Final Project – Design, Simulation, and Layout of a Times Four (x4)

Clock Multiplier

EE 421L Digital IC Design

Schematics Due: 11/13/19 at 11:30am

Layout and Documentation Due: 11/20/19 at

11:30am

Last Edited on

11/19/19 at 10:23pm using Word

Go To Simulations Using The

Current Starved Inverters…

Go To How to Improve Initial

Design…

Go To Part II – Layout of the Times

Four (x4) Clock Multiplier

Click here to see the final layout.

Click here to

download EE421L_FinalProject.zip

For this

project, a circuit will need to be designed to take in a 9-11 MHz input clock

signal and generate a frequency between 36-44 MHz clock signal.

This circuit

is a x4 Multiplier, where the output clock frequency is the input clock

frequency multiplied by 4.

For simplification,

the input clock will have a 50% duty cycle.

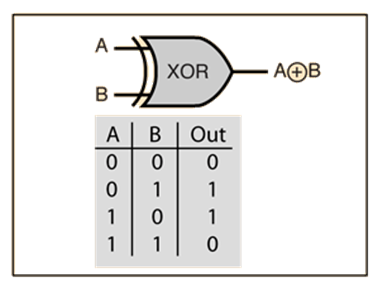

How are we

able to generate a pulse that is faster than our input?

For this, we

will look at an XOR gate.

Figure 1, An XOR gate, with Truth

Table

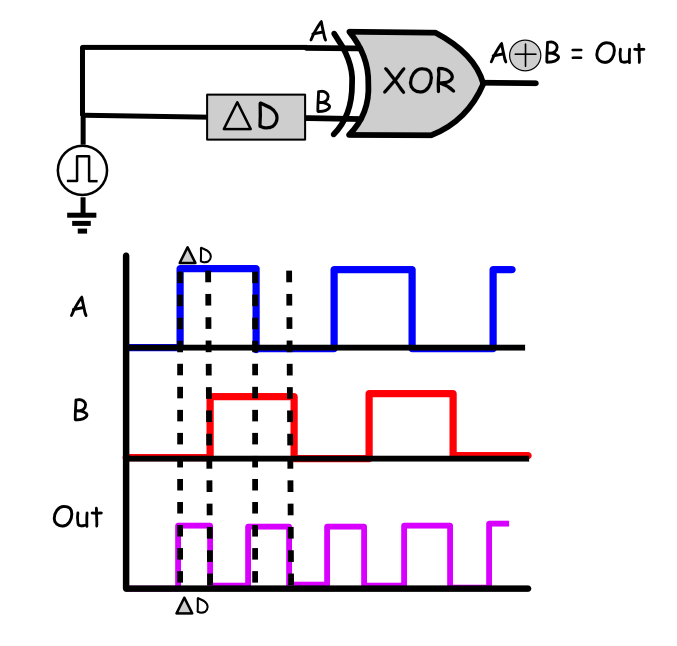

Figure 2, A Representation of how the

frequency can be doubled using an XOR gate.

If we get a

genuinely nice delay ΔD, we can then use the XOR gate to generate a pulse

that is double the input frequency (since the XOR only outputs during a

rise/falling edge of the input signal, and there are 2 of these events every

period, or 2/T = 2ƒ).

After we get

this doubled frequency, we will then use the output in another XOR gate to

double the doubled-input frequency (so times 4).

--------------------------------------------------------

Part I: Schematics and Design

Discussions

To multiply

the frequency by four, we will first look at how to multiply the input

frequency by two using the XOR gate.

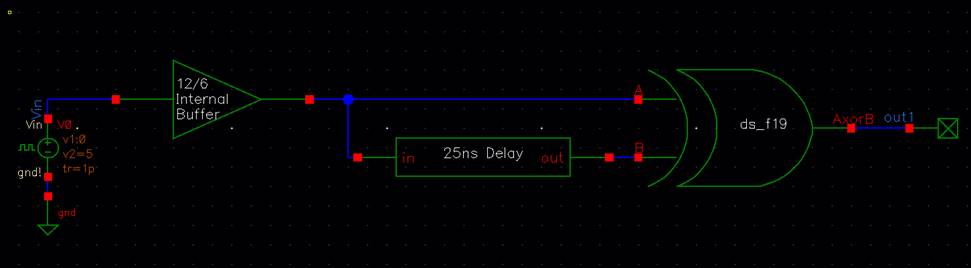

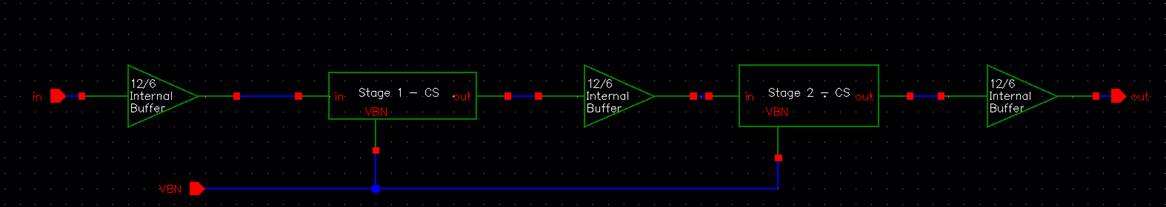

Figure 3, the first stage x2

Multiplier

Note, the

reason for the beginning buffer is so that just in case the rise time of the

input is not fast enough, we can buff the incoming signal so that it can be

processed into the XOR gate and delay.

The buffer in

the beginning are two 12u/6u inverters.

We will be

designing at an input frequency of 10 MHz (a period of 100ns or a 50ns/50ns

duty cycle).

The delay of

the 2nd input of the XOR gate should be around 25ns.

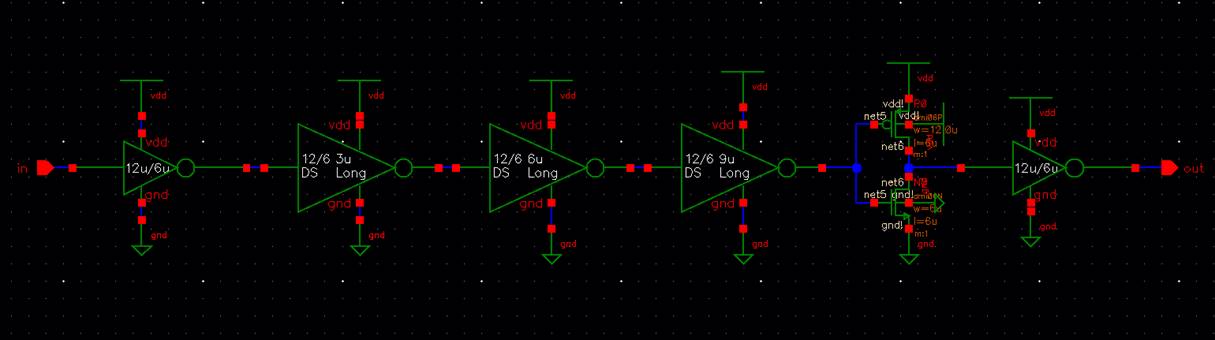

Here is the

delay block:

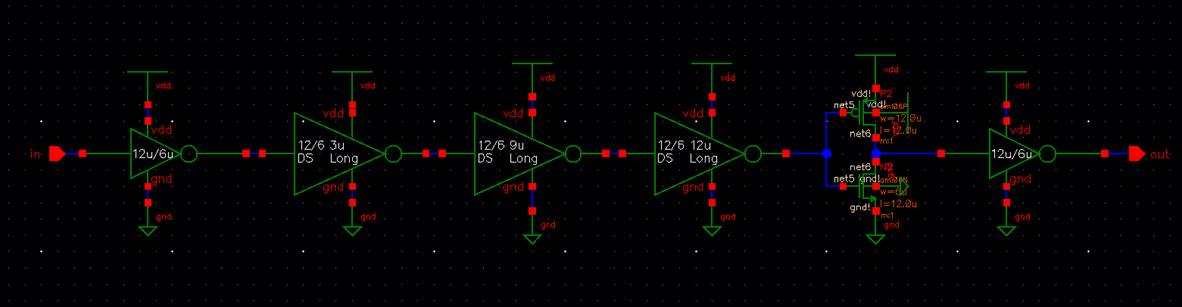

Figure 4, the Delay block that will

delay the input by around 25ns.

For this, we begin

with one 12u/6u inverter (using minimum length), and we have 4 long inverters,

with each inverter having a longer length than the previous inverter.

I chose this

progression because of how the input capacitance was affecting each inverter. I

made it to where the larger lengths were first, but then the RC delay length of

the signal would be cut down tremendously, and thus there was too much

capacitance at the beginning stage. With this topology, each stage will have a

steady increase of total capacitances so that we can propagate the full length

of the signal.

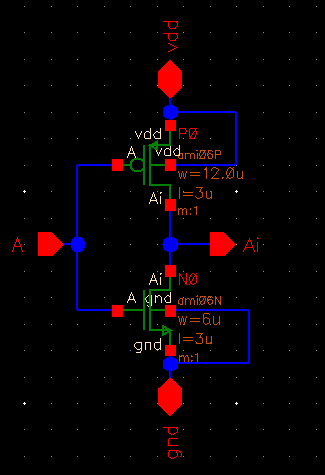

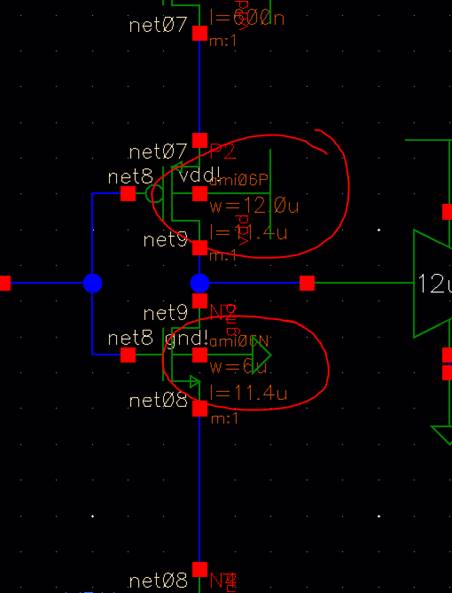

Schematic of

the first long inverter:

Figure 5, Schematic of a Long Inverter

- 12u/6u, Length of 3u

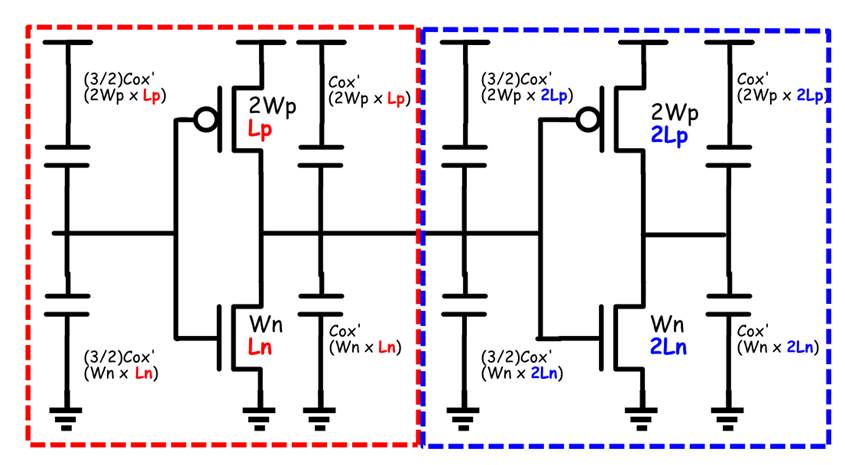

Idea of the

total capacitances:

Figure 6, The Capacitances of the Long

Inverters.

In Figure 6,

as you can see, as we increase the length of L, we also increase the

capacitance of both the input and output of the long inverter.

