Shadden Abdalla

November 30, 2018

EE421, Fall 2018

CMOS Switching Power Supply (SPS) Boost Converter

Contents

Summary of Results and

Tradeoffs

.2-3

Result Tables and

Circuit Specifications

...4-10

Bandgap

...11-14

Comparator

...15-21

Buffer

...22

Oscillator

23-24

NAND

.25

Inverters x8 and x64

26

Ring oscillator and NAND

...

28-31

Duty cycle and frequency.

28-29

NMOS Switch

..31-33

Whole schematic

simulation with off-chip components

34

Initial Conditions

...

....34

Choosing a Diode

.

.

35

Load Resistance and

Current

.

..35-36

Capacitor and Ripple

Frequency and Tradeoffs

37

Input Current over

Voltage Divider

...38

Choosing an Inductor and

Tradeoffs

..39

Outputting 5V over

Varying VDD

40

Circuit Reaction to

Varying Temperature

.41

On Chip Boost SPS

Schematic and Symbol

.42

Entire Layout

43-44

Bonding and Probe Pads

45

Simulating Circuit with

Symbol and Off Chip Components

46-47

Efficiency Over VDDs of

3.75V and 4.75V

48-59

Efficiency vs. Load

Current

...53 and 59

References*

...

60

*References were used for further

information. There were no works cited in this report.

---------------------------------------------------------------------------------------------------------------------

Summary

of Results and Tradeoffs

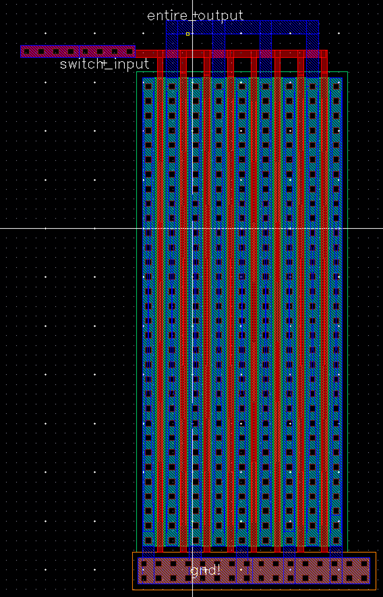

This report details the design, simulation and layout

of a CMOS Switching Power Supply (SPS) Boost Converter. This power supply reads

in an input voltage of VDD that could range from 3.75V to 4.75V and outputs a

constant output voltage of 5V. It consists of many components. The first is a

bandgap, which reads in the VDD input voltage and outputs a constant output

voltage of 1.25V. The second is a voltage divider that connects Vout to the comparators minus input, that draws between

10uA and 50uA of current: 36.78mA of current to be exact. The bandgaps output

voltage is the positive input into the comparator. The comparator reads the two

input voltages and outputs a logic zero if the minus input is greater than the

positive input and outputs a logic one if the bandgap output voltage is greater

than the input voltage from the voltage divider. Then the output of the

comparator, enable, is sent into the oscillator and buffer that I made using a

NAND, thirty inverters, and then a buffer that sends a cleaned-up signal output

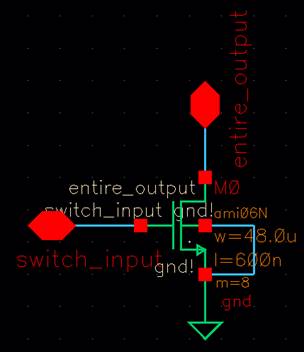

of the first ten inverters into the gate of the NMOS switch of size 48u/600n

with a multiplier of eight. More details about the outputs and project

specifications are below in the tables for easier viewing.

Choosing

NMOS Switch and Tradeoffs

The resistance of the MOSFET that I used is 31.25ohms

and the capacitance is 576fF. The NMOS has a larger width because it must be a

strong MOSFET that can switch quickly. Larger MOSFETs

with a larger width have very small internal gate resistances. The small

resistance causes it to be high-speed and be able to carry high currents. This

circuit generates resonance which will create a voltage that oscillates around

a point, which is what we see in our simulations as we try to reach 5 volts.

Because of the resonance and the oscillation that results from it, the MOSFET

holds a current that creates a voltage that oscillates. The drain to source

resistance is influenced by the gate to source voltage. Lowering the resistance

of the MOSFET causes the gate to source voltage to increase. Increasing the

temperature also causes the drain to source resistance to increase. The

capacitance is also extremely high in the MOSFET which is why we need the

buffer to reduce delay of capacitance. A tradeoff found when using a strong

NMOS is the larger layout versus less delay, however the layout can be reduced

by using fingers.

Choosing

Diode of 1N5819

I choose this diode because the

maximum voltage is 40V, average rectified forward current is 1A, dissipates

1.25W of power, maximum thermal resistance of 100 degrees Celsius per Watt.

This thermal resistance is perfect because I measured the operation of the

circuit up to 100 degrees Celsius. This diode is a

good choice for a power supply because it operates at temperatures up to 100

degrees Celsius and works at 90 degrees Celsius without any thermal runway.

Thermal runway is when the internal heat of the circuit increases much faster

than the circuit can dissipate that heat. When there is too much heat, the

circuit can fry and become destroyed. This diode is a good choice because it

operates at high temperatures and can handle a faster increase of heat up to 90

degrees Celsius, which is a high enough value for a power supply.

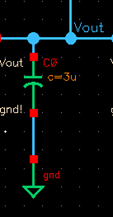

Choosing Capacitor and Tradeoffs

The output of my circuit oscillates around 5V with very little ripple because the capacitor I choose, 3u, is large enough to reduce ripple significantly. Capacitors are also affected heavily by temperature, and the amount of ripple current that the capacitor contains is related to temperature as well. When we fabricate this chip and put it on a printed circuit board, we will be using ceramic capacitors. The ceramic capacitors that we use that work at higher temperatures have less ripple current versus capacitors at lower temperatures. The capacitor works almost like a decoupling capacitor which is used to reduce noise especially in power supply signals. It is important to have a large capacitor when dealing with power signals because it helps smooth the signal and makes it easier to read. The ripple is reduced significantly, and the output voltage only oscillates from 4.98V to 5.003V. Since the frequency that I am using is above 10MHz, (it is 15MHz) this is considered a high-speed design. It is more difficult to increase the current when the speed is very high, so a LARGE CAPACITOR helps with that since at high speeds the impedance is lower because of the high frequency. The faster speed makes it harder to conduct large amounts of current because the impedance goes down which is one of the tradeoffs of using that frequency, however, adding a large capacitor gets rid of the issues and my circuit was able to conduct large amounts of current. Adding a large capacitor adds delay, however the buffer helps reduce that delay.

Choosing

Inductor and Tradeoffs

The frequency of my circuit is high which means that the impedance of the inductor will increase, and the capacitance of the capacitor will do the opposite. Because of the faster frequency, the impedance will rise which is a tradeoff, however, I wanted my design to be high speed. For there to be more current in the load resistor, the inductor value also must be lower because inductors will have higher impedances when there is a high frequency.

Thus, based on ohms law, we want to make the inductor smaller to get a higher current so that there is less impedance in the circuit.

My

entire schematic including off chip components.

My

entire schematic including off chip components.

