Project - ECE 421L

Non-Inverting Buffer Circuit

Design a non-inverting buffer circuit that presents less than 100 fF input capacitance to

on-chip logic and that can drive up to a 1 pF load with output voltages greater than 7V (an output logic 0 is near ground

and an output logic 1 is greater than 7V). Assume VDD is between 4.5V and 5.5V, a valid input logic 0 is 1V or less, a valid

input logic 1 is 3V or more. Show that your design works with varying load capacitance from 0 to 1pF. Assume the slowest

transition time allowed is 4 ns.

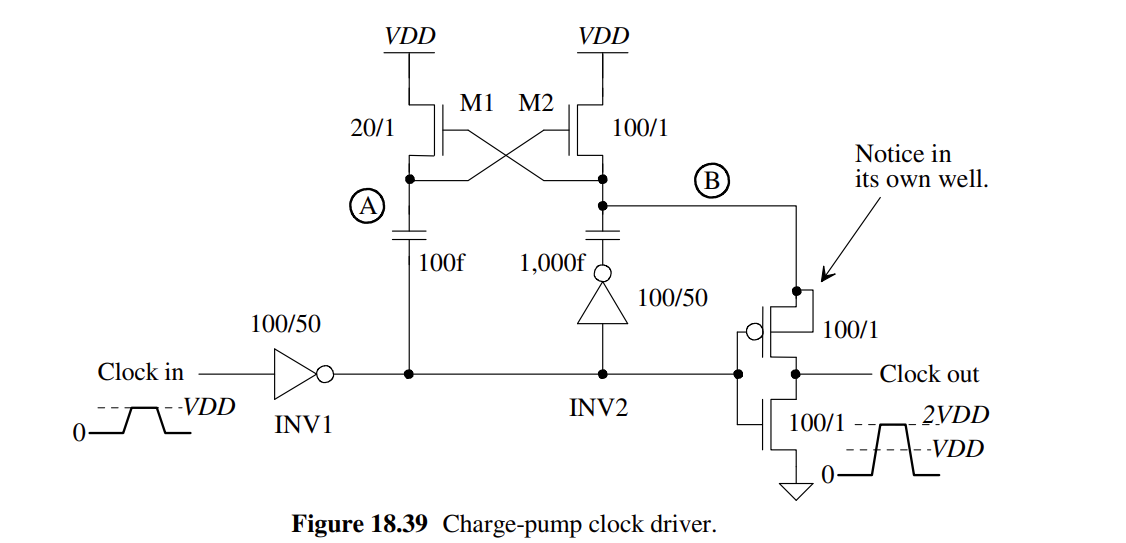

Intuitive Summary of How it Works:

- InputDesign Limitations and Considerations:

- Input Capacitance Constraint < 100fF

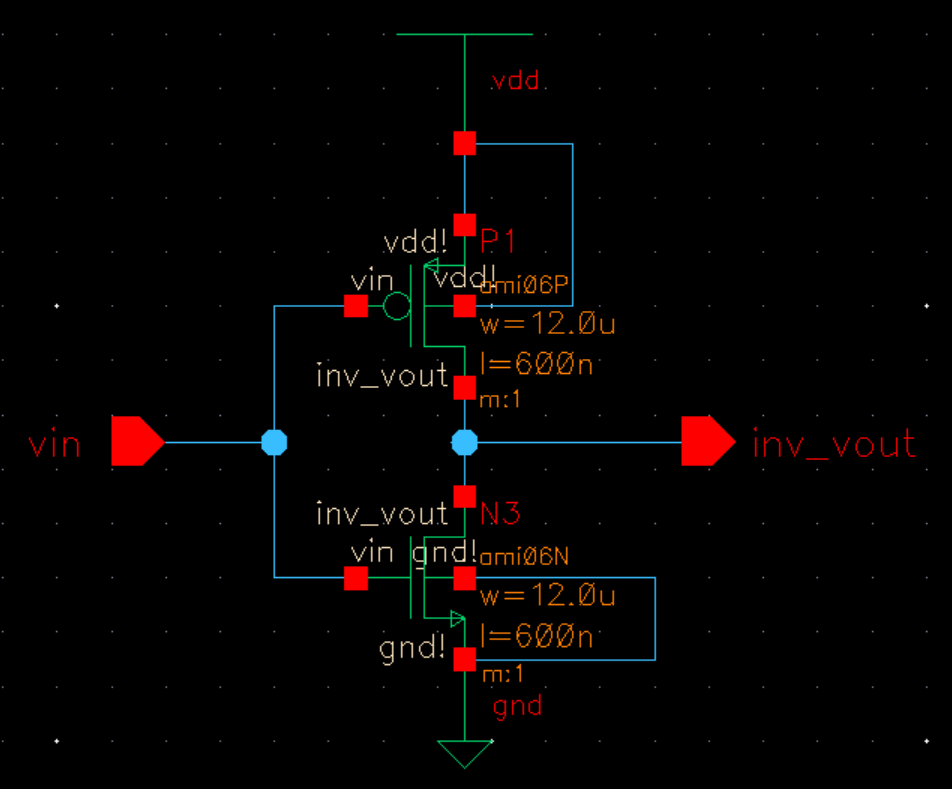

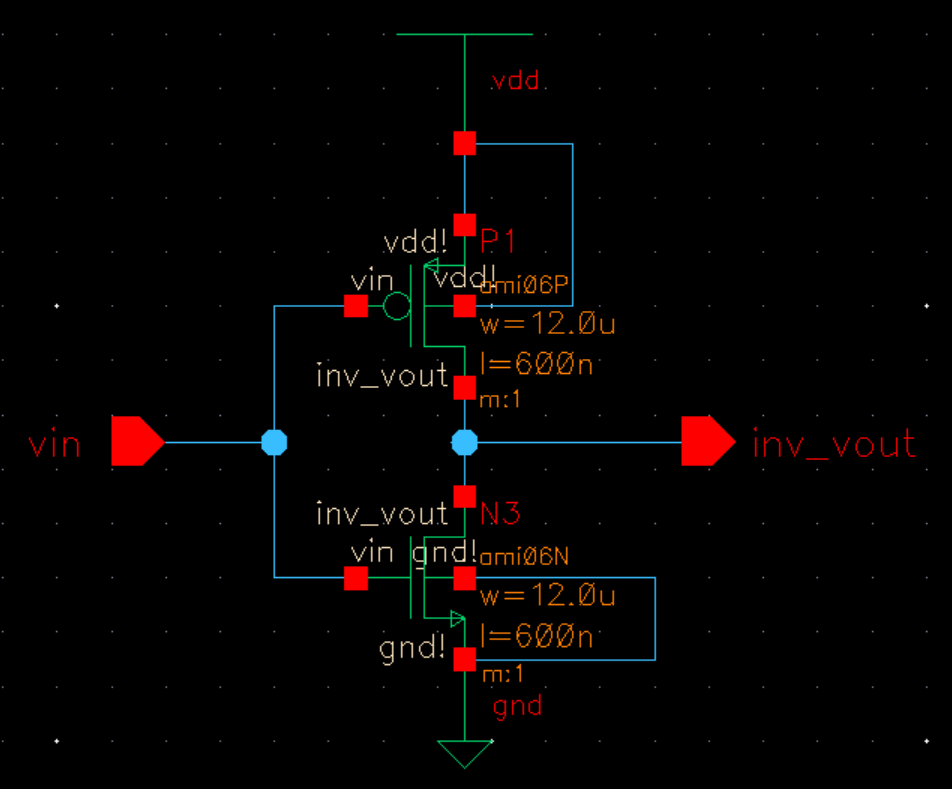

We must calculate the capacitance of the initial CMOS inverter to do this we can use the equation.

Cin = Cox' * (Wn * Ln + Wp * Lp)

For our Circuit & Inverter:

Cox' = 2.5fF/um^2

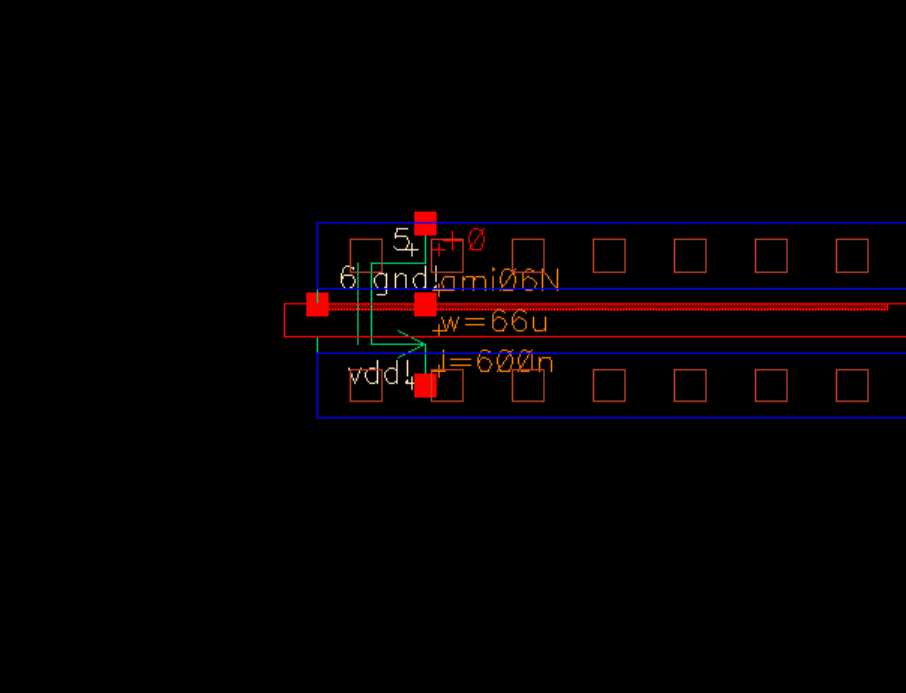

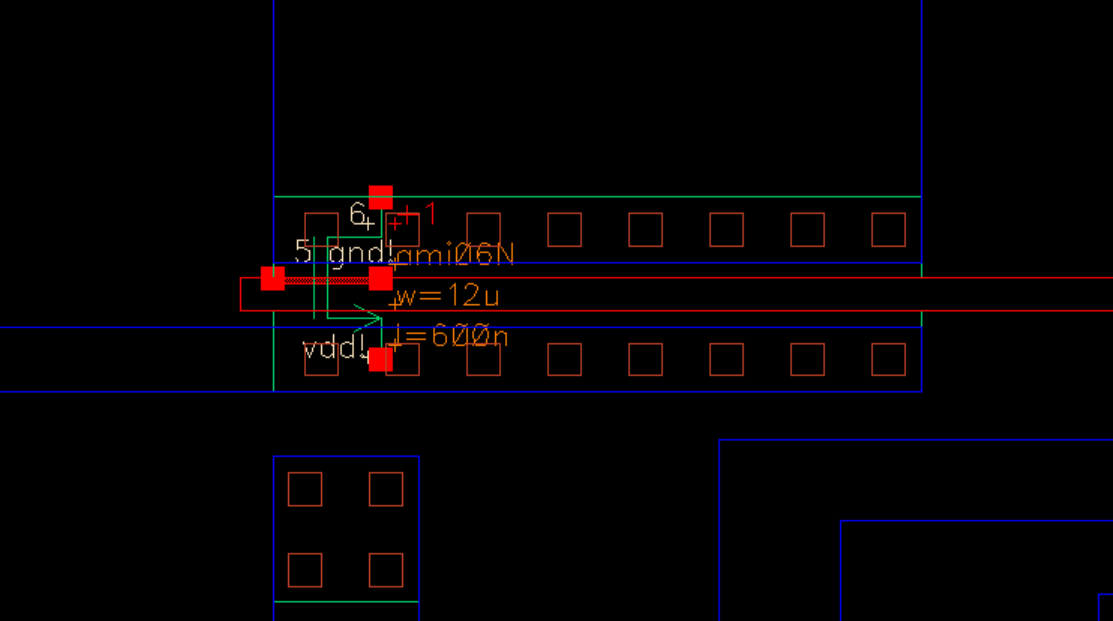

Wn = 12um (NMOS width)

Wp = 12um (PMOS width)

L = 600n (NMOS & PMOS length respectively)

So our input capacitance ends up being 36fF which is under the 100fF restriction thus it meets the requirements.

