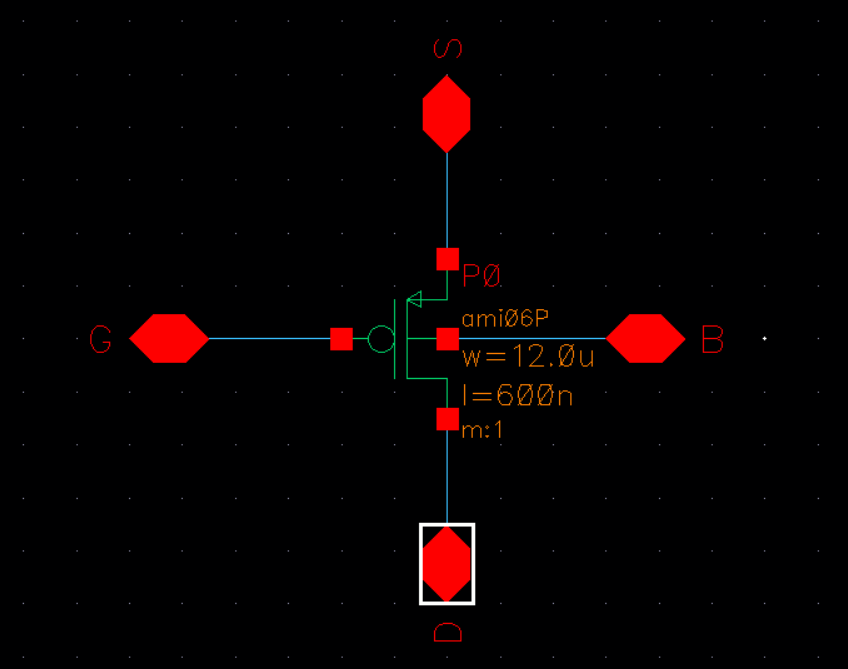

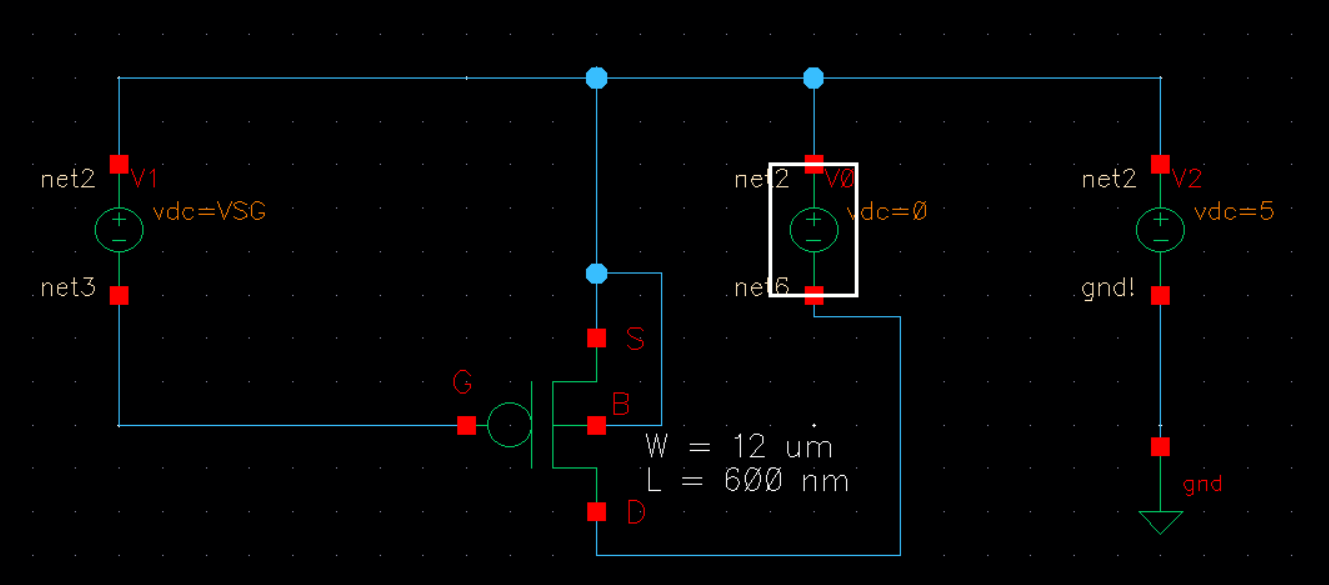

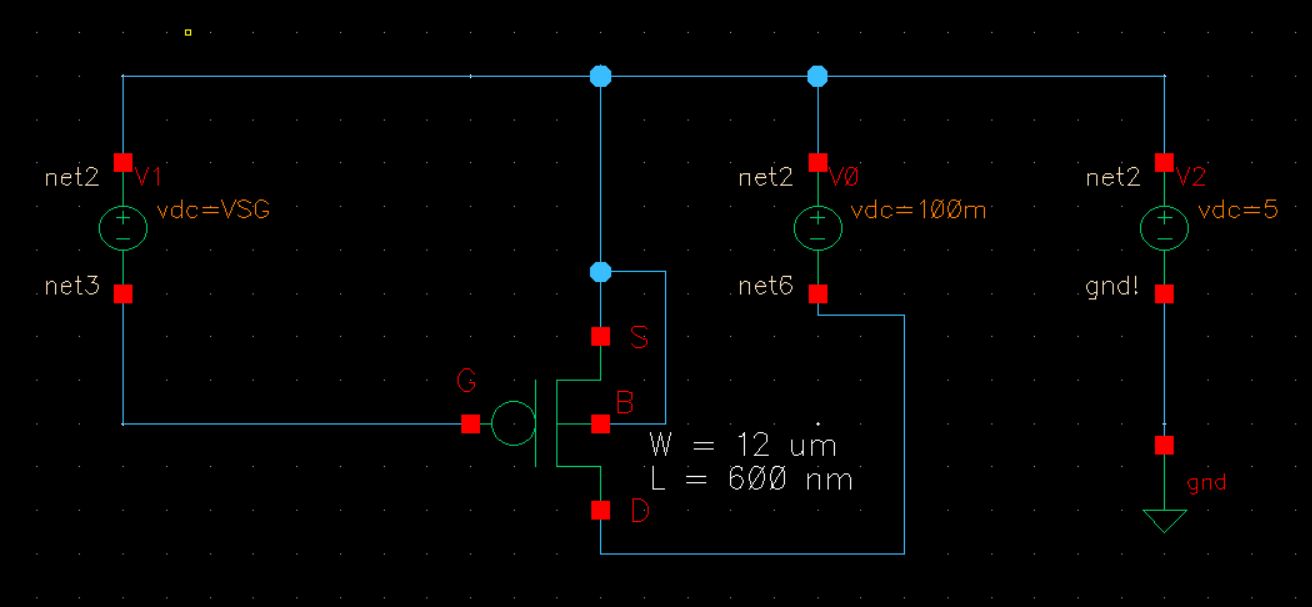

Now repeat for PMOS.

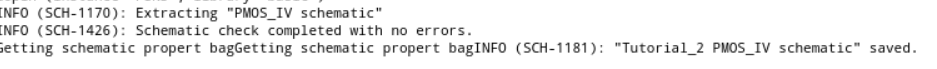

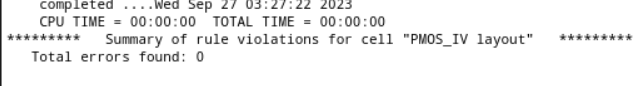

Create the schematic then check and save.

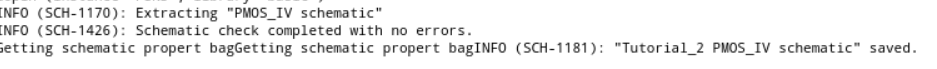

Create a symbol.

Create a layout, then DRC and extract and LVS.

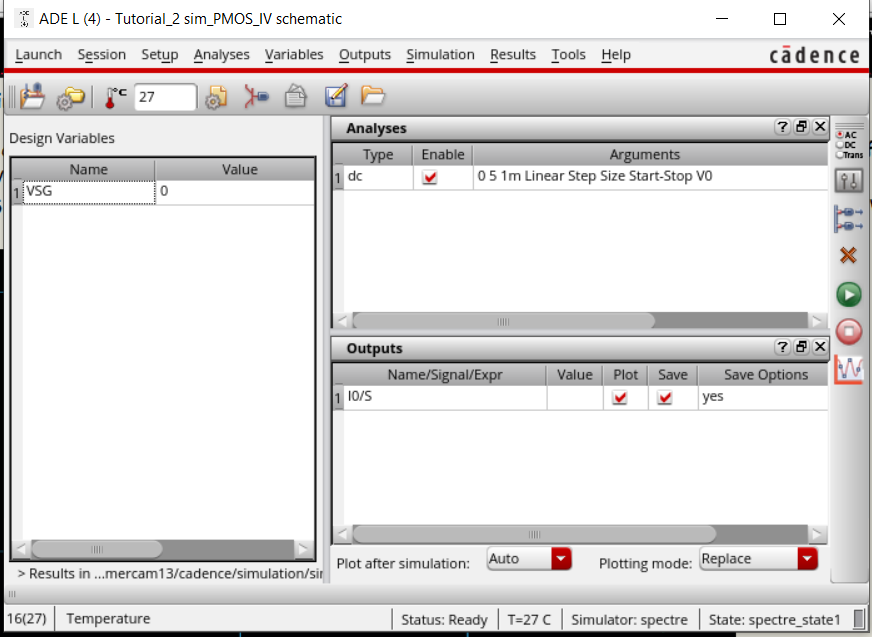

Next, I will simulate the PMOS.

Now I will simulate the extracted layout.

____________________________________________________________________________________________________________________________________

Lab:

Generate 4 schematics and simulations (see the examples in the Ch6_IC61 library, but note that for the PMOS body should be at vdd! instead of gnd!)