TABLES with Final Values

Output voltages at

varying VDD values

|

VDD |

VOUT (V) |

|

3.75V |

5.0005 |

|

4V |

5.00046 |

|

4.25V |

5.001628 |

|

4.5V |

5.02437 |

|

4.75V |

5.037032 |

Output voltages at

varying temperatures using VDD of 3.75V

|

Degrees Celsius |

VOUT (V) |

|

0 |

4.9887 |

|

25 |

5.0017 |

|

50 |

4.9931 |

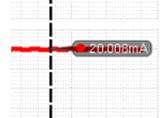

Load and Voltage

Divider Current Values

|

Type of Current |

Value in mA |

|

Load

current RL |

20.008 |

|

Voltage

Divider current |

36.78 |

Off-chip

component values/names

|

Name |

Value |

|

Diode |

1N5819

OnSemi |

|

Load

resistor |

250ohms |

|

Capacitor |

3uF |

|

Resistor

used in voltage divider |

34kohms |

|

Inductor |

30uH |

Load Current for

Varying Temperatures, VDD = 3.75V

|

Temperatures

in Celsius |

Current

in mA |

|

0 |

19.955 |

|

25 |

20.001 |

|

50 |

19.937 |

|

75 |

19.907 |

|

100 |

19.8934 |

|

Average

Current |

19.93868 |

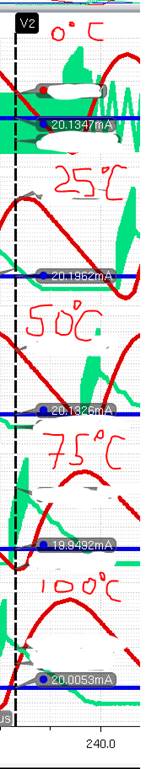

Load Current for

Varying Temperatures, VDD = 4.75V

|

Temperatures

in Celsius |

Current

in mA |

|

0 |

20.1347 |

|

25 |

20.1962 |

|

50 |

20.1326 |

|

75 |

19.949 |

|

100 |

20.0053 |

|

Average

Current |

20.08356 |

Inverters

used and values

|

Normal |

12u/6u |

|

Weak |

W=L=64

/ W=L=6u |

|

Normal

x8 |

48u/24u

with m=2 |

|

Normal

x64 |

48u/24u

with m=16 |

Frequency

and Duty Cycle

|

Frequency |

15.03MHz |

|

Duty

Cycle |

49% |

Efficiency Over Different Temperatures for a VDD of 3.75V

|

Temperatures in Celsius |

Efficiency (%) |

|

0 |

83 |

|

25 |

77 |

|

50 |

84.7 |

|

75 |

82.4 |

|

100 |

78.9 |

|

AVERAGE

EFFICIENCY |

81.2 |

Efficiency Over

Different Temperatures for a VDD of 4.75V

|

Temperatures in Celsius |

Efficiency (%) |

|

0 |

83 |

|

25 |

85.7 |

|

50 |

89 |

|

75 |

92.1 |

|

100 |

84.7 |

|

AVERAGE EFFICIENCY |

86.9 |

Efficiency Versus Load Current 3.75V

|

Temperature |

Load Current |

Efficiency |

|

0 |

19.955 |

83 |

|

25 |

20.001 |

77 |

|

50 |

19.937 |

84.7 |

|

75 |

19.907 |

82.4 |

|

100 |

19.8934 |

78.9 |

|

Average |

19.938 |

81.2 |

Efficiency Versus Load Current 4.75V

|

Temperature |

Load Current |

Efficiency |

|

0 |

20.13747 |

83 |

|

25 |

20.1962 |

85.7 |

|

50 |

20.1326 |

89 |

|

75 |

19.949 |

92.1 |

|

100 |

20.0053 |

84.7 |

|

Average |

20.0835 |

89.9 |

I(VDD) Values over

Varying Temperatures

|

Temperature in Celsius |

For VDD=3.75V |

For VDD=4.75V |

|

0 |

187.5mA |

263.89mA |

|

25 |

196.78mA |

158.56mA |

|

50 |

123.77mA |

151.42mA |

|

75 |

111.86mA |

144.23mA |

|

100 |

114.03mA |

141.77mA |

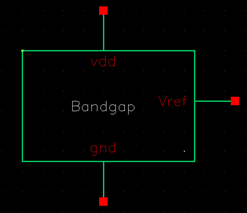

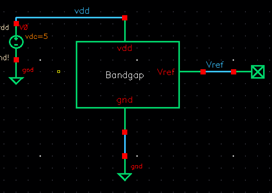

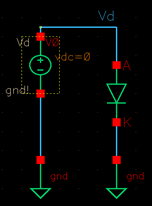

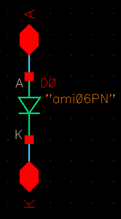

PART 1: BANDGAP

The bandgap circuit should read an input voltage and output a steady voltage of 1.25V.

Below is the schematic and symbol of the bandgap.

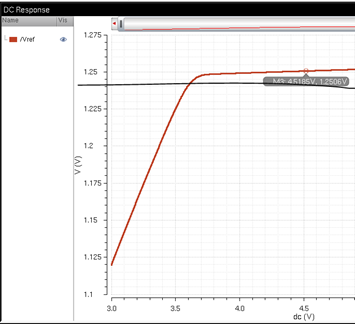

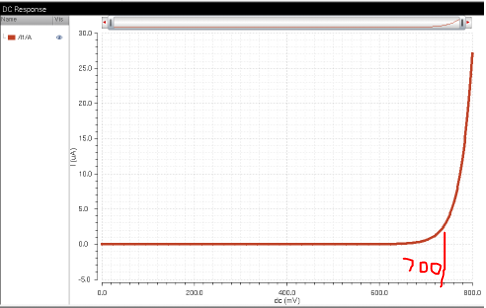

Bandgap simulations:

The simulation

of the bandgap shows that it works as intended. It is tested with an input

voltage of 5V and outputs a constant voltage of 1.25V. A parasitic PNP bipolar

transistor was also used in the bandgap circuit. The schematic, simulation and

layout of the PNP are below. The simulation shows the diodes current which

increases at the switching point of a diode, about 0.7 volts or 700mV.

The simulation

of the bandgap shows that it works as intended. It is tested with an input

voltage of 5V and outputs a constant voltage of 1.25V. A parasitic PNP bipolar

transistor was also used in the bandgap circuit. The schematic, simulation and

layout of the PNP are below. The simulation shows the diodes current which

increases at the switching point of a diode, about 0.7 volts or 700mV.

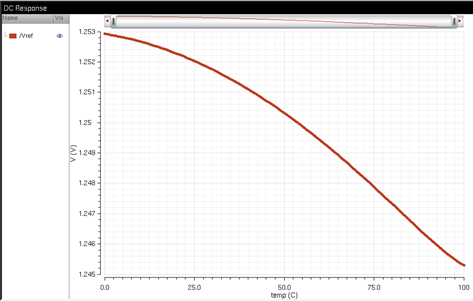

BANDGAP

TEMP

Below is the

temperature simulation of the bandgap. The bandgap should output a constant

1.25V regardless of temperature. The graph plots the voltage change from a

temperature of 0 to 100 degrees Celsius. The voltage changes very slightly and

decreases from 1.253V to 1.245V which is a negligible change. The circuit also

works regarding temperature changes.

Below is the

temperature simulation of the bandgap. The bandgap should output a constant

1.25V regardless of temperature. The graph plots the voltage change from a

temperature of 0 to 100 degrees Celsius. The voltage changes very slightly and

decreases from 1.253V to 1.245V which is a negligible change. The circuit also

works regarding temperature changes.

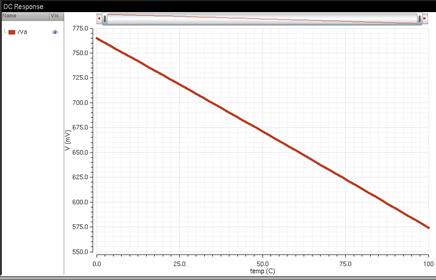

To the right is

the temperature simulation of the PNP. The voltage changes very slightly with

the change in temperature. It decreases from 775mV to 550mV from 0 to 100

degrees Celsius.

To the right is

the temperature simulation of the PNP. The voltage changes very slightly with

the change in temperature. It decreases from 775mV to 550mV from 0 to 100

degrees Celsius.

Then I laid out the bandgap. I used poly2 resistors to reduce layout size and to make the

design more concise.

Then I laid out the bandgap. I used poly2 resistors to reduce layout size and to make the

design more concise.

