Lab Project - ECE

421L

Authored by David Pinales,

Today's date: 11/6/21

Email: pinales@unlv.nevada.edu

Lab description: design a register file (RF) that uses an 8-bit

word and has 32 words. The RF uses a 5-bit address to access the 32 8-bit

words. Other inputs to the RF are the 8-IO lines for reading and writing, a

control signal, RW, for indicating either a read or write to the RF, and

VDD/ground.

Introduction:

The increasing

proliferation of battery-powered gadgets in recent years has made low power

memory design a need in the business. As the number of transistors rises, the

leakage current increases, making the SRAM unit a power demanding block from

both a static and dynamic standpoint. Nowadays, the SRAM block is also a key

aspect of SOC architecture. The key concerns in developing the memory are power

dissipation and area. Memory density scaling must continue to match logic

scaling advances in memory design.

Components of SRAM:

The main SRAM building blocks include various

components. All these components or blocks used in the SRAM are listed as

follows:

• SRAM cell • Pre-Charge Circuit • Write Driver

circuit • Sense Amplifier • Address decoder

6-Transistor SRAM Single Cell:

Description:

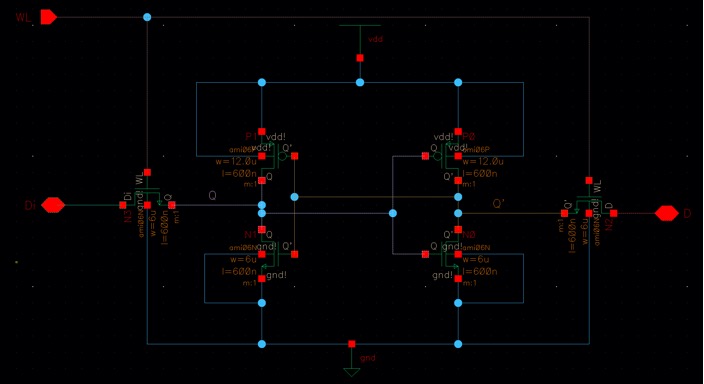

The 6 Transistor SRAM Cell is a component in

which operates for low voltage, low power behaviors. This component uses a

bistable latches system in which tells the circuitry on how to handle the bits

coming in. M1 and M2 PMOS are the pull up transistors whereas M3 and M4 NMOS

are the driver transistors. Access is provided through a word line (WL) that

connects to M5 and M6 pass transistors, resulting in Di and D (Data) lines that

are utilized for both reading and writing. These bit lines help to increase the

noise margin. Differential circuitry allows for noticeable output voltage

fluctuations. It stores logic 0 or 1 if the power is turned on, therefore

unlike DRAM cells, it does not need to be updated. The size of the transistors

in SRAM architecture is critical to its proper operation. Beginning with

inverters, the width of the NMOS is 1.5um, and because the NMOS is

almost twice as conductive as the PMOS, W=1.5um is used to balance their

conductivity. The gateway transistors, on the other hand, must be 2 or 3 times

bigger than the NMOS transistors from the inverters to be conductive enough to

modify the logic level held by these transistors. However, they should not be

too enormous so that they take up too much room. For these gateway transistors,

I chose a width of 6um.

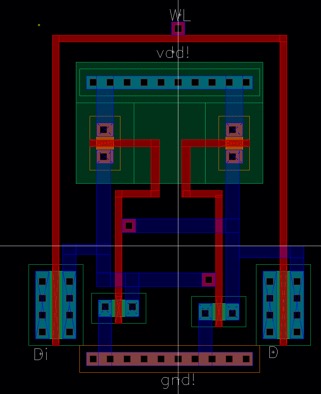

Schematic:

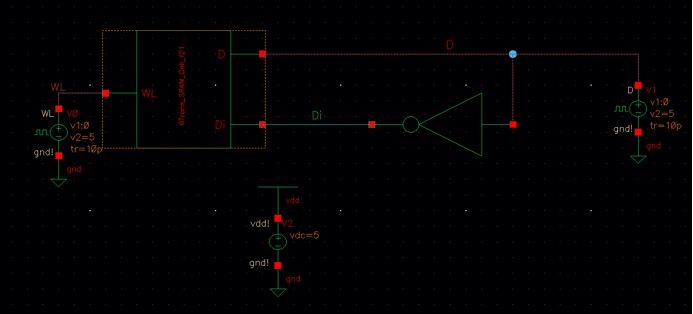

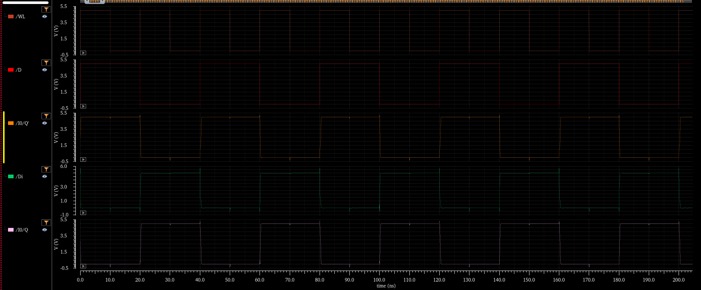

Simulation:

Holds

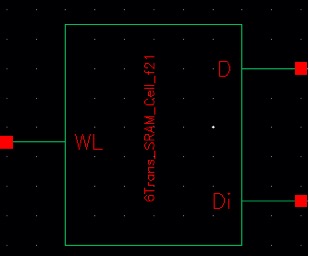

Symbol:

Layout:

The write driver is responsible for swiftly

discharging the bit lines to a level underneath the cell's write margin before

or while the word lines of the selected cell are active. Which bit line is

discharged is determined by the data supplied. Only when a writing operation is

intended is the WL signal activated. Otherwise, the WL separate the bit lines

from the write drivers. It is quicker because it has fewer stacked transistors

in its discharge route, but it is more complicated. Typically, the writer of

the operation is not a time-critical transaction, simpler configurations that

loosen the layout constraints are recommended for the write driver. It is made

up of CMOS inverters and NMOS pass transistors and may be scaled up since the

number of transistors required to construct a column is not dependent on the

number of transistors.

8-Bit Memory Word Cell:

Description:

Here we are combining our Single 6T component

into a 8-Bit memory word cell.

Schematic:

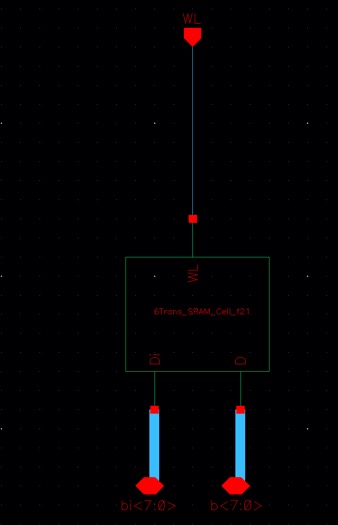

Symbol:

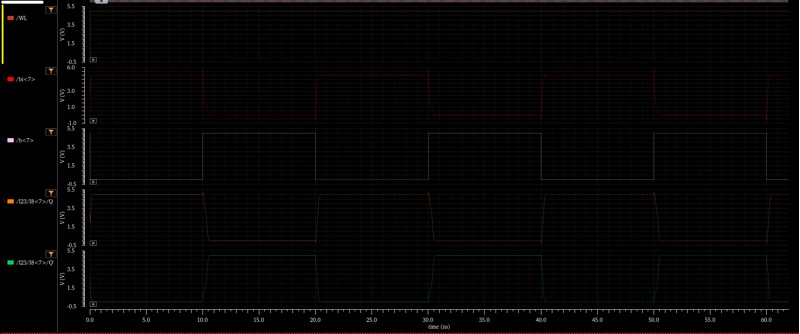

Simulation:

With WL enabled to HIGH, We

can see the bit are Holding well.