- Driving 0 to 1 pF capacitor and 4.5 to 5.5VDD range

Driving a Capacitor will lower Vout in accordance to how big the capacitance is, since in our design the output minimum is 7v we must ensure that driving the capacitance of 1pF won't lower our output below 7v.- Input Logic Low and High Limits

For this circuit 0-1v must be considered as input low and 3-5v must be considered as input high, for this to occur we must alter the width ratio of the

initial NMOS PMOS Inverter, to lower the minimum required input max voltage to accept at least 3v as input high we must increase Beta(N) which simply means as the NMOS width increases against the PMOS the lower Vin has to be to activate the inverter. Having the width of both NMOS and PMOS be 12u case a value where with 5.5vdd the switching point was still below 3v for voltage high while maintaining 1v as LOW. Switching point can be calclualted by the following formula

Vsp = (sqrt(Bn/Bp*VTHN+(VDD-VTHP))/(1+sqrt(Bn/Bp))

Our values are:

Rn' = 20k

Rp' = 40k

Cox' = 2.5fF/um^2

Wn=Wp=12um

L=0.6um

Which provides sufficient room switching point of 3v for HIGH.

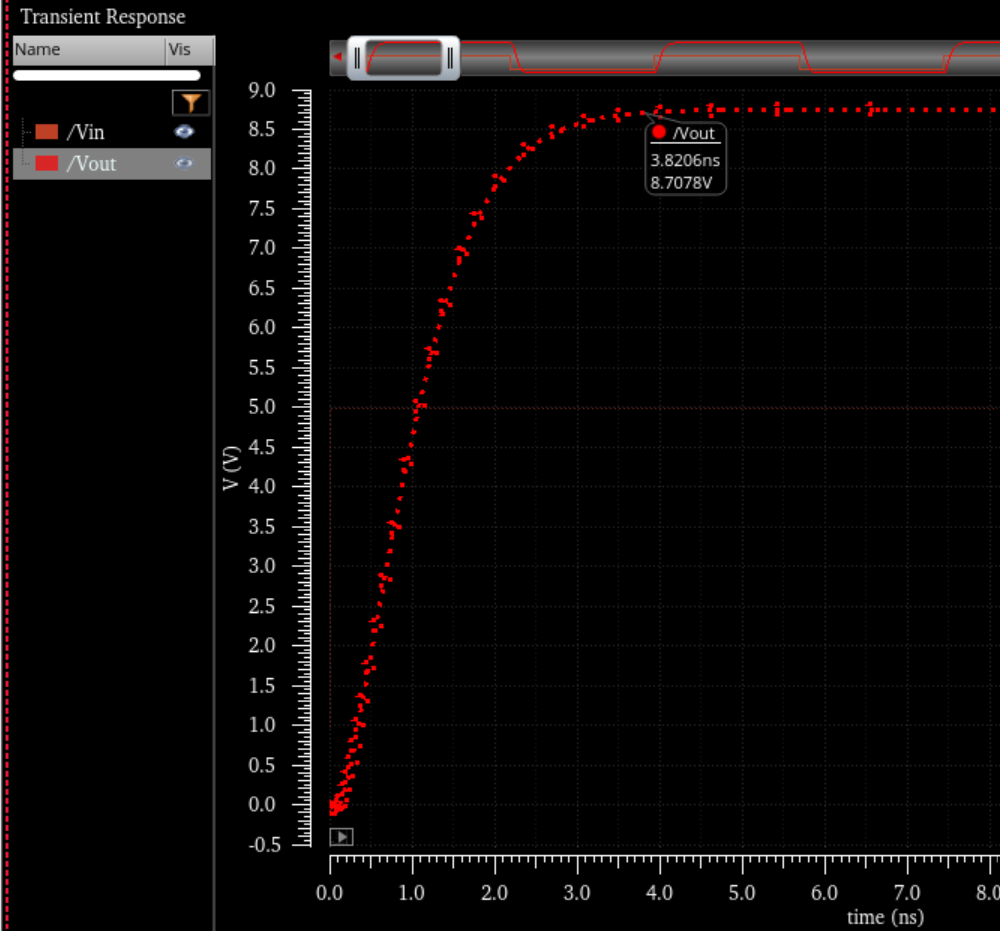

- 4ns Maximum Transition Time

The transition delay is based on the load capacitance and the sizes of the NMOS and PMOS transistors on the inverter, in this design the delay max is 4ns.- Other considerations

Transistor sizing:

It

is important for transistors to be large enough to drive enough current

through them this is especially important for the PMOS in the output

inverter as it has to drive 2VDD to the output, with its width also

reducing resistance which reduces the delay. However Sizing it too

large will increase the capacitance which is why the input inverter

cannot have NMOS and PMOS transistors that are too large to keep the

input capacitance low and waste power. But also having greater width

can decrease resistence which will in turn reduce delay in most cases

so it important to consider it on a case by case basis.

Capacitor Sizing:

In

this design I opted to use MOSFET's in strong inversion as the

capacitance to have a more compact layout size. Strong inversion

requires that VGS being greater than VTH, electrons will become

attracted together and short the drain which will result in a plate

forming for a capacitor.

The capacitance per area is greater than a poly capacitor, this is because MOSFETs

Cox'(2.5/um^2) capacitance per area is much higher than the poly capacitor's.

C0 = 1.1pF = 2.5fF/um^2 * Wl * Wn

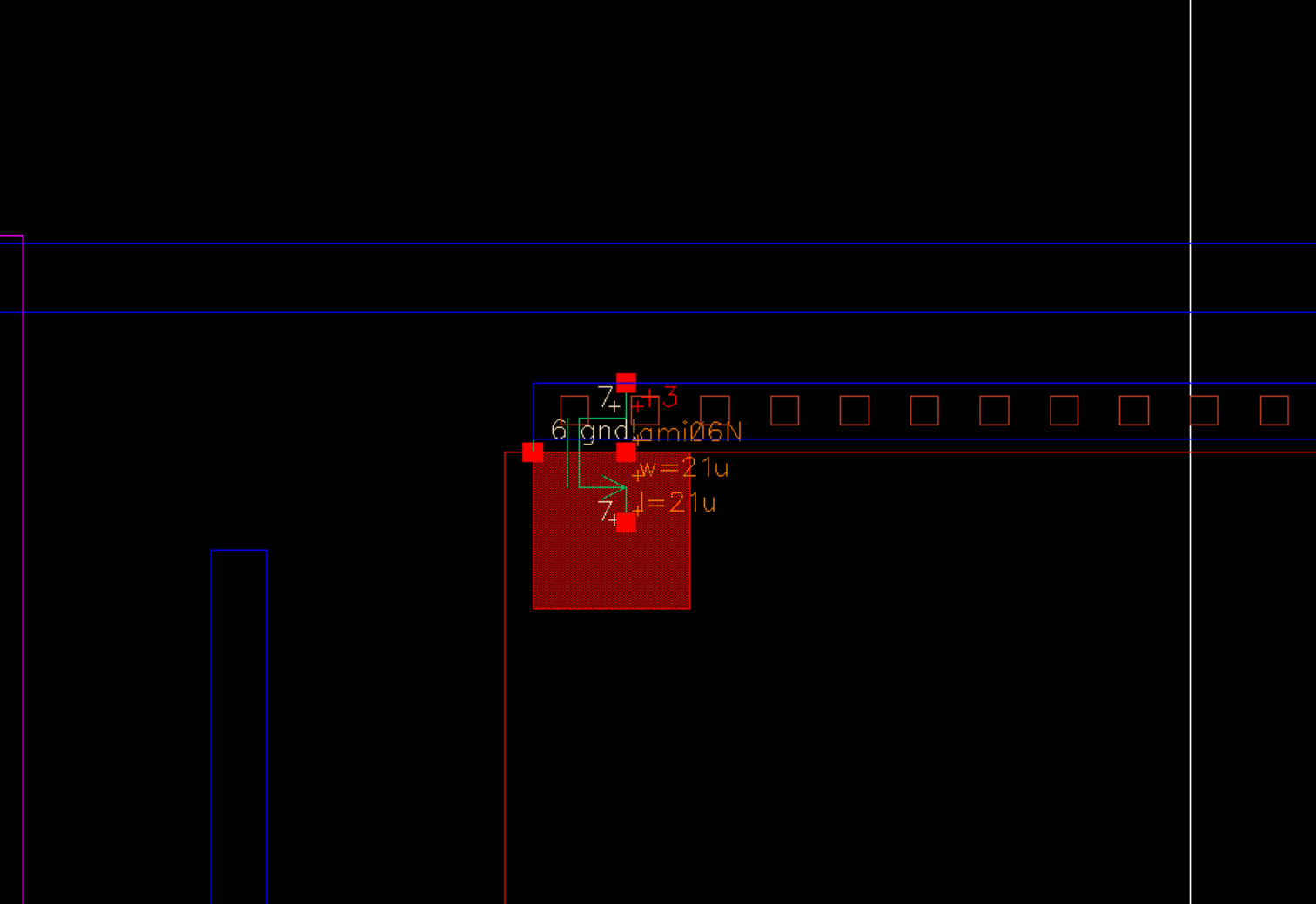

Wn & Wl=~ 21um;

C1 = 9pF = 2.5fF/um^2 *Wl um * Wn

Wn & Wl = 60um

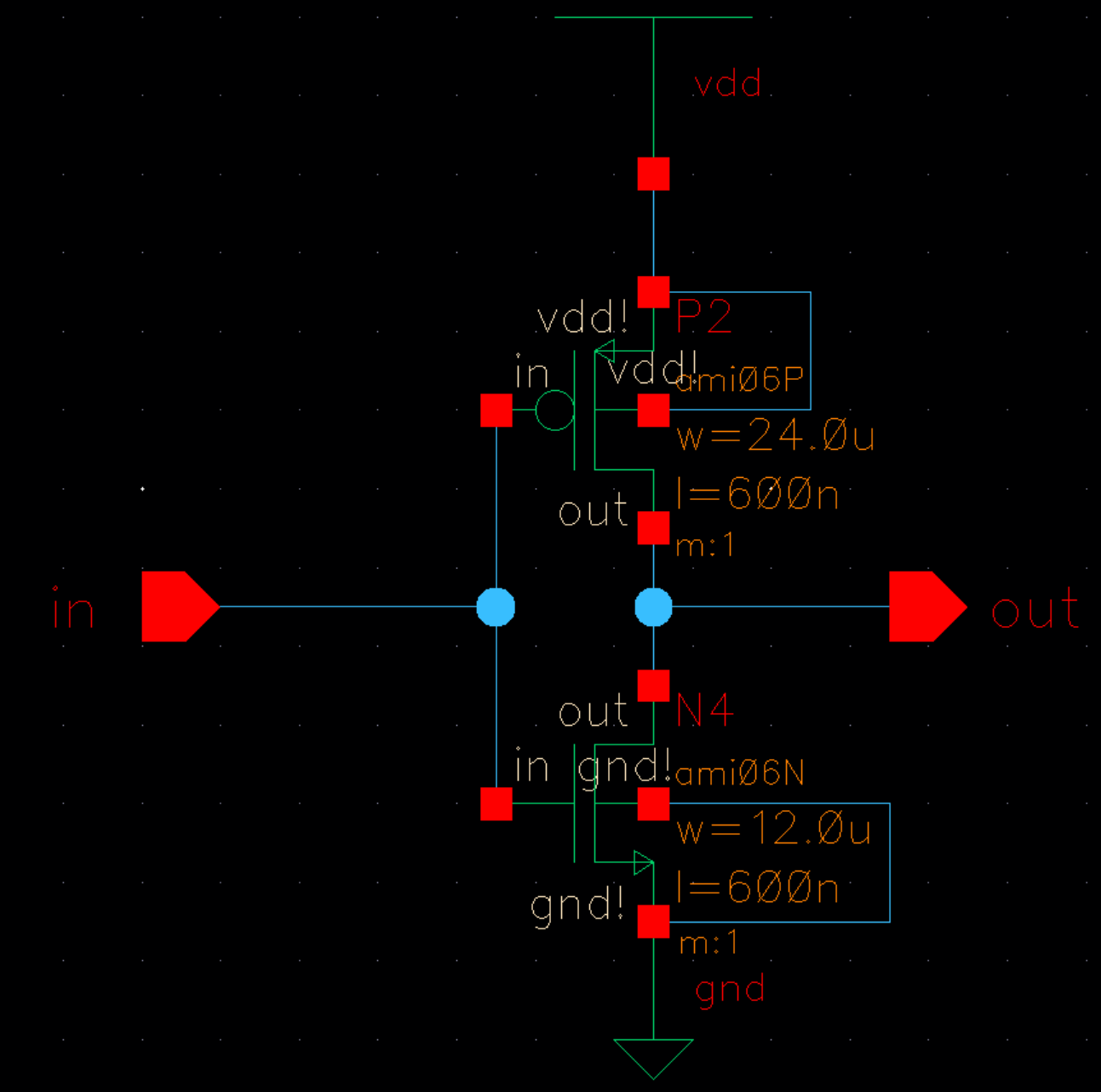

Inverter 2 Sizing:

Since inverter 1 takes care of the 1v max LOW extreme and the 3v min HIGH extreme the switching point can be set to 2.5V as that is half of

our standard VDD.

