![]() PCB Assembly

PCB Assembly

Technician

Craft

Produced by Daniel Senda

†

Page Information

∑

This PCB assembly page is

intended to demonstrate some technician work that Daniel has done while working

in the Dr. Baker Research Group.

∑

A good number of these

boards were designed for graduate students, so the assembly process begins by

meeting with the appropriate graduate student. At times, it is more efficient

to just solder on the package, glue the chip to the package, wire-bond the chip

to package, and epoxy the wire-bonded chip (if necessary) before continuing

with the rest of the assembly process.

∑

The next step in the process

is to gather all the components that will be needed. By doing so, Daniel gets a

better idea in terms of the order to populate the board.

∑

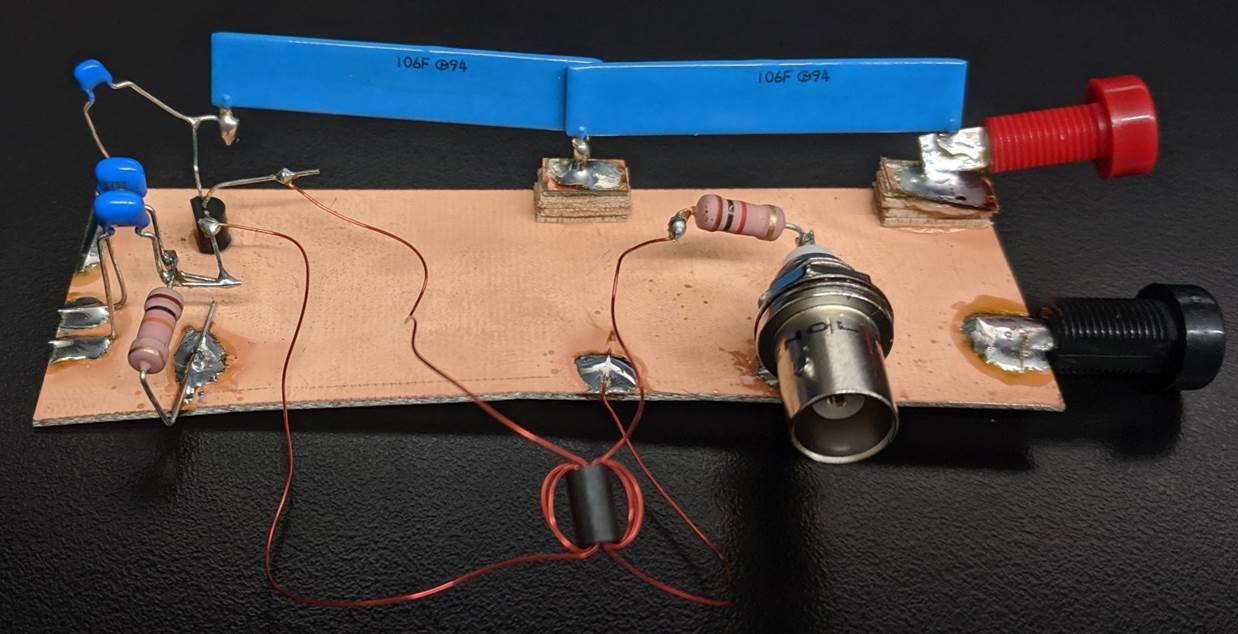

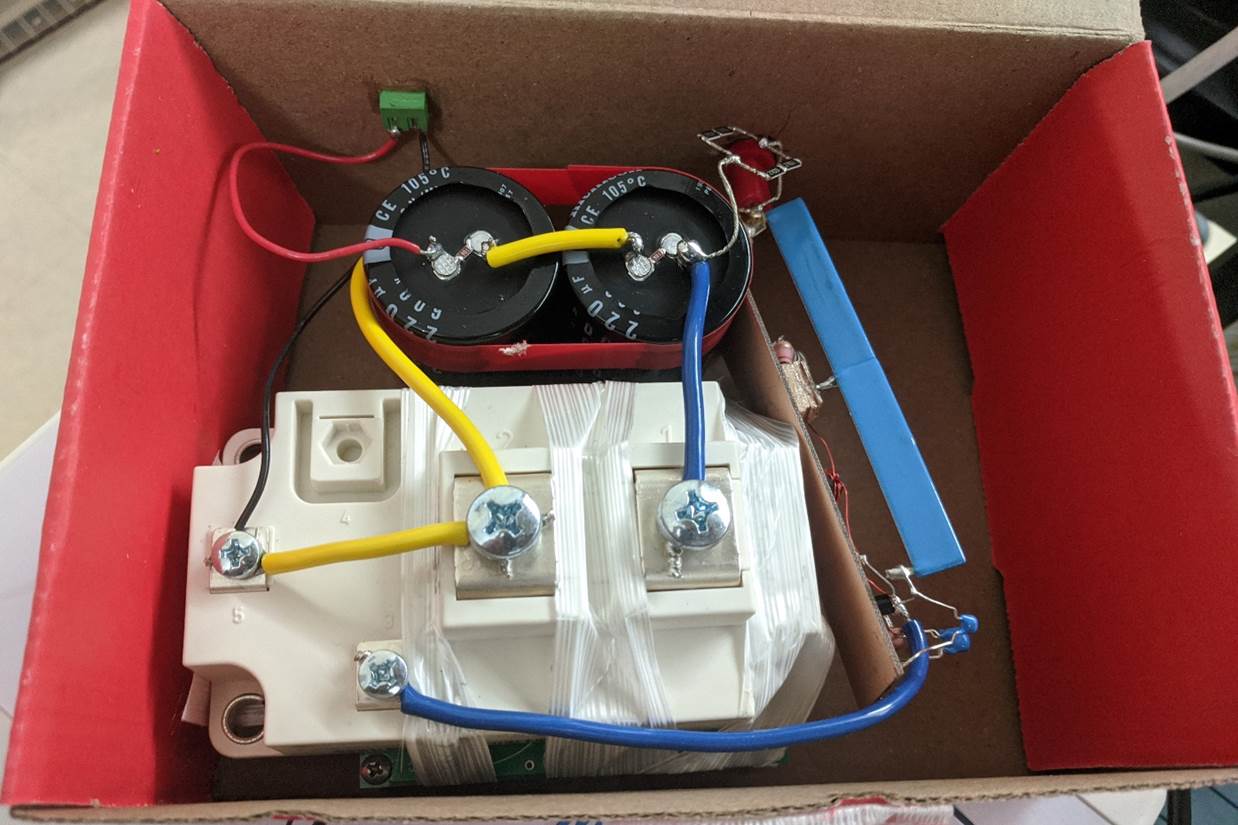

Finally comes the populating

part, where all the components get soldered onto the board.† The types of soldering jobs done usually

consist of through-hole and surface-mount devices (SMD).

∑

Below is a series of

pictures that show the finished boards that are ready for use. Note: If the PCB

was designed by Daniel, the subheading will contain a link with more

information about the design.