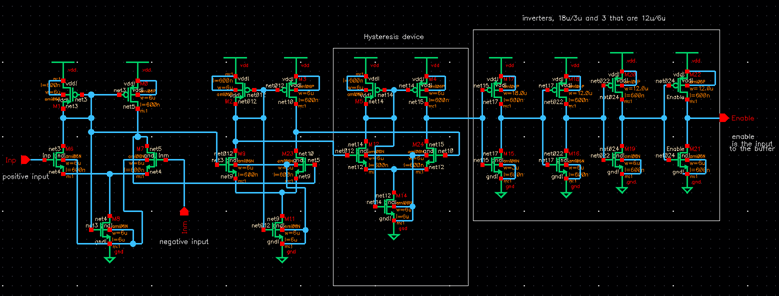

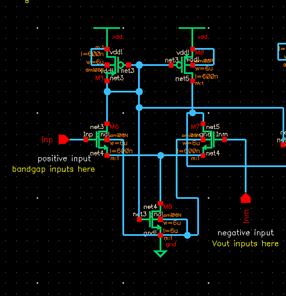

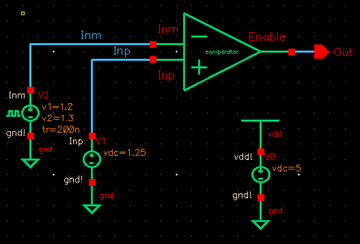

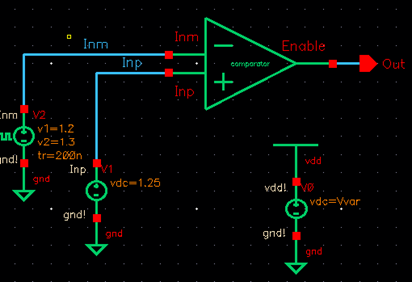

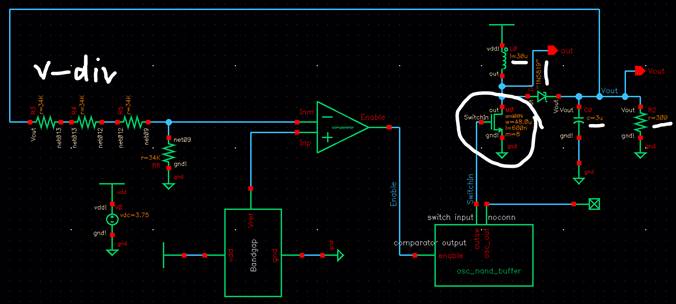

PART

2: COMPARATOR

Below is the

entire comparator and some zoomed in snips of the left, middle and right parts.

It consists of three differential amplifiers and four inverters. There are two

inputs, Inp and Inm, and an

output, Enable. Each differential amplifier introduces hysteresis so one of

them is labeled accordingly.

Below is the

entire comparator and some zoomed in snips of the left, middle and right parts.

It consists of three differential amplifiers and four inverters. There are two

inputs, Inp and Inm, and an

output, Enable. Each differential amplifier introduces hysteresis so one of

them is labeled accordingly.

Left side: one differential amplifier and the inputs. I used four

terminal NMOS and PMOS devices of 6um/600nm widths and lengths respectively.

The bodies of all PMOS devices are tied to VDD. The bodies of all NMOS devices

are tied to gnd. The bandgap output of 1.25V should input to the Inp terminal and Vout after being

divided with a voltage divider should input into the Inm

terminal as highlighted in yellow.

Left side: one differential amplifier and the inputs. I used four

terminal NMOS and PMOS devices of 6um/600nm widths and lengths respectively.

The bodies of all PMOS devices are tied to VDD. The bodies of all NMOS devices

are tied to gnd. The bandgap output of 1.25V should input to the Inp terminal and Vout after being

divided with a voltage divider should input into the Inm

terminal as highlighted in yellow.

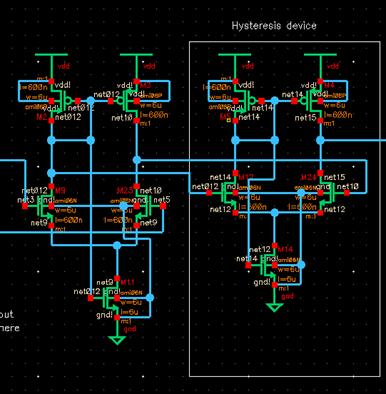

Middle: two differential amplifiers. I used four terminal NMOS

and PMOS devices of 6um/600nm widths and lengths respectively. The bodies of

all PMOS devices are tied to VDD and the bodies of all NMOS devices are tied to

gnd.

Middle: two differential amplifiers. I used four terminal NMOS

and PMOS devices of 6um/600nm widths and lengths respectively. The bodies of

all PMOS devices are tied to VDD and the bodies of all NMOS devices are tied to

gnd.

The right most PMOS and NMOS is connected to the first of

four inverters on the right side. The inverters sharpen the signal and since

there are four of them, they do not invert the signal. There would need to be

an odd number of inverters for the signal to be inverted because the even

number just cancels out the first inversions.

Right: inverters.

The first inverter has widths of 18um/3um which reduces the delay

in the output signal. When using an inverter of 18um/3um you can see in the

simulation below that the output changes exactly at the crossing point of both

the input signals. When all four of the inverters are of the same input,

however, the output is delayed slightly, and the input is not perfectly aligned

with the output. This is shown in the simulations below.

The first inverter has widths of 18um/3um which reduces the delay

in the output signal. When using an inverter of 18um/3um you can see in the

simulation below that the output changes exactly at the crossing point of both

the input signals. When all four of the inverters are of the same input,

however, the output is delayed slightly, and the input is not perfectly aligned

with the output. This is shown in the simulations below.

With four 12um/ 6um inverters on the left and with one 18um/3um inverter and three 12um/6um inverters on the right. It is apparent that the signal is slightly more accurate when using a 18um/3um inverter. The results are not extremely significant so technically you could use either topology.

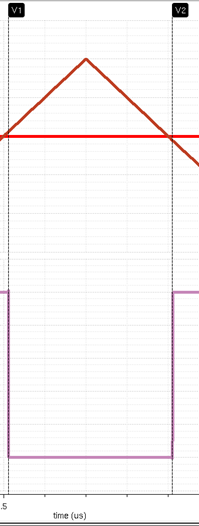

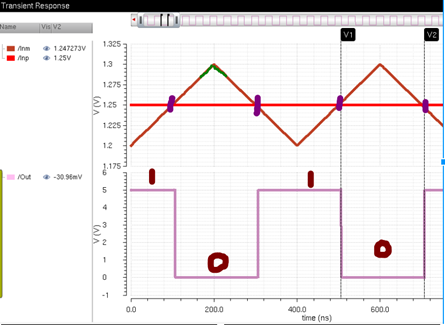

COMPARATOR

CIRCUIT SIMULATION regular transient simulation

COMPARATOR

CIRCUIT SIMULATION regular transient simulation

I simulated the

comparator to verify its accuracy before moving on. I mimicked the bandgap by

inputting a constant DC voltage of 1.25V into the positive input and inputted a

pulsing signal from 1.2V to 1.3V into the minus terminal because the output

from the voltage divider will not be a perfect signal; it will have ripples and

noise. A pulsing signal mimics the output from Vout

as closely as possible. I used a VDD of 5 volts for this smaller simulation

even though I will be using a range of 3.75V to 4.75V in my entire SPS

simulation. It is important to note that including a VDD of a different value

in a symbol and then using that symbol in the entire schematic will cause

significant error. The symbol must be saved without any VDD values so that it

can be controlled in the schematic where the symbol is used. As stated in the

previous project requirements, when the input from the minus terminal is

greater than 1.25V from the bandgap the output goes low and when the input from

the minus terminal is lower than 1.25V the output goes high.

I simulated the

comparator to verify its accuracy before moving on. I mimicked the bandgap by

inputting a constant DC voltage of 1.25V into the positive input and inputted a

pulsing signal from 1.2V to 1.3V into the minus terminal because the output

from the voltage divider will not be a perfect signal; it will have ripples and

noise. A pulsing signal mimics the output from Vout

as closely as possible. I used a VDD of 5 volts for this smaller simulation

even though I will be using a range of 3.75V to 4.75V in my entire SPS

simulation. It is important to note that including a VDD of a different value

in a symbol and then using that symbol in the entire schematic will cause

significant error. The symbol must be saved without any VDD values so that it

can be controlled in the schematic where the symbol is used. As stated in the

previous project requirements, when the input from the minus terminal is

greater than 1.25V from the bandgap the output goes low and when the input from

the minus terminal is lower than 1.25V the output goes high.

This is demonstrated in

the simulation to the left. The area highlighted shows the input from the minus

terminal as high, showing a 0 logic output.

Just directly to its left you can see the bandgap voltage rising higher than the input voltage from the pulsing signal that mimics the Vout voltage, and the output voltage that corresponds to that relationship is a logic 1. After the simulations were complete, I laid out the comparator schematic. The pins are vdd!, gnd!, Inp, Inm and Enable. Inm is the input from the voltage divider, Inp is the input from the bandgap, and Enable is the output that feeds into the buffer before reaching the switch.

PARAMETRIC TEMPERATURE

SIMULATION - COMPARATORS

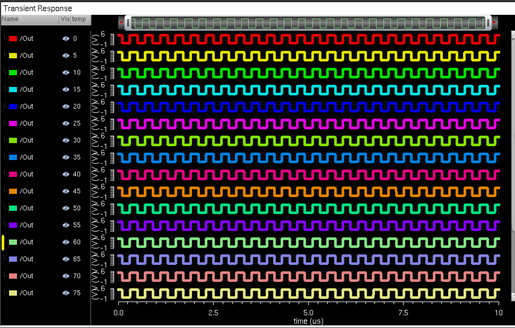

Parametric:

I simulated

comparators functionality in regard to changing

temperature using a parametric analysis from 0 to 100 degrees Celsius. I kept

the step size small, 5 degrees Celsius to see if there is any variation of the

simulation in regard to specific temperatures. There

was no significant variation.