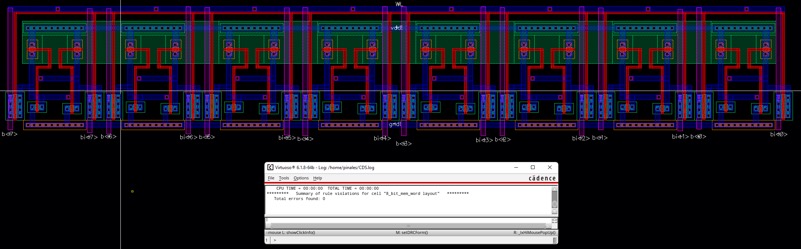

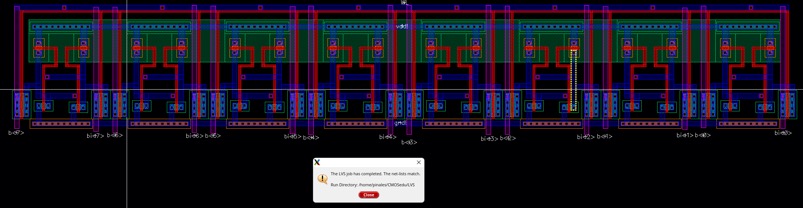

Layout for 8bit memory single cell:

8-Bit Word Array:

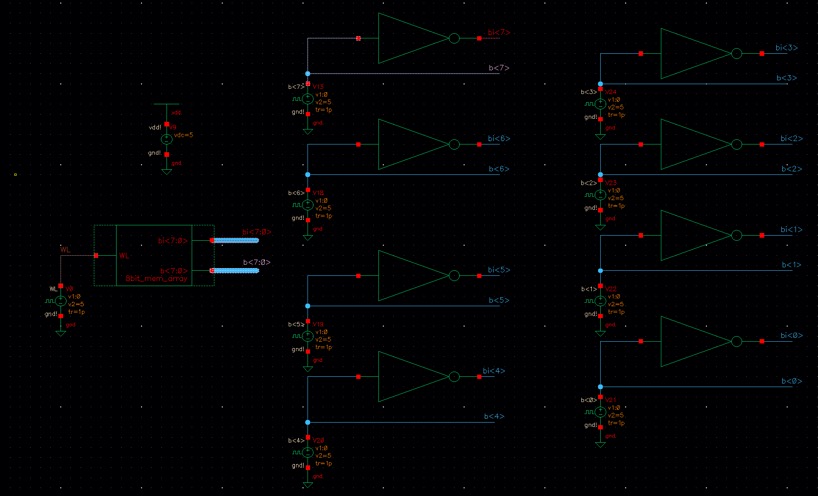

Schematic for 8bit word array (32*):

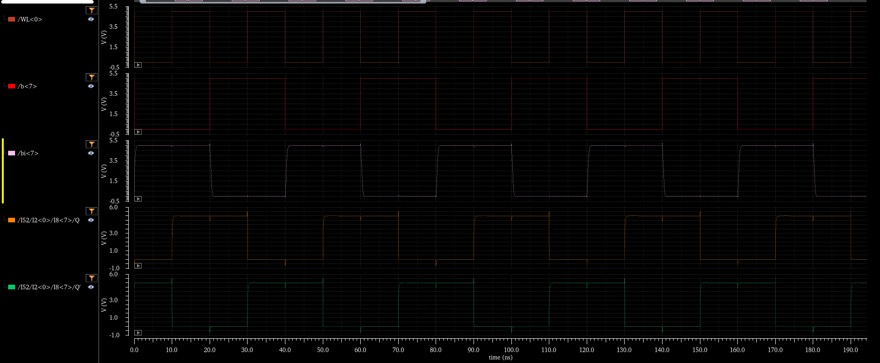

Simulation:

As we descend into Bit<7>, Row<0>,

We can see how the push through given components are holding well with both

operations so Write and read are displayed

![]()

![]()

![]()

![]()

![]()