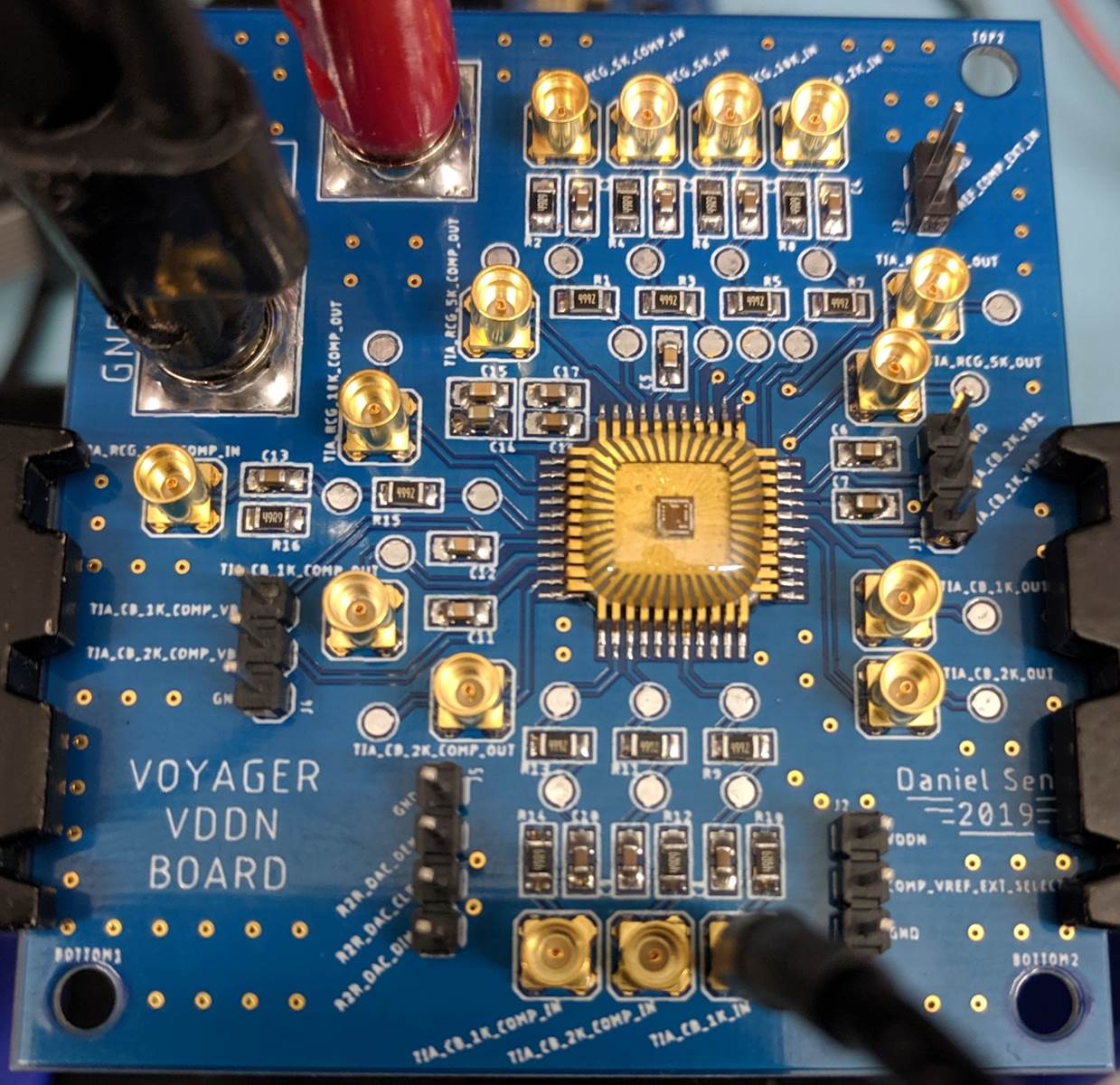

Voyager VDDN Board Assembled

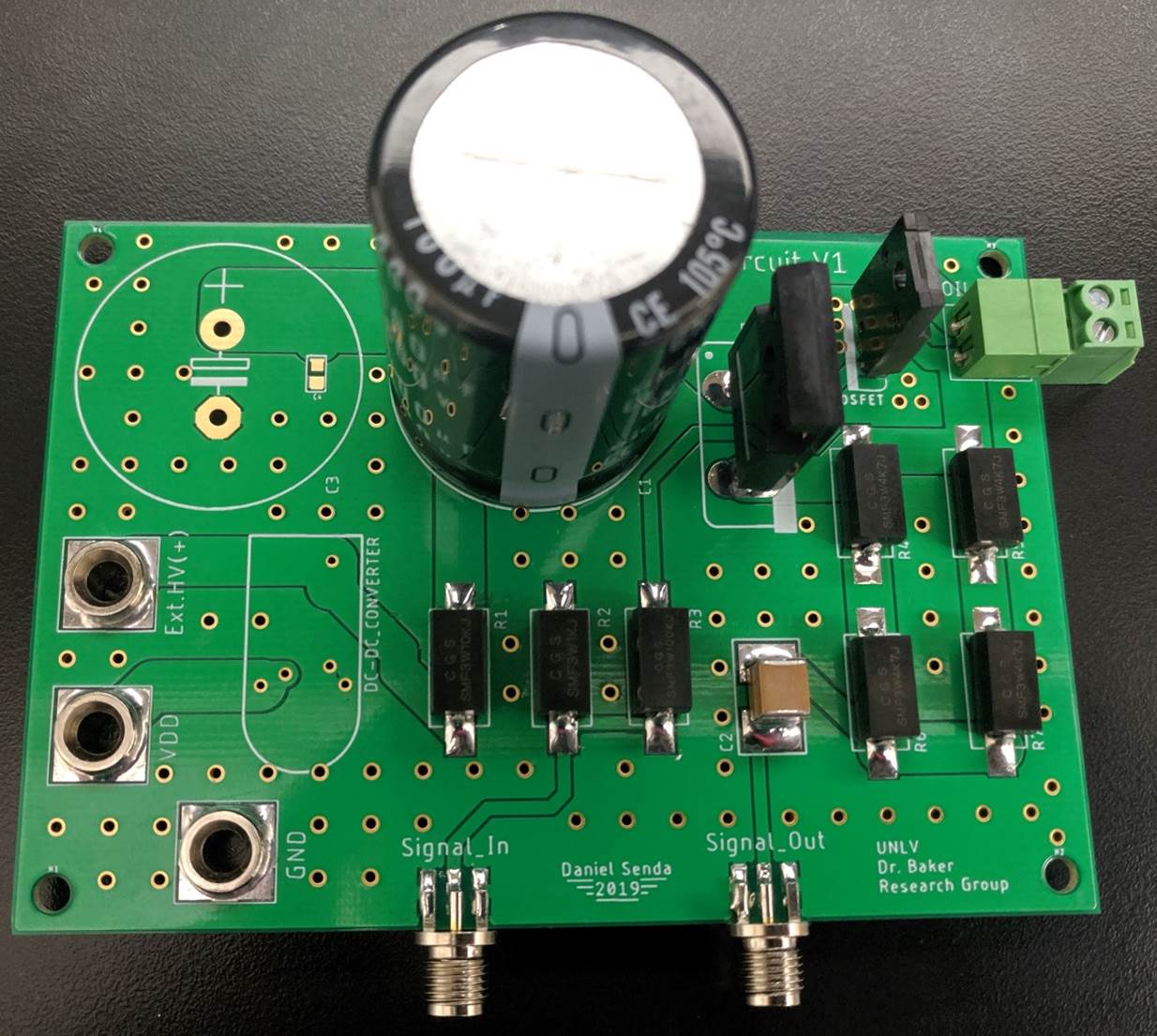