I simulated

comparators functionality in regard to changing

temperature using a parametric analysis from 0 to 100 degrees Celsius. I kept

the step size small, 5 degrees Celsius to see if there is any variation of the

simulation in regard to specific temperatures. There

was no significant variation.

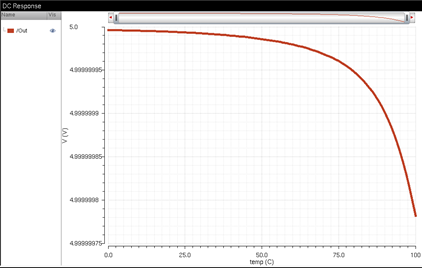

DC sweep: The voltage only went down to 4.99V from 5V as the

temperature increased from 0 degrees Celsius to 100 degrees Celsius.

DC sweep: The voltage only went down to 4.99V from 5V as the

temperature increased from 0 degrees Celsius to 100 degrees Celsius.

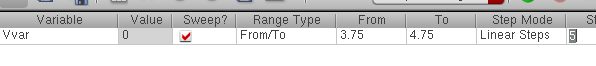

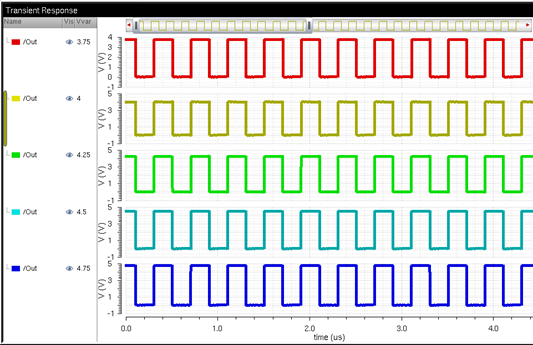

PARAMETRIC SIM OF VARYING VOLTAGE

When I first ran this simulation, I used a VDD of 5V. To make sure

that the simulation works in my entire circuit with a VDD of 3.75V-4.75V, I

implemented a variable over my VDD and ran a parametric simulation to test all of those voltages. I choose 5 voltages in that range.

When I first ran this simulation, I used a VDD of 5V. To make sure

that the simulation works in my entire circuit with a VDD of 3.75V-4.75V, I

implemented a variable over my VDD and ran a parametric simulation to test all of those voltages. I choose 5 voltages in that range.

The comparators output

is the same for every voltage tested using the parametric analysis. This shows

that the comparator will work with the VDD in the entire circuit when

simulating it altogether.

---------------------------------------------------------------------------------------------------------------------

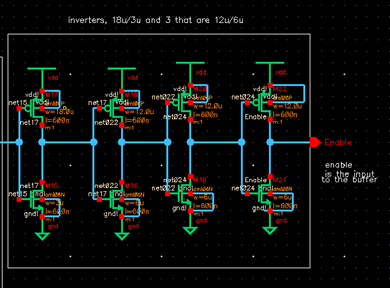

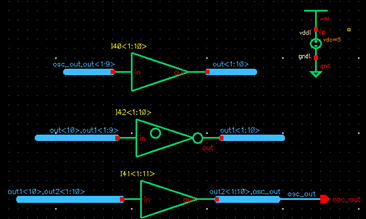

PART 3: BUFFER

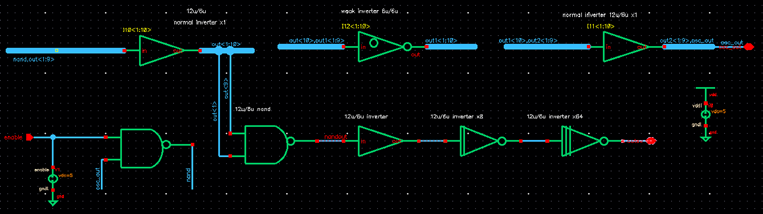

The buffer

consists of many parts. The first part is the oscillator that will create the

oscillating signal that results from the comparator. The oscillators input

will be the output of a NAND. Then two of the outputs of the first ten

inverters are fed into another NAND whose output is fed into three more

inverters to sharpen the signal. The first inverter that takes in the signal

from the NAND is a normal 12um/6um inverter. The second one is the same normal

inverter multiplied by eight and the third one is the normal inverter

multiplied by sixty-four. The output of the largest inverter is the signal that

reaches the switch (NMOS). The larger the inverter, the sharper the output is.

From the buffer, we can calculate the frequency and the duty cycle

of our signal.

The buffer

consists of many parts. The first part is the oscillator that will create the

oscillating signal that results from the comparator. The oscillators input

will be the output of a NAND. Then two of the outputs of the first ten

inverters are fed into another NAND whose output is fed into three more

inverters to sharpen the signal. The first inverter that takes in the signal

from the NAND is a normal 12um/6um inverter. The second one is the same normal

inverter multiplied by eight and the third one is the normal inverter

multiplied by sixty-four. The output of the largest inverter is the signal that

reaches the switch (NMOS). The larger the inverter, the sharper the output is.

From the buffer, we can calculate the frequency and the duty cycle

of our signal.

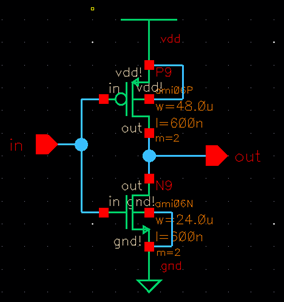

First, I simulated the oscillator to make sure that it worked. The oscillator I used consists of thirty-one inverters. The first ten are normal sized, 12um/6um, the next ten are weak inverters with lengths and widths of 6um on each device, and the last eleven are regular inverters.

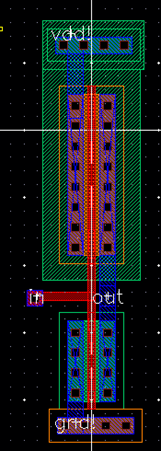

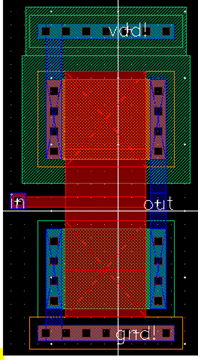

Below is the

normal inverters schematic, layout and symbol.

Below is the

normal inverters schematic, layout and symbol.

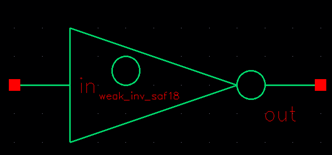

Then I created a

weak inverter, with length and width of 6um for both devices. Below is the

schematic, layout and symbol. I put a circle inside of the weak inverters

symbol so that it is easier to differentiate from the other inverters.

Then I created a

weak inverter, with length and width of 6um for both devices. Below is the

schematic, layout and symbol. I put a circle inside of the weak inverters

symbol so that it is easier to differentiate from the other inverters.

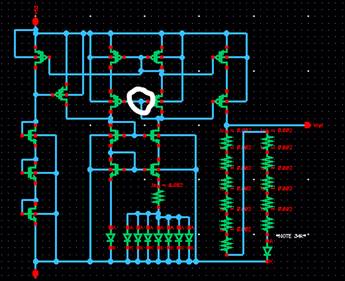

ENTIRE OSCILLATOR

Then, I tested the oscillator with thirty-one inverters to make sure it oscillates before connecting it to the other components. It oscillates so now we can connect it to the other components and test it. I decided to use a NAND as my inverter to simplify the circuit. NANDS are commonly used when creating buffers, which is what we are doing in this case. Two NANDs connected to each other act like a buffer. Since I am using a NAND as an inverter, I am going to reduce the number of inverters I have in my oscillator in order to continue to have an odd number of inverters.

Entire oscillator simulation below:

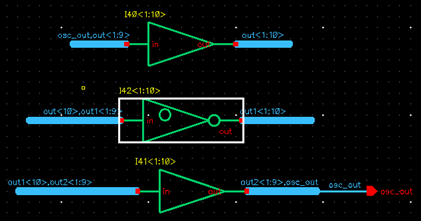

I created a separate schematic and layout for a ring

oscillator with only thirty inverters, specific for connecting the entire

circuit. I did not simulate this circuit because it is not supposed to work.