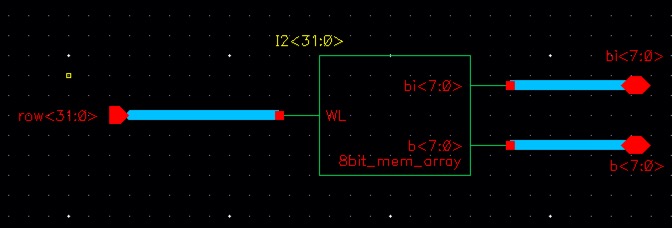

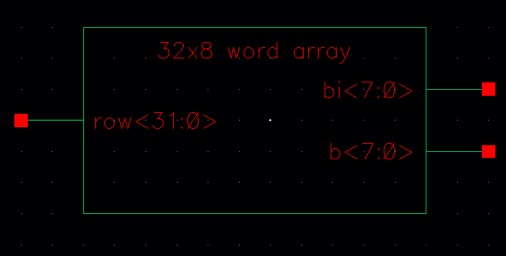

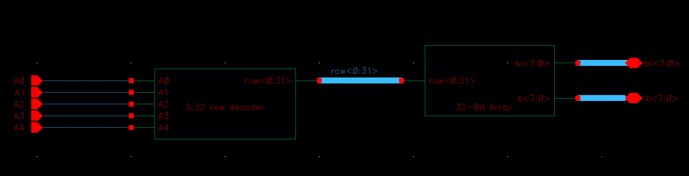

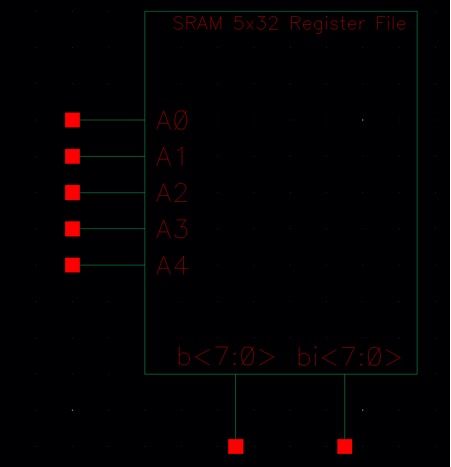

Symbol For 32x8 Word Array:

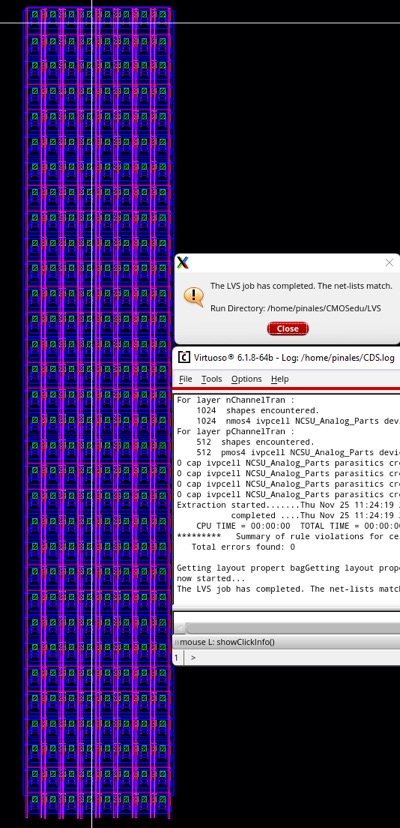

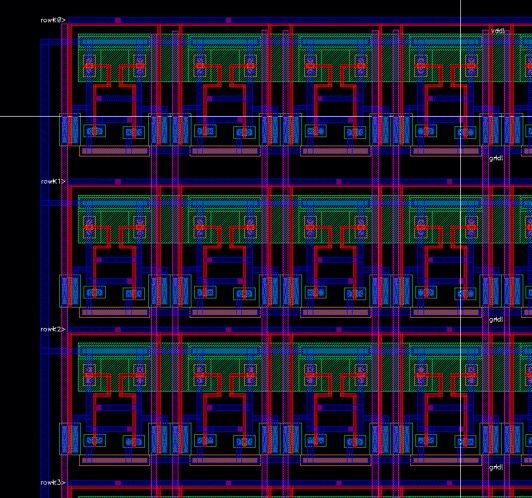

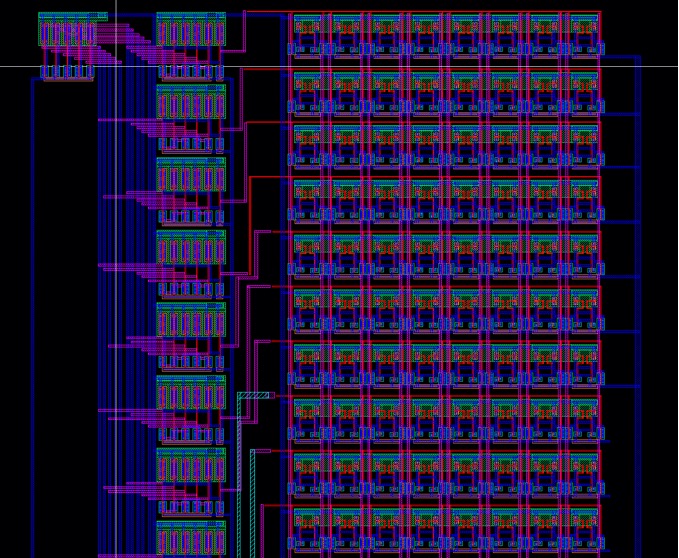

Layout:

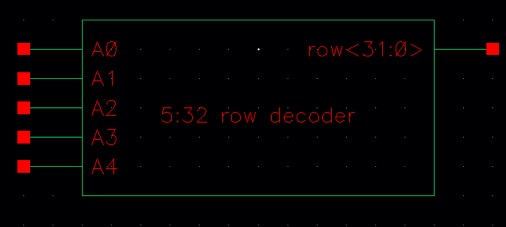

Address (5:32) Decoder:

Description:

Multiple words are put in one row in programs

that use the standard word size (M<128). Interleaved bits of words in a row

share peripheral circuitry such as a sense amplifier, write driver, and row

decoder. In this case, an address decoder is utilized to decode the input

address and enable the word line. 7 dynamic NAND CMOS decoders are employed

here. One is employed as a row decoder, which picks a certain word line by

increasing its voltage level. The column decoder determines which column to

use. In this case, a 5:32 NAND CMOS decoder is employed, with an inverter added

to access it during the write phase. As the project details ask for a

5-to-32-bit decoder.

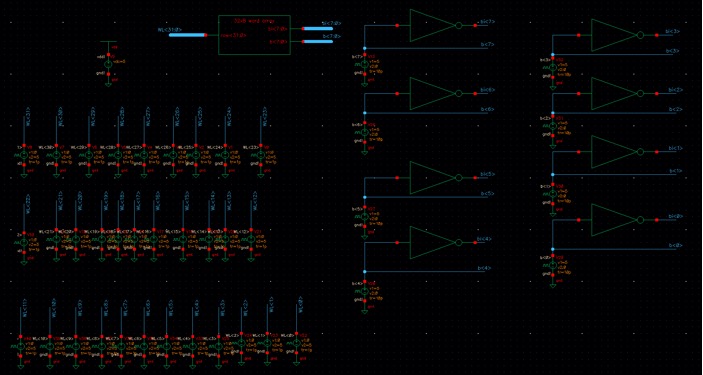

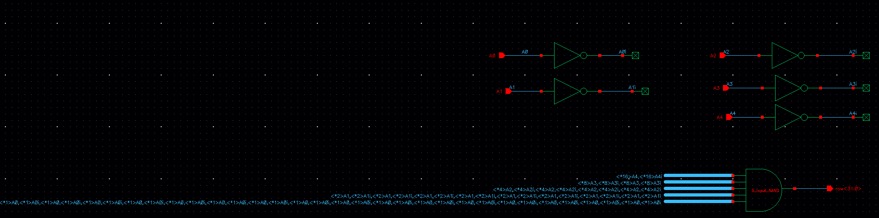

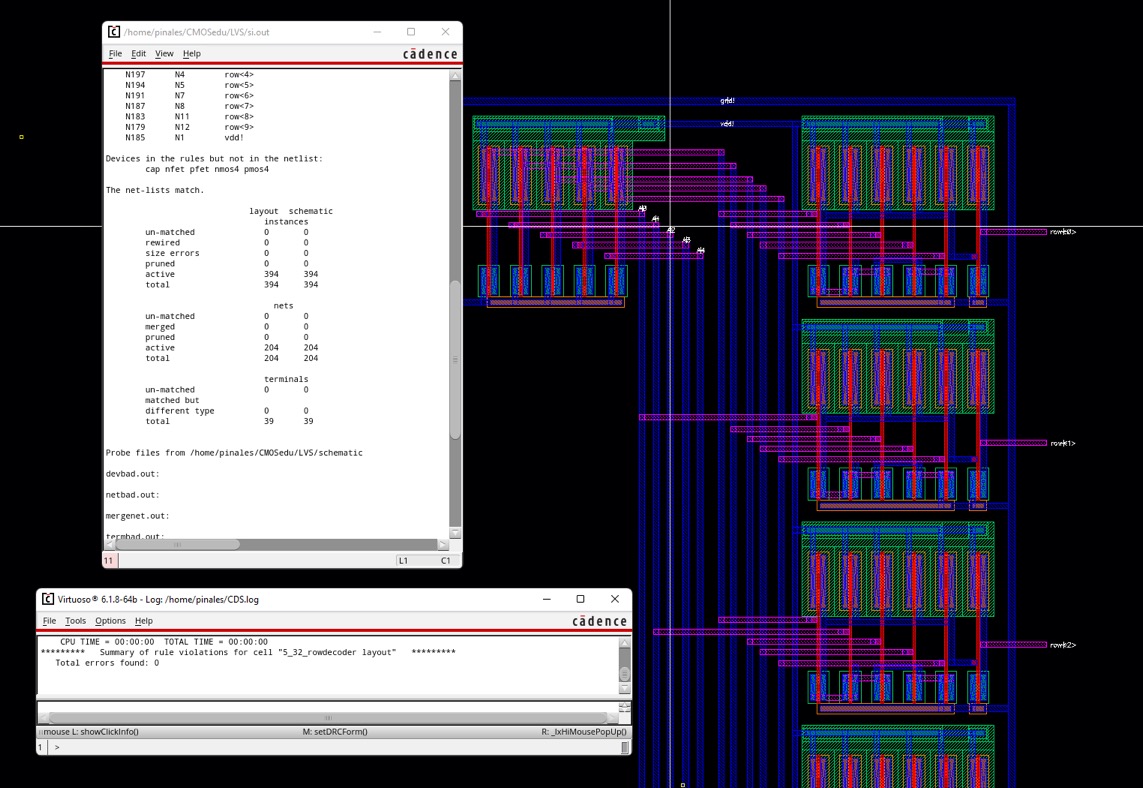

Schematic (5:32 Row Decoder):

Symbol:

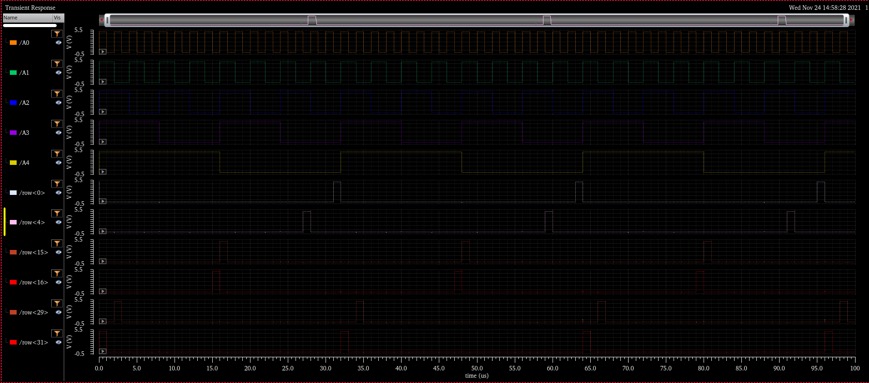

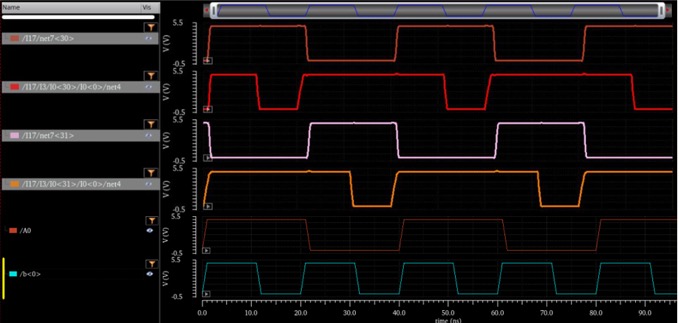

Simulation:

Here can be seen gathering different parameters

from individual rows. I chose the given rows to show the variety of Behaviors

occurring.

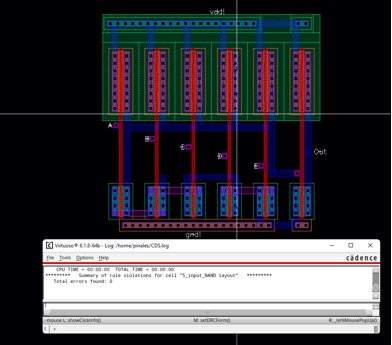

Layout - 5 Input-NAND:

Layout of 5:32 Decoder:

32 bit-word

SRAM Register File:

Description:

For the result,

I have combined my 5:32 Decoder into the 32:8 Bit word array to finalize my

32-Bit SRAM Register File.

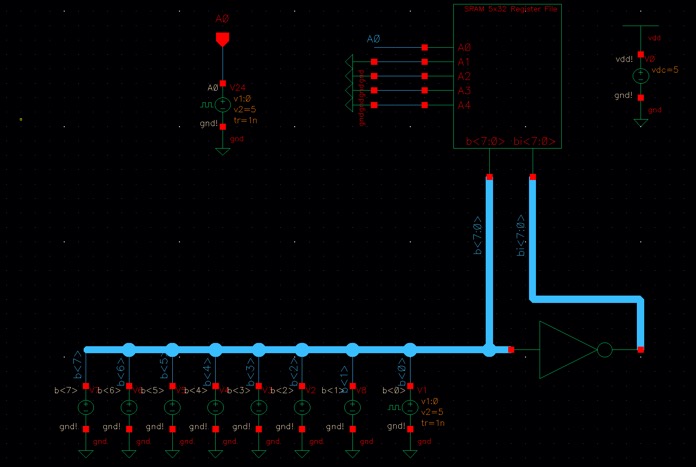

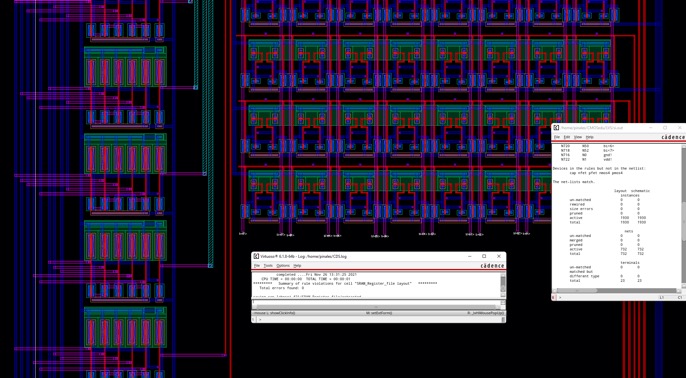

Schematic/ Simulation:

*As you've seen, the registration file is

operational.

We set

the specific address of "00001" when A0 is high, which writes to

row<30>. This causes I0<30> to follow b<0>.

When A0 is low, the address "00000" is

called, and we are writing to RL31>, thus I0<31> now comes after

b<0>*

Symbol:

Layout:

![]()

![]()

![]()

![]()

![]()