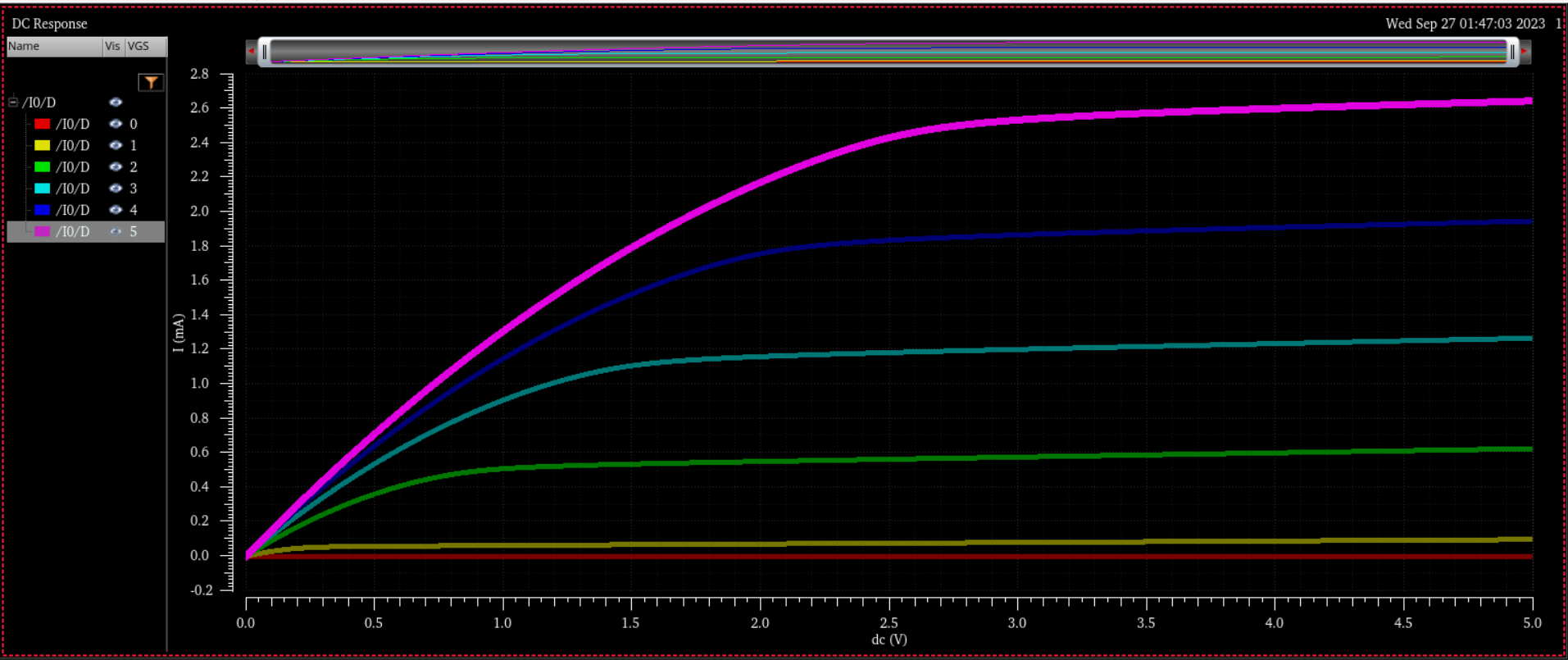

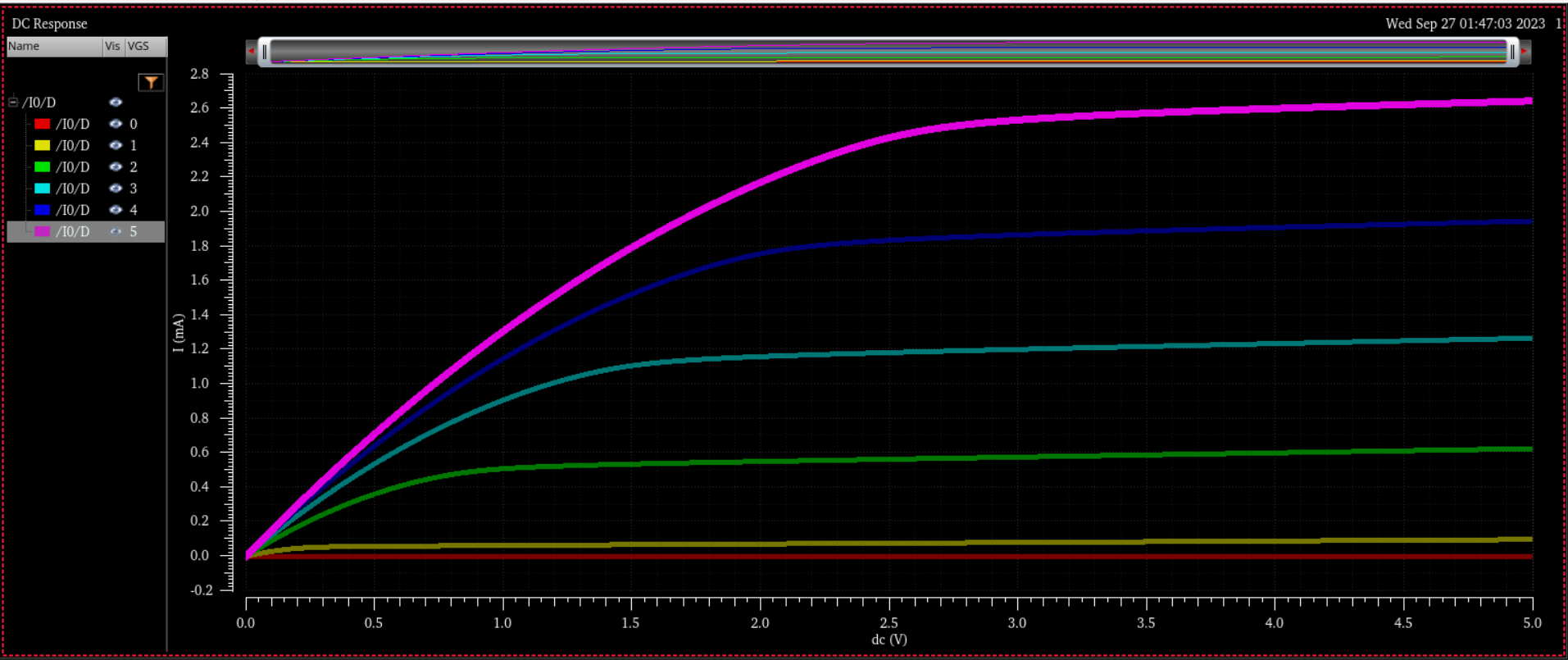

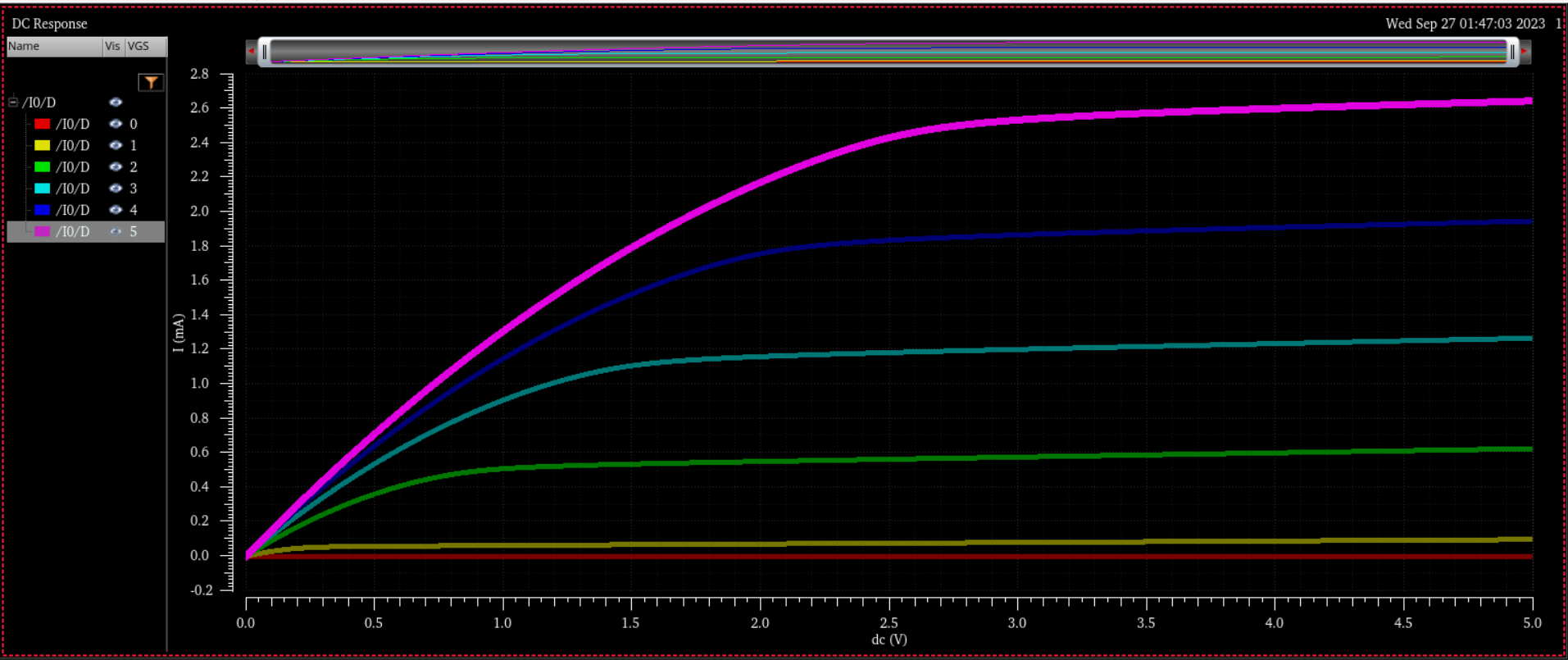

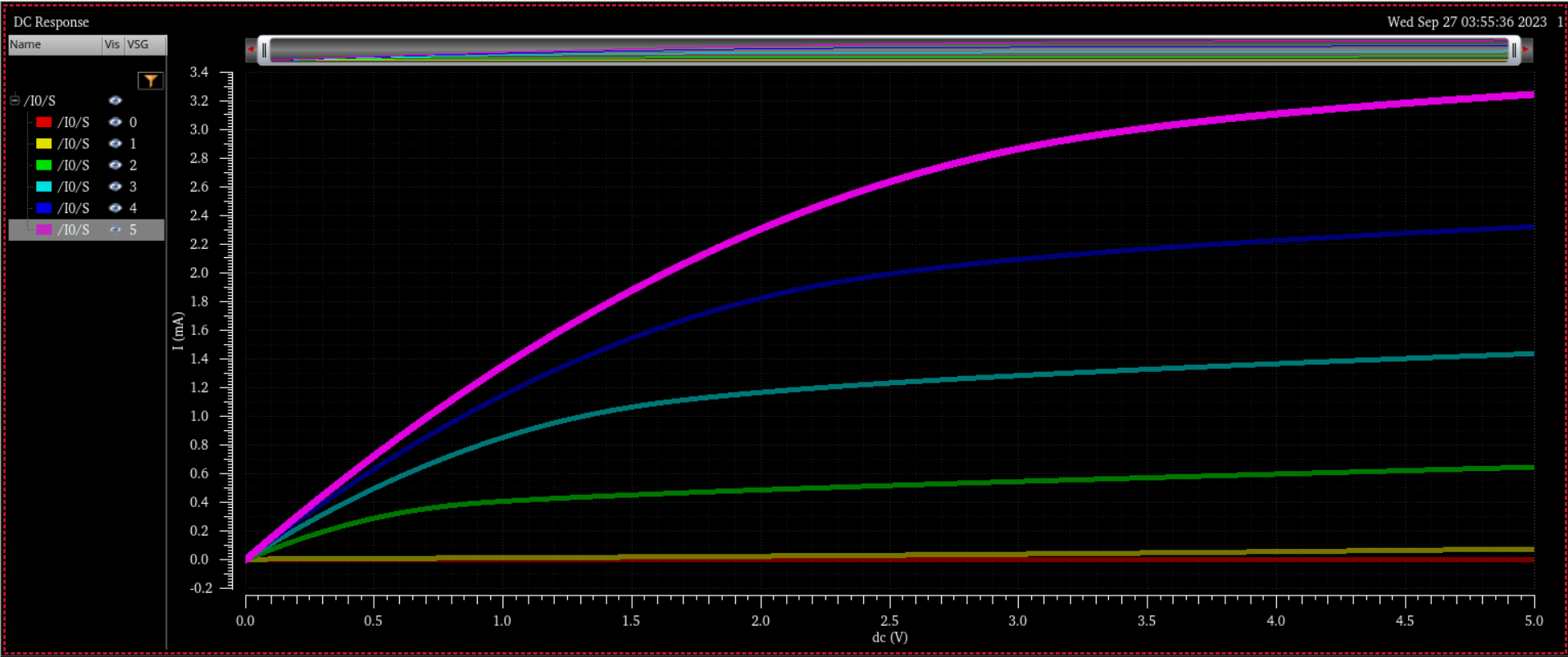

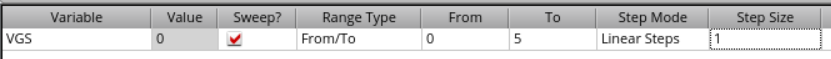

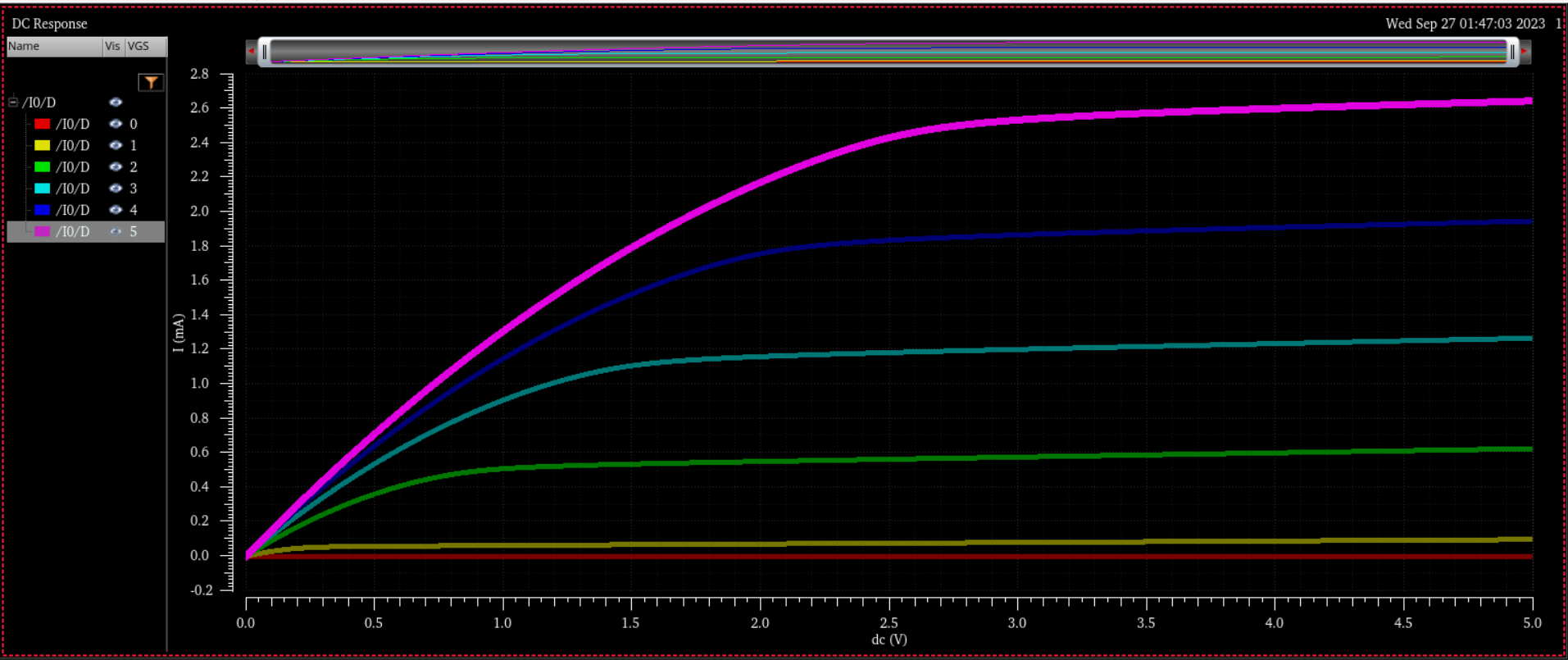

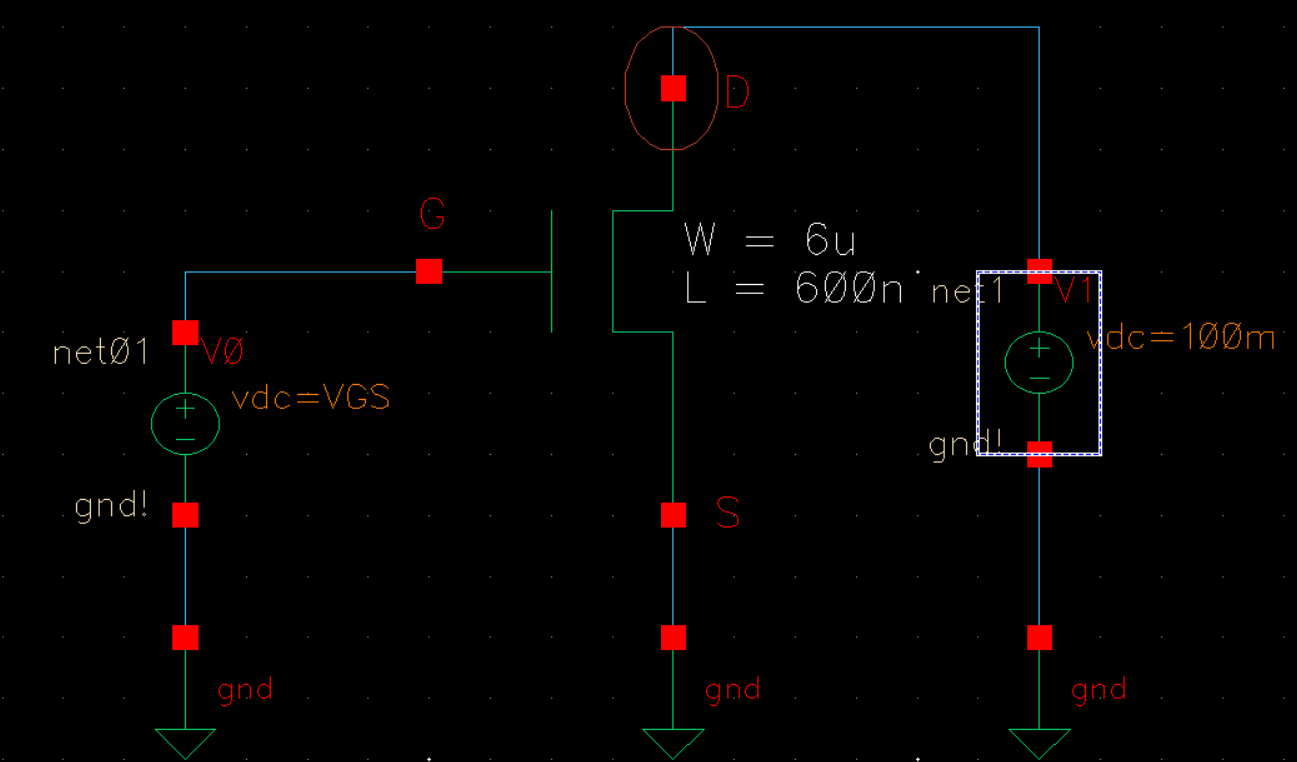

- A schematic for simulating ID

v. VDS of an NMOS device for VGS varying from 0 to 5 V in 1 V steps

while VDS varies from 0 to 5 V in 1 mV steps. Use a 6u/600n

width-to-length ratio.

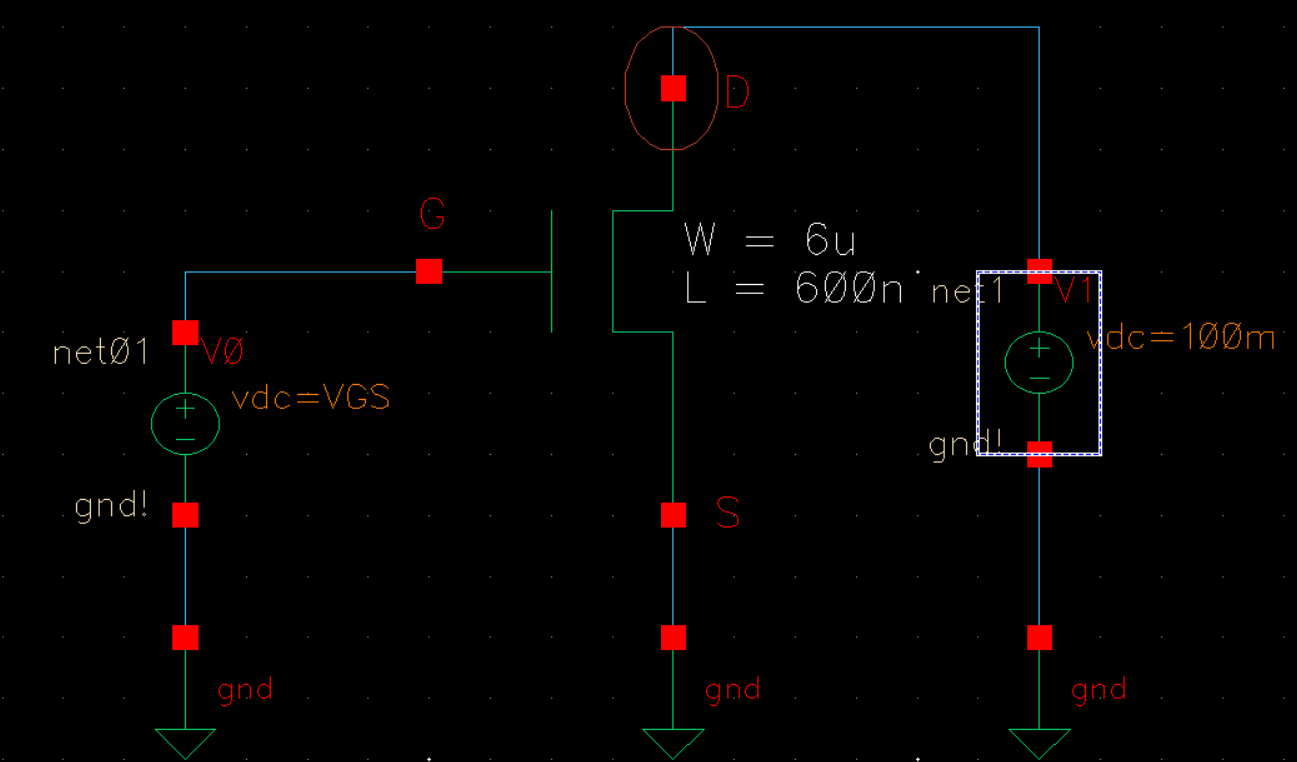