This buffer will not oscillate because it has an even number of inverters.

Below is the

oscillator with an even number of inverters.

Below is the

oscillator with an even number of inverters.

Below is the layout of

the inverter.

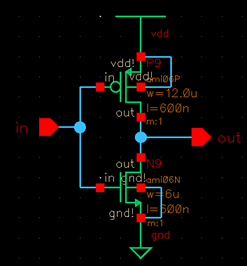

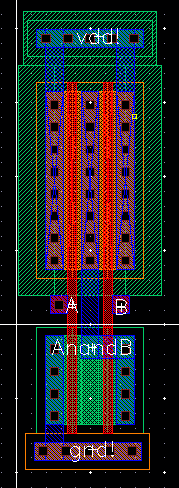

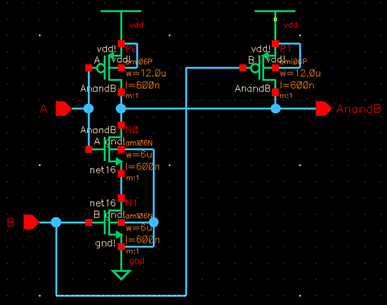

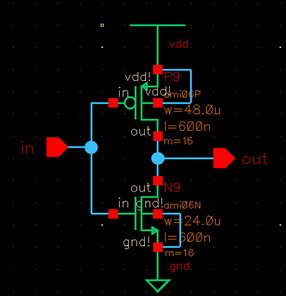

NAND

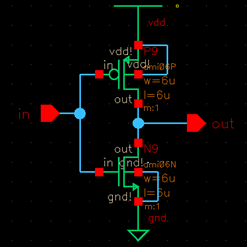

I created a

NAND using four terminal MOSFETs, PMOSes of

12um/0.6nm and NMOSes of 6um/0.6um.

I created a

NAND using four terminal MOSFETs, PMOSes of

12um/0.6nm and NMOSes of 6um/0.6um.

NORMAL

INVERTER x8

To simplify the

layout, I first calculated the width that would result from multiplying the

original dimensions by eight.

To simplify the

layout, I first calculated the width that would result from multiplying the

original dimensions by eight.

12 um * 8 = 96 um

6 um * 8= 48 um

Instead of creating an inverter with these widths, I divided the goal width by two and instead increased the multiplier of my inverter by two to make the layout more concise.

layout of the x8 inverter

layout of the x8 inverter

Normal inverter multiplied by 8 symbol

NORMAL

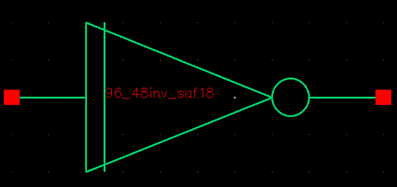

INVERTER x64

12 um * 6;4 = 768 um

6 um * 64 = 384 um

Instead of using these values, I used 48 um and 24 um with a multiplier of 16 to simplify the layout and make it as concise as possible. If one were to layout an inverter of the entire size without multipliers, the height of the inverter would be the entire height of a chip, and would cause immense error, cost too much and take up too much room in the entire layout of the chip. Our goal is to make the layout as small as possible, and multipliers help achieve that goal.

Below is the

layout of the inverterx64 with multipliers of 16.

Below is the

layout of the inverterx64 with multipliers of 16.

The contacts are zoomed in for better viewing. The input is connected to metal1-poly connectors and the output is connected to metal1 to metal 2 vias.

Now we have all of the parts and

we can put them all together to find the duty cycle, frequency, and the output

that be the input to the switch (NMOS) that will drive the current that we

need.

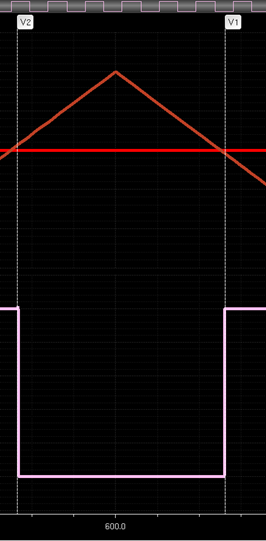

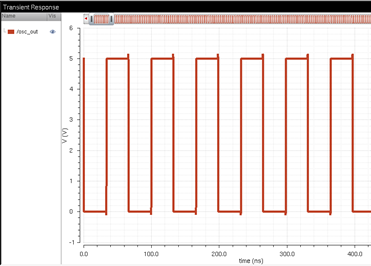

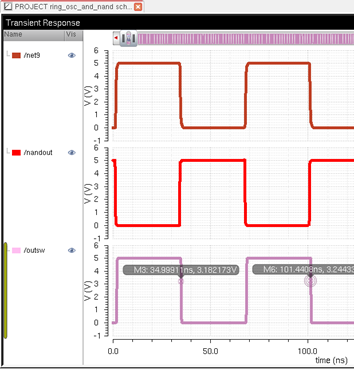

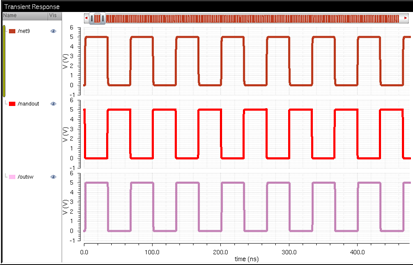

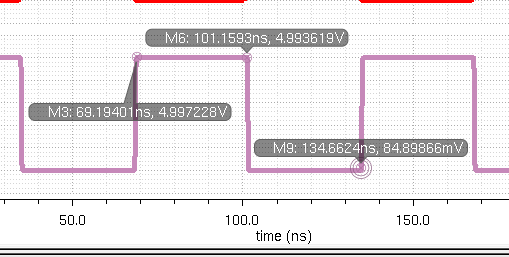

RING OSCILLATOR WITH NAND

RING OSCILLATOR WITH NAND

T = period = 101.44ns-34.99ns = 66.5ns

F = 1/T= 1/ 66.5nanoseconds=

15.03MHz

frequency

DUTY

CYCLE

DUTY

CYCLE

Duty cycle is how much

more time it is high than it is low. It is high for 31.96 nanoseconds and it is

low for 33.5nanoseconds. So the duty cycle is 31.96 /

(31.96 + 33.5) = 0.488 so there is a 49% duty cycle.

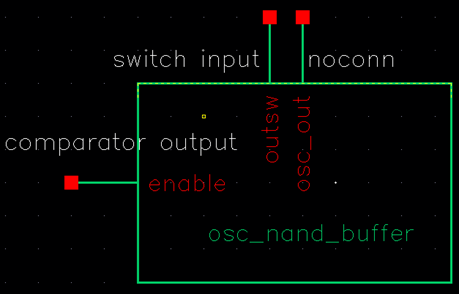

The symbol for

the NAND input, the oscillator and the buffer is

below:

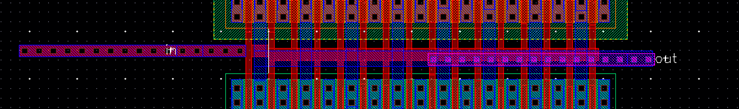

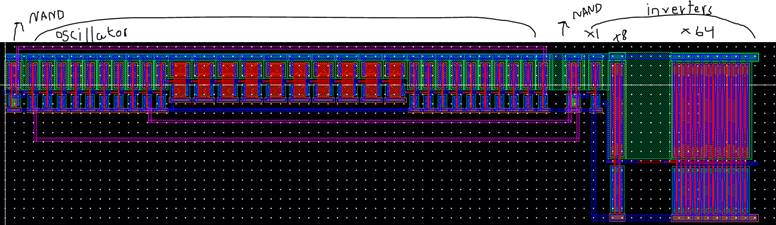

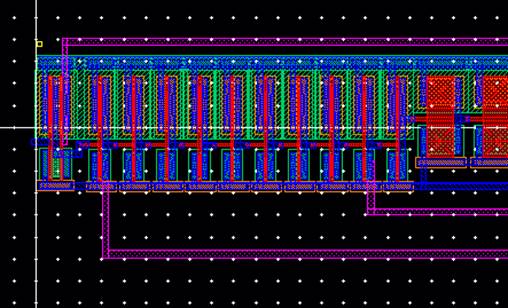

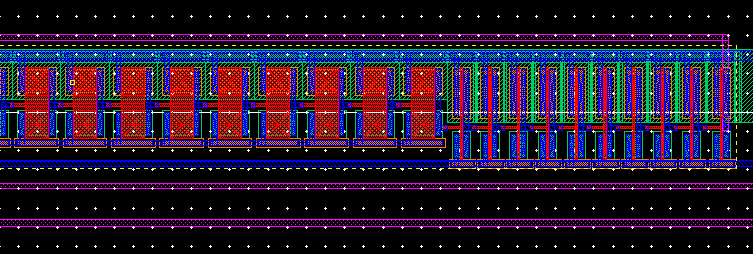

LAYOUT for the entire NAND input,

oscillator and the buffer:

LAYOUT for the entire NAND input,

oscillator and the buffer:

The

photo on the left shows the input NAND and the first ten normal inverters and

the first two weak inverters.