****Added Features that assist for Static Noise

Margin****

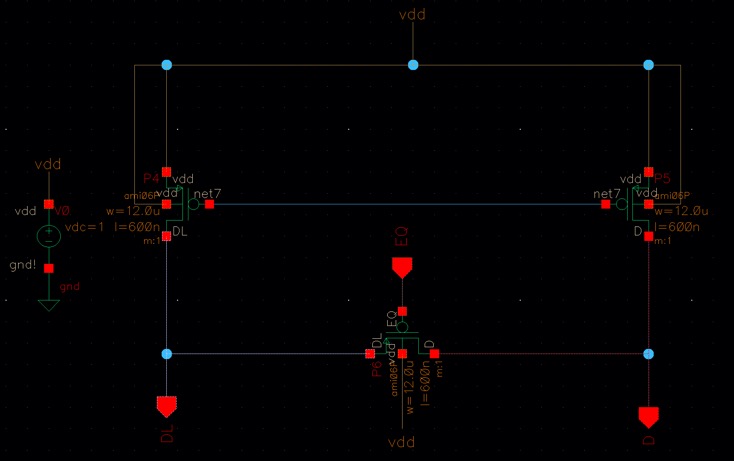

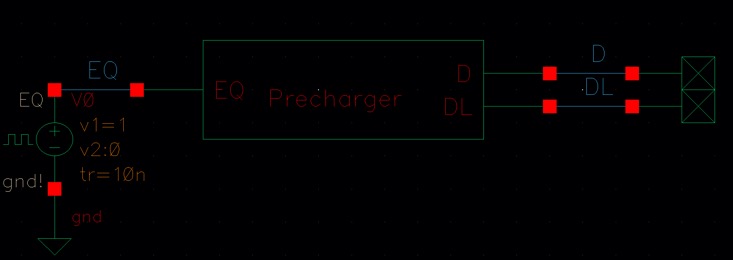

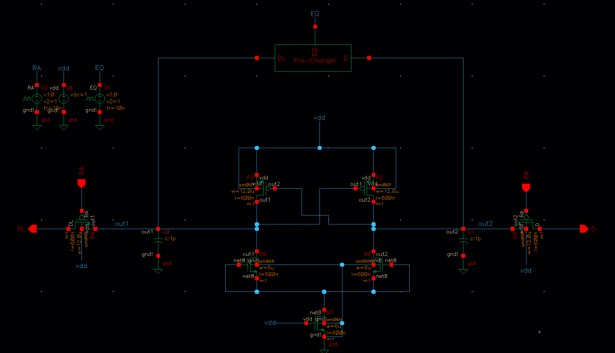

Pre-charger:

Description:

The pre-charge of the bit lines is critical to

the proper operation of the SRAM. To accomplish the read operation, the bit

lines must be charged at the same voltage. Following the writing and reading

operations, one of the bit lines is drained, resulting in an unwanted voltage

differential between the bit lines. Following these procedures, the pre-charge

circuit equalizes the bit line voltages to the supply voltage. M1 and M2 PMOS

transistors will precharge the operation, and M3 PMOS

transistor will equalize the operation when Vdd is

presented in this input. My schematic below depicts the circuit diagram of the precharge circuitry, and Vdd=1v

is used.

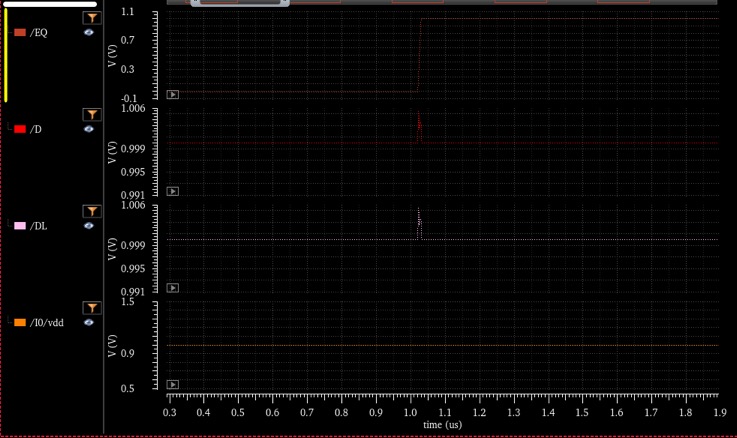

Schematic:

Simulation:

Symbol:

Sense

Amplifier:

Description:

A modest

analog differential voltage is created on the bit lines during a read access is

amplified by the sensing amplifier. A full swing single ended digital output is

produced because of the amplification. Because the drive transistors do not

need to fully discharge the bit lines, the use of SA (Sense Amplifier)

minimizes the size of the SRAM cell. In general, read operations are the

slowest, causing a delay in the cell. Because of the length of the metal and

the number of transistors, bit lines have a higher capacitance and require more

time to discharge. The hardest choices for sense amplifiers here are time

control and load capacitor selection. The SAE signal is used for it. In this

case, a latch type sense amplifier is employed, with two cross coupled inverters

providing differential output that amplifies the signal and provides complete

swings, and two capacitors storing the level of the bit lines.

Schematic:

Conclusion

As the result still had some noise margin

induced by the component’s, the most optimal way to reduce all the noise and

contain a perfect SRAM model the additional components listed would be ideal.

With the result being as is, we still were able to obtain logic levels of 1 and

0 to induce the read or write capabilities the SRAM Register File. Furthermore,

more can be done as mentioned with the descriptions of the other components

left out, the implementation of the Pre-charger and the sense amplifier would

be ideal if another SRAM file were to be made.

Return

to other fellow 421L engineer labs