Simulatons:

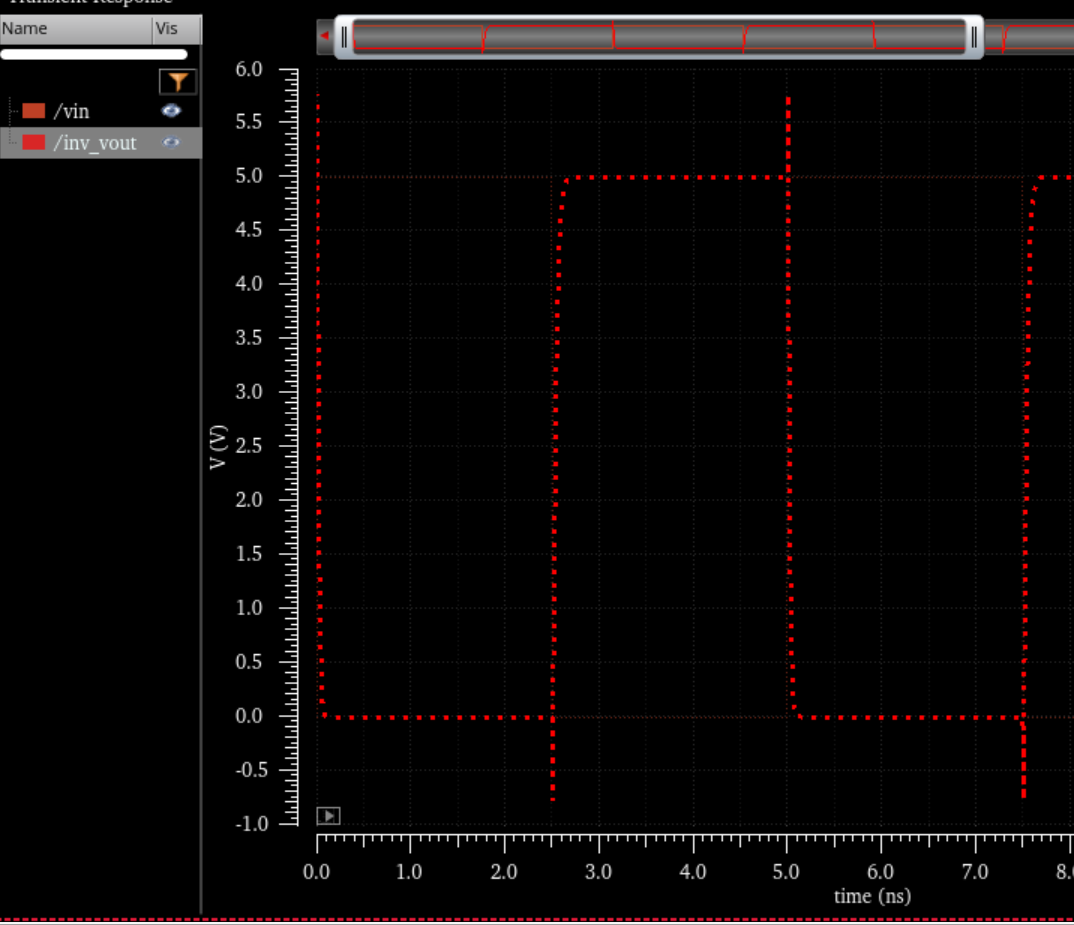

Input Inverter:

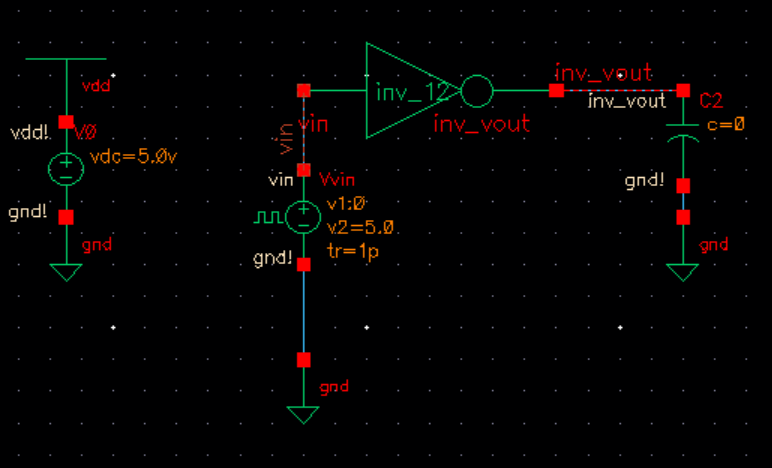

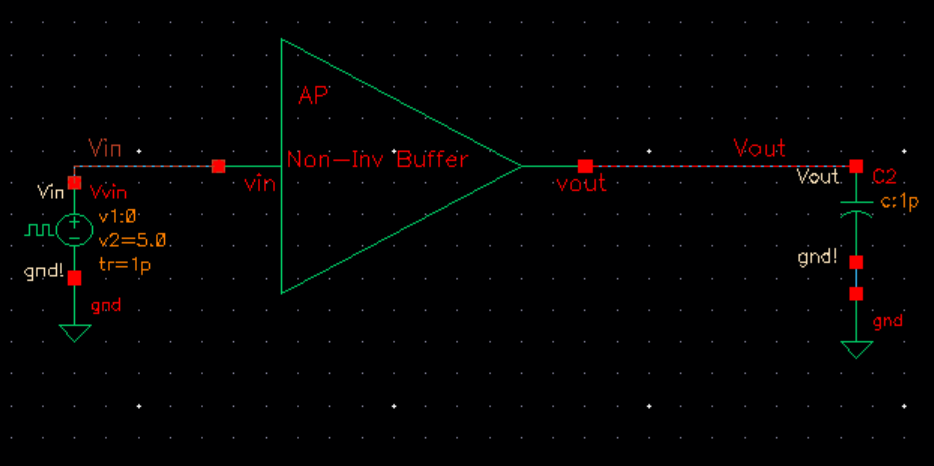

This is our sim Circuit for the first inverter:

During Normal Operation the inverter Runs Smoothly

During Normal Operation the inverter Runs Smoothly

When simming we can see the extremes of 1vin max of low to 3vin min of high does register as a output high VDD and output Low as expected and in turn this means the entire circuit will operate within the range of 0-1vin LOW and 3-5vin HIGH which meets the requirements.