I will be using the schematic used made in the pre-lab to simulate.

As VGS increases, Id increases with respect to VDS.

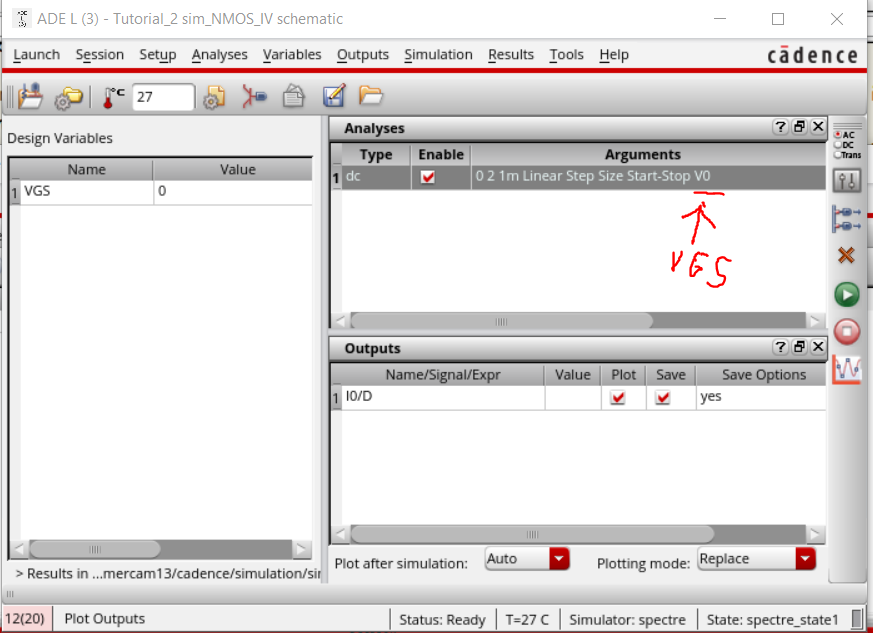

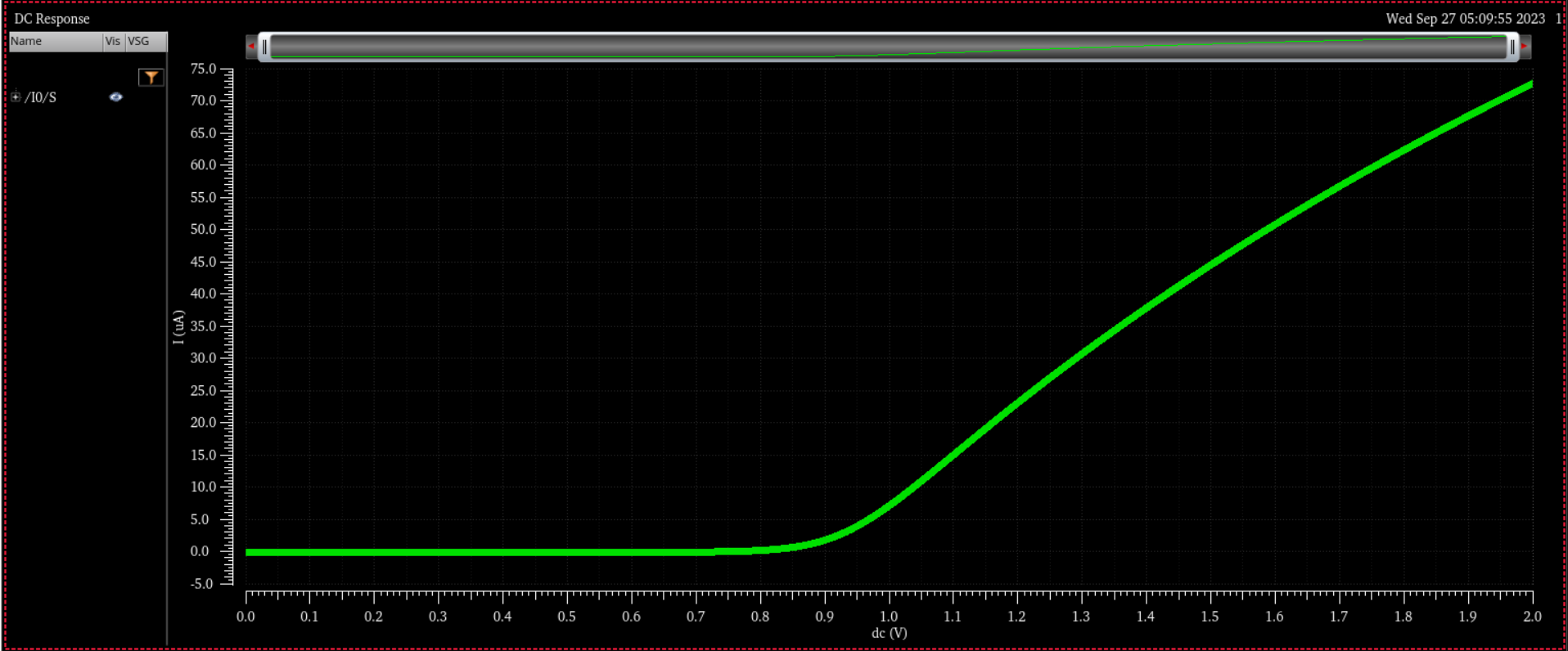

- A

schematic for simulating ID v. VGS of an NMOS device for VDS = 100 mV

where VGS varies from 0 to 2 V in 1 mV steps. Again use a 6u/600n

width-to-length ratio.

Using the same schematic, I modify the values of VDS to 100mv. Then simulate where VGS varies from 0 to 2V in 1mV steps.

With an increasing VGS, Id increases too.