The

photo below shows the center, the rest of the weak inverters and all ten of the

final normal inverters.

To

the left are the final NAND which leads to the normal inverter, inverterx8 and

inverterx64.

---------------------------------------------------------------------------------------------------------------

PART 4: NMOS

SWITCH

PART 4: NMOS

SWITCH

The NMOS switch needs to be a strong MOSFET that can switch

quickly. Larger MOSFETs with a larger width have very small internal gate

resistances. The small resistance causes it to be high-speed and be able to

carry high currents. This circuit generates resonance which will create a

voltage that oscillates around a point, which is what we see in our simulations

as we try to reach 5 volts. Because of the resonance and the oscillation that

results from it, the MOSFET holds a current that creates a voltage that

oscillates. The drain to source resistance is influenced by the gate to source

voltage. Lowering the resistance of the MOSFET causes the gate to source

voltage to increase. Increasing the temperature also causes the drain to source

resistance to increase. The capacitance is also extremely high in the MOSFET

which is why we need the buffer to reduce the delay from the capacitance.

Resistance of the MOSFET:

The MOSFETs we used are in the C5

process in which the RN value of an NMOS is 20kohms. We can calculate the

entire resistance by using the equation:

In this case, Rsquare is 20kohms, l= 600nm and w=48u*8=384um. The width

is multiplied by 8 because I am using a multiplier of 8. Increasing the width

decreases the resistance because of the relationship between the l and w in the

equation, since w is in the denominator.

![]()

This resistance is

extremely small and is almost negligible.

Capacitance of the MOSFET:

In the C5 process, the Cox is 2.5fF/um^2. To calculate the CoxN

we can use the equation:

![]()

![]()

![]() = 576fF which is higher than

we would want ideally. Since this

capacitance is larger, we can see that the capacitance goes up and the

resistance goes down. This is one of the tradeoffs of a larger switch.

= 576fF which is higher than

we would want ideally. Since this

capacitance is larger, we can see that the capacitance goes up and the

resistance goes down. This is one of the tradeoffs of a larger switch.

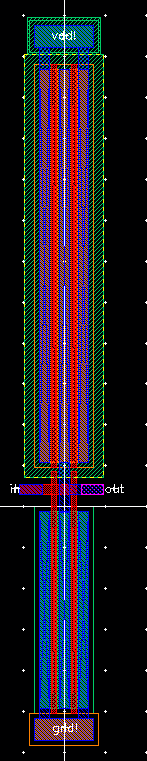

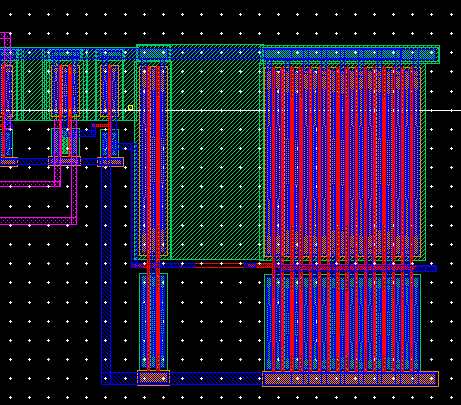

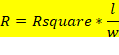

LAYOUT

OF THE SWITCH

LAYOUT

OF THE SWITCH

I

used an NMOS with multiplier of 8 to simplify my layout and make it more

concise. The source of the NMOS device is connected to ground and the gate is

connected to some metal one to poly connectors. The output from the oscillator

and buffer should be the input to the gate, which is labeled switch_input. The drain of the NMOS is where the output of

the circuit, which should be 5V, will be read.

-------------------------------------------------------------------------------------------------------------------

ENTIRE SCHEMATIC with off chip components

Below I will discuss how I simulated the entire schematic

with off chip components and why I choose these specific sizes and

specifications.

Initial

conditions:

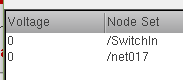

For

the schematic to simulate, there had to be some initial conditions set in the

circuits. There were two initial conditions that I simulated. The first one is the input to the switch and

the second one is a net in the bandgap that needed an initial condition to

begin.

For

the schematic to simulate, there had to be some initial conditions set in the

circuits. There were two initial conditions that I simulated. The first one is the input to the switch and

the second one is a net in the bandgap that needed an initial condition to

begin.

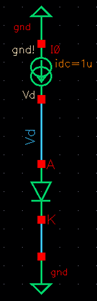

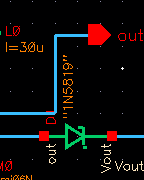

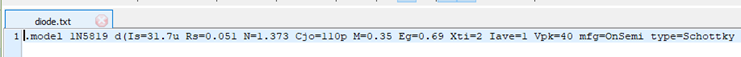

Diode

Diode

Diode model

text file: on Semiconductor Schottky Diode 1N5819. I chose this diode because

maximum voltage is 40V, average rectified forward current is 1A, and non-repetitive

peak current is 25A. It dissipates 1.25W of power and has a maximum thermal

resistance of 100 degrees Celsius per Watt which is good characteristic for

measuring the circuits outputs over varying temperatures that include 100

degrees Celsius. The maximum thermal resistance is 45 degrees Celsius per Watt.

This diode is a good choice for a power supply because it operates at

temperatures up to 100 degrees Celsius and works at 90 degrees Celsius without

any thermal runway. Thermal runway is when the internal heat of the circuit

increases much faster than the circuit can dissipate that heat. When there is

too much heat, the circuit can fry and become destroyed. This diode is a good

choice because it operates at high temperatures and can handle a faster

increase of heat up to 90 degrees Celsius, which is a high enough value for a

power supply.

Diode model

text file: on Semiconductor Schottky Diode 1N5819. I chose this diode because

maximum voltage is 40V, average rectified forward current is 1A, and non-repetitive

peak current is 25A. It dissipates 1.25W of power and has a maximum thermal

resistance of 100 degrees Celsius per Watt which is good characteristic for

measuring the circuits outputs over varying temperatures that include 100

degrees Celsius. The maximum thermal resistance is 45 degrees Celsius per Watt.

This diode is a good choice for a power supply because it operates at

temperatures up to 100 degrees Celsius and works at 90 degrees Celsius without

any thermal runway. Thermal runway is when the internal heat of the circuit

increases much faster than the circuit can dissipate that heat. When there is

too much heat, the circuit can fry and become destroyed. This diode is a good

choice because it operates at high temperatures and can handle a faster

increase of heat up to 90 degrees Celsius, which is a high enough value for a

power supply.

Above is the

model file that I put in the project folder.

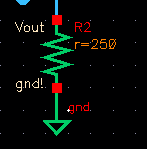

Load Resistor and load current

Load Resistor and load current

The load current shown

in yellow is 19.5mA which shows that the circuit can drive currents near 20mA.

Decreasing the load resistor can increase the current even further.

The load current shown

in yellow is 19.5mA which shows that the circuit can drive currents near 20mA.

Decreasing the load resistor can increase the current even further.

![]() θ

θ ![]()

Increasing the Load Resistor

decreases the load current. This is because of how ohms law works. If Vout = 5V and RL=300ohms, I = 5V/300ohms which is 16.6mA.

I increased the load current to 300 ohms to demonstrate, which is shown

on the left. The current reduced by about 3mA.

Increasing the Load Resistor

decreases the load current. This is because of how ohms law works. If Vout = 5V and RL=300ohms, I = 5V/300ohms which is 16.6mA.

I increased the load current to 300 ohms to demonstrate, which is shown

on the left. The current reduced by about 3mA.

To the right is the load

current with changing temperatures.