This is why I placed a small “pre-buffer” at the beginning of

the delay, so that this capacitance does not affect the first

input of the XOR gate.

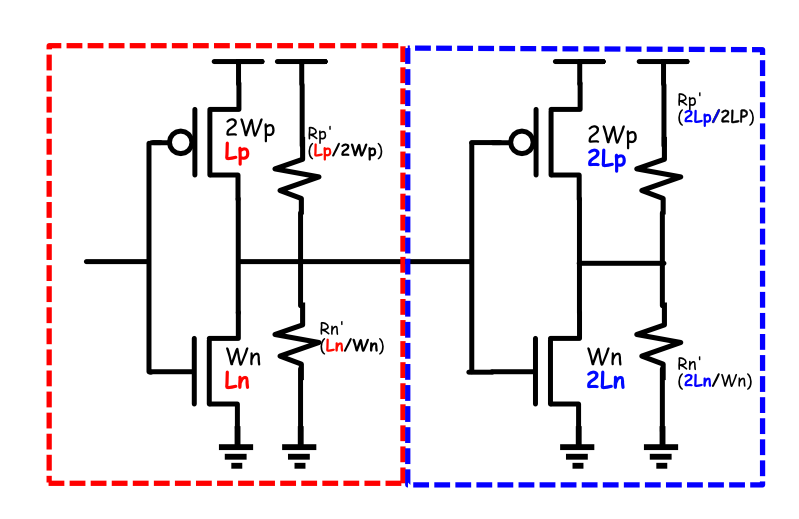

Also, with

increasing the length, the effective resistances of the long inverters

increase.

Figure 7, The Effective Resistances of

the Long Inverters.

Changing the

lengths will surely increase the capacitances, thus having a longer delay as

the signal propagates from one inverter to the next. However, the effective

resistance goes up, which will also increase delay, but will change the

strength of the MOSFETs to where the actual length of the input will change.

This topology of using a few long length inverters instead of a bunch of

regular 12/6 inverters will save on layout, however we

will need to then consider the RC delays of both the PMOS and NMOS and design

to where there is an equal amount of delay for when either MOSFET is turned on.

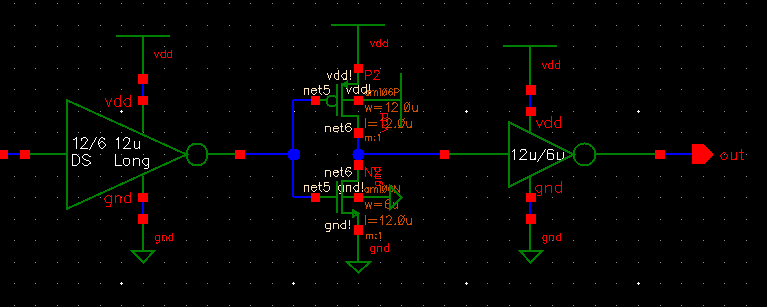

Looking at the

end of the delay:

Figure 8, an Inverter with no symbol,

followed by a regular 12/6 inverter

We have an

inverter with no symbol. This is used so that we can finely tune our delay to

whatever we need it to be.

The inverter

at the end is used to buff up the signal, and so that the output as a small

output capacitance so that it can be used to feed into the input of the XOR

gate.

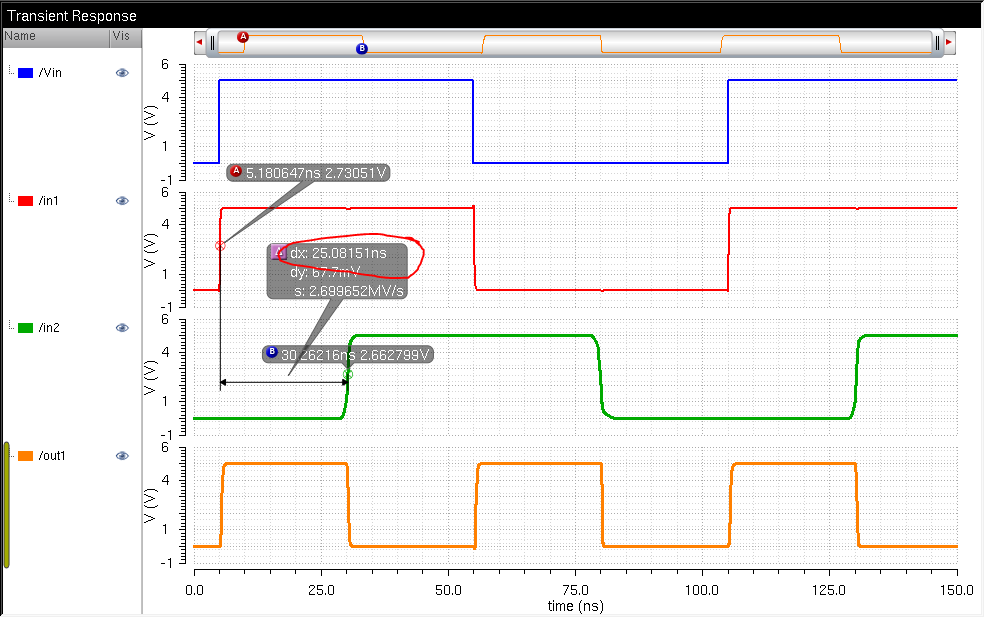

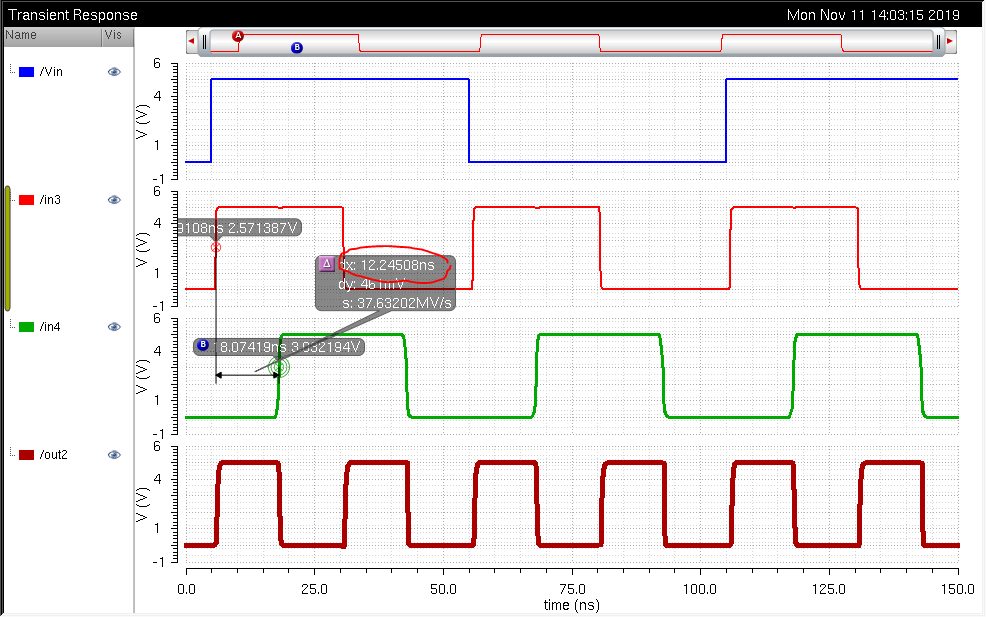

Output of the first XOR Gate,

input 1 (Red), Delayed input 2 (Green), Doubled frequency output (Orange)

Now, lets look

at the output of the first XOR gate with this delay block:

Figure 9, the Output of the XOR gate (Orange), and showing Input 1 (Red) and delayed Input 2 (Green).

This shows

that our XOR gate is doubling the frequency. Now, we will use this output of

the XOR gate to feed into another XOR gate.

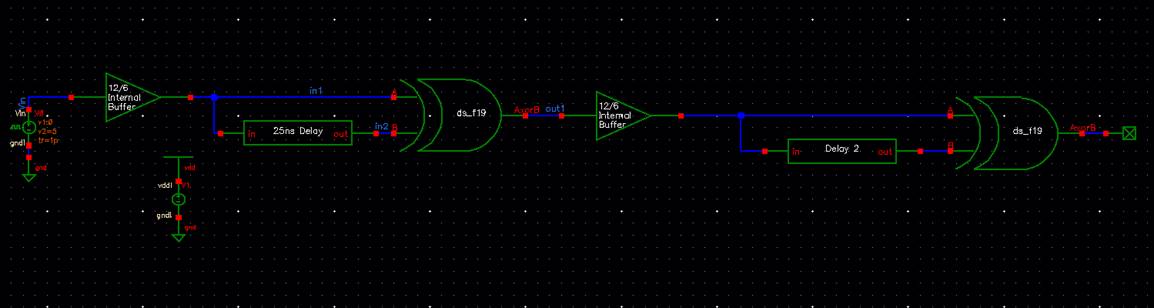

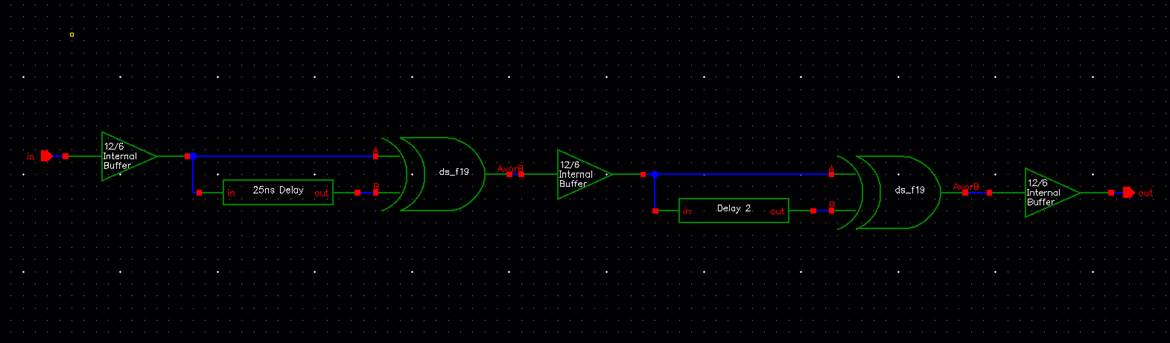

Below we have

the following circuit:

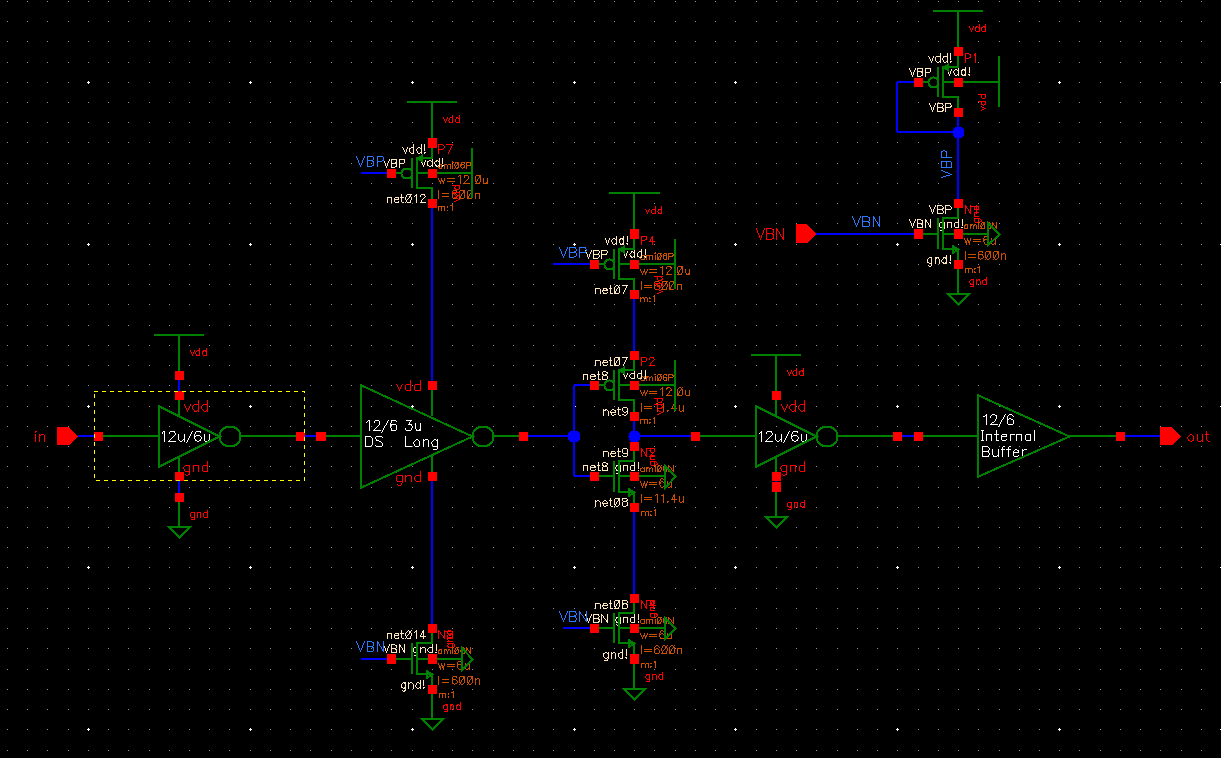

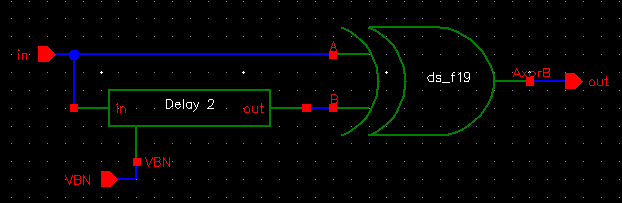

Figure 10, the x4 Frequency Multiplier

Circuit

The output of

the first XOR gate will feed into a 12/6 buffer, similar to

what we had in the beginning of the circuit so that our first XOR gate can

process the signal.

By analogy, we

can think of the 2nd stage XOR as the 1st stage XOR but

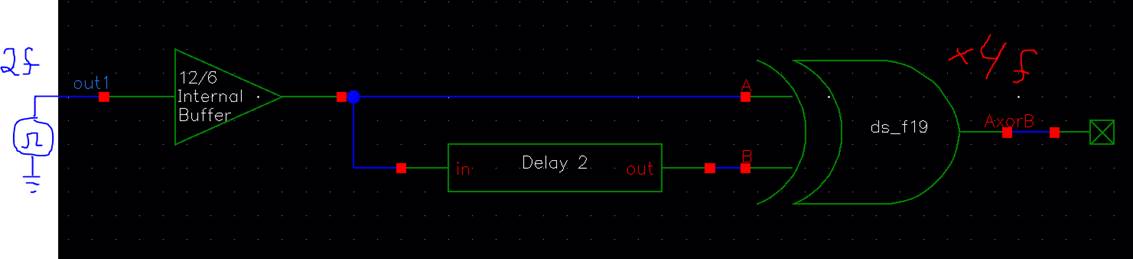

with a different input frequency:

Figure 11, Simple view of the 2nd

Stage XOR Gate. Note its similarity to the 1st Stage XOR Gate.

The output of

Stage 1 is a 20 MHz signal (50ns or 25ns/25ns Duty Cycle). Therefore, our 2nd

delay should be around 12.5ns.

Here is the 2nd

delay:

Figure 12, The 2nd Delay

block. Note its similarity to the first delay block, but with a different

Length size.

In this delay

block, we have a similar topology to that of the first delay block, but the

lengths are smaller and do not increase dramatically as the first delay.

We could have

implemented less inverters with larger lengths, but then our RC time constant

will be much slower in the middle and the input signal will not propagate fully

into the circuit and the output signal will not be a 50/50 duty cycle.

Output of the second XOR Gate,

input 1 (Red), Delayed input 2 (Green), Doubled frequency output (Dark Red)

Looking at the

output of the 2nd XOR Gate:

Figure 13, The Output of the 2nd

XOR gate (Dark Red), with Input 1 (Red) and the delayed Input 2 (Green).

Here, we can

see that we get our delay, and therefore, our XOR gate is doubling the doubled

input frequency (so x4).

Creating a

cell view for our x4 frequency multiplier:

Figure 14, The x4 Frequency Multiplier

Schematic View

Figure 15, The x4 Frequency Multiplier

Symbol View

---------------------------------------------------------------------------------------------------

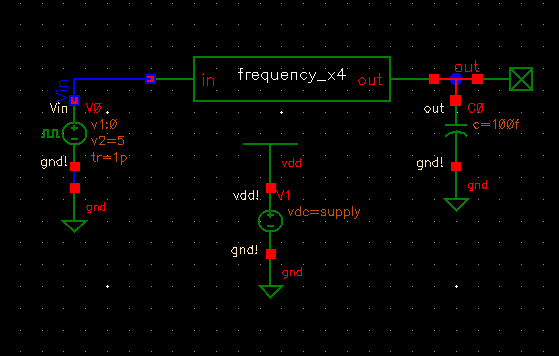

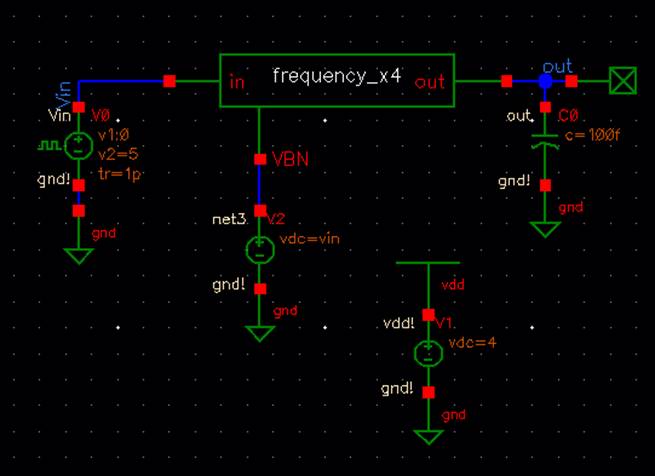

Here is the

following simulation circuit:

Figure 16, The x4 Frequency Simulation

Circuit

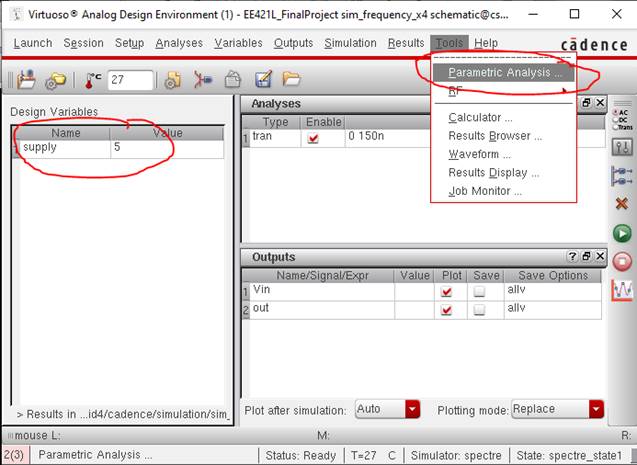

Input Frequencies at Different

VDD Power Supply Voltages:

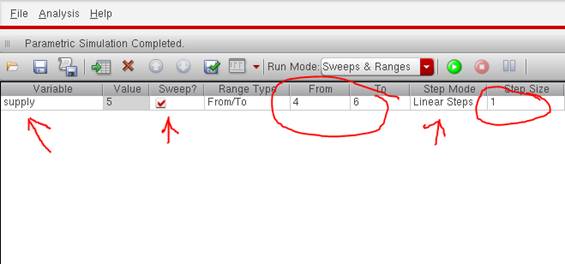

Testing at

different input frequencies and using the Parametric Analysis Tool to change

our voltage supply in the ADE:

Figure 17, my ADE Setup

Figure 18, Using the Parametric

Analysis Tool

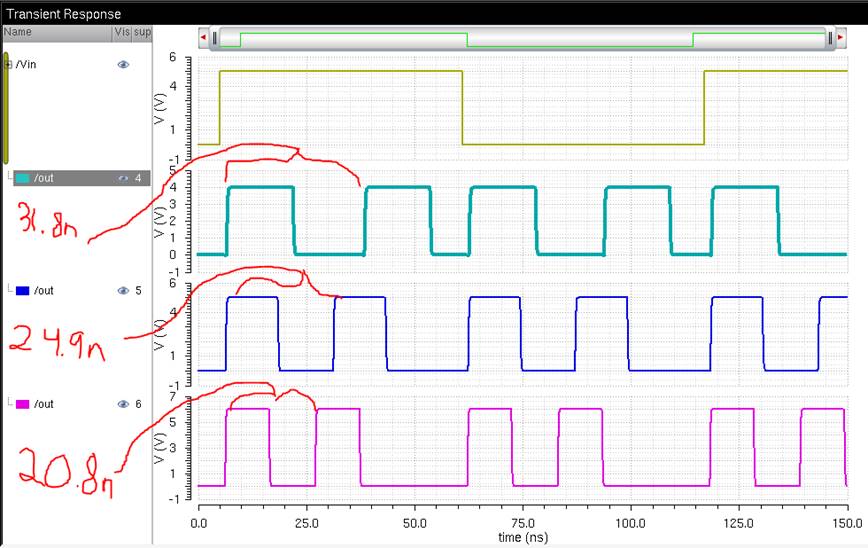

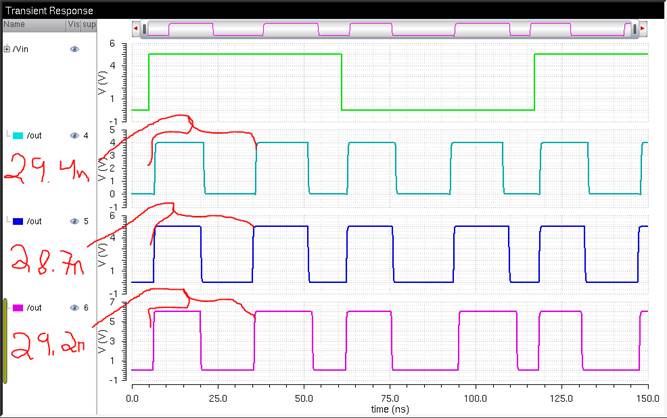

9MHz:

Figure 19, Input Frequency = 9 MHz,

With changing Voltage Supply (4V Turquois, 5V Blue, 6V Magenta)

10MHz:

Figure 20, Input Frequency = 10 MHz,

With changing Voltage Supply (4V Turquois, 5V Blue, 6V Magenta)

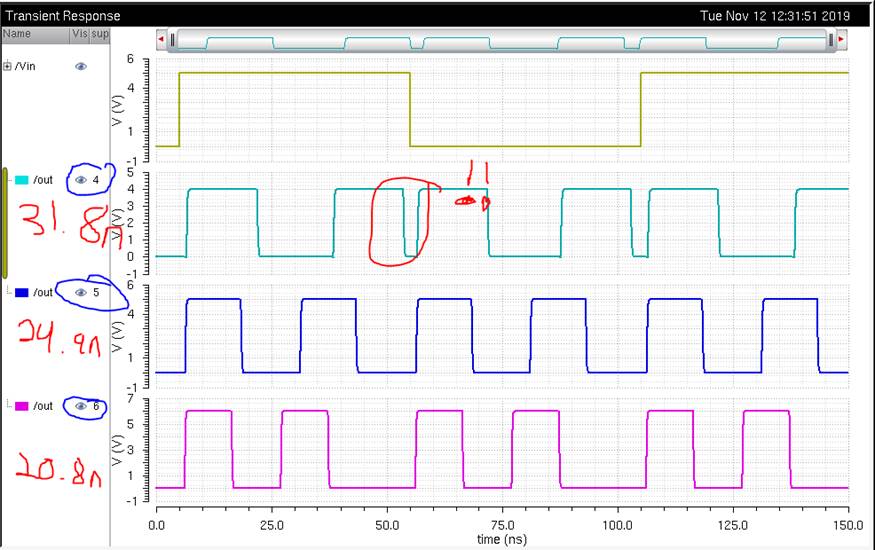

11 MHz:

Figure 21, Input Frequency = 11 MHz,

With changing Voltage Supply (4V Turquois, 5V Blue, 6V Magenta)

|

Input

Frequency = 9MHz |

4V |

5V (Ideal) |

6V |

|

9 MHz

(110ns) |

31.4 MHz |

40.1 MHz |

48.1 MHz |

|

10 MHz

(100ns) |

31.4 MHz |

40.1 MHz |

48.1 MHz |

|

11 MHz

(90ns) |

31.4 MHz |

40.1 MHz |

48.1 MHz |

Looking at

this, as the voltage supply voltage changes from 4V to 6V, with lower supply

voltages, we get a “slower” frequency at the output of our x4 frequency multiplier.