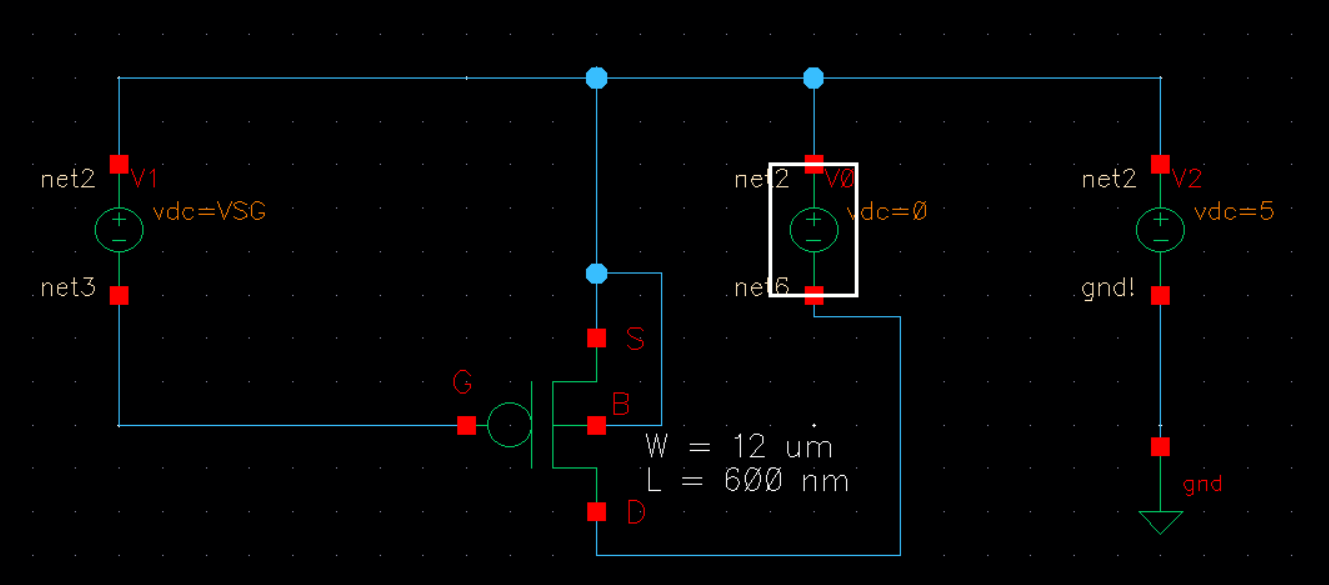

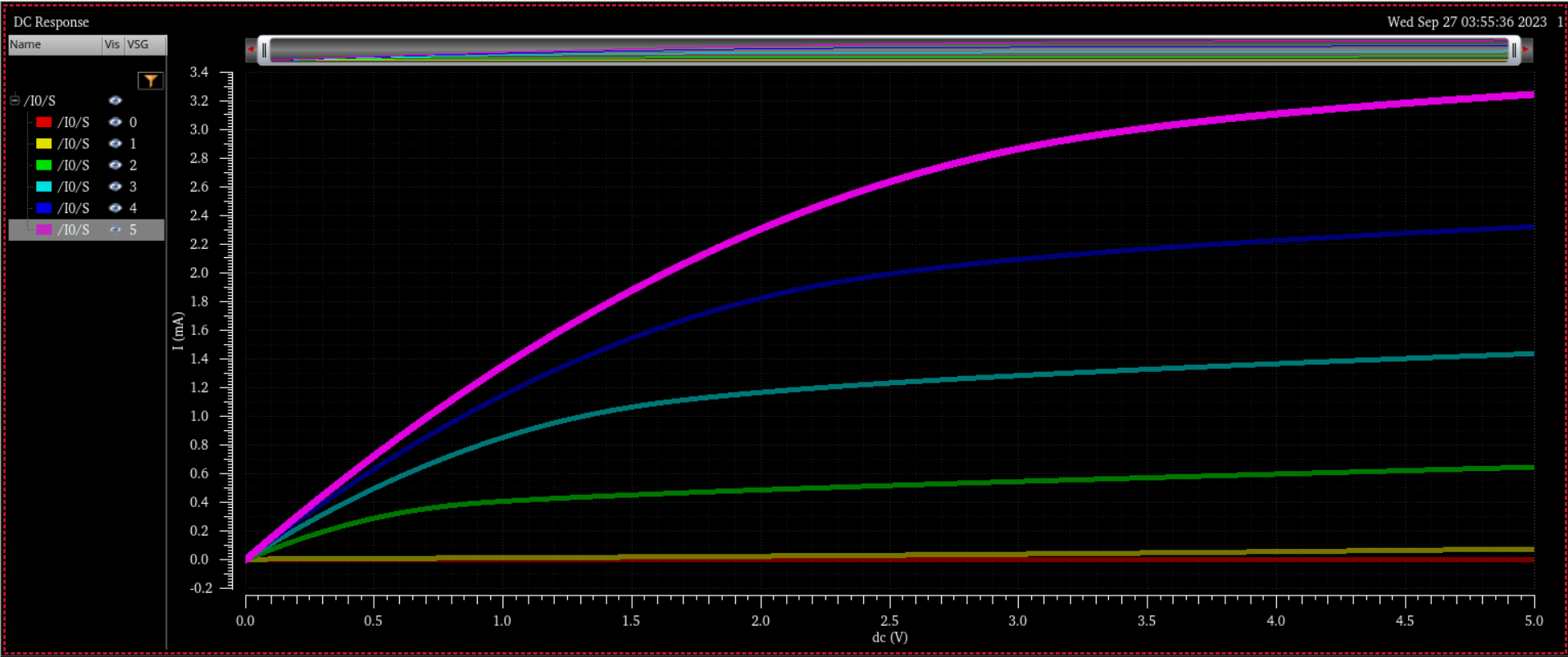

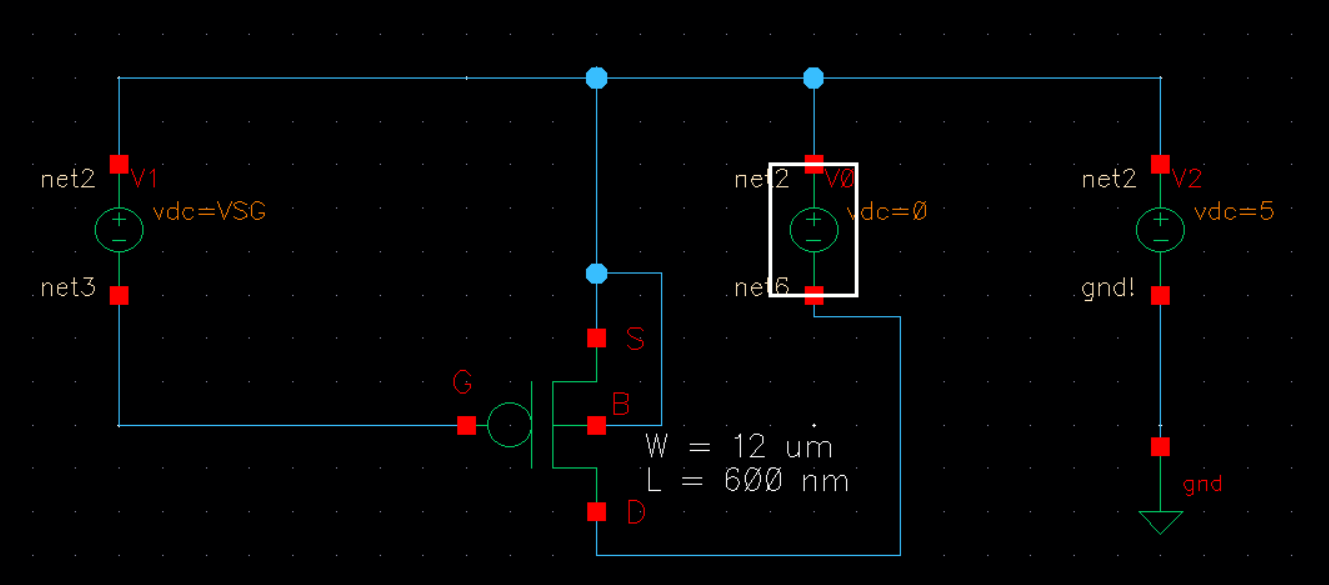

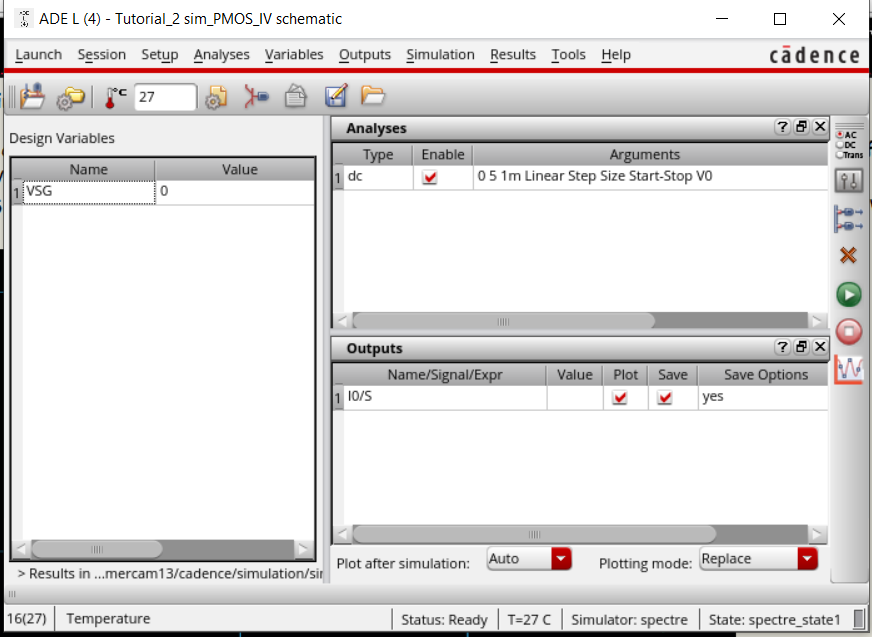

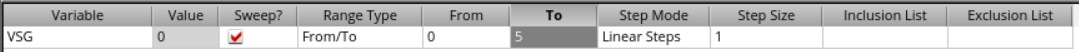

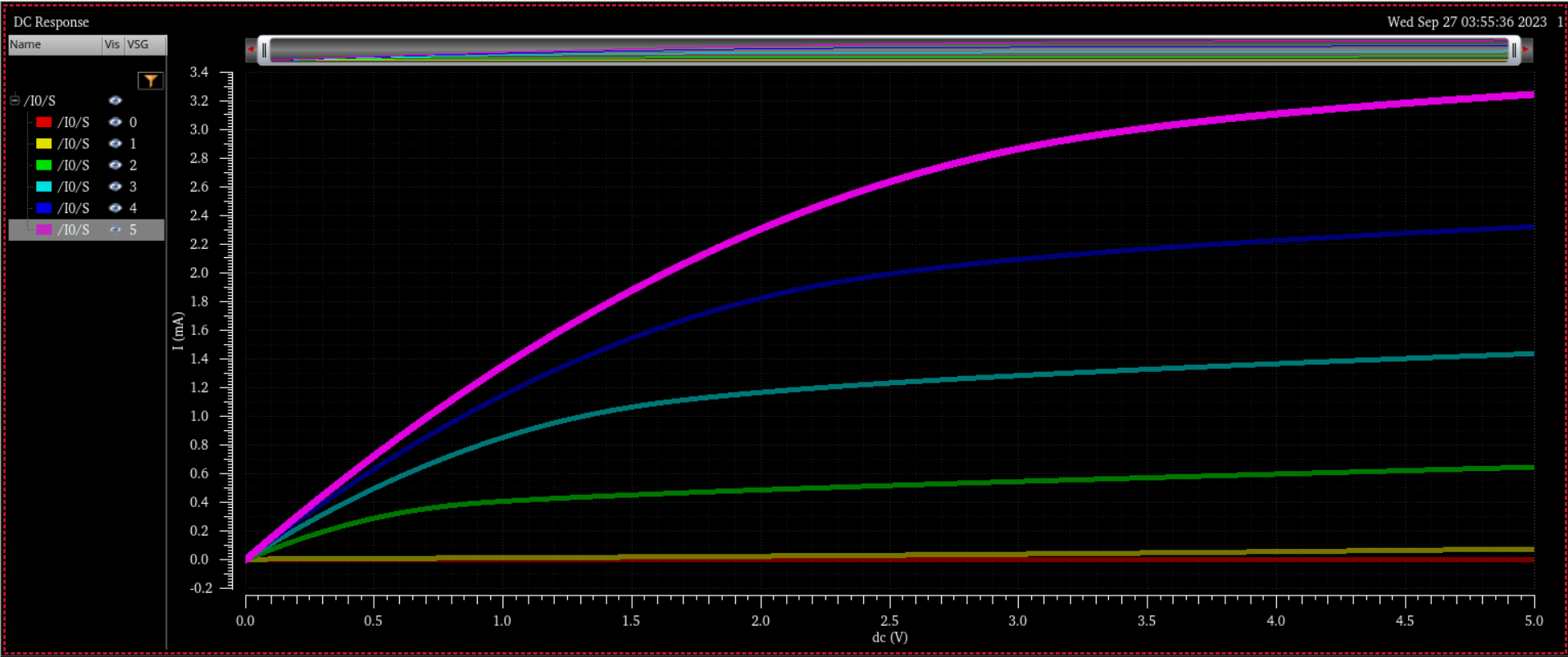

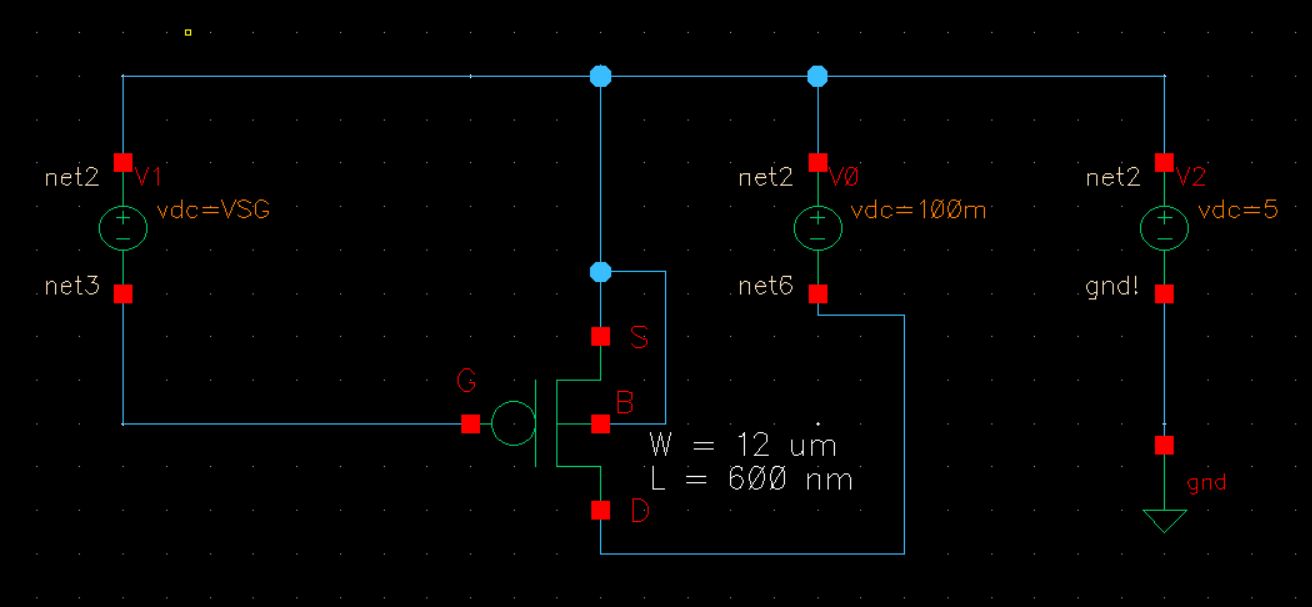

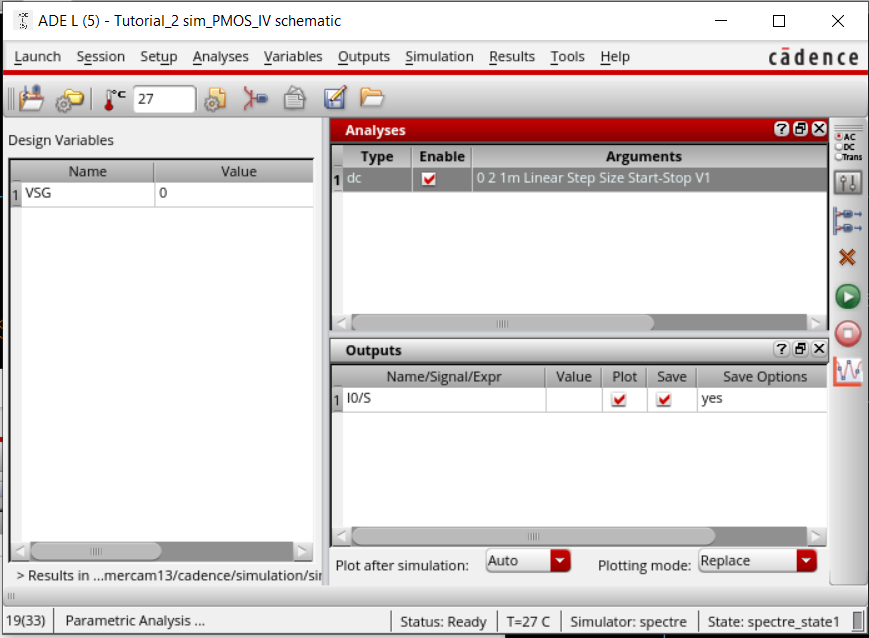