TMS V1

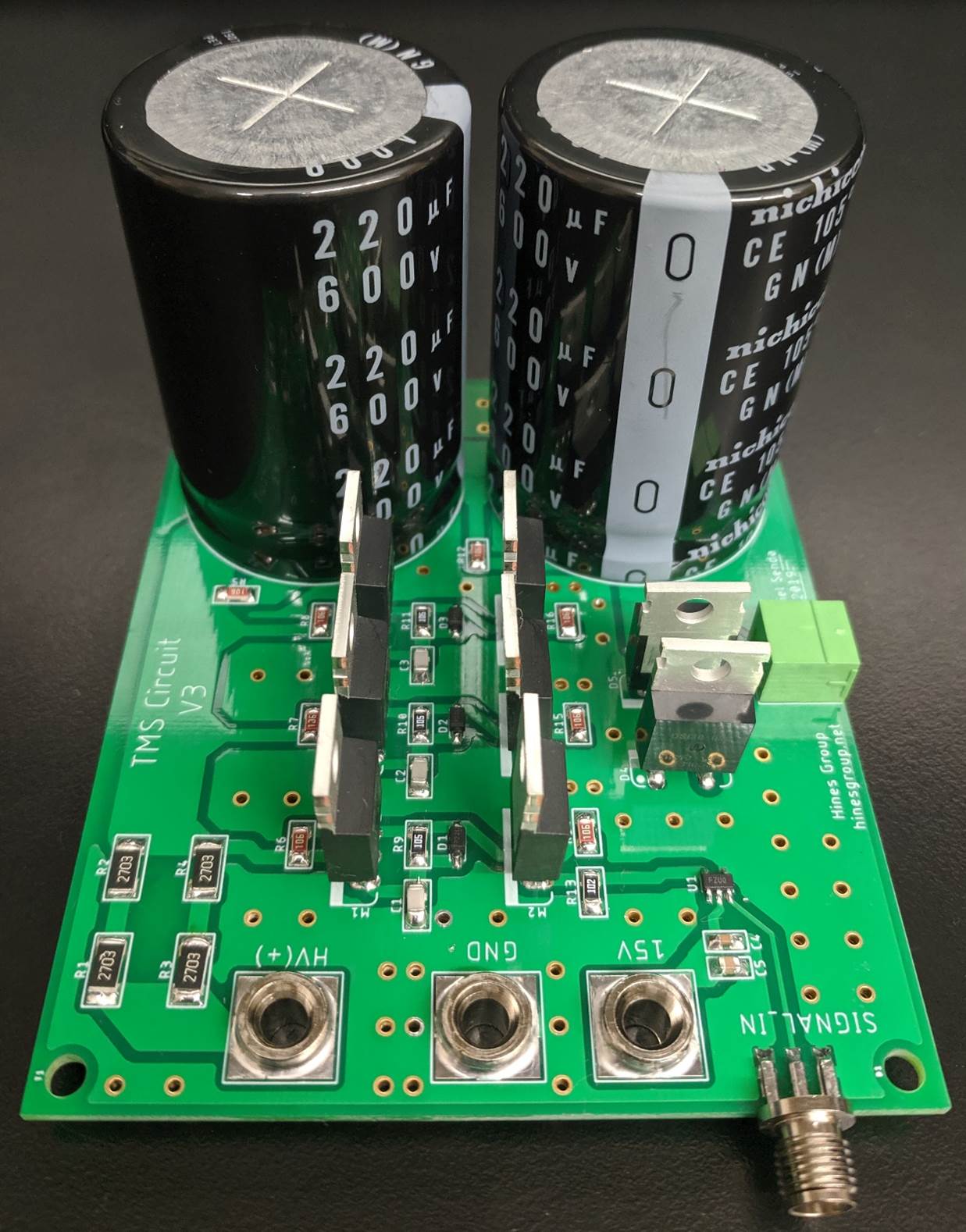

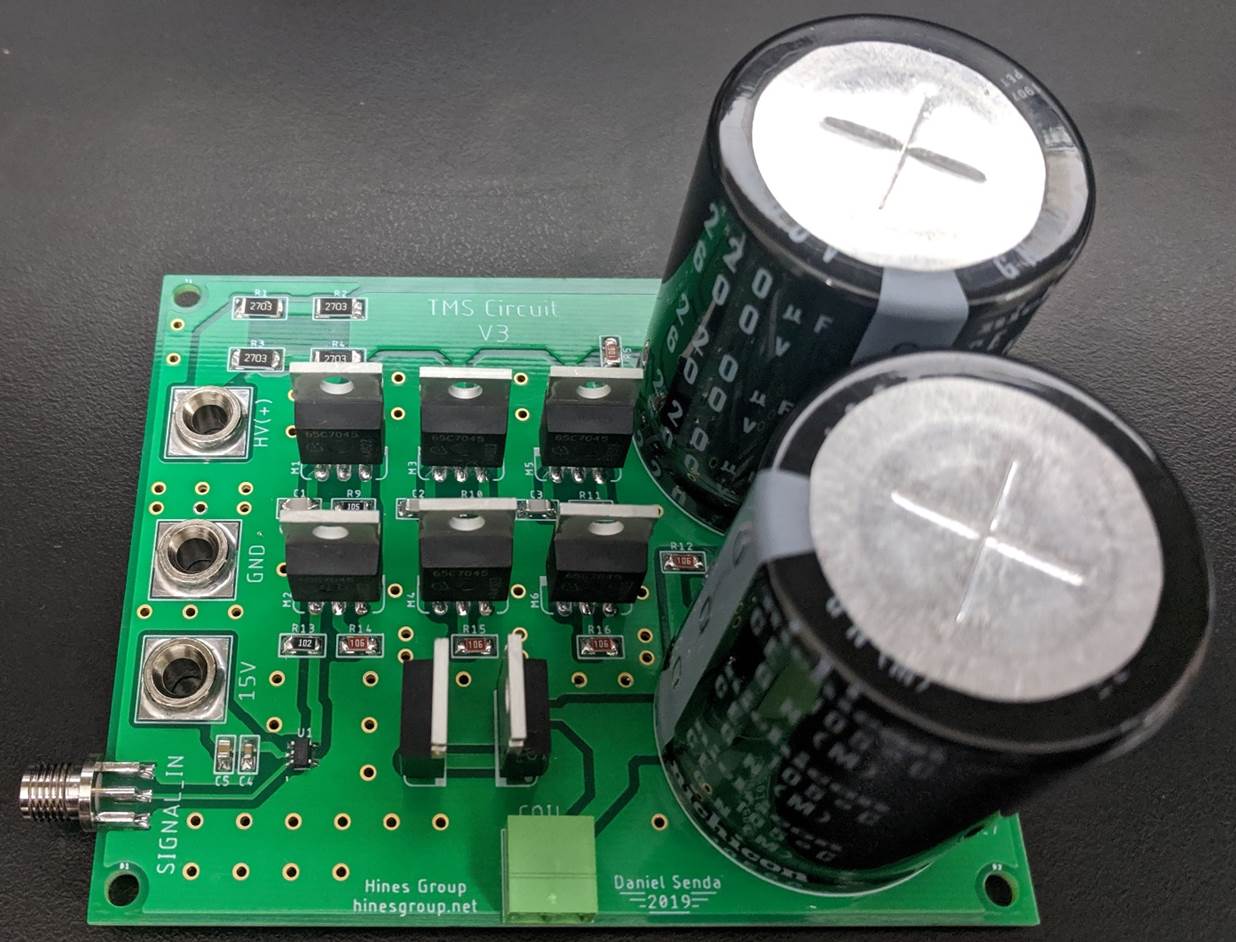

TMS

V3

Avalanche

Pulser

TMS

IBGT Prototype

Additional Links

††††††††††† →

Return to Danielís main page