This is due to having less current flowing from VDD! to GND! With the supply

voltage at 4V (Turquois), our output

is at a “lower” frequency, but if the input frequency is too fast, the signal

overlaps to the next period of the input frequency.

With the

supply voltage at 6V, our output is a “higher” frequency (Magenta), but at lower frequencies, you see

that we do not have a good duty cycle.

At the nominal

voltage of 5V (Blue), the signals

are sitting at a good middle ground of 40.1 MHz.

Before we

proceed, we have a problem.

The delays are

NOT a function of our input

frequency.

For this, we

will want a delay that can change depending on what our input frequency is.

---------------------------------------------------------------------------------------

How to Improve our Initial Design:

Suppose we

modify the delays to have a Current Staved Inverter.

Figure 22, Modifying the first delay

block with Current-Starved Inverters

A Current

Starved Inverter is basically an inverter, but the current from VDD! to GND! is

limited, or “starved”, and the current in the inverter will change, thus

changing the delay.

If there is

little current in the inverter, then the circuit behaves as if there is less

power, therefore, the inverters gets slow.

If there is

lots of current in the inverter, the circuit may just behave as a regular

inverter.

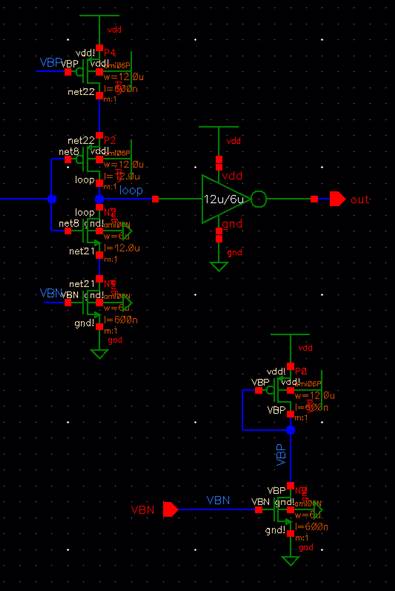

Here is a

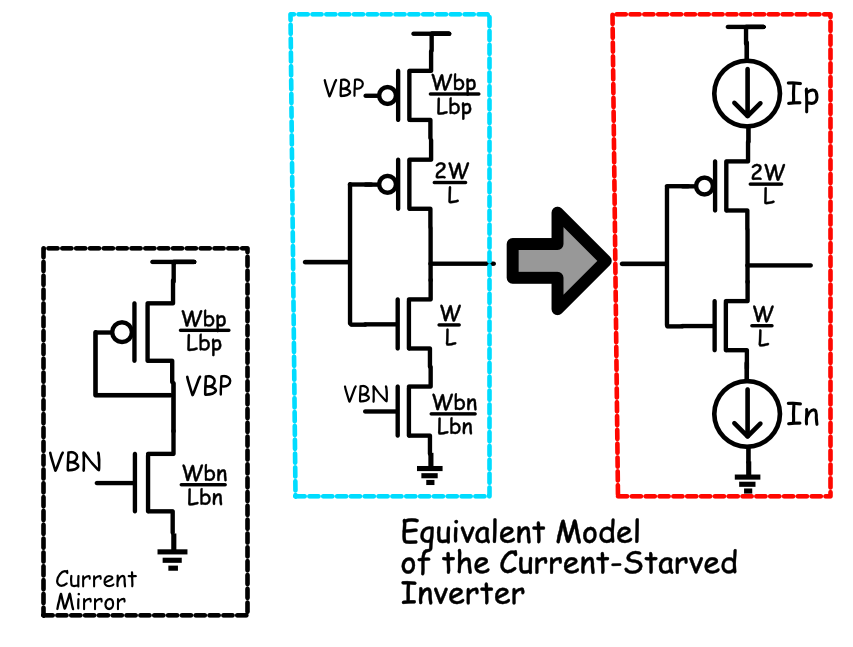

quick figure of the Current Starved Inverter:

Figure 23, The Current Starved

Inverter Equivalent Model

For this, we

have a small current-mirror that will take in a bias voltage, VBN, for the NMOS

and output a bias voltage, VBP for the PMOS and these will drive the current

mirrors above and below the inverter.

We will then

modify our frequency multiplier and delay blocks so that they will have this

new bias voltage input.

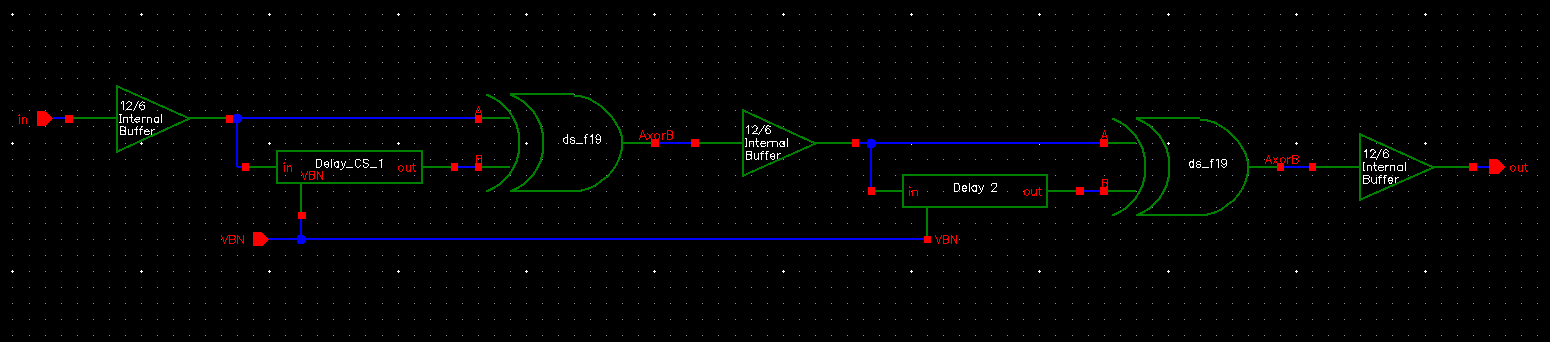

Figure 24, Modifying the Frequency

Multiplier with voltage-controlled Delays.

The 2nd

delay block will be designed to take in the same bias voltage as the first

delay block.

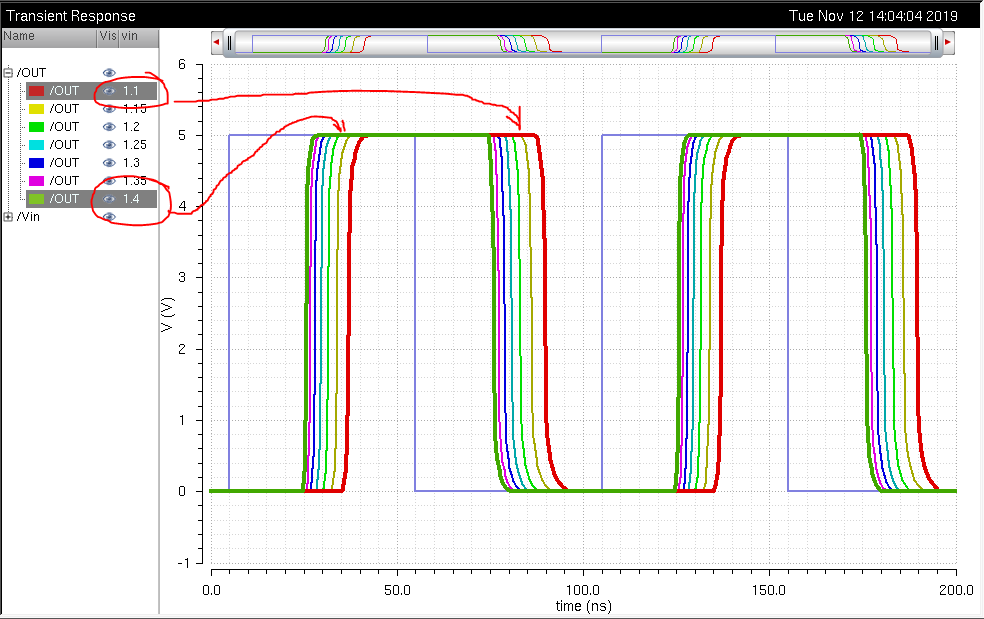

Delay 1 Simulation: Input Frequency

At 10 MHz, Sweeping VBN

Figure 25, Delay Block 1 with current

starved Inverters

Figure 26, Looking at the delays as

the input bias voltage sweeps from 1.1V to 1.4V.

From this we

can say as we sweep the bias voltage, we get larger delays with lower VBN (aka,

the inverter is being “starved” of current).

From 1.1V to

1.4V, we will be ok if we have our bias voltage swing +/-100mV. We will then

design so that our bias voltage is high so we can have a linear bias input

voltage.

By analogy, we

will also do the same with the 2nd delay block but considering that

we will take in the same high input voltage as used in delay block 1.

Figure 27, Delay Block 2 with

Current-Starved Inverters

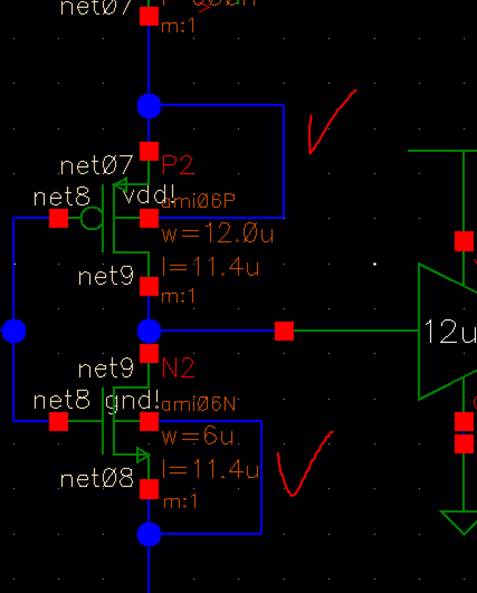

Question: Where do I connect

the body of the NMOS and PMOS of the Current-Starved Inverters?

For this

special case, we will tie the body of the PMOS to the Source of the PMOS, and

the body of the NMOS to the Source of the NMOS.

This will then

reduce the Source-Body effect, and our Threshold Voltage will stay relatively

low. We could connect the bodies of the PMOS and NMOS to VDD! and GND!, respectively, but then the Threshold Voltage will

increase and we can run at a possibility that the inverters will switch on

correctly.