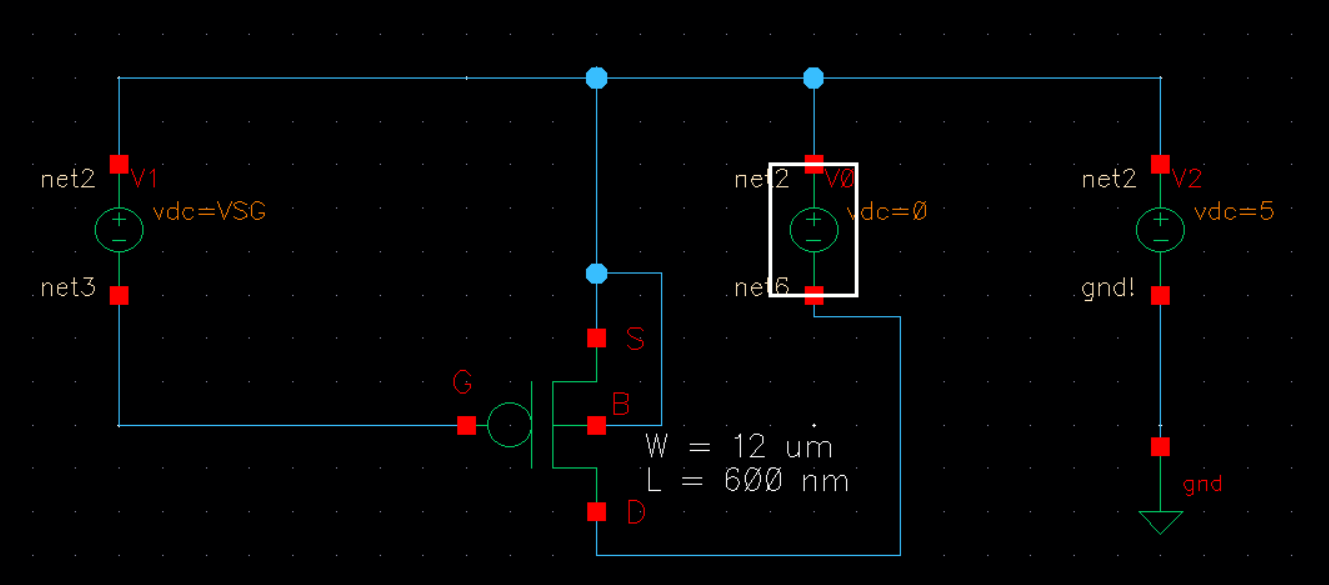

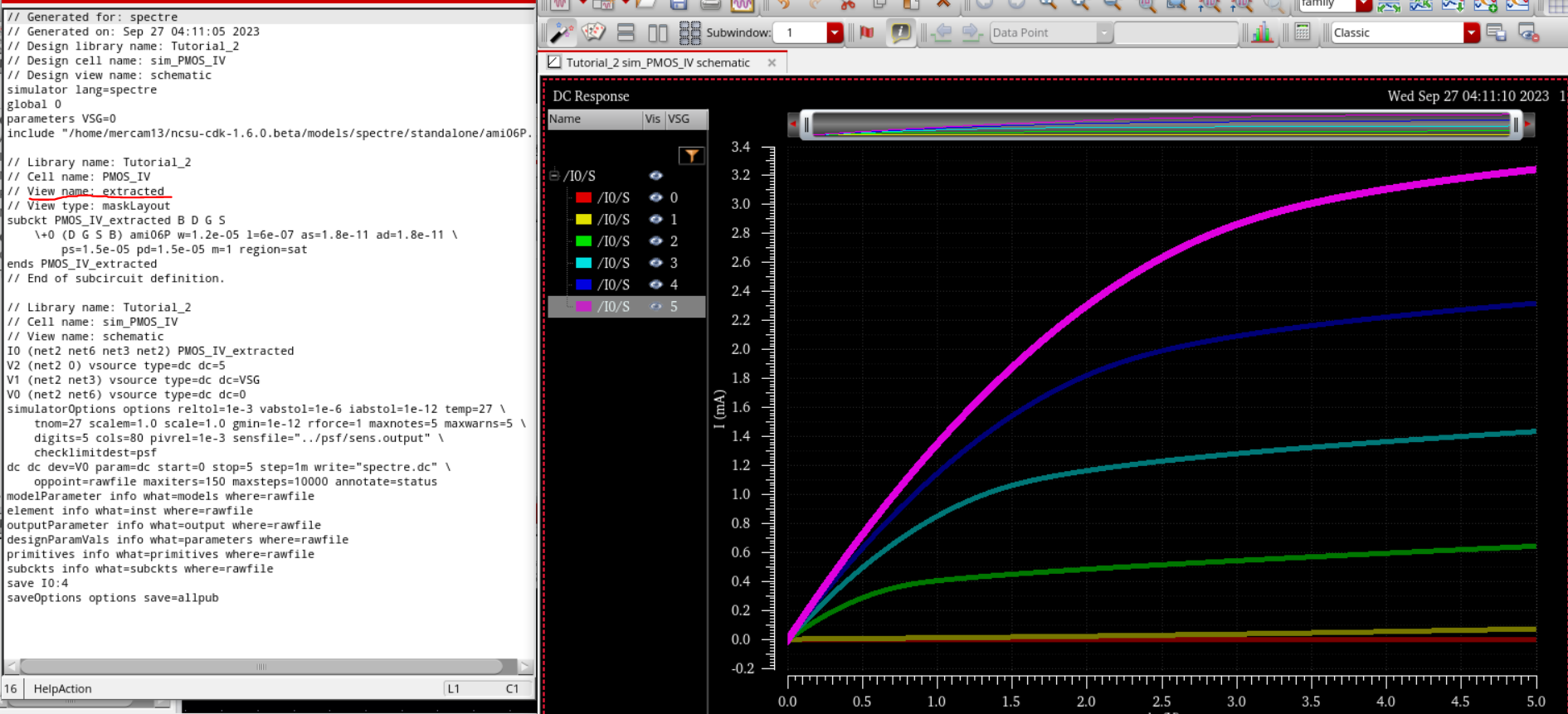

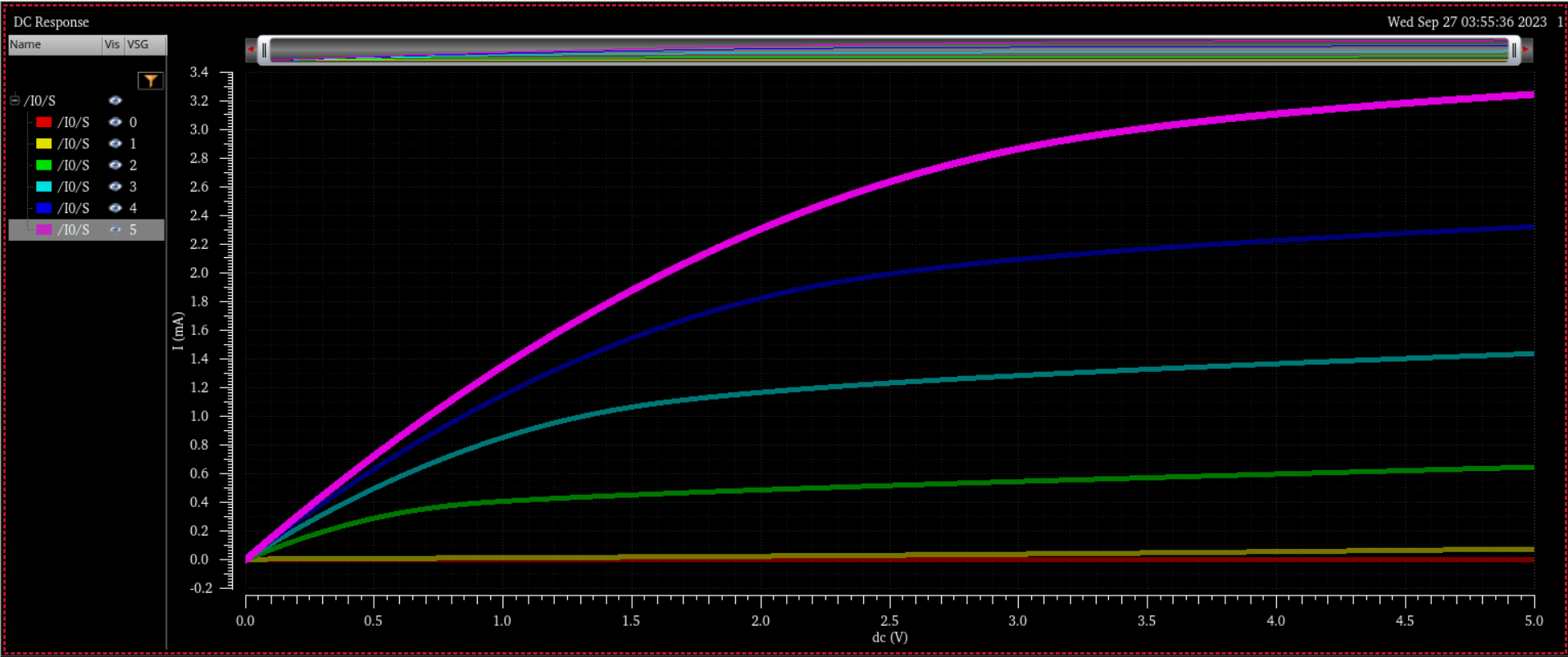

- A

schematic for simulating ID v. VSD (note VSD not VDS) of a PMOS device

for VSG (not VGS) varying from 0 to 5 V in 1 V steps while VSD varies

from 0 to 5 V in 1 mV steps. Use a 12u/600n width-to-length ratio.