Capacitor

and Ripple and Frequency Tradeoffs

Capacitor

and Ripple and Frequency Tradeoffs

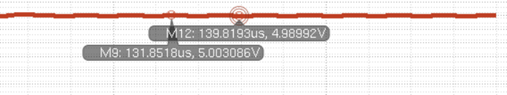

The output of the circuit

oscillates around 5 volts. This is possible with less ripple because the

capacitor is large enough to reduce the ripple significantly. Capacitors are

also affected heavily by temperature, and the amount of ripple current that the

capacitor contains is related to temperature as well. When we fabricate this

chip and put it on a printed circuit board, we will be using ceramic

capacitors. The ceramic capacitors that we use that work at higher temperatures

have less ripple current versus capacitors at lower temperatures. The capacitor

works almost like a decoupling capacitor which is used to reduce noise

especially in power supply signals. It is important to have a large capacitor

when dealing with power signals because it helps smooth the signal and makes it

easier to read. The ripple is reduced significantly, and the output voltage

only oscillates from 4.98V to 5.003V. Since the frequency that I am using is

above 10MHz, (it is 15MHz) this is considered a high-speed design. It is more

difficult to increase the current when the speed is very high, so a LARGE

CAPACITOR helps with that since at high speeds the impedance is lower because

of the high frequency. The faster speed makes it harder to conduct large

amounts of current because the impedance goes down which is one of the

tradeoffs of using that frequency, however, adding a large capacitor gets rid

of the issues and my circuit was able to conduct large amounts of current.

The output of the circuit

oscillates around 5 volts. This is possible with less ripple because the

capacitor is large enough to reduce the ripple significantly. Capacitors are

also affected heavily by temperature, and the amount of ripple current that the

capacitor contains is related to temperature as well. When we fabricate this

chip and put it on a printed circuit board, we will be using ceramic

capacitors. The ceramic capacitors that we use that work at higher temperatures

have less ripple current versus capacitors at lower temperatures. The capacitor

works almost like a decoupling capacitor which is used to reduce noise

especially in power supply signals. It is important to have a large capacitor

when dealing with power signals because it helps smooth the signal and makes it

easier to read. The ripple is reduced significantly, and the output voltage

only oscillates from 4.98V to 5.003V. Since the frequency that I am using is

above 10MHz, (it is 15MHz) this is considered a high-speed design. It is more

difficult to increase the current when the speed is very high, so a LARGE

CAPACITOR helps with that since at high speeds the impedance is lower because

of the high frequency. The faster speed makes it harder to conduct large

amounts of current because the impedance goes down which is one of the

tradeoffs of using that frequency, however, adding a large capacitor gets rid

of the issues and my circuit was able to conduct large amounts of current.

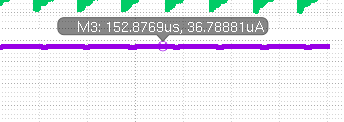

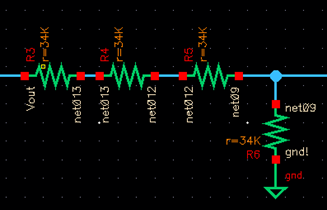

Input

current Over Voltage Divider

Input

current Over Voltage Divider

The input current over the voltage dividers is about 36.8uA which is within the range that I was aiming for which is in between 10uA and 50uA. The input supplies a high enough current.

To achieve this, I used 34k resistors to create a 3:1 voltage divider and supply 1.25 volts. I used these resistors to attain a current within the 10uA to 50uA range using Ohms law, V=IR.

V=IR

V=IR

5V = I * (34k + 34k + 34k + 34k)ohms

5V = I * (136k ohms)

I = 5V / 136,000ohms = 36.76uA which is almost the same as the current in the simulation.

VOLTAGE DIVIDER

The 3:1 voltage divider divides the 5V output voltage into 1.25V (the input to the minus terminal of the comparator) to match the voltage of the bandgap circuit.

To prove this: Vin * R2/(R2+R1) = Vout ⇒ 5V * (34kohms / 136kohms)

= 5V * (0.25)[no unit here because

the kohms cancel each other to form a ratio, creating

the voltage divider] = 1.25V.

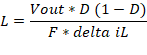

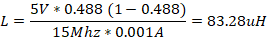

Choosing an Inductor &

Current Tradeoffs

![]() The frequency of my circuit is

high which means that the impedance of the inductor will increase, and the

capacitance of the capacitor will do the opposite. Because of the faster

frequency, the impedance will rise which is a tradeoff, however, I wanted my design

to be high speed. For there to be more current in the load resistor, the

inductor value also must be lower because inductors will have higher impedances

when there is a high frequency.

The frequency of my circuit is

high which means that the impedance of the inductor will increase, and the

capacitance of the capacitor will do the opposite. Because of the faster

frequency, the impedance will rise which is a tradeoff, however, I wanted my design

to be high speed. For there to be more current in the load resistor, the

inductor value also must be lower because inductors will have higher impedances

when there is a high frequency.

Thus, based on ohms law, we want

to make the inductor smaller to get a higher current so that there is less

impedance in the circuit.

These equations help us select

what inductor to choose:

Delta iL

is calculated to be 5% of the maximum average current which is estimated to be 5%

of 20mA and is 0.001A.

This value is a rough estimate,

and when testing my circuit, I choose a much smaller inductor value of 30uA for

the current to increase.

When simulating the inductor

value of 30uA, the current across the inductor is 76.27mA.

Recalculating the value using

this amperage:

0.00381A = 5%

![]()

---------------------------------------------------------------------------------------------------------------------

PART 5: Output of 5V over a varying voltage input

of 3.75V to 4.75V

![]() I used a parametric analysis with a step size of 5 to measure the output

over varying voltages of 3.75V to 4.75V to make sure that my simulation works

for every value in the range I was given. All five of the input values worked.

I used a parametric analysis with a step size of 5 to measure the output

over varying voltages of 3.75V to 4.75V to make sure that my simulation works

for every value in the range I was given. All five of the input values worked.

![]() Testing

the circuits reactions to varying temperatures from 0 to 50 degrees Celsius

Testing

the circuits reactions to varying temperatures from 0 to 50 degrees Celsius

![]()

![]() I used parametric analysis to simulate

the output voltage Vout, regarding varying

temperatures from 0 to 50 degrees Celsius. The simulation above shows that all

three voltages are about 5V exactly, and the circuit works in with varying

temperatures. The diode I choose helps with that since it operates well in

relationship to higher temperatures.

I used parametric analysis to simulate

the output voltage Vout, regarding varying

temperatures from 0 to 50 degrees Celsius. The simulation above shows that all

three voltages are about 5V exactly, and the circuit works in with varying

temperatures. The diode I choose helps with that since it operates well in

relationship to higher temperatures.

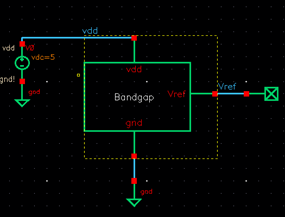

ON

CHIP BOOST SPS SCHEMATIC

![]() This

schematic is made into a symbol which will be on the chip and is tested

separately with the off-chip components.

This

schematic is made into a symbol which will be on the chip and is tested

separately with the off-chip components.

![]()

To

the left is the symbol view of the schematic above which will be used for the

simulations with the on-chip components.

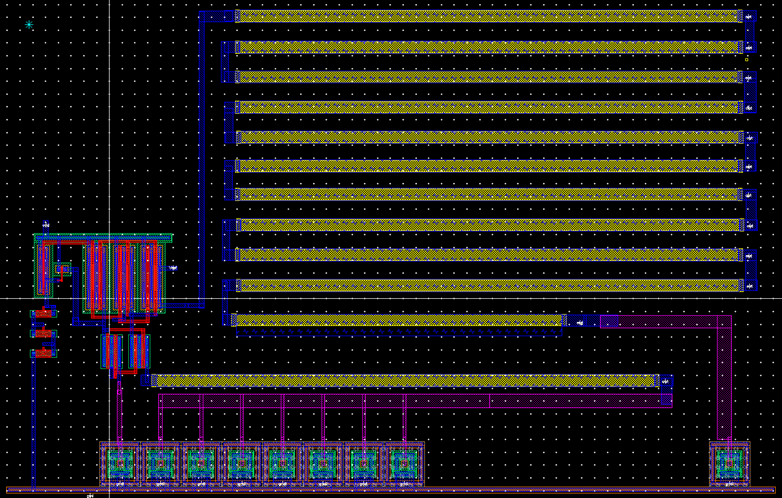

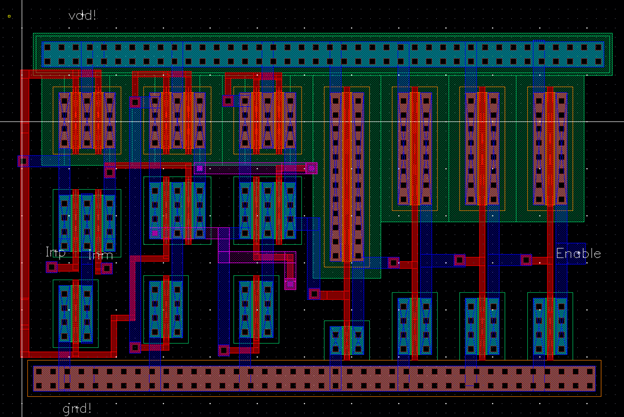

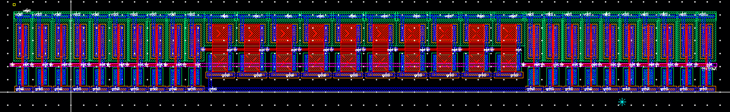

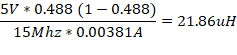

LAYOUT

![]()