Figure 28 and 29, Connecting the bodies

of the PMOS and NMOS to their respective Sources.

Simulation with The Current-Starved Inverters:

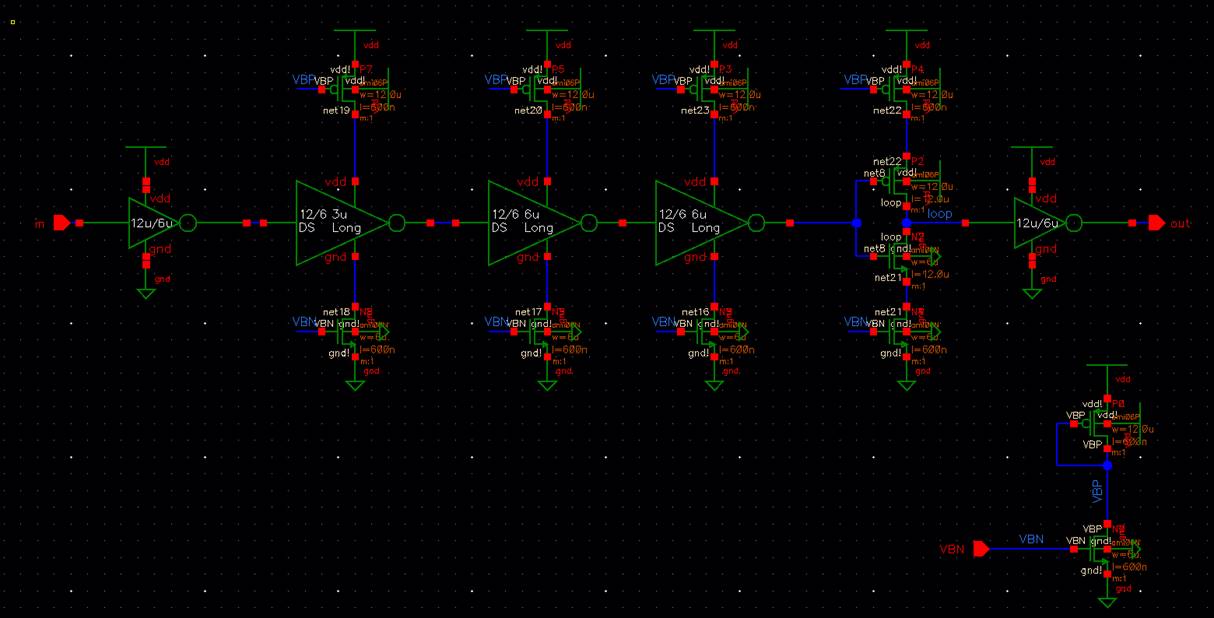

Figure 30, The x4 Frequency Multiplier

with the Current-Starved Inverters.

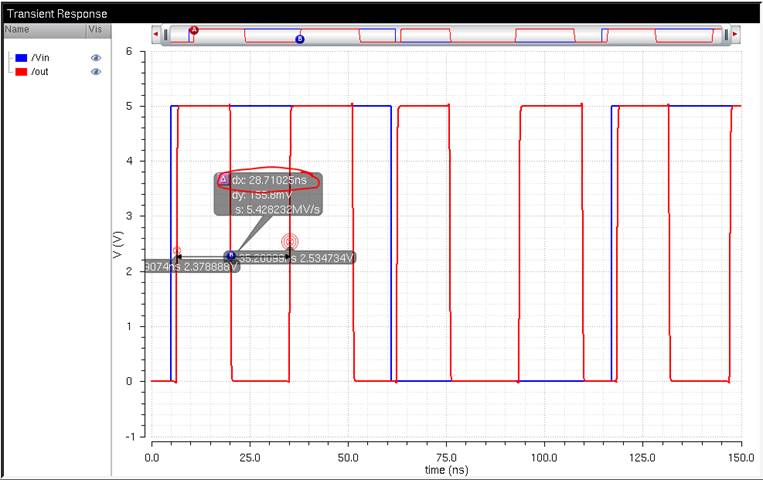

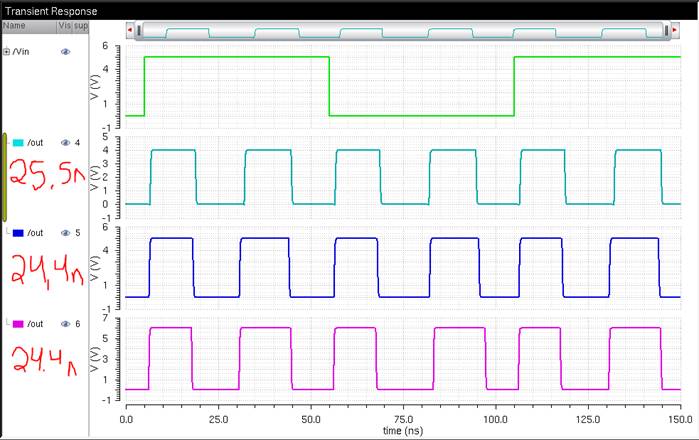

9 MHz: VBN =

1.15V

Figure 31, Sim Showing Current Starved

Inverters, Delay ≈ 14.4ns

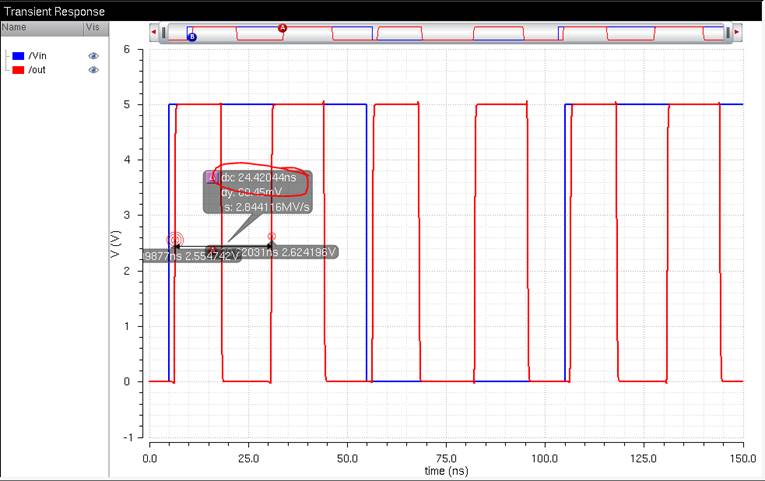

10 MHz: VBN =

1.25V

Figure 32, Sim Showing Current

Starved Inverters, Delay ≈ 12.3ns

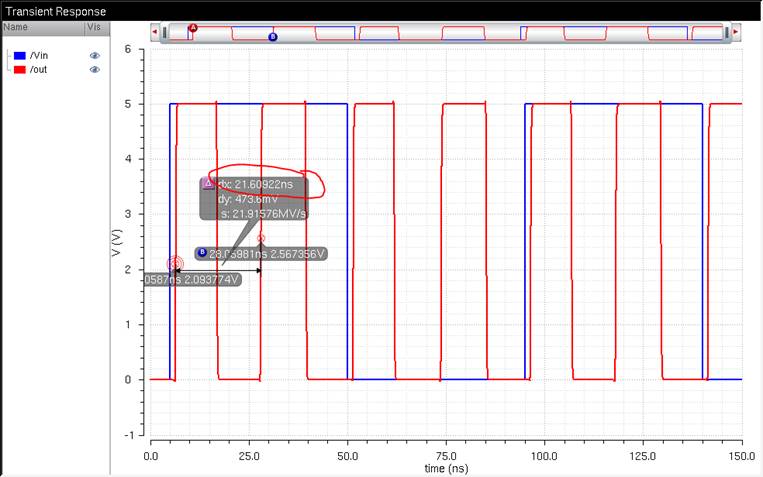

11 MHz: VBN =

1.35V

Figure 33, Sim Showing Current Starved

Inverters, Delay ≈ 7.2ns

For The Supply Voltage = 5V (Ideal)

|

Bias Voltage

VBN |

Input

Frequency |

Output

Frequency |

Delay |

|

1.15V |

9 MHz |

34.8 MHz |

14.4ns |

|

1.25V |

10 MHz |

40.9 MHz |

12.3ns |

|

1.35V |

11 MHz |

46.3 MHz |

7.2ns |

This shows that

the Current Starved Inverters work and are changing the delays so that we can

try to have a 50% duty cycle.

Changing the Power Supply:

For the change

in power supply (And using the same Bias Voltages from above):

9 MHz (110ns

period): VBN = 1.15V

Figure 34, Input Frequency = 9 MHz,

Voltage Supply (4V Turquois, 5V Blue, 6V Magenta), Using Current Starved (CS) Inverters

10 MHz (100ns

period): VBN = 1.25V

Figure 35, Input Frequency = 10 MHz,

Voltage Supply (4V Turquois, 5V Blue, 6V Magenta), With CS Inverters

11 MHz (90ns period):

VBN = 1.35V

Figure 36, Input Frequency = 11 MHz,

Voltage Supply (4V Turquois, 5V Blue, 6V Magenta), With CS Inverters

|

Input Frequency |

Bias Voltage |

Supply

Voltage |

||

|

VBN |

4V |

5V |

6V |

|

|

9 MHz

(110ns) |

1.15V |

34 MHz |

34.8 MHz |

34.2 MHz |

|

10 MHz

(100ns) |

1.25V |

39.2 MHz |

40.9 MHz |

40.9 MHz |

|

11 MHz

(90ns) |

1.35V |

42.9 MHz |

46.2 MHz |

46.9 MHz |

This finally

concludes that the Current-Starved Inverters are changing the delays, and

consequently the output frequency.

Conclusions Part I:

The XOR gate can

be used to double the input frequency by taking the input signal and XOR the

signal with a delayed version of itself.

Using the

delays of the inverters can help with a specific frequency, however, these

delays are constant with different input frequencies.

A Change in

the power supply with a regular inverter delay can keep delays consistent, but

even with a different constant voltage supply, the delays will be constant with

different input frequencies.

The Current-Starved

Inverter is one take at changing the delays by “starving” the delay inverters

of current, consequently slowing down the inverter.

The negative

of this approach is you will need double the transistors, thus, using more

power. Also, the input bias voltage will output nonlinear delays.

There is a

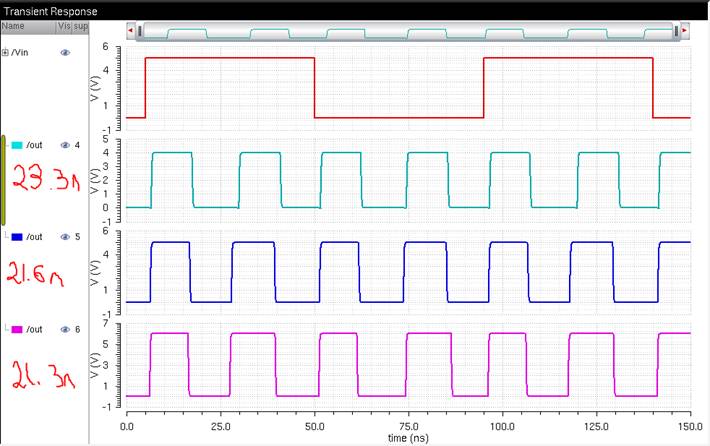

discussion found in Chapter 19 of CMOS – Circuit Design, Layout, and

Simulations – 4th Edition regarding linearizing the current, and

thus linearizing the delays.

Here is a

quick figure on how to linearize the current in the CS Inverter:

Figure 37

Based on the

Square-Law, the Current is a function of the square of VGS.

Looking at

M5R, if made much wider compared to the rest of the circuit, the VGS will be

more independent of the Input Bias Voltage and more on Vthn.

This will then

try to linearize the current in our current mirror and thus, the delays could

be linear with respect to the Input Bias Voltage.