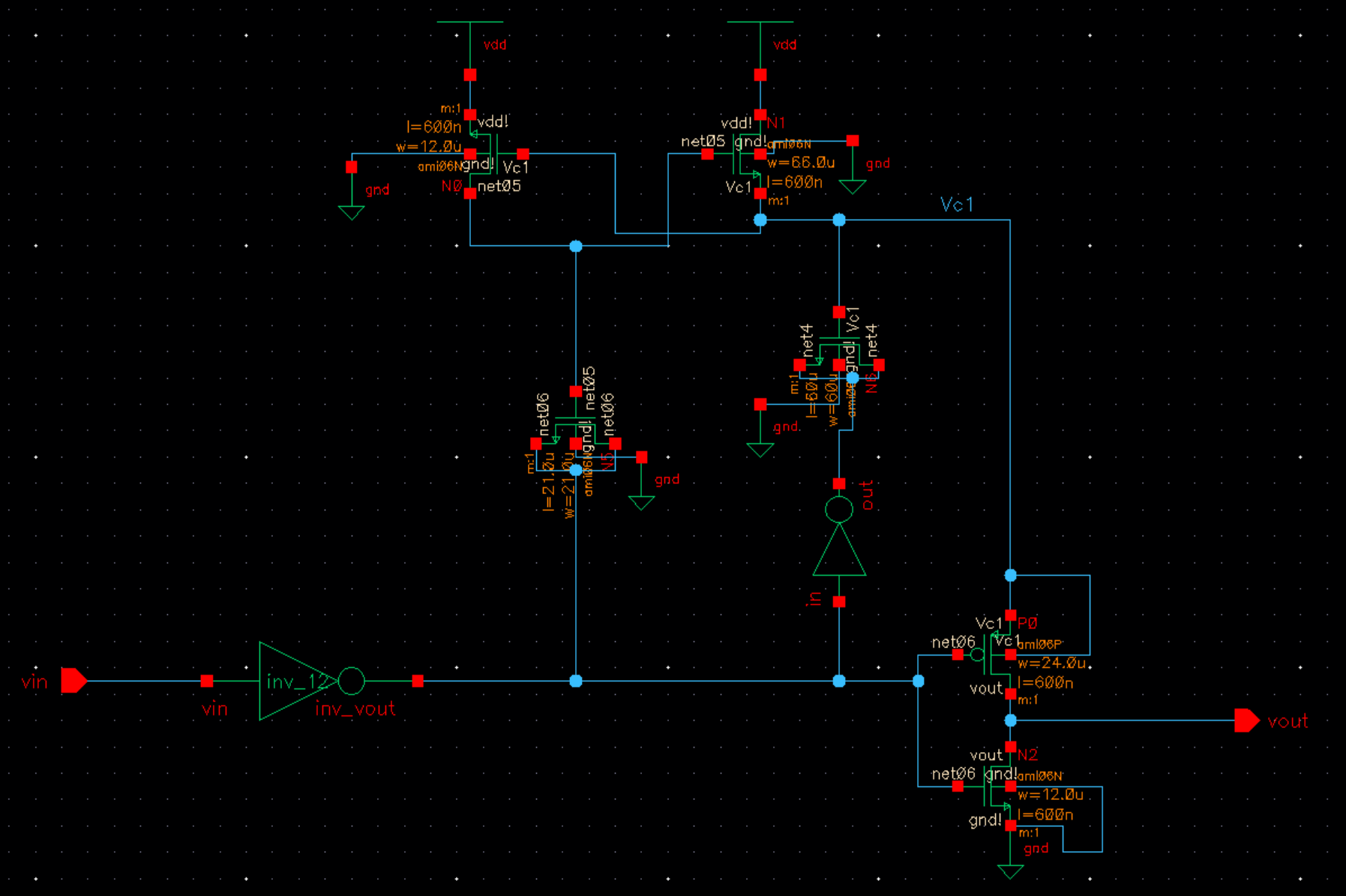

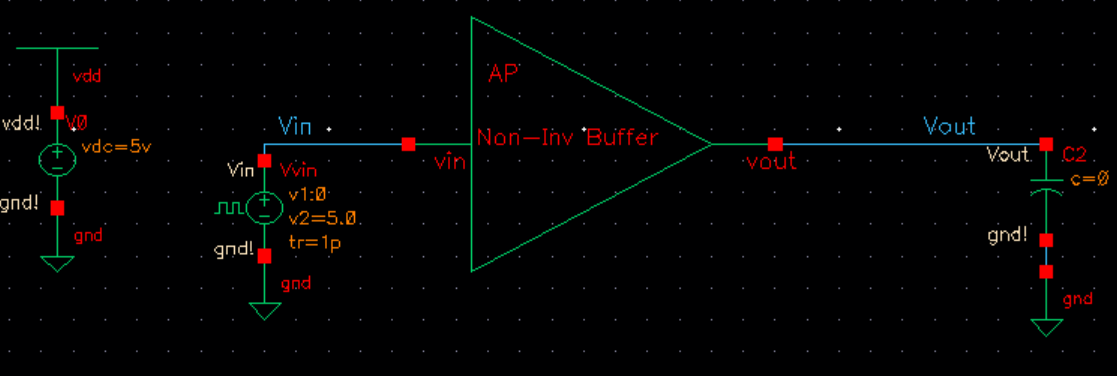

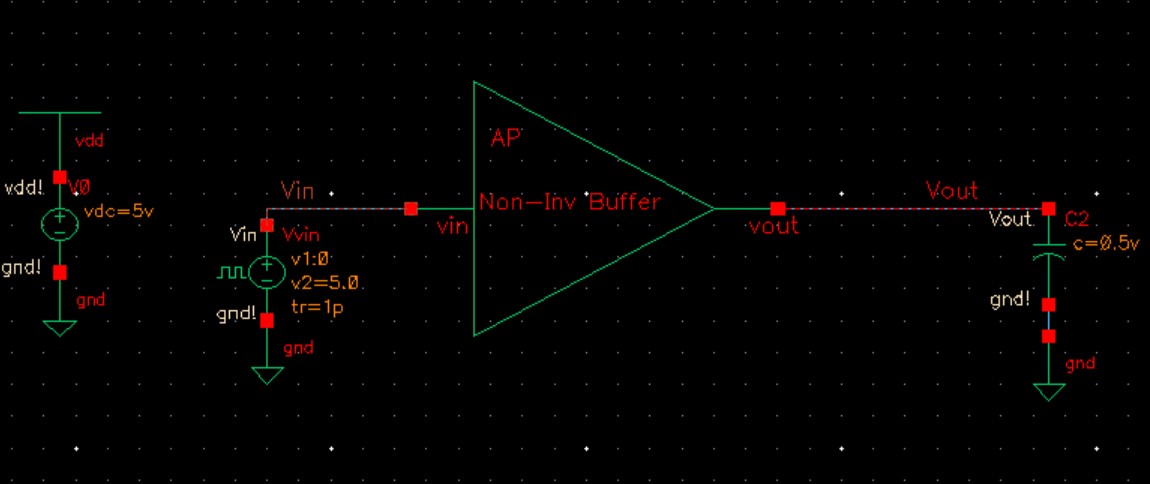

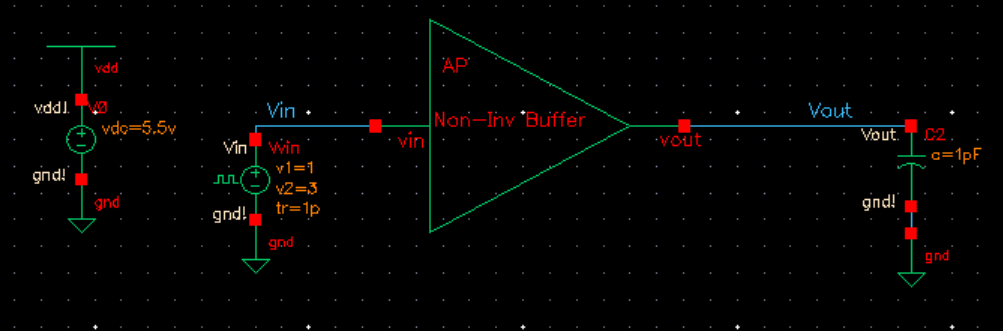

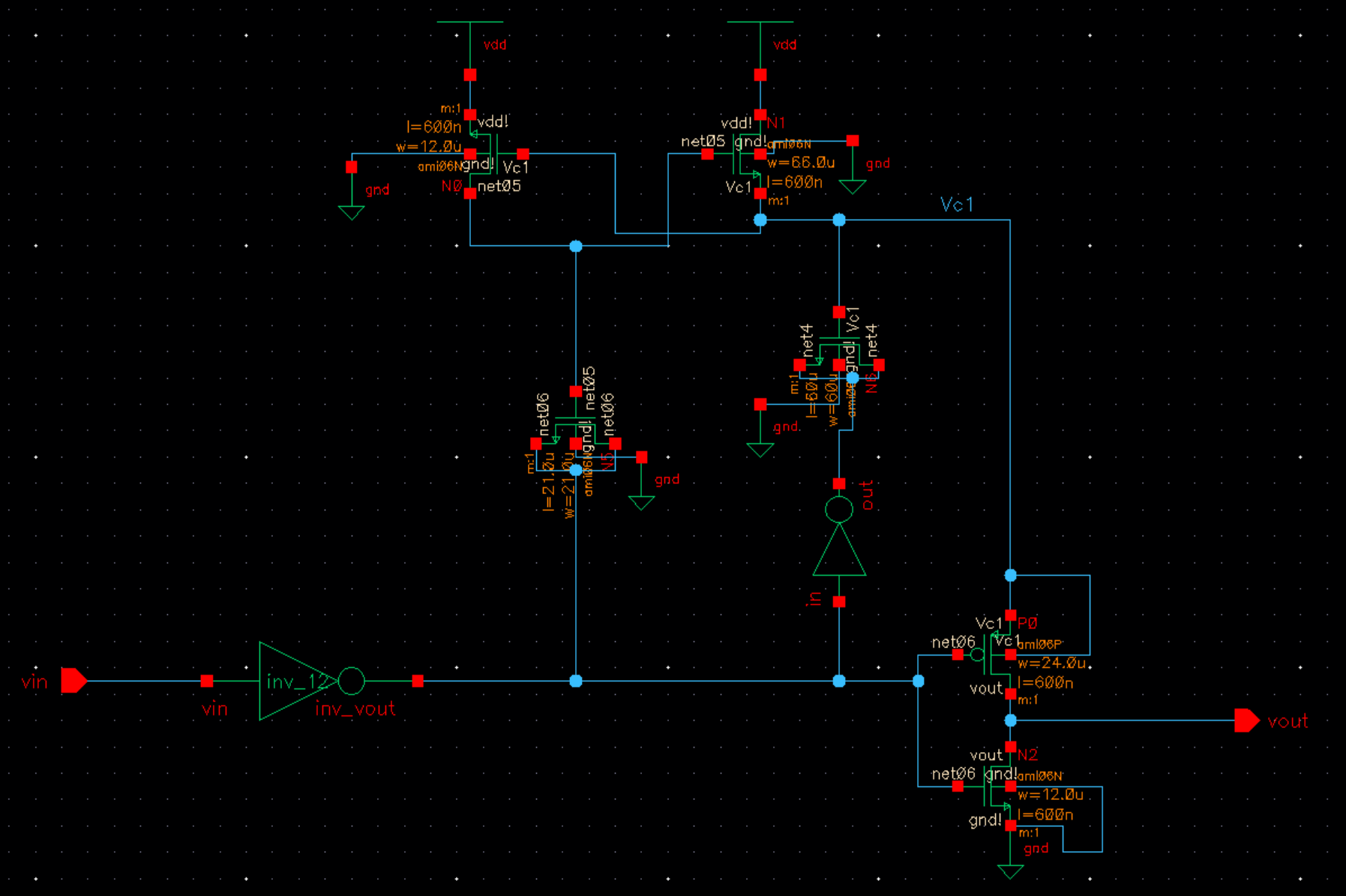

Main Circuit: Non-Inverting Buffer:

Second Inverer Schematic, the input inverter schematic can be found earlier in the report:

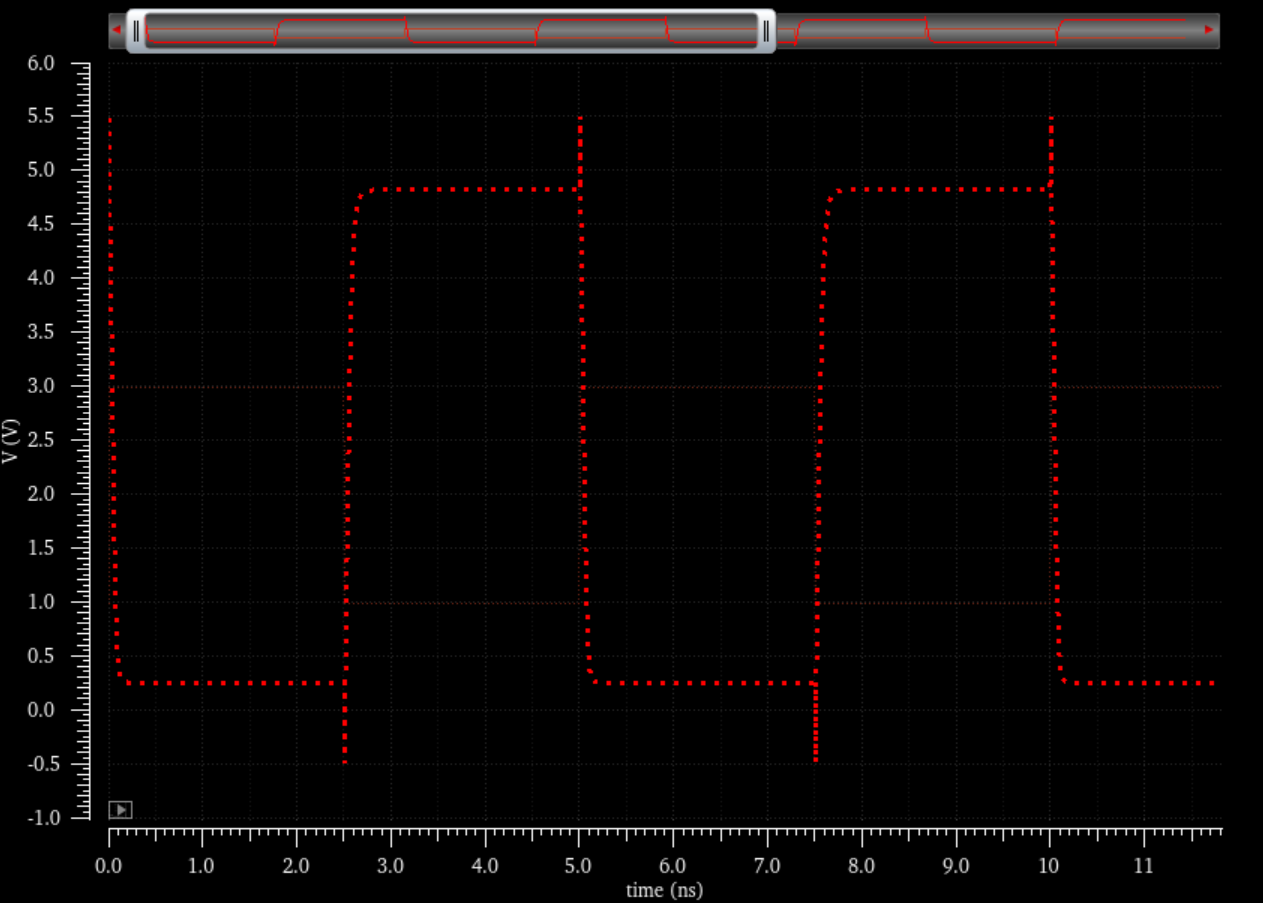

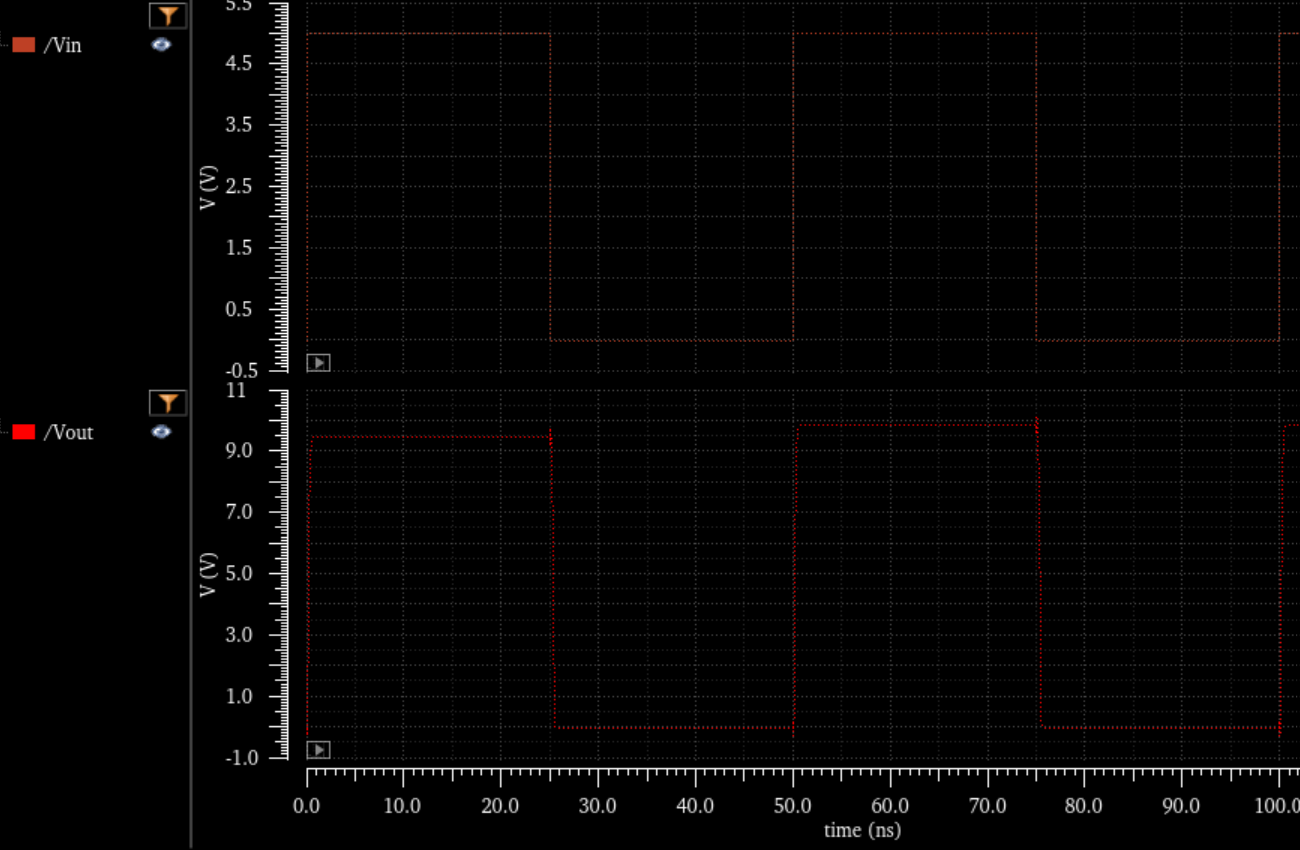

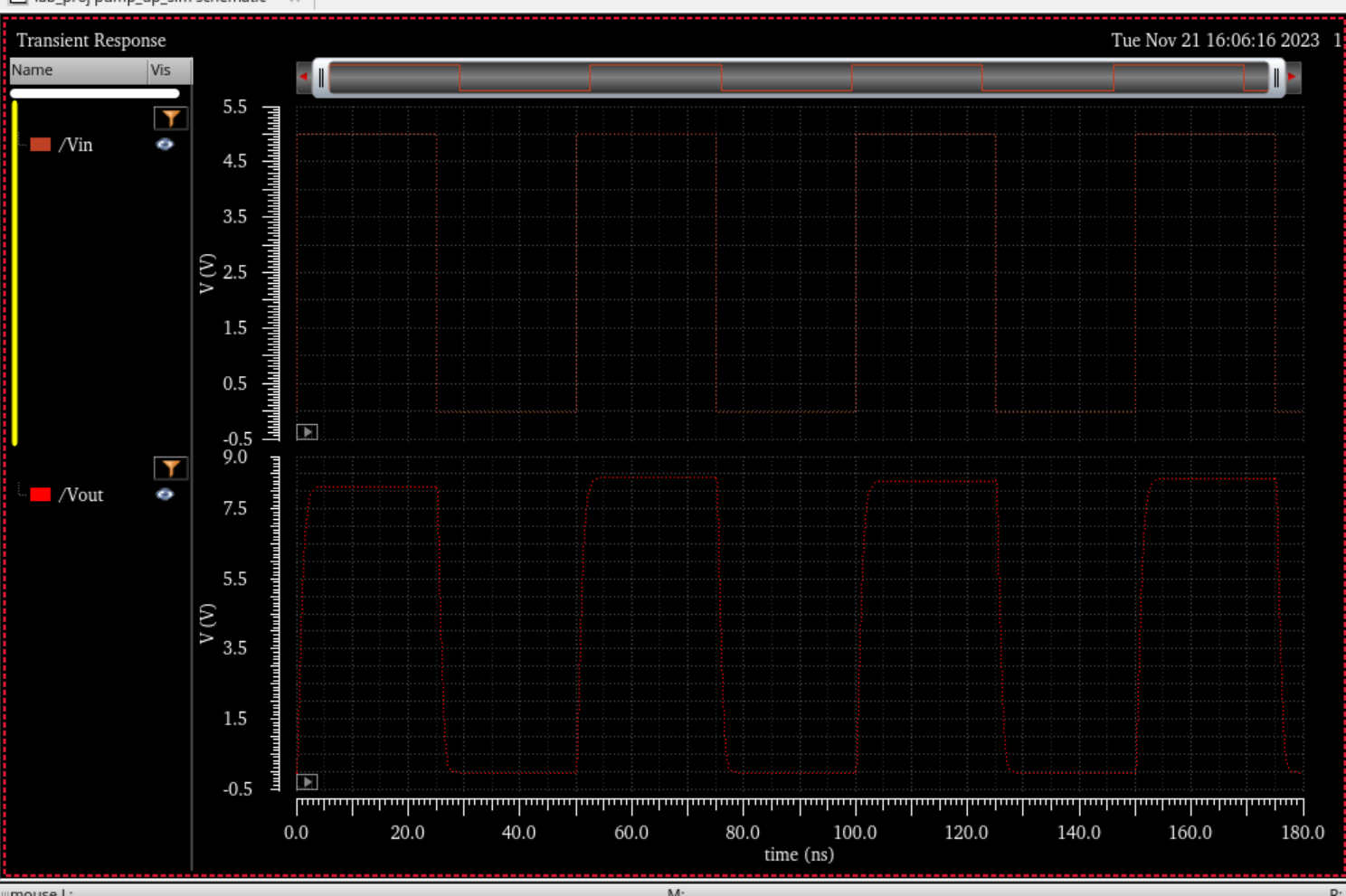

Lets do an Ideal Condition Simulation:

VDD: 5v Vin 0v-5v Load Cap = 0pF

VDD: 5.5v Vin 0v-5v Load Cap = 0pF

VDD: 4.5v Vin 0v-5v Load Cap = 0pF

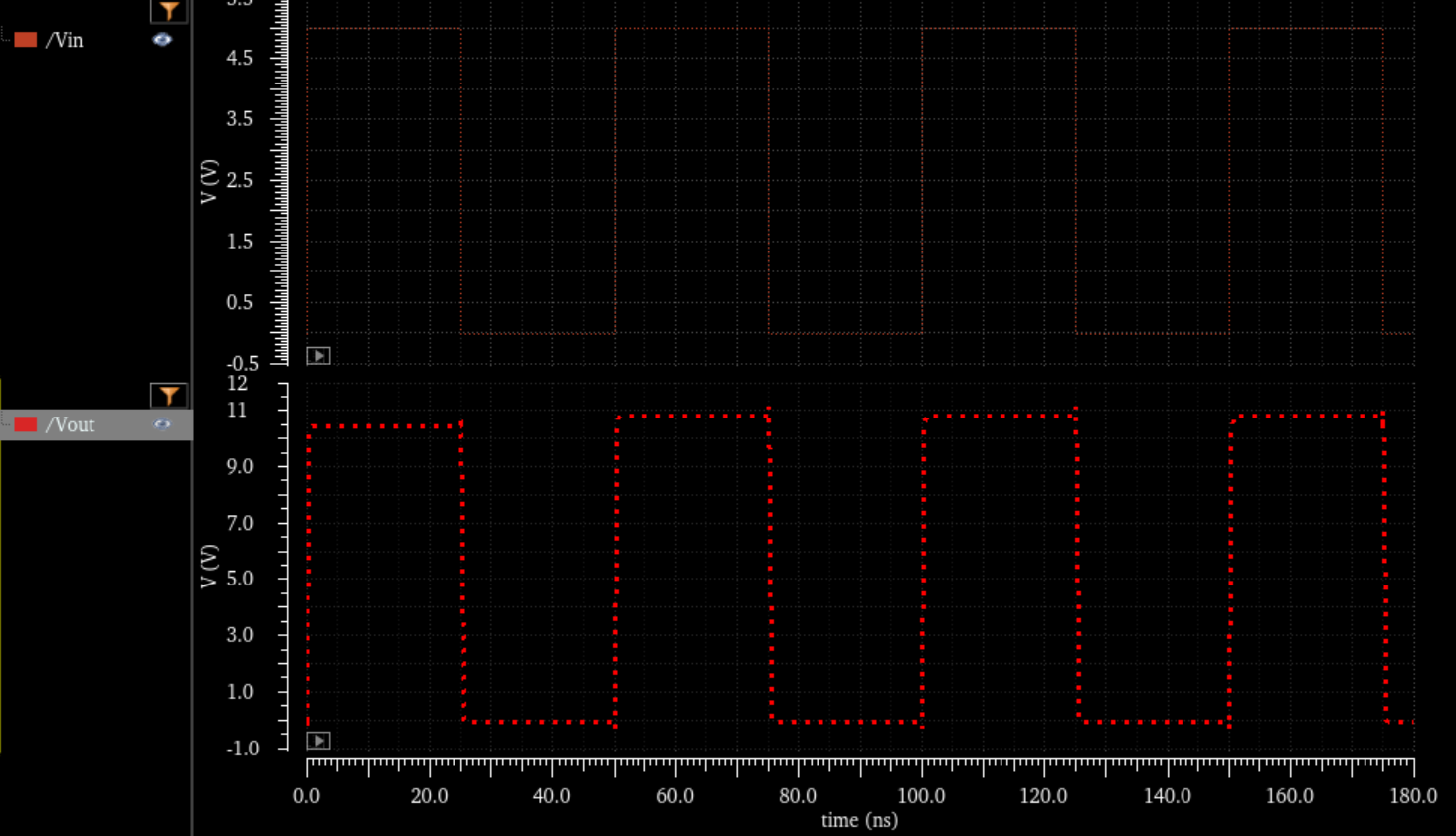

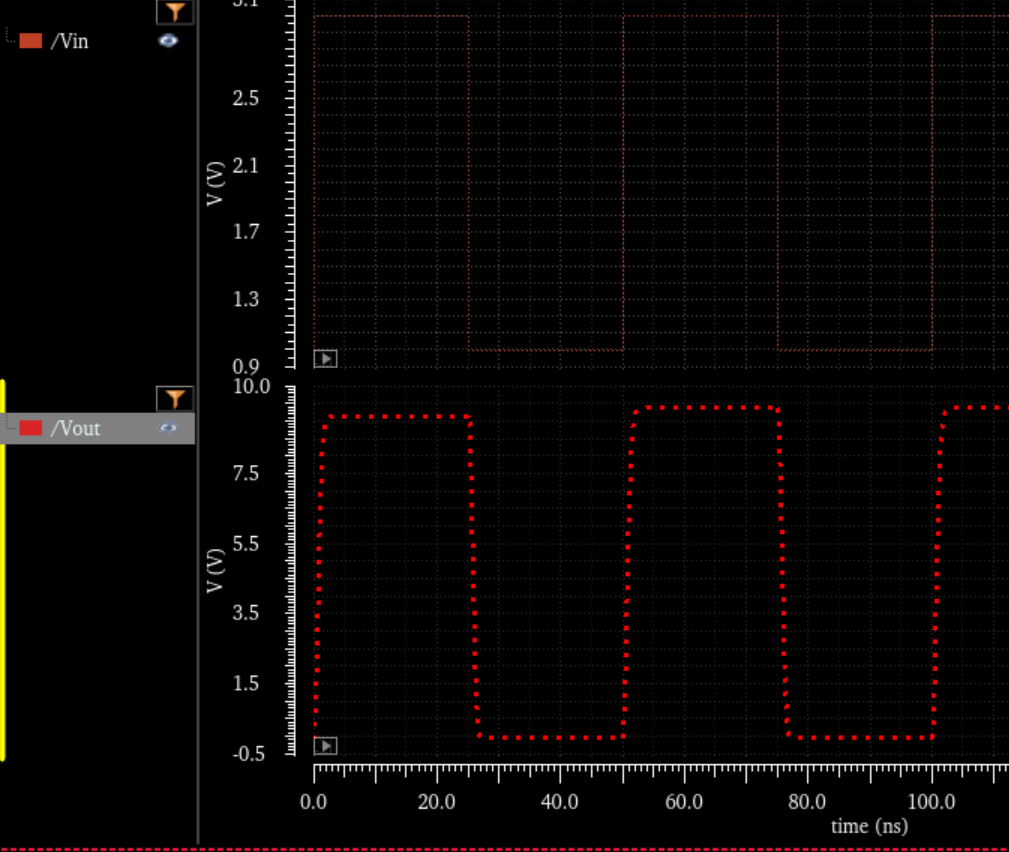

Now Lets try with a Load Capacitor:

VDD: 5v Vin 0v-5v Load Cap = 1pF

VDD: 4.5v Vin 0v-5v Load Cap = 1pF

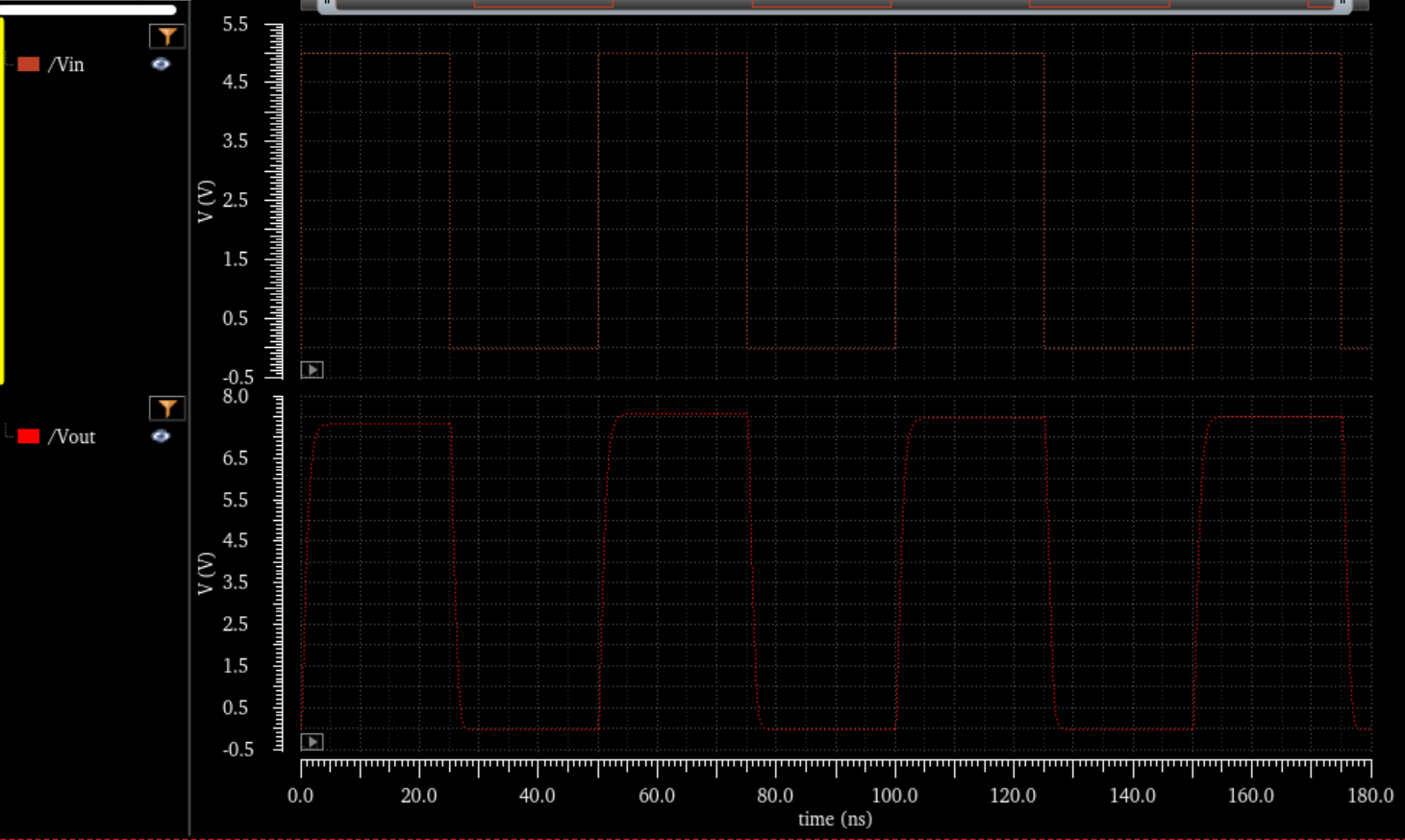

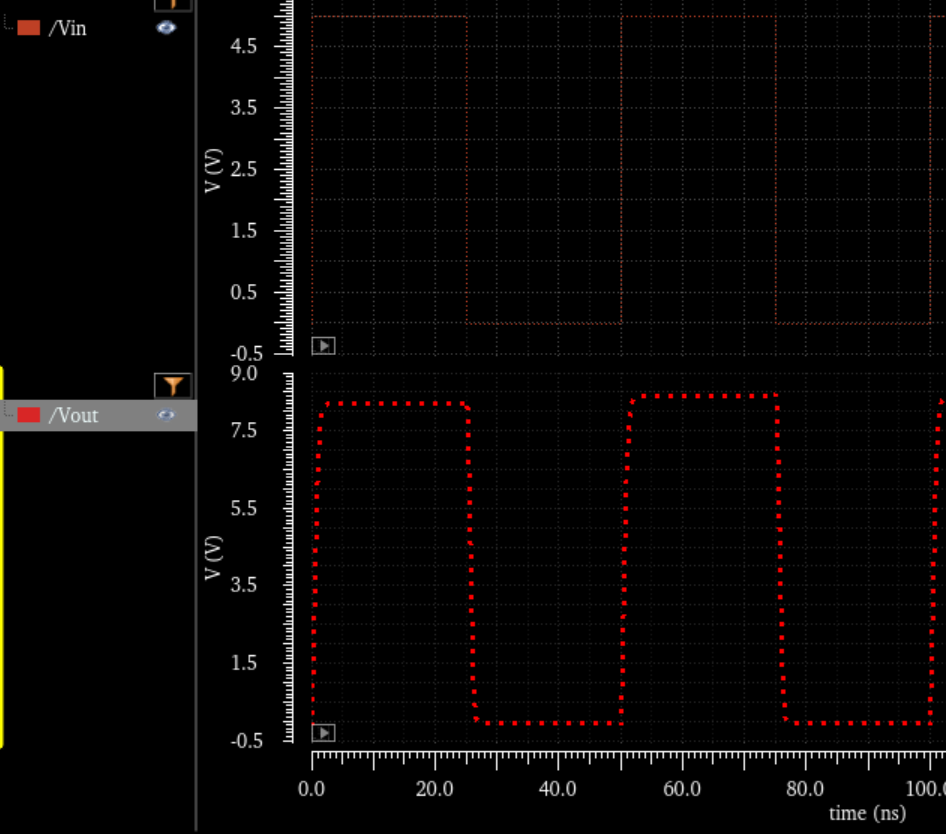

Now We will try with 0.5pF

VDD: 5v Vin 0v-5v Load Cap = 0.5pF

VDD: 4.5v Vin 0v-5v Load Cap = 0.5pF

VDD: 5.5v Vin 0v-5v Load Cap = 0.5pF

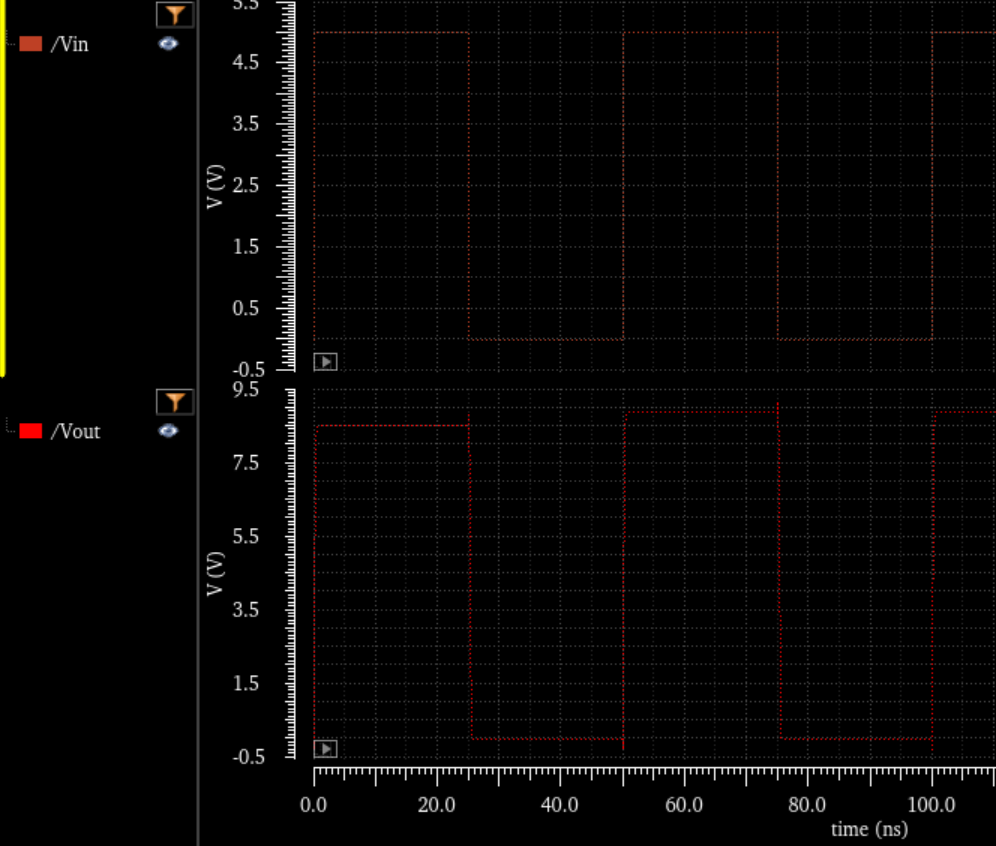

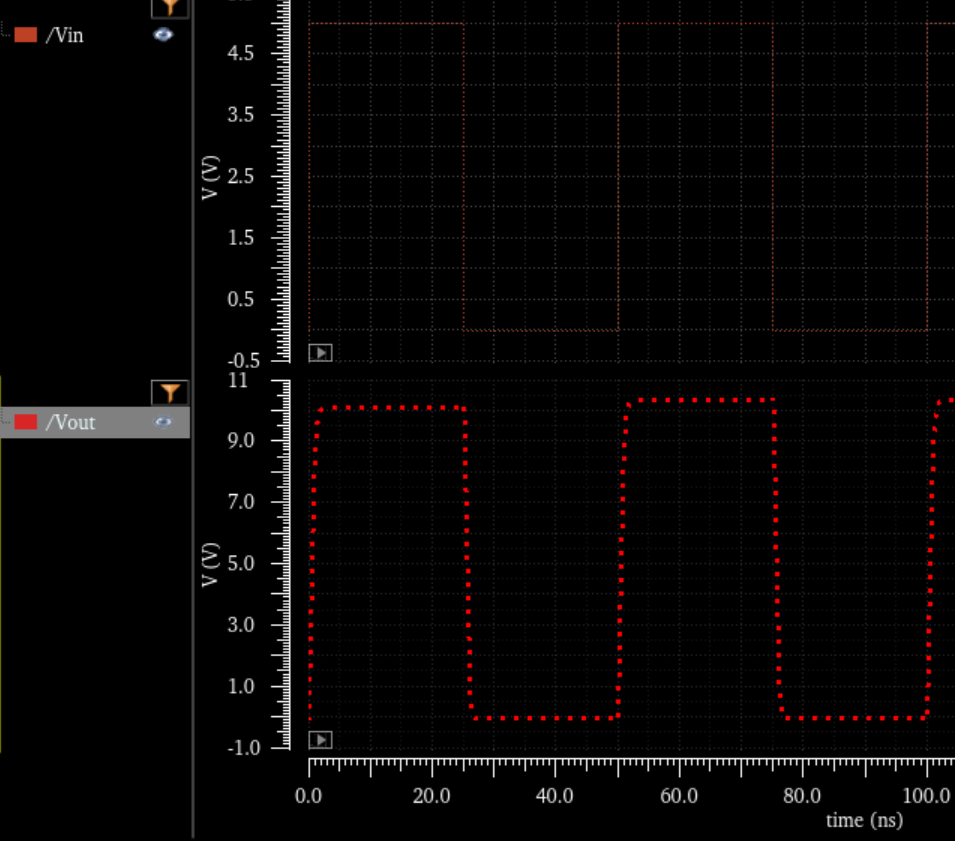

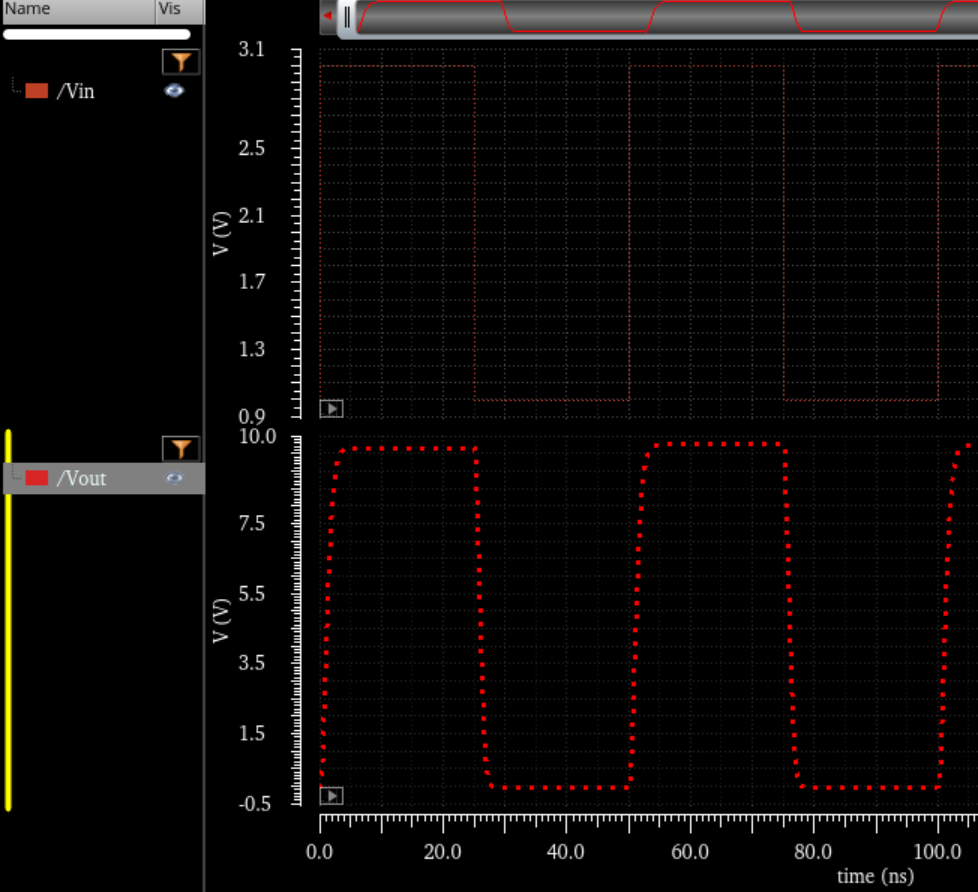

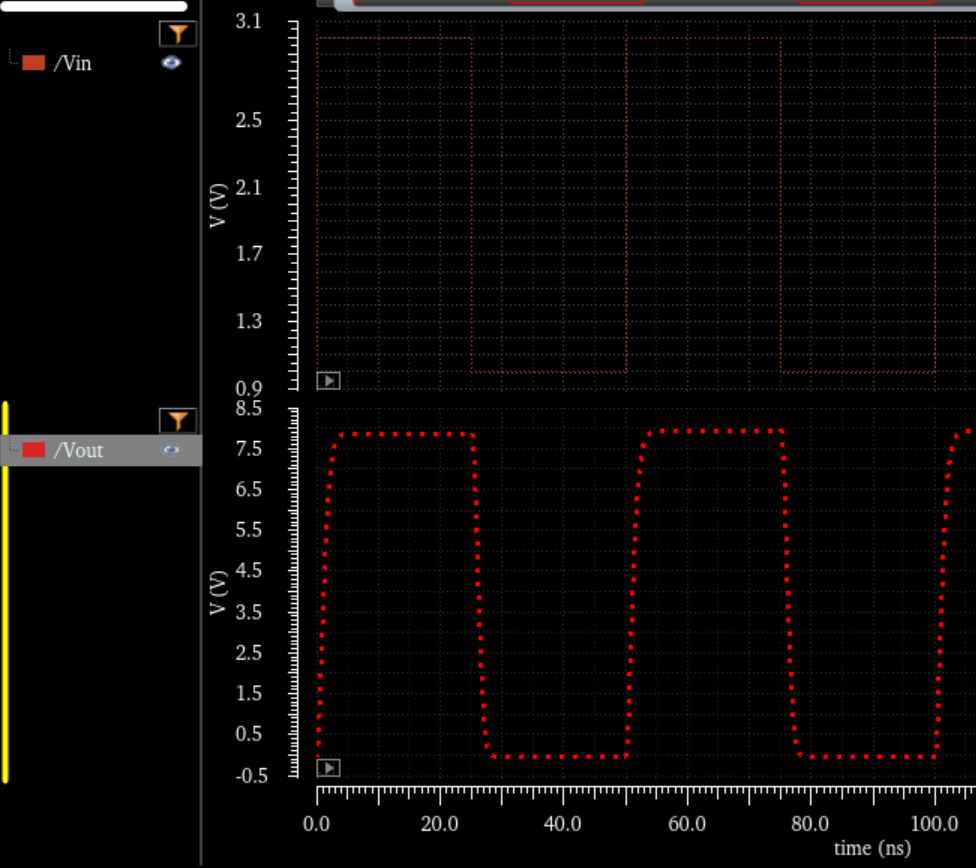

Now lets do the most extreme cases:

VDD: 5.5v Vin 1v-3v Load Cap = 1pF

VDD: 4.5v Vin 1v-3v Load Cap = 1pF

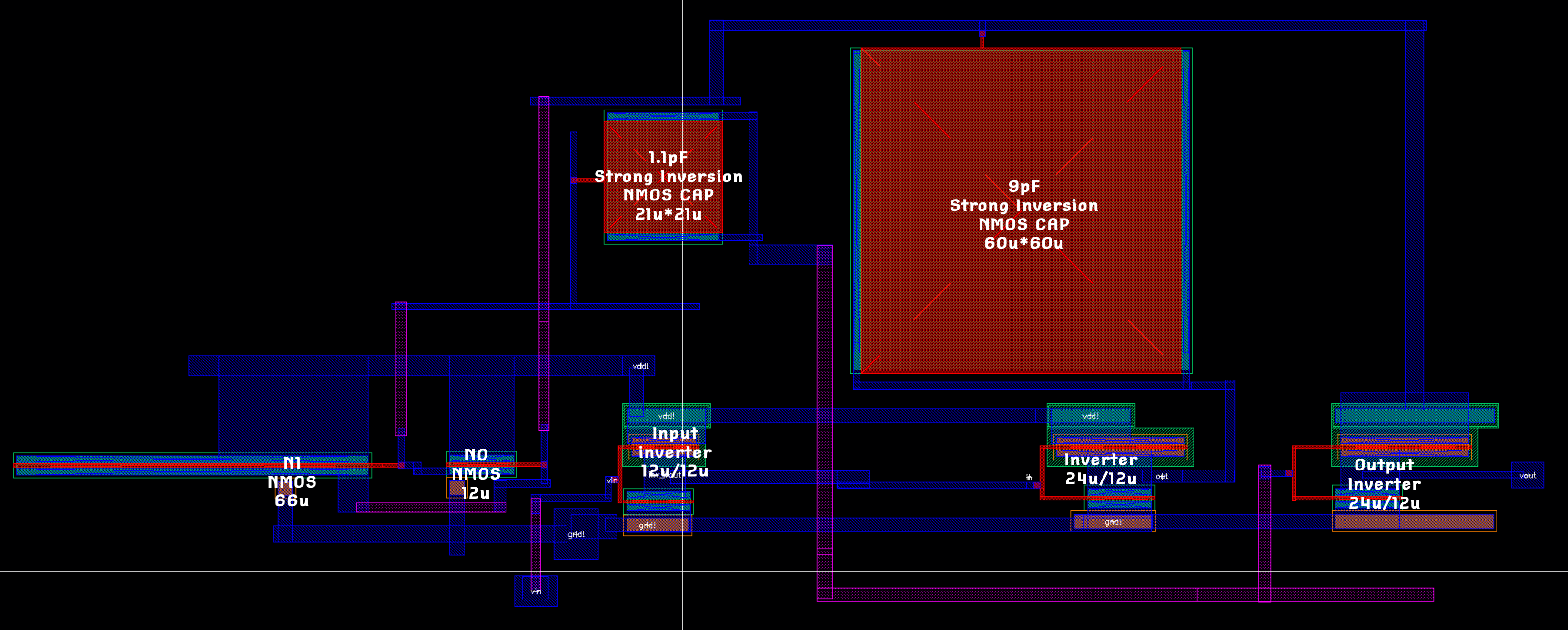

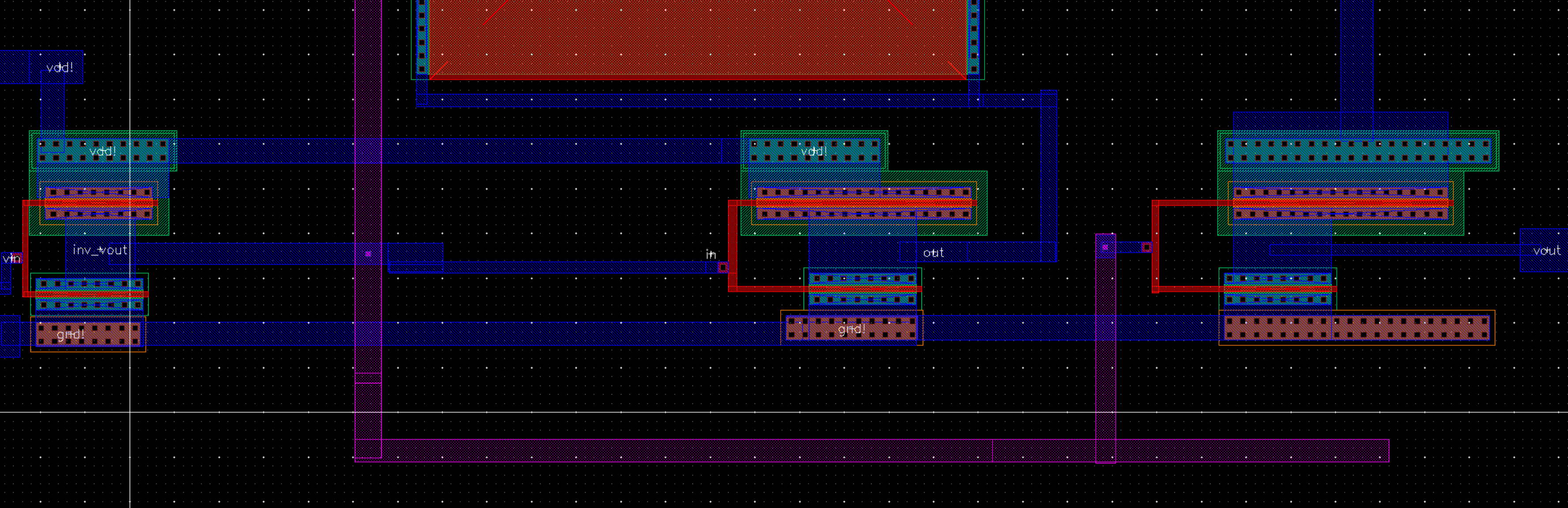

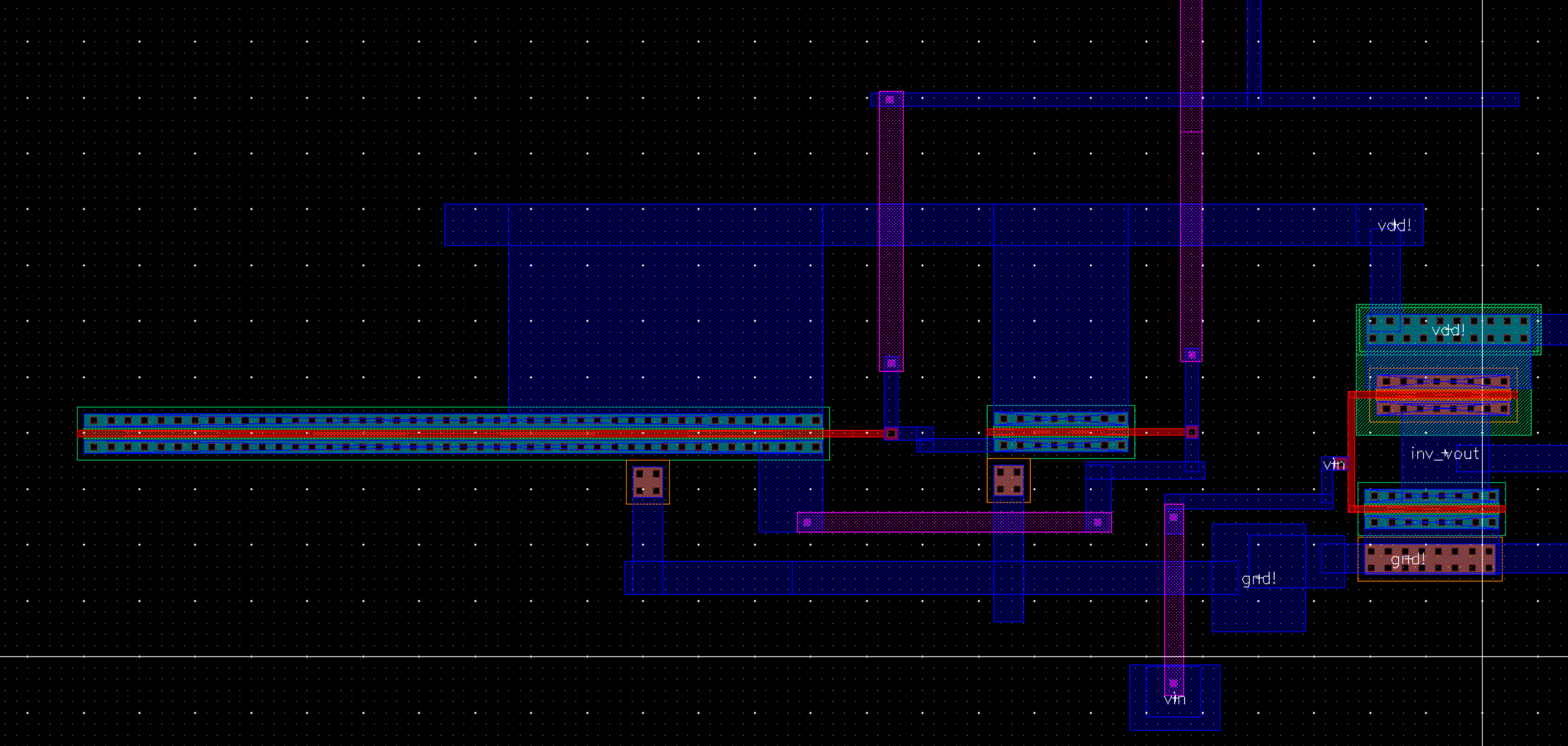