Layout

of the on-chip components

![]()

![]()

![]()

BONDING

AND PROBE PADS

The

output feeds into the Vfeed back so we would only

need one probe pad. The photo below is extremely exaggerated as if the pad on

the die is larger than the components on the PCB. Ideally there would be a

trace connecting the components to the package and that would be wire bonded to

the pad on the die.

![]()

![]()

![]()

![]()

![]() Circuit with symbol

Circuit with symbol

![]()

![]()

![]()

The

above simulation shows the output voltage at 5V, the load current at 20mA and

the current over the voltage divider at 36.8mA which is in between 10mA and

50mA. The signal, enable, that is the output of the comparator and then enters

the buffer to output the signal, switchin, which is

what enables and disables the switch and allows the whole circuit to work

properly as shown above.

Simulation starts at 100u

and ends at 300u to reduce unnecessary viewing of the startup signal.

EFFICIENCY

for 4.75v

![]()

For this efficiency calculation, I will be using 2 VDD

values of 3.75V and 4.75V. I will

also only simulate from about 215us to 300us because that is when the signal is

at steady state. This reduces error when calculating the average current

because of the startup current and voltages.

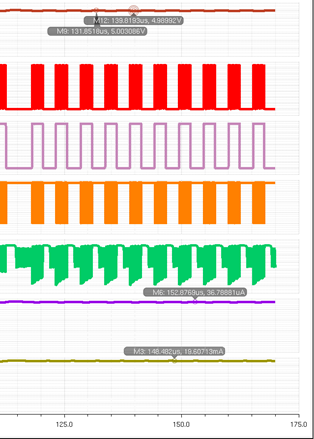

The

schematic below shows Vout, the load current and the

current of our battery with changing temperatures from 0 to 100 degrees

Celsius.

![]() The blue

traces are the load current, the green traces are the currents over VDD and

the red is the output voltage.

The blue

traces are the load current, the green traces are the currents over VDD and

the red is the output voltage.

![]()

![]() The left is the load current with

varying temperature, the middle is Vout with varying temperature, and the left

is I(VDD) with varying temperature. The current goes down with rising

temperature.

The left is the load current with

varying temperature, the middle is Vout with varying temperature, and the left

is I(VDD) with varying temperature. The current goes down with rising

temperature.

![]()

Load

Current for Varying Temperatures, VDD = 4.75V

|

Temperatures

in Celsius |

Current

in mA |

|

0 |

20.1347 |

|

25 |

20.1962 |

|

50 |

20.1326 |

|

75 |

19.949 |

|

100 |

20.0053 |

|

Average Current |

20.08356 |

Now using the I(VDD) values found over varying temperatures, I

calculated the efficiency of the circuit.

![]()

SIMULATING

EFFICIENCY FOR 4.75V

For 0 degrees Celsius using RMS:

Rms(I(VDD))

= 112.9mA

![]()

![]()

For 0 degrees Celsius

using Average:

![]() Average(I(VDD))

= 25.3mA

Average(I(VDD))

= 25.3mA ![]()

For 25 degrees Celsius

using Average:![]()

![]()

![]() For 50 degrees Celsius

using Average:

For 50 degrees Celsius

using Average:

![]()

![]() For 75 degrees Celsius

using Average:

For 75 degrees Celsius

using Average:

![]()

![]() For 100 degrees Celsius

using Average:

For 100 degrees Celsius

using Average:

![]()

Based on these results, the

efficiency was best using 75 degrees Celsius.

Efficiency Over Different Temperatures for a VDD of 4.75V

|

Temperatures in Celsius |

Efficiency (%) |

|

0 |

83 |

|

25 |

85.7 |

|

50 |

89 |

|

75 |

92.1 |

|

100 |

84.7 |

|

AVERAGE

EFFICIENCY |

86.9 |

![]()

Based

on this graph comparing efficiency and the load current over varying

temperatures over a VDD of 4.75, it is apparent that as the temperature

increases, the load current also increases as well as the efficiency. They are

all correlated.

SIMULATING EFFICIENCY

FOR 3.75V

![]() I

used another parametric analysis to simulate the changes in voltages, the load

current and the current over vdd.

I

used another parametric analysis to simulate the changes in voltages, the load

current and the current over vdd.

![]()

To the left is the simulation with

markers for I(VDD) for VDD=3.75V. The straight lines across are the load

current values, and the cleaner oscillations are the output voltages, Vout which oscillate from 4.99V to 5.002V.

![]()

![]() The

left image shows the load current values over varying temperatures. The right

image shows the I(VDD) values for VDD= 3.75.

The

left image shows the load current values over varying temperatures. The right

image shows the I(VDD) values for VDD= 3.75.

Load

Current for Varying Temperatures, VDD = 3.75V

|

Temperatures

in Celsius |

Current

in mA |

|

0 |

19.955 |

|

25 |

20.001 |

|

50 |

19.937 |

|

75 |

19.907 |

|

100 |

19.8934 |

|

Average Current |

19.93868 |

Calculating

efficiency using the average I(VDD)

![]()

For a temperature of 0

degrees Celsius:

Average

current is: 32:11mA

![]()

![]()

For a temperature of 25

degrees Celsius:

![]() Average

current is:

Average

current is:

![]()

For a temperature of 50

degrees Celsius:

Average

current is:![]()

![]()

For a temperature of 75

degrees Celsius:

Average

current is:

![]()

![]()

For a temperature of 100

degrees Celsius:

![]() Average

current is:

Average

current is:

![]()

Efficiency Over Different Temperatures for a VDD of 3.75V

|

Temperatures in Celsius |

Efficiency (%) |

|

0 |

83 |

|

25 |

77 |

|

50 |

84.7 |

|

75 |

82.4 |

|

100 |

78.9 |

|

AVERAGE

EFFICIENCY |

81.2 |

![]() Based

on this graph comparing efficiency and the load current over varying

temperatures over a VDD of 3.75, it is apparent that as the temperature

increases, the load current also increases as well as the efficiency. They are

all correlated.

Based

on this graph comparing efficiency and the load current over varying

temperatures over a VDD of 3.75, it is apparent that as the temperature

increases, the load current also increases as well as the efficiency. They are

all correlated.

References

Baker,

R. Jacob. CMOS: Circuit Design, Layout,

and Simulation. IEEE Press, 2010.

Glaser,

Chris. Does Inductor Ripple-Current Percentage Still Matter in Low-Power

Step-Down Converters? Electronic Design,

23 Nov. 2015, www.electronicdesign.com/power/does-inductor-ripple-current-percentage-still-matter-low-power-step-down-converters.

Hauke,

Brigitte. Basic Calculation of a Boost Converter's Power Stage - Texas

Instruments. Texas Instruments - Basic

Calculation of a Boost Converter's Power Stage, Jan. 2014,

www.ti.com/lit/an/slva372c/slva372c.pdf.

Joshi,

Anoop. Http://Ljournal.ru/Wp-Content/Uploads/2017/03/a-2017-023.Pdf. Testing PSRR with High-Frequency Ripple -

Cadence, 2017, doi:10.18411/a-2017-023.

Li,

Jasper. How to Select a Proper Inductor for Loaw

Power Boost Converter - Texas Instruments. Texas

Instruments- How to Select a Proper Inductor for Low Power Boost Converter,

June 2016, www.ti.com/lit/an/slva797/slva797.pdf.

Zednicek,

Tomas. Ripple Current and Its Effects on the Performance of Capacitors. European Passive Components Institute,

30 Aug. 2017,

passive-components.eu/ripple-current-and-its-effects-on-the-performance-of-capacitors/.