This concludes

Part I of the Final Lab Project.

------------------------------------------------------------------

Part II: Layout of the Times

Four (x4) Clock Multiplier

For this design,

we will stick with our Current Starved Inverters in our final layout design.

Note! Please, if you are a future student

reading this, the biggest tip is to create a cellview

for everything, even a small NMOS connected to VDD!

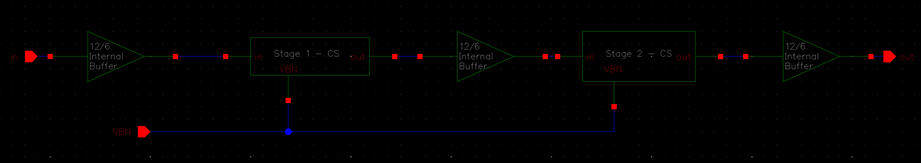

We will have

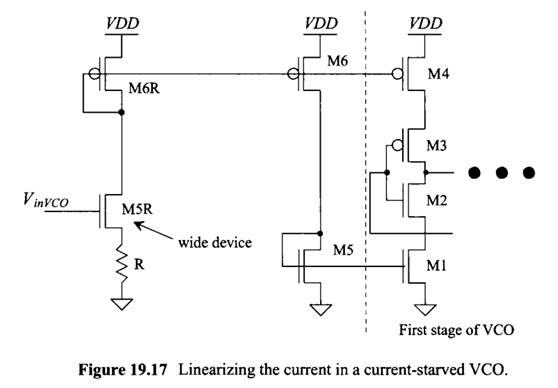

the following circuit:

Figure 38, The Times Four (x4) Clock

Multiplier

However, for simplicity

and to make Layout-to-Schematic verification easier, we will have the following

simple circuit:

Figure 39, The Times Four (x4) Clock

Multiplier, Simple View

In this schematic,

every block has a single input, therefore, the final layout will be very

simple.

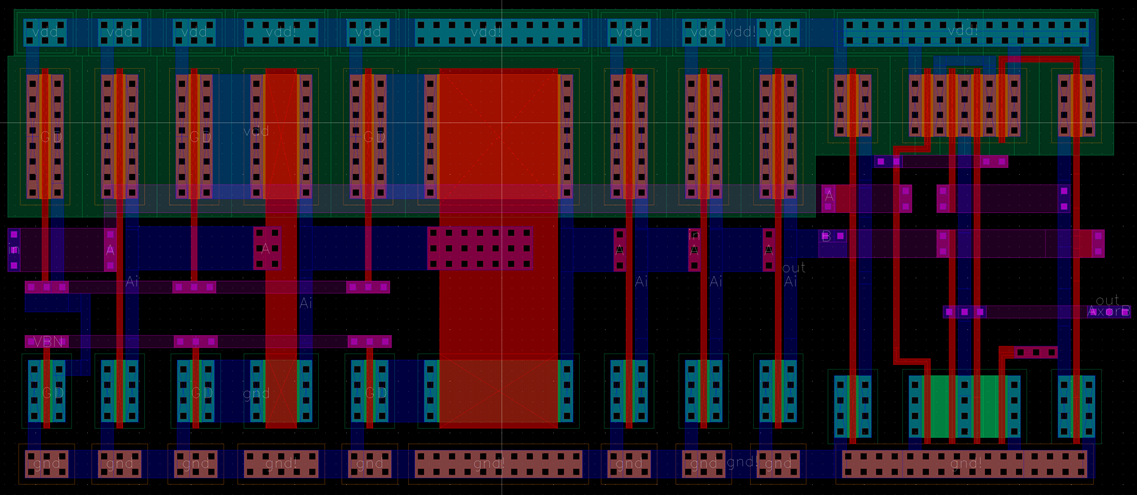

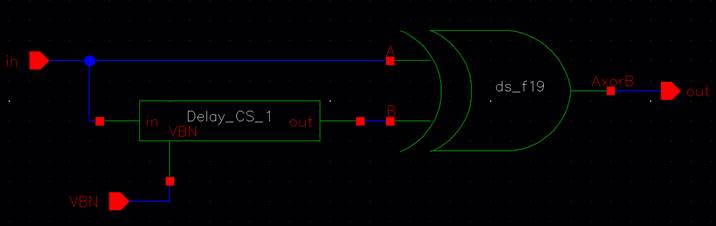

Here is Stage

1, using Current Starved Inverters:

Figure 40, The First Stage Block

Schematic

The layout for

this circuit will be complicated, but will be much

easier to debug since we are focusing on just this section, and not an entire circuit.

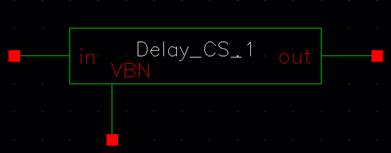

Symbol of the

first delay block:

Figure 41, The First Delay Block, with

Current Starved Inverters, Symbol View

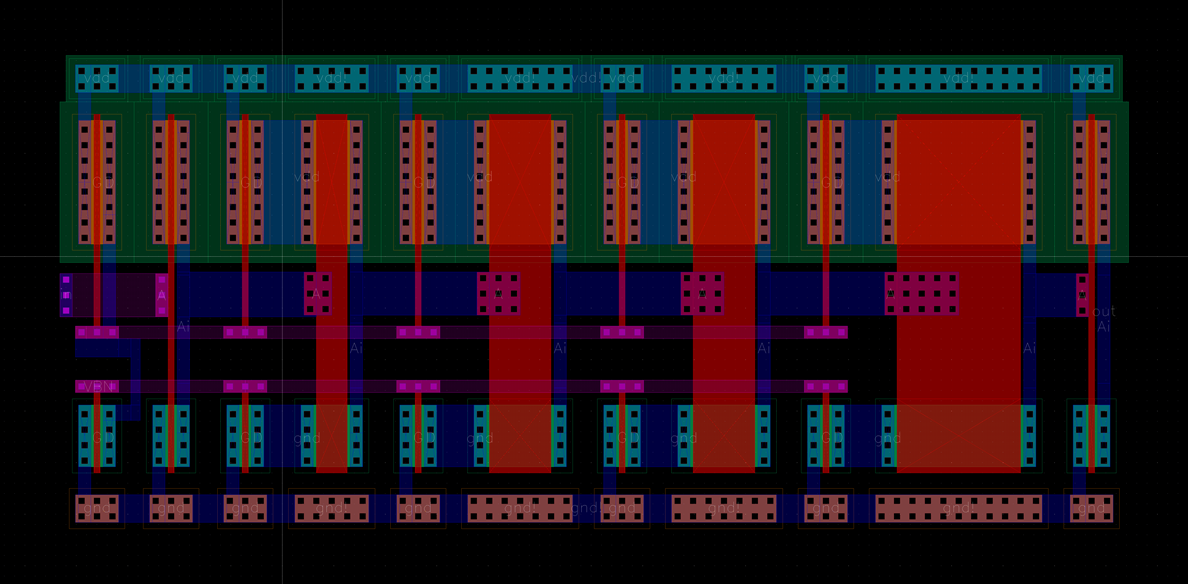

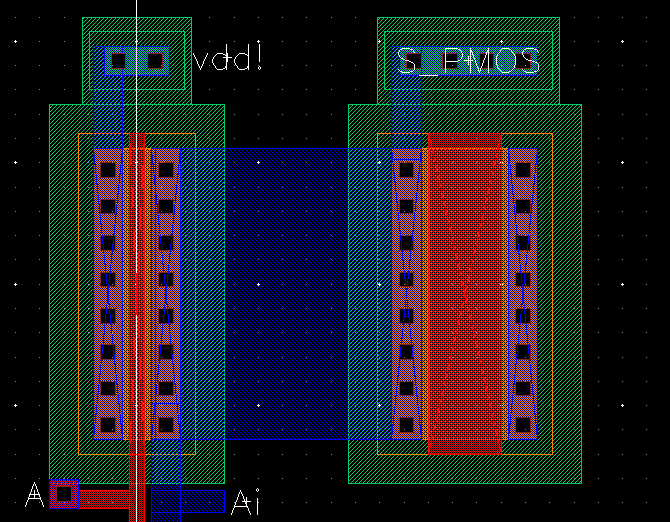

Here is the

layout of the first delay block, using Current Starved Inverters:

Figure 42, The Layout of the First

Delay Block Using Current Starved Inverters, High

Resolution x5 (Click on Image or “High Resolution x5 for Higher Resolution)

We made the

gap in between the PMOS (top) and NMOS (bottom) big so that we can plan ahead for future layouts.

The lighter

pink 1x3 rectangles connecting the gates of the L = 600nm CMOS devices are the

gates of the current mirrors.

The Long L Devices

are the big red rectangles.

The input pin

is “in”, output pin is “out”, the input bias voltage pin for the current

mirrors is “VBN”. All pins are on metal 1.

Question: Why am I not connecting

the bodies of the Long Length Inverters to their sources?

To change the

potential of the body of a PMOS, consider the following:

Figure 43, Long Length PMOS with

different body potential

This is our

Long Length Device with a different body potential.

As shown, the

N-Wells will be at different potentials and will need to be separated a certain

distance.

This will then

make our overall layout much larger than it should be and wastes space.

Using a

Source-Body PMOS will reduce the body effect, but will

use lots of layout.

Having the

N-Well connected to VDD! will add a body effect, but

can be considered negligible.

Now, we can

use this delay block to connect to our XOR gate.

Here is the

first stage block of our x4 clock multiplier:

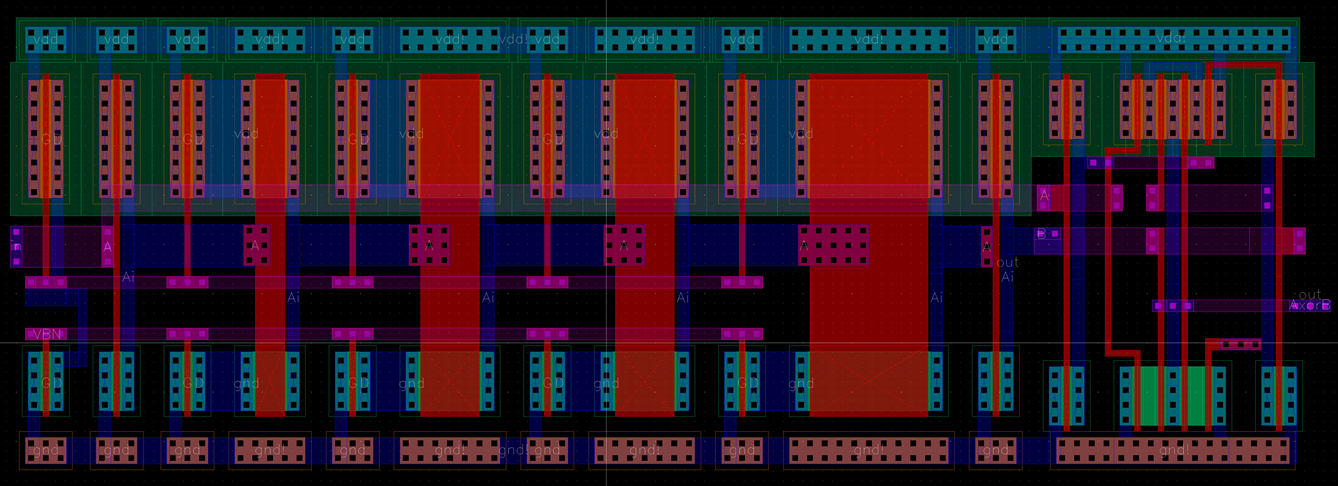

Figure 44, The First Stage Block,

Symbol View

Here is the

Layout of the First Stage Block:

Figure 45, The First Stage Block

Layout View, High Resolution x4

In the

beginning is our delay block. The XOR gate is at the far right of the layout

(smaller PMOS device).