Using

the PMOS schematic created in the pre-lab, I will be simulating Id v.

VSD where VSG varies from 0 to 5V in 1V steps while VSD varies from 0

to 5V in 1mV steps.

As VSG increases, Id increases with respect to VSD.

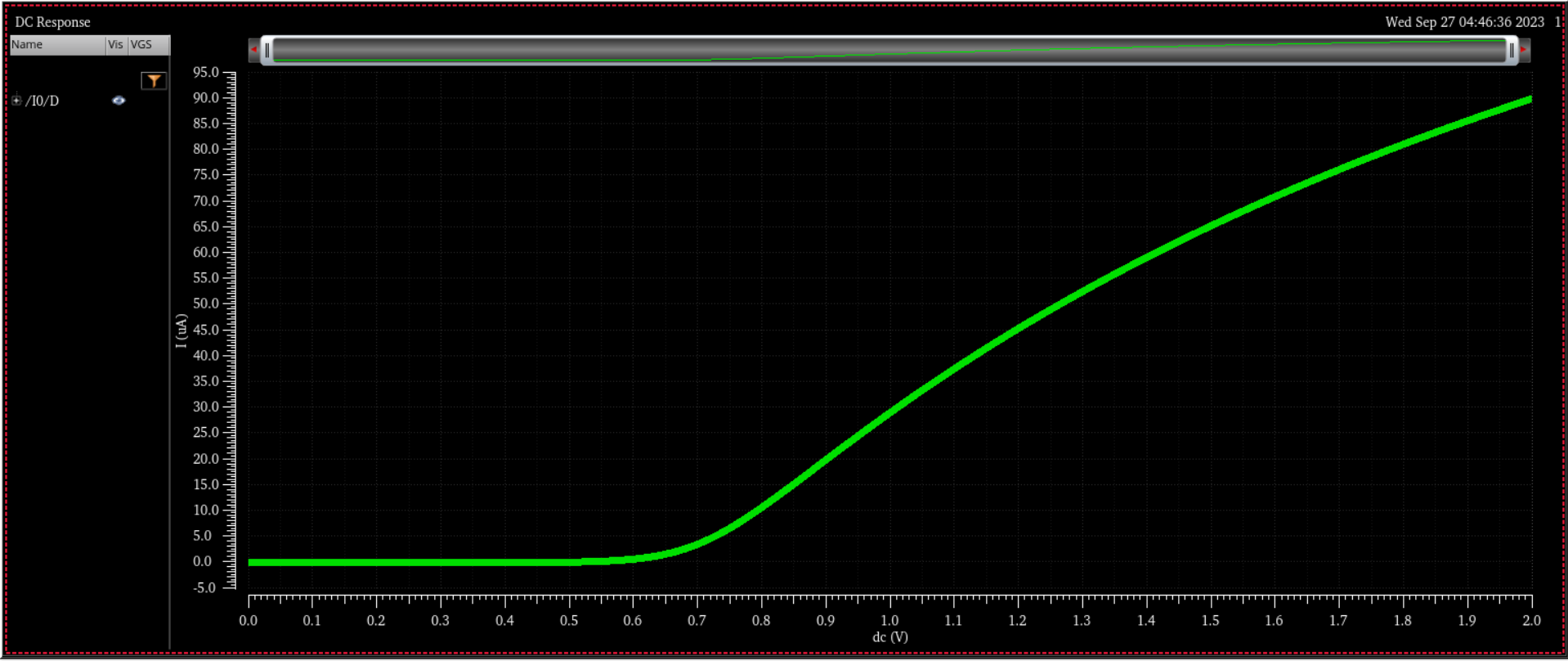

- A

schematic for simulating ID v. VSG of a PMOS device for VSD = 100 mV

where VSG varies from 0 to 2 V in 1 mV steps. Again, use a 12u/600n

width-to-length ratio.

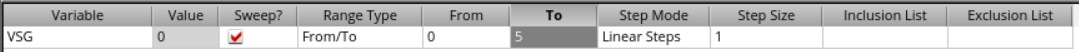

Modifying the PMOS schematic, I will simulate ID v. VSG for VSD=100mv and VSG varies from 0 to 2V in 1mV steps.

As VGS increases, Id increases with respect to VGS.

Note: The threshold voltage is higher because of the electrons being half as mobile as NMOS.