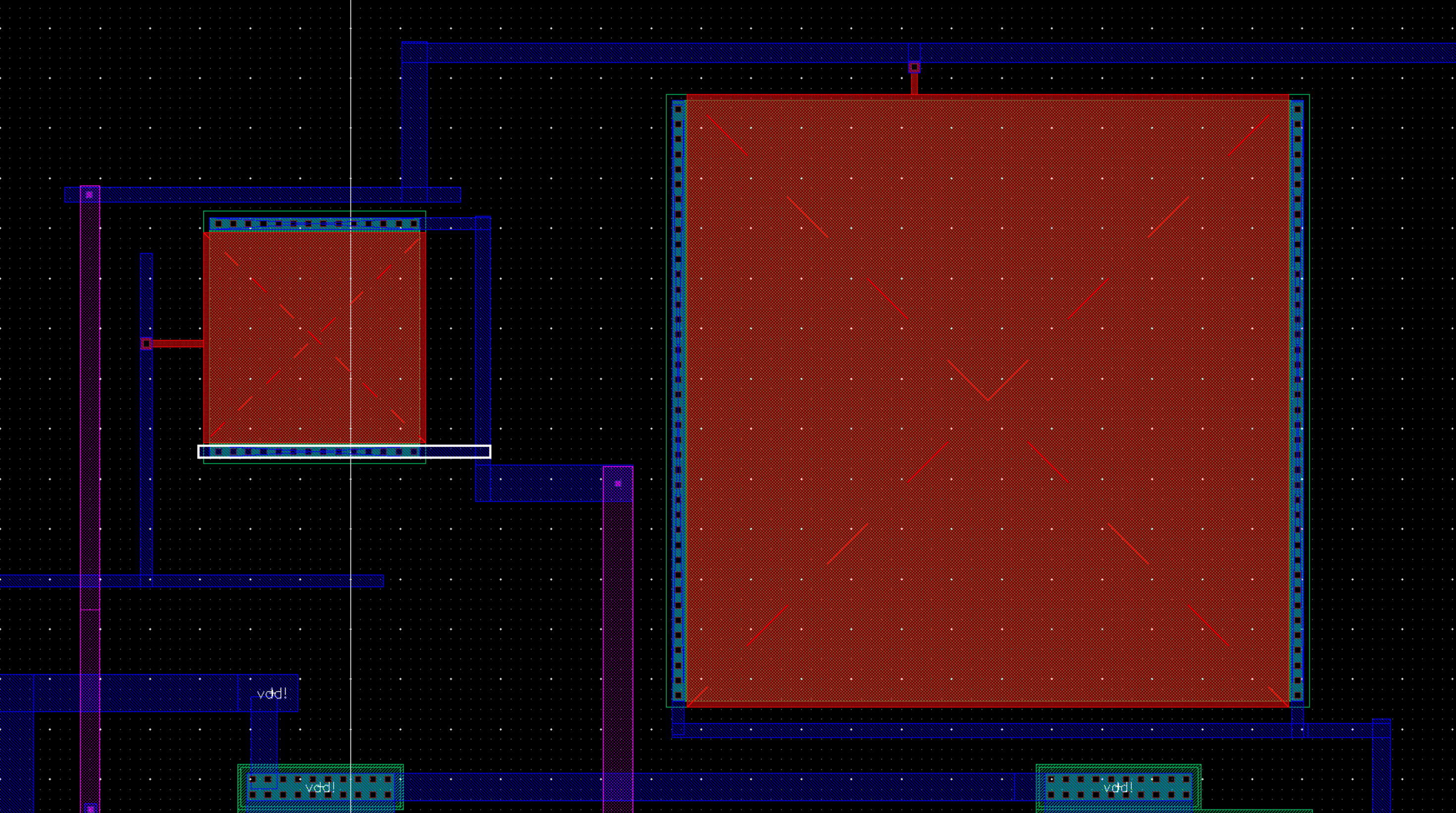

Main Layout:

Here is the schematic for reference:

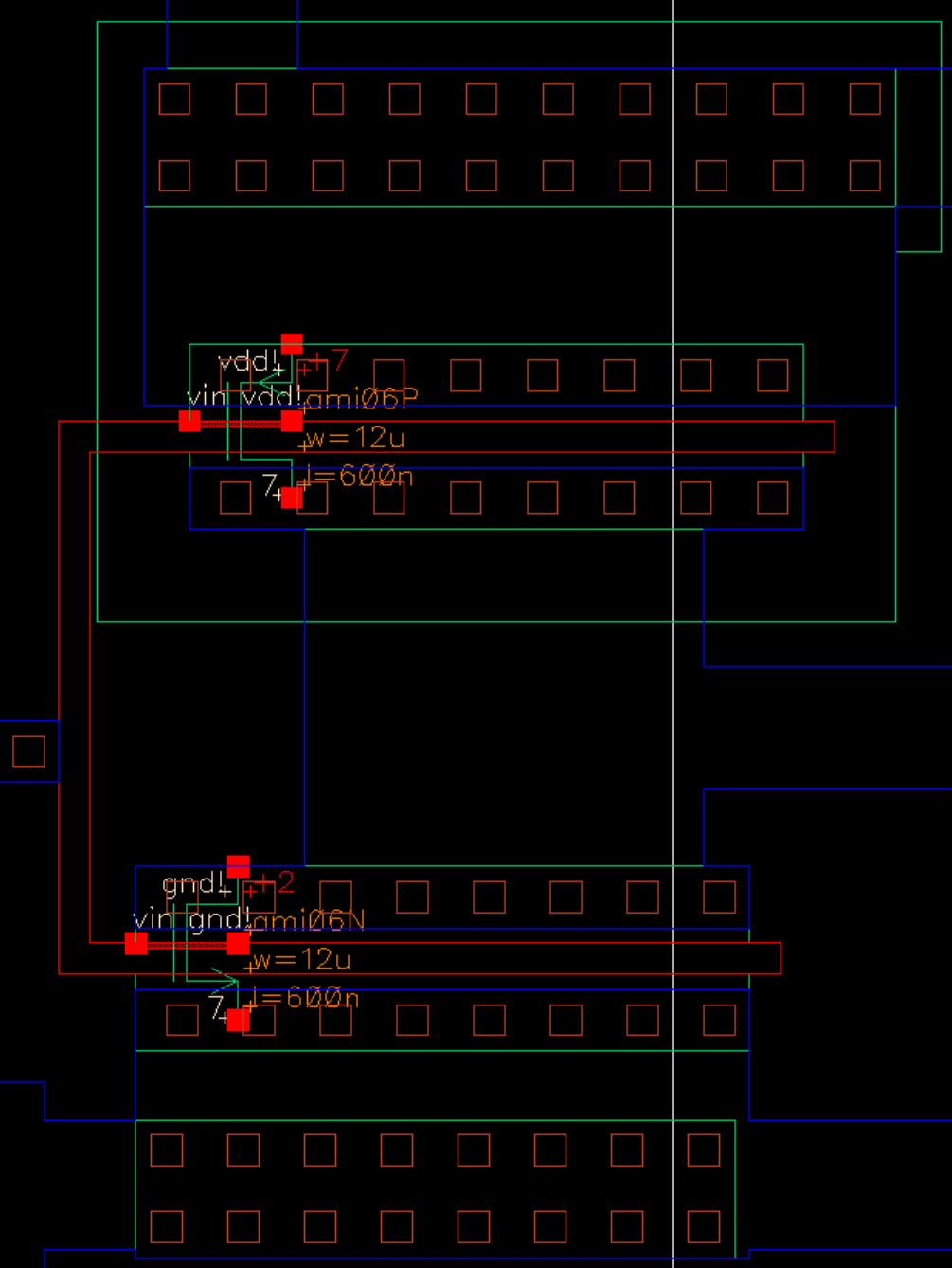

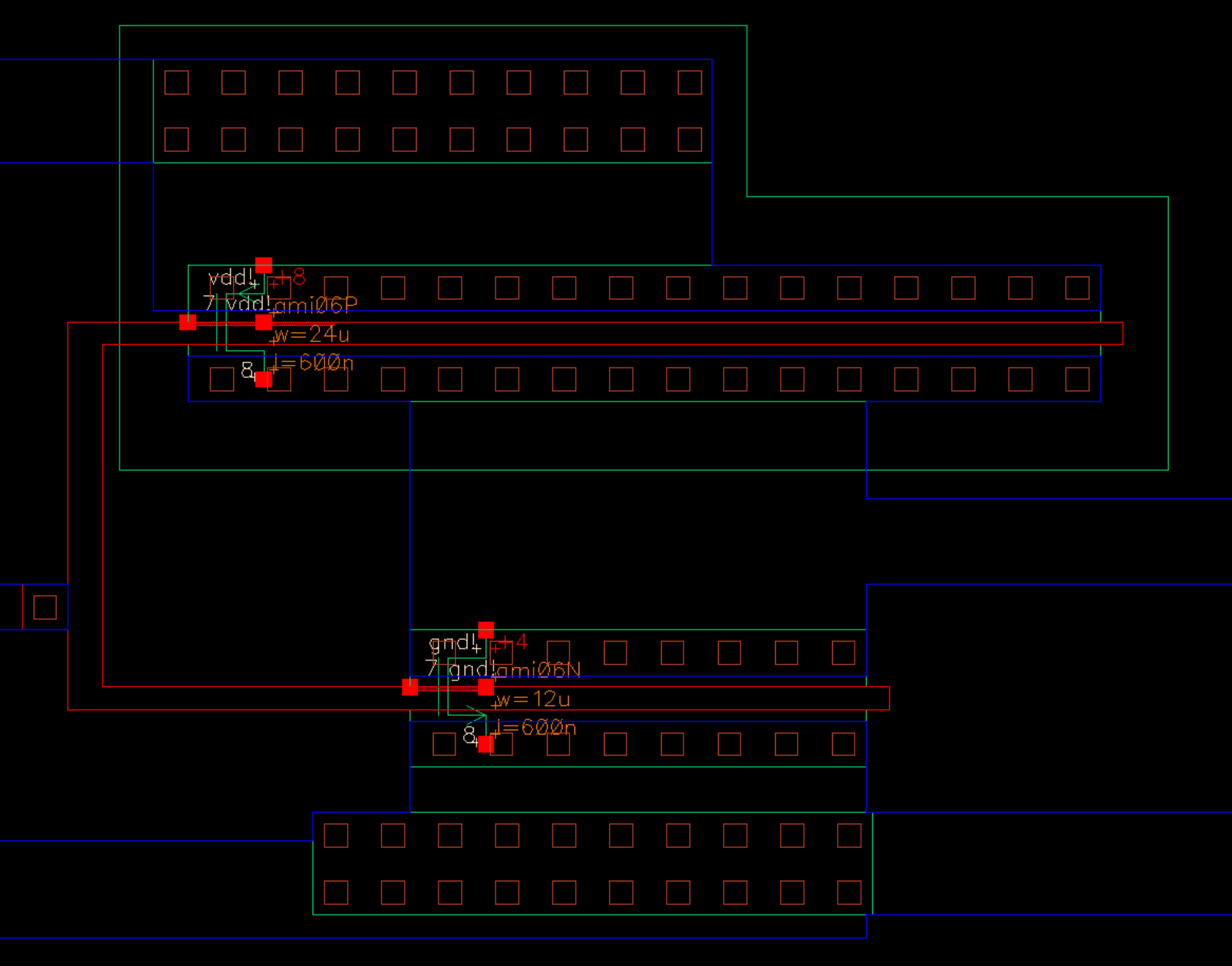