There is a metal

2 wire from the beginning of the delay all the way to the first input of the

XOR gate.

The second

input of the XOR gate comes from the output of the delay block.

The input bias

voltage pin is called “VBN”. Note, VBN is a pin that will always need to be

wired.

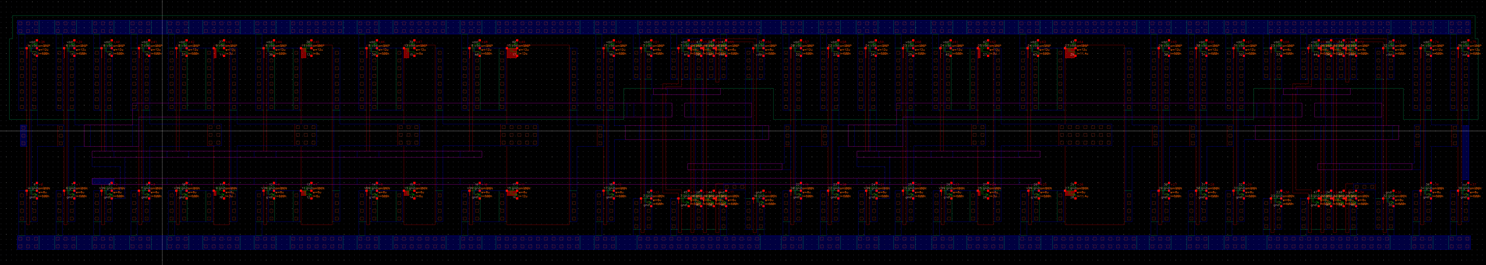

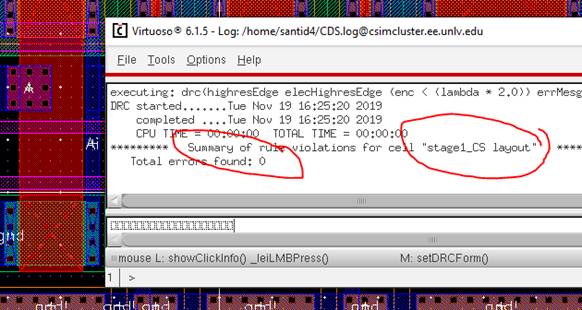

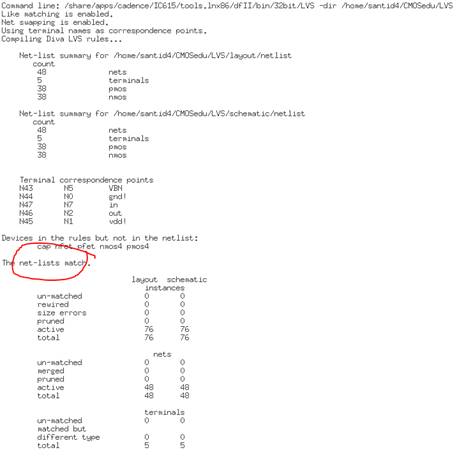

Verification of the First

Stage:

So usually

there will be Design Rule Checks (DRCs) and Layout-To-Schematic (LVS) tests.

All cellviews discussed previously have passed both DRC and

LVS.

We will do a big

DRC and LVS check for the first stage (just to make sure the first half of the

circuit works).

DRC of the

First Stage Block:

Figure 46, DRC of the First Stage

Block, Passes DRC

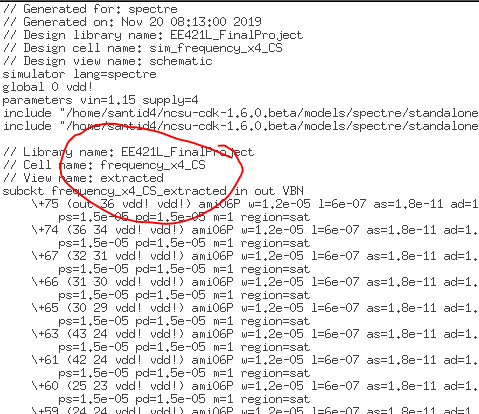

Extracted:

Figure 47, Extracted View of the First

Stage Block, High Resolution x5

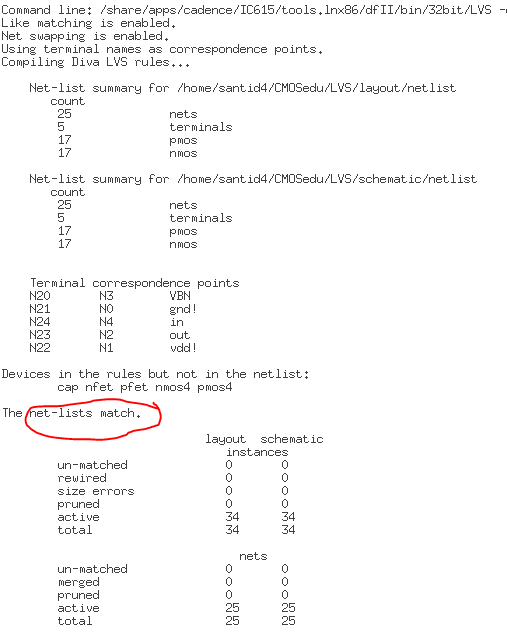

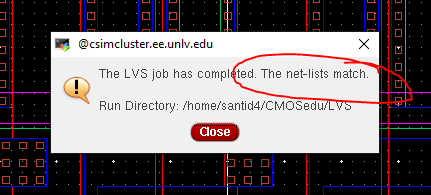

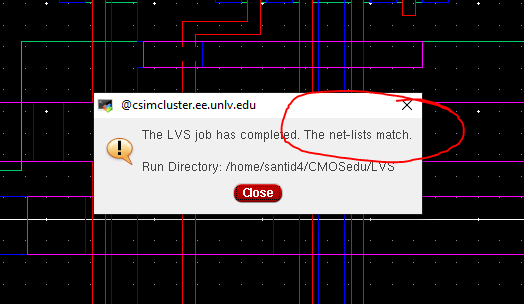

LVS:

Figure 48 and 49, LVS Output file and LVS Passing.

From this,

since this first stage passed all DRC and LVS verifications, all cell views

used within the first stage should passively pass all tests.

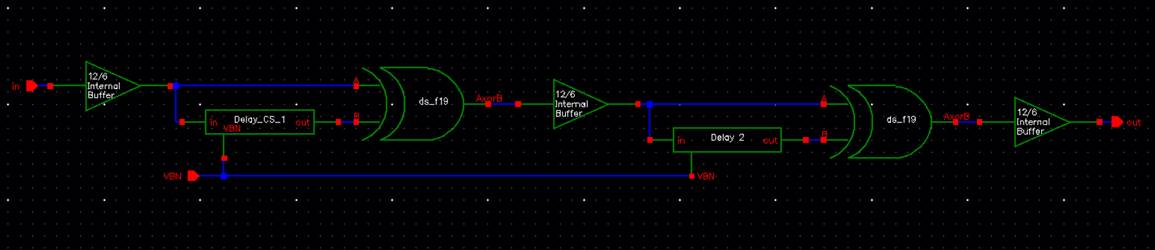

Moving on to

the Second Stage Block:

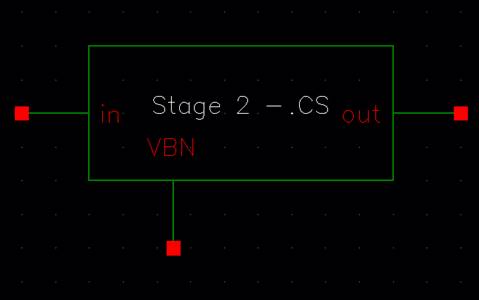

Figure 50, Second Stage Block

Schematic

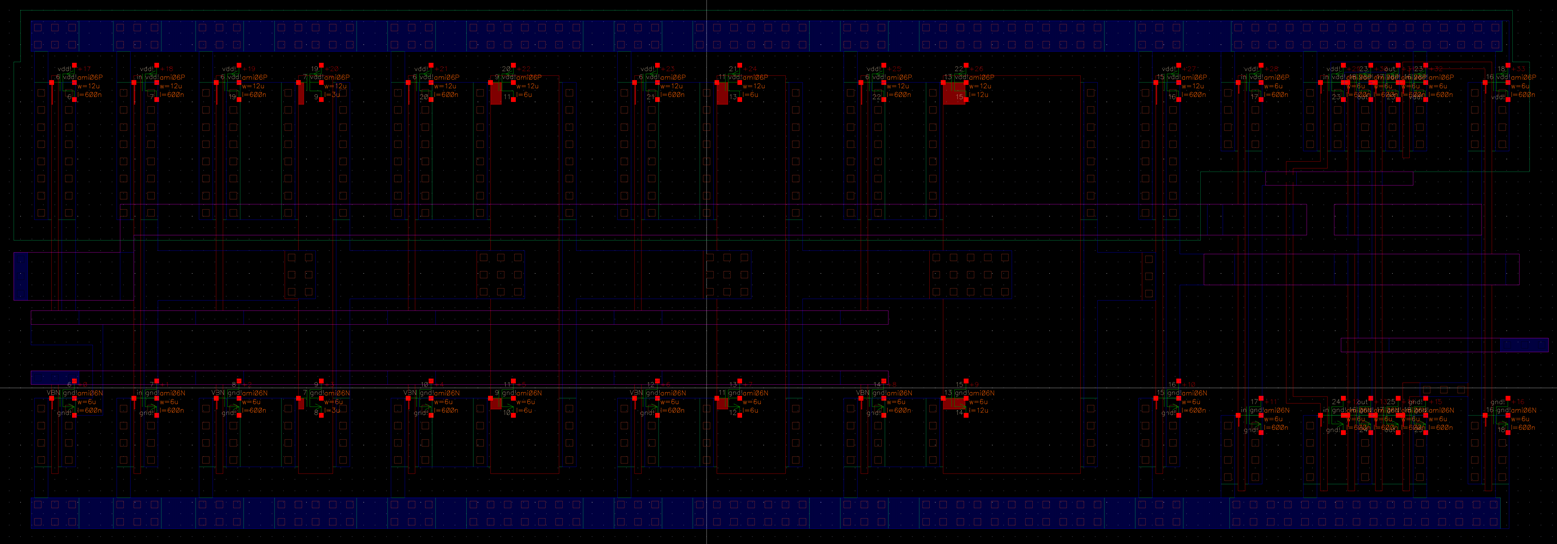

Now, Looking

at the second delay, with Current Starved Inverters:

Figure 51, The Second Delay Block,

With Current Starved Inverters, Layout View, High

Resolution x4

Symbol View:

Figure 52, The Second Delay Block,

With Current Starved Inverters, Symbol View

Here is the

Second Stage Layout:

Figure 53, The Second Stage Block,

With Current Starved Inverters, Layout View, High

Resolution x4

Note that it

looks similar to the First Stage Block.

The Input pin

is “in”. The Output Pin is “out”. The Input Bias Voltage Pin (Center Left) is

“VBN”.

Yes, we can

label the pins the same names as other blocks. Instantiating these blocks will

ignore the pins.

Symbol View:

Figure 54, The Second Stage Block,

With Current Starved Inverters, Symbol View.

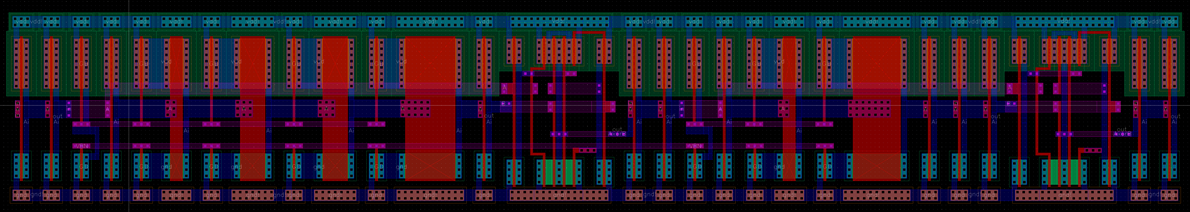

Now that

everything has been designed, lets put it all together.