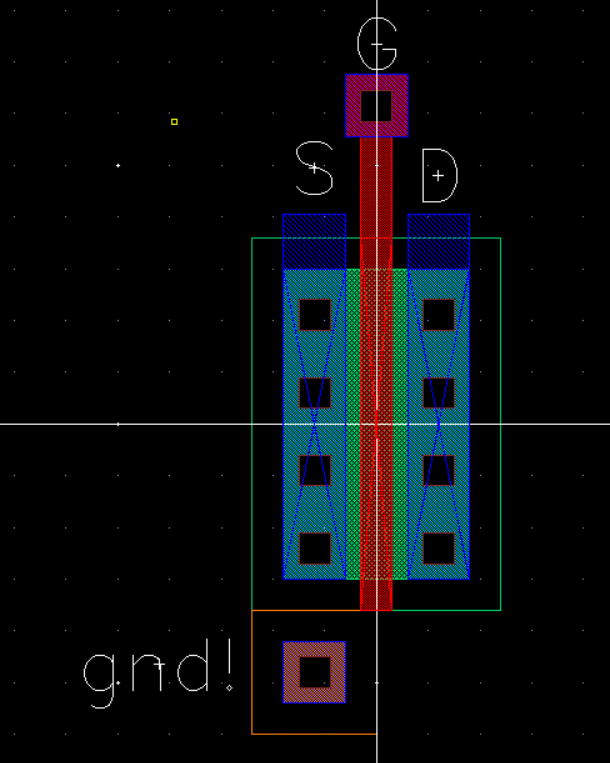

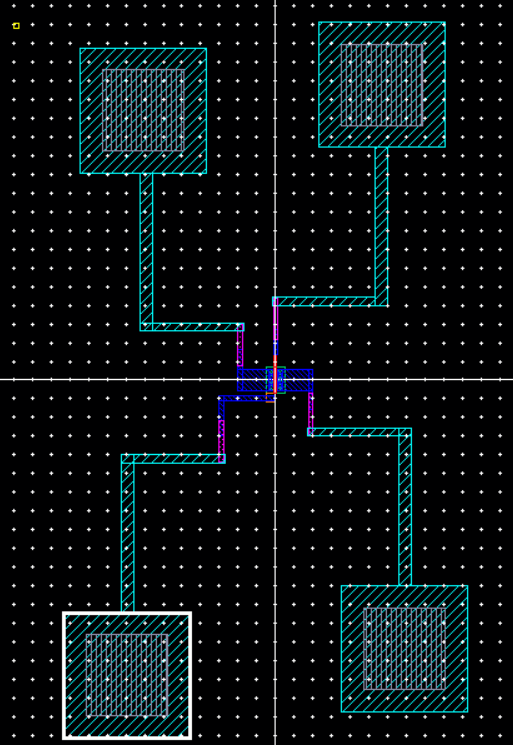

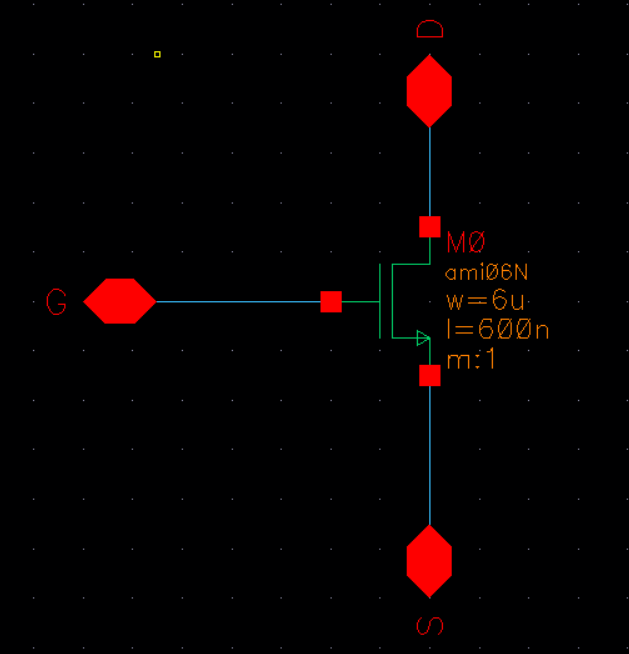

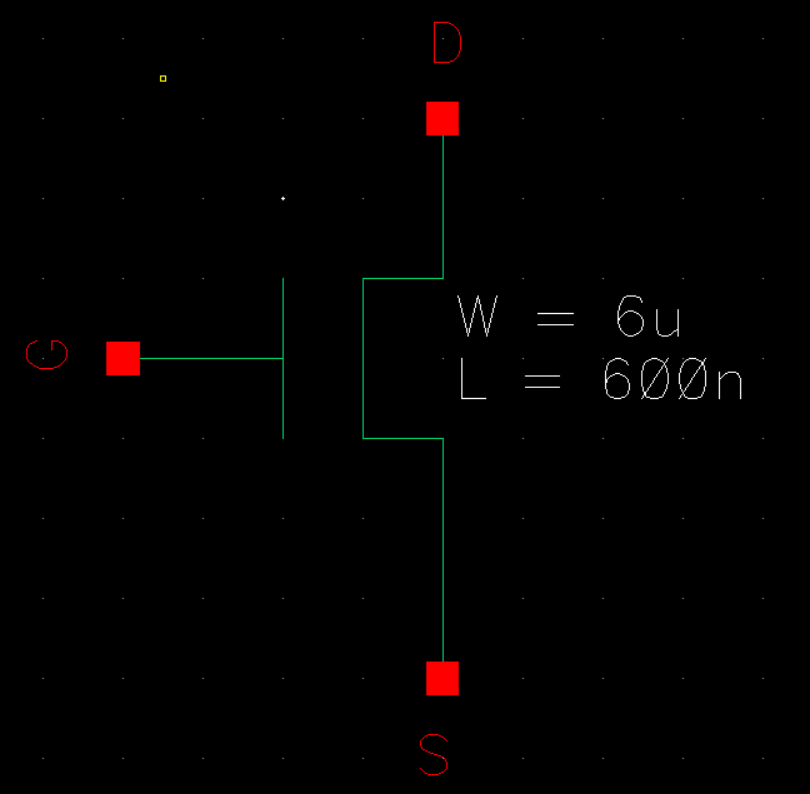

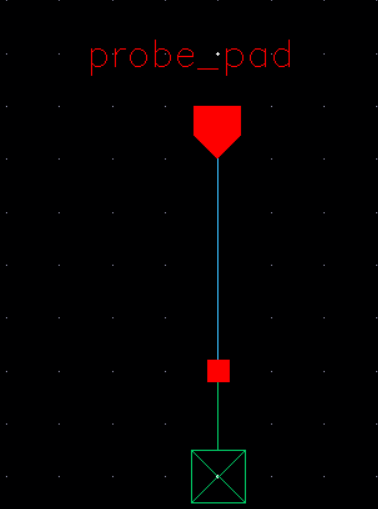

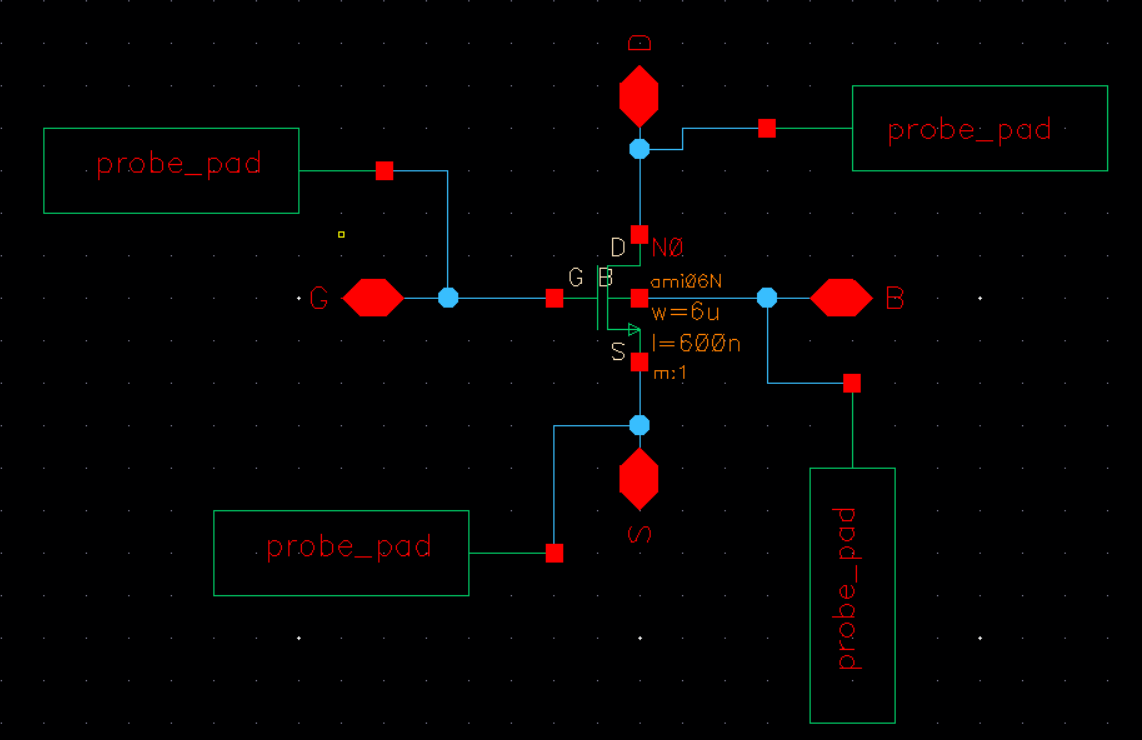

- Lay

out a 6u/0.6u NMOS device and connect all 4 MOSFET terminals to probe

pads (which can be considerably smaller than bond pads [see MOSIS design rules] and directly adjacent to the MOSFET (so the layout is relative small).

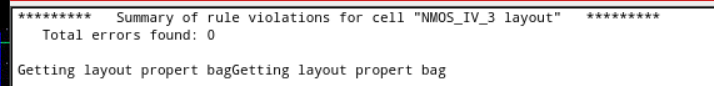

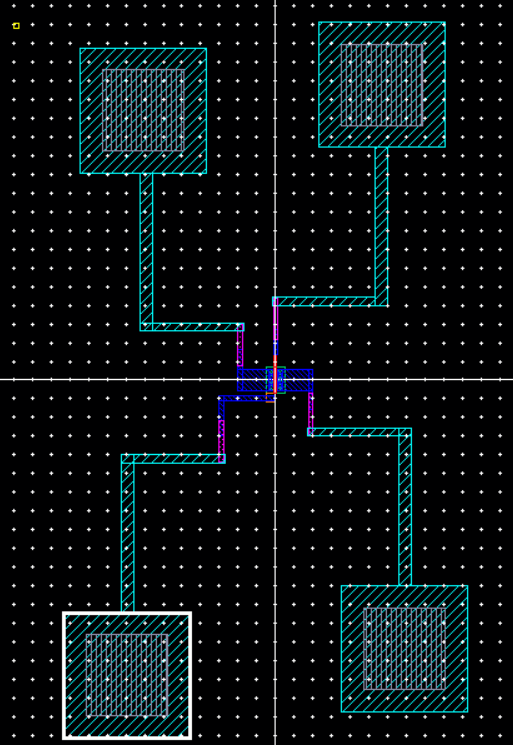

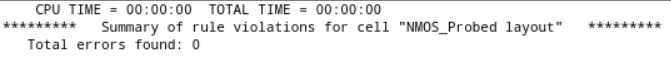

- Show your layout passes DRCs.

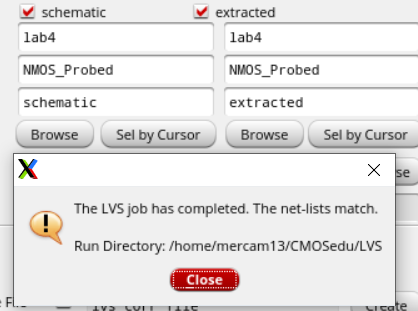

- Make a corresponding schematic so you can LVS your layout

For this part of the lab, I will be creating and using probe pads.

I will create a layout first.

Then a schematic and a symbol.

Now, I will create an NMOS schematic with the probe pads.

Then I will create a layout of the NMOS with probe pads then DRC.

Now I will extract and LVS.

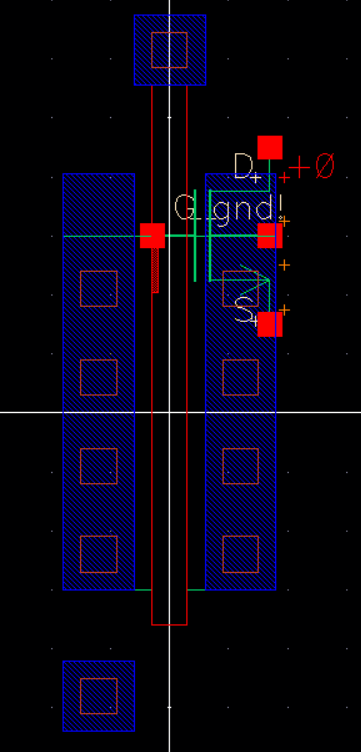

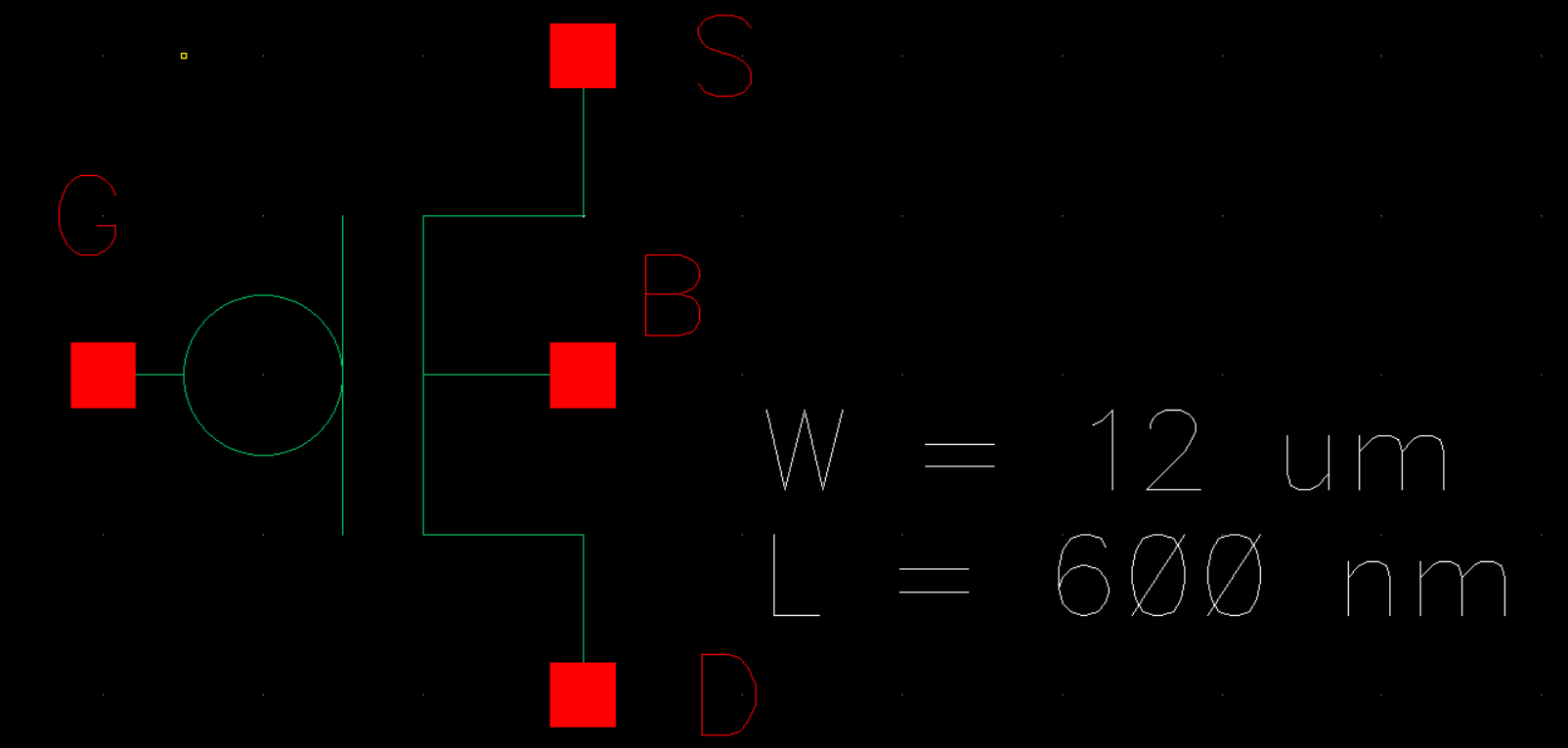

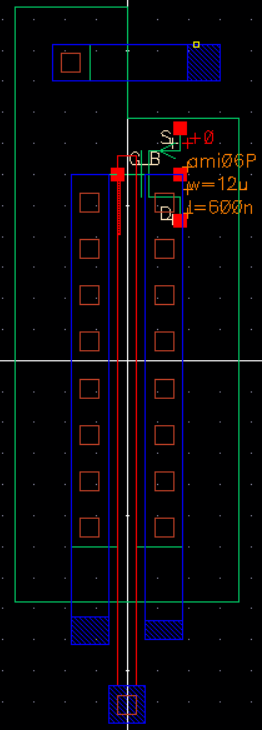

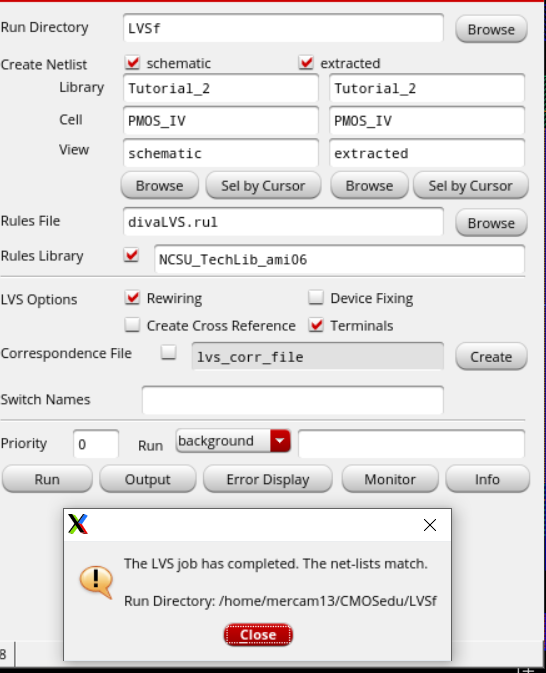

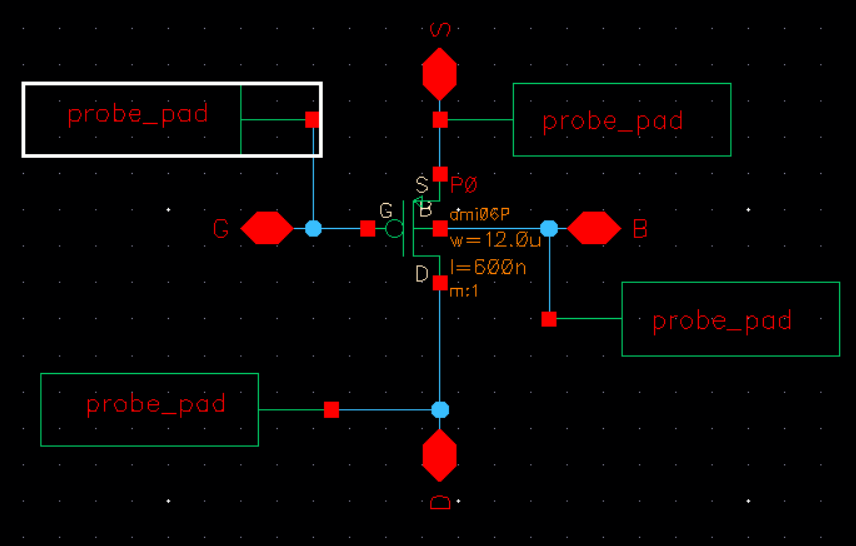

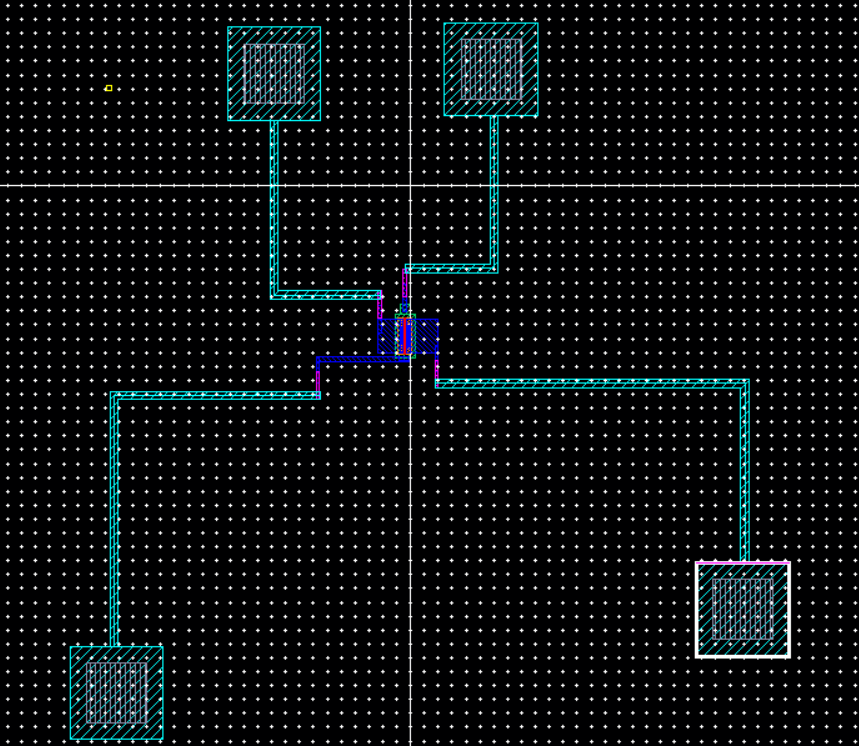

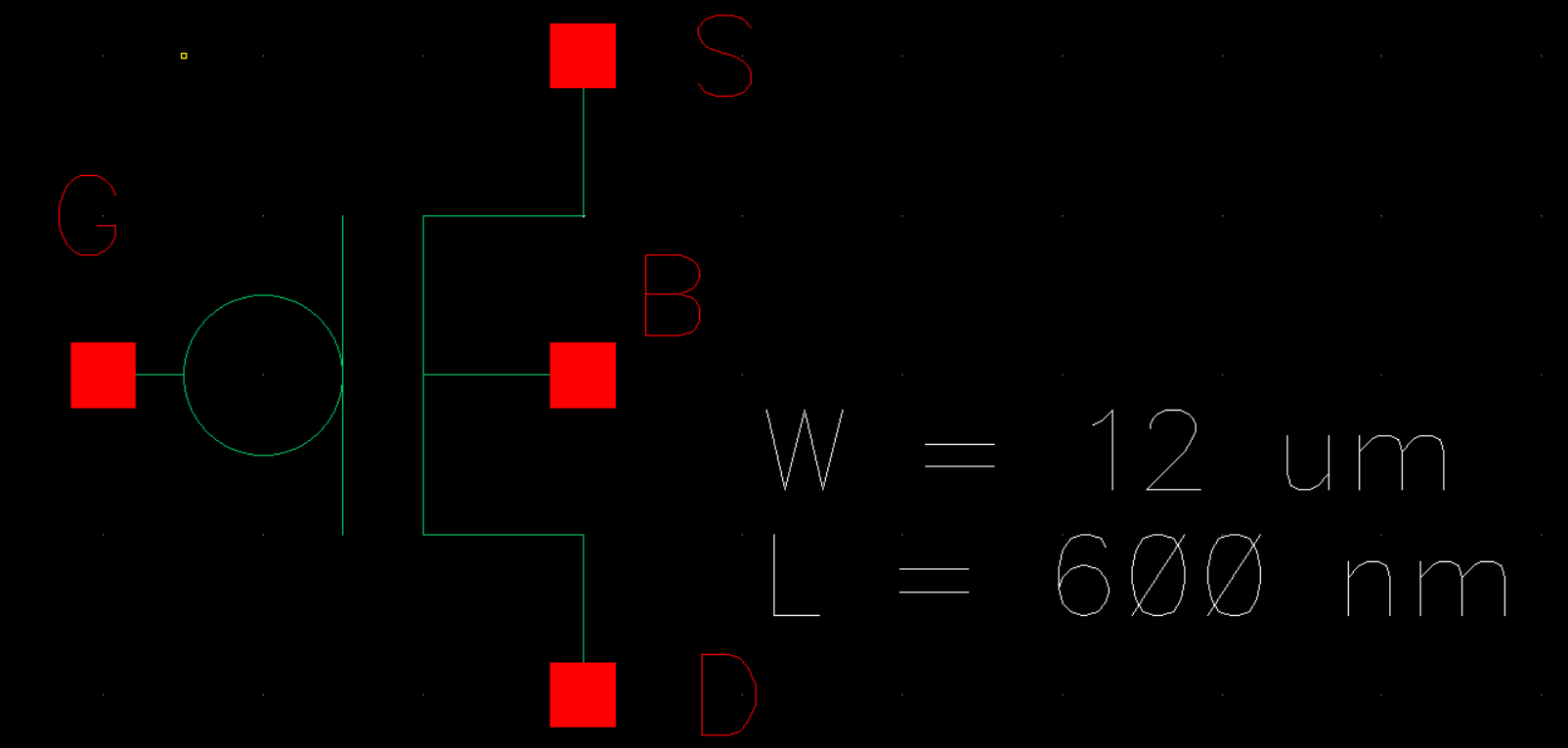

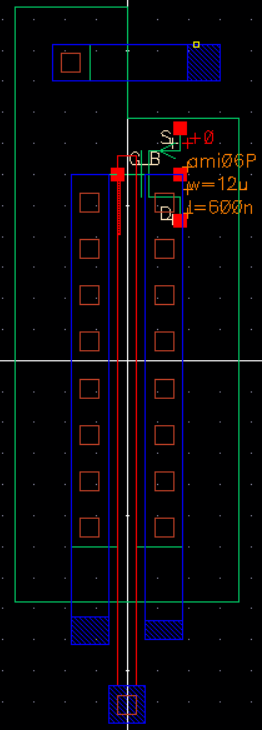

- Lay out a 12u/0.6u PMOS device and connect all 4 MOSFET terminals to probe pads.

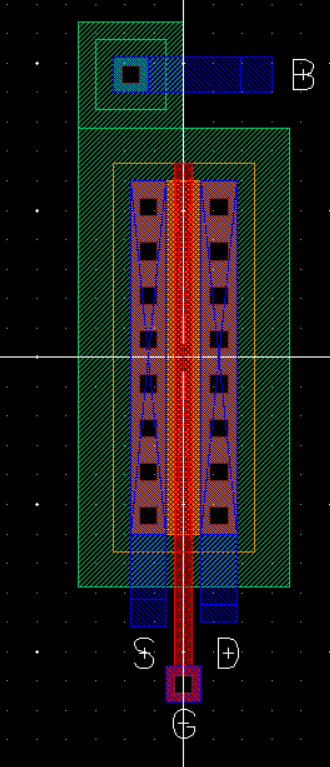

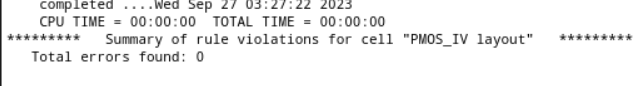

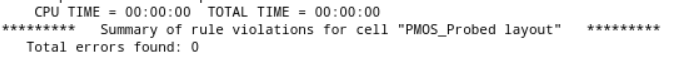

- Show your layout passes DRCs.

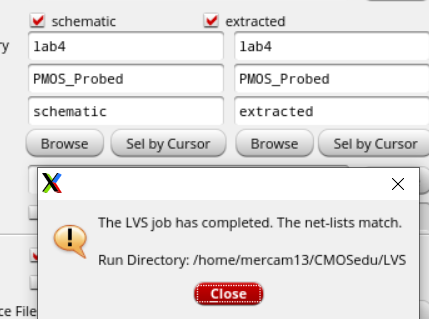

- Make a corresponding schematic so you can LVS your layout.

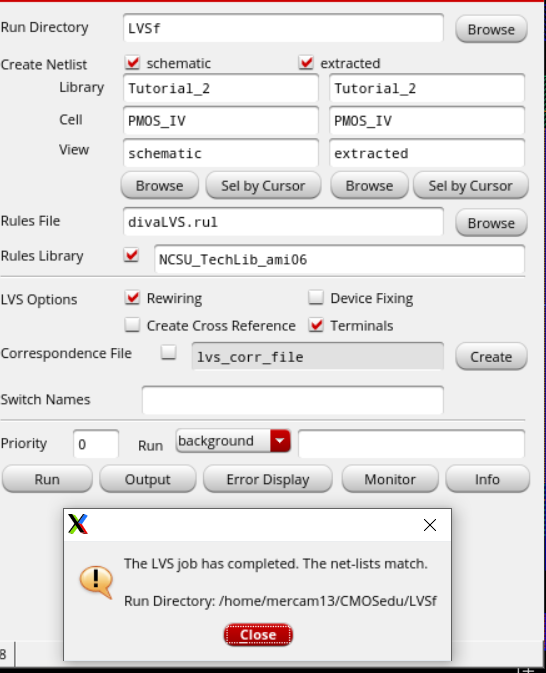

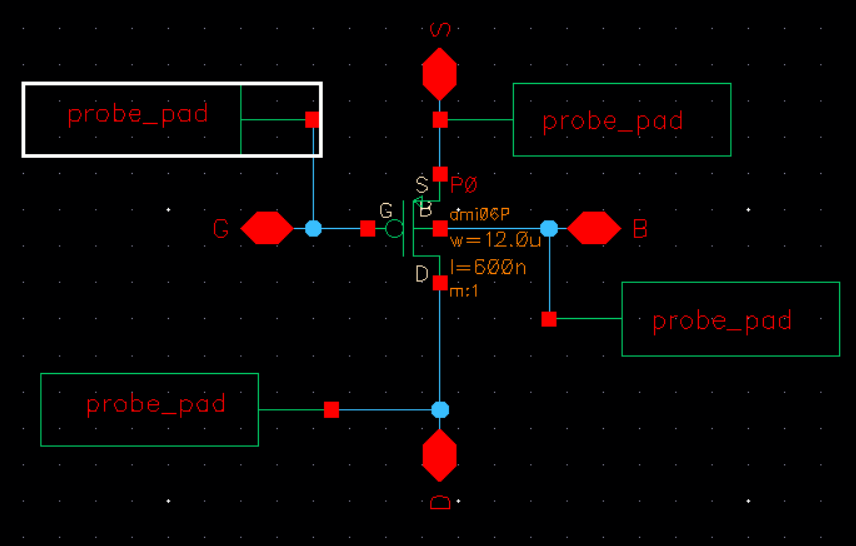

Repeat steps from above with PMOS and modifying the parameters to meet 12u/0.6u.

First, create an PMOS schematic with the probe pads.

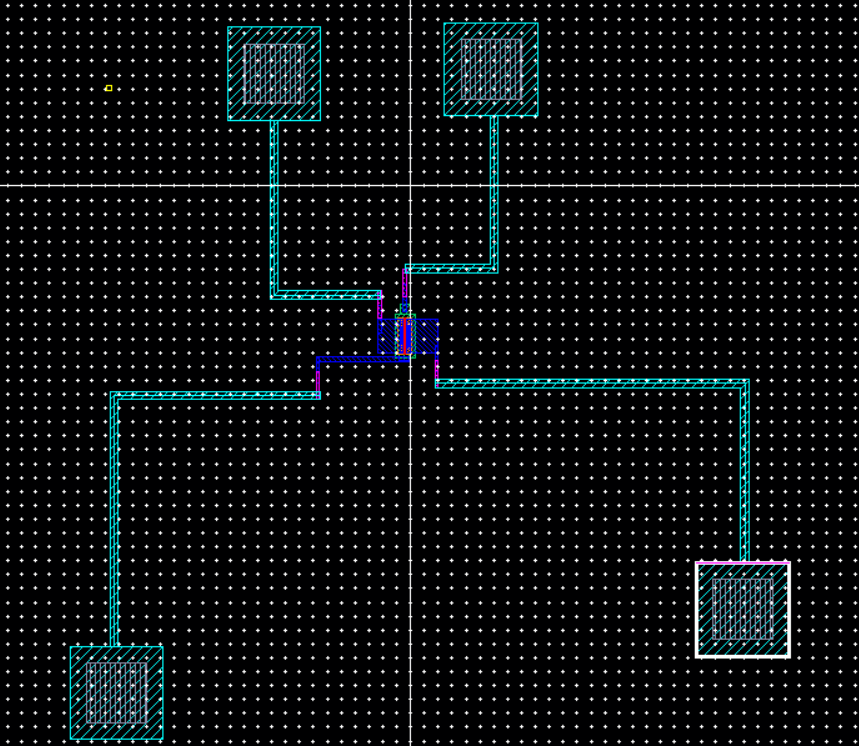

Then create a layout of the PMOS with probe pads then DRC.

Now extract the layout and do LVS.

Return to EE421 Labs