Revisiting our

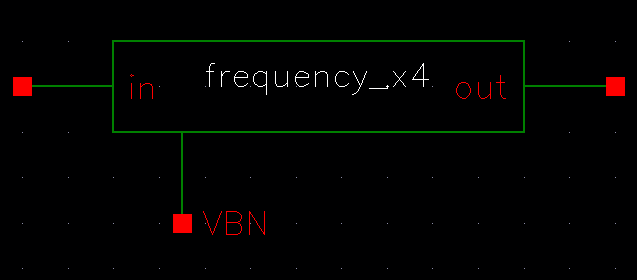

simple Times Four (x4) Clock Multiplier:

Figure 55, The Times Four (x4) Clock

Multiplier, Schematic View, High Resolution

x4

Since

everything has been created (the buffers and stages), it will be very easy to

connect everything together.

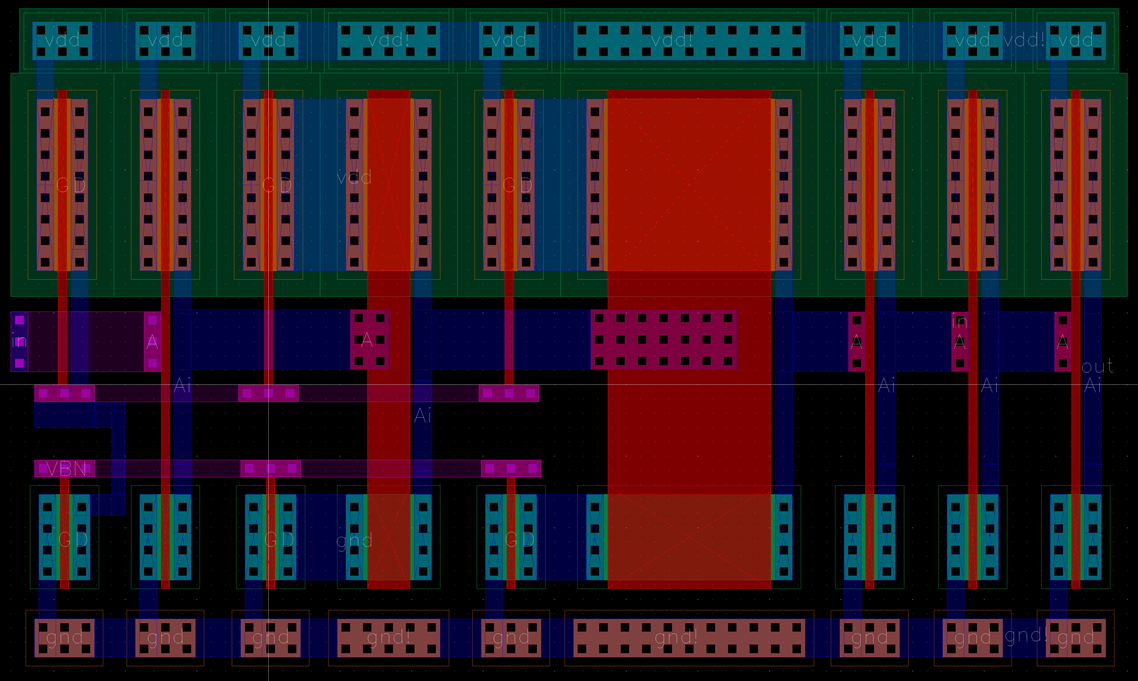

Layout View Of the Times Four (x4) Clock Multiplier:

Figure 56, The Times Four (x4) Clock

Multiplier, Layout View, High Resolution x6

Symbol View:

Figure 57, The Times Four (x4) Clock

Multiplier, Symbol View.

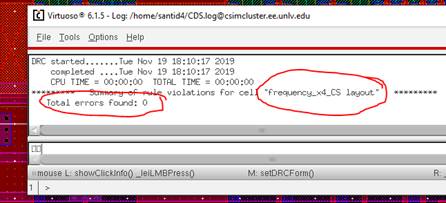

DRC of the

entire Clock Multiplier Circuit:

Figure 58, DRC of the Times Four (x4)

Clock Multiplier, Passes DRC.

Extracted

View:

Figure 59, The Times Four (x4) Clock

Multiplier, Extracted View, High

Resolution x6

LVS:

Figure 60 and 61, Output File and

Passing LVS.

Since the LVS

of the entire circuit passes, consequently, the entire hierarchy of the circuit

(all blocks, inverters) will passively pass DRC and LVS tests.

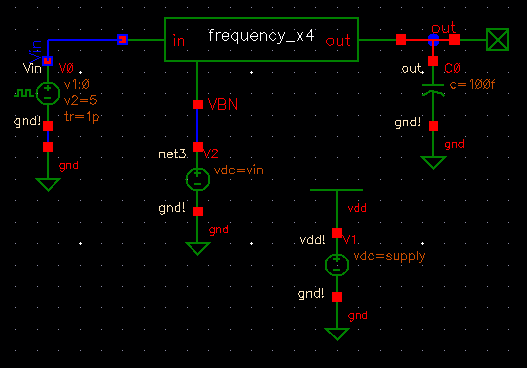

Final Simulation:

We will rerun

a simulation using the extracted schematic.

For this, we

will redo the 9MHz Clock with changing power supply.

Opening up the simulation circuit (Clock is 110ns period):

Figure 62, Simulating the Times Four

(x4) Clock Multiplier at 9MHz, with variable supply.

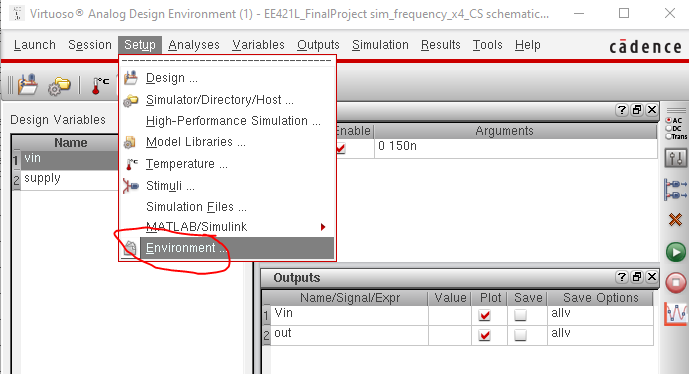

Launching the

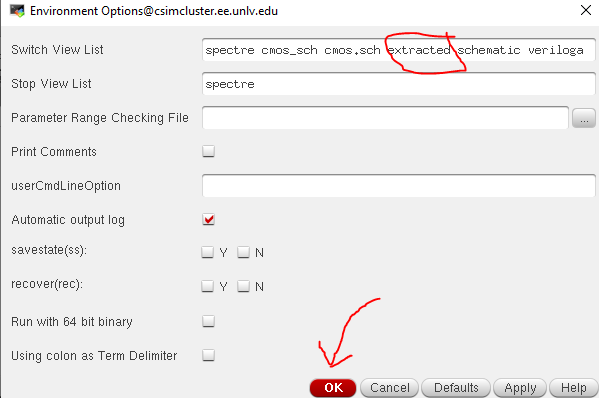

Analog Design Environment, loading a previous state, and clicking Setup -> Environment:

Figure 63, Menu of the ADE, Setting up

the Environment

In the

Environment Window, placing the word “extracted” in front of “schematic”:

Figure 64, Setting up the Environment

to run the Extracted view of our Clock Multiplier

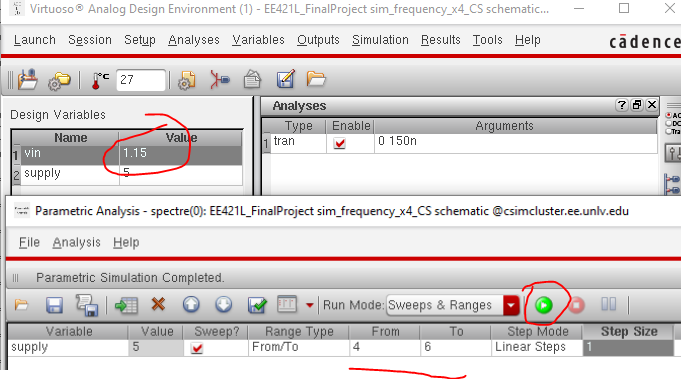

Setting vin

(VBN) to 1.15V, and doing a parametric analysis of the supply voltage:

Figure 65, Setting up the Parametric

Analysis on our Extracted circuit:

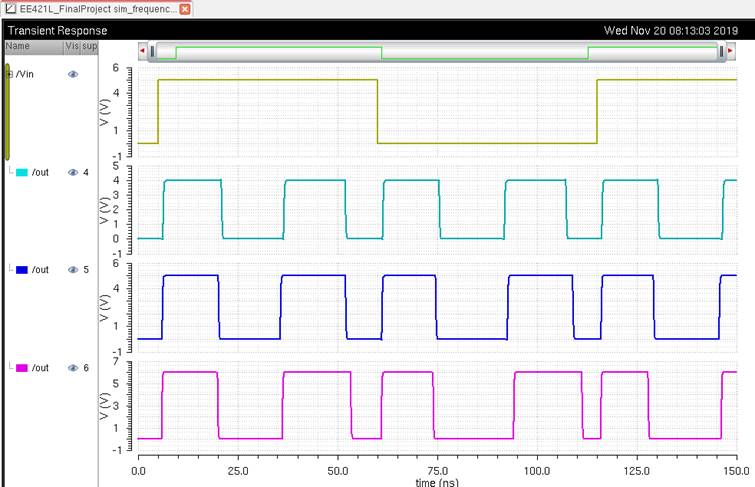

Results:

Figure 66, Simulation of the Extracted

Circuit, Input Frequency = 9 MHz, VBN =1.15V, Voltage Supply (4V Turquois, 5V Blue, 6V Magenta), Using Current Starved (CS) Inverters

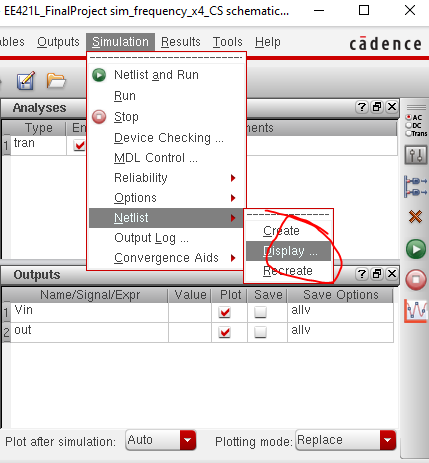

Now to prove

that we have ran the extracted view, in the ADE, Simulation -> Netlist ->

Display:

Figure 67, Steps to view if we ran the

Extracted View

Results:

Figure 68, Proof that the Extracted

View Ran!

Now, we will download

the entirety of the project, “EE421L_FinalProject.zip” and you can view the files

here.

Figure 69, Nice.

Conclusions II:

For the lab

layout, we got to see the positives of creating many cell views, in which all

the rule checks and verifications worked out much easier and faster.

The only

negative with this approach is that layouts will not be optimized, and there

are some instances that could have merged into a compact form.

For the bodies

of the long length inverters, those have been changed so that the bodies of all

PMOS/NMOS devices are connected to VDD!/GND!,

respectively, so that the layout will be smaller and compact.

For this

class, the body effect can be considered negligible, however, it plays a role

when going into analog design.

This ends part

II of the final lab project, and of the report.

------------------------------------------------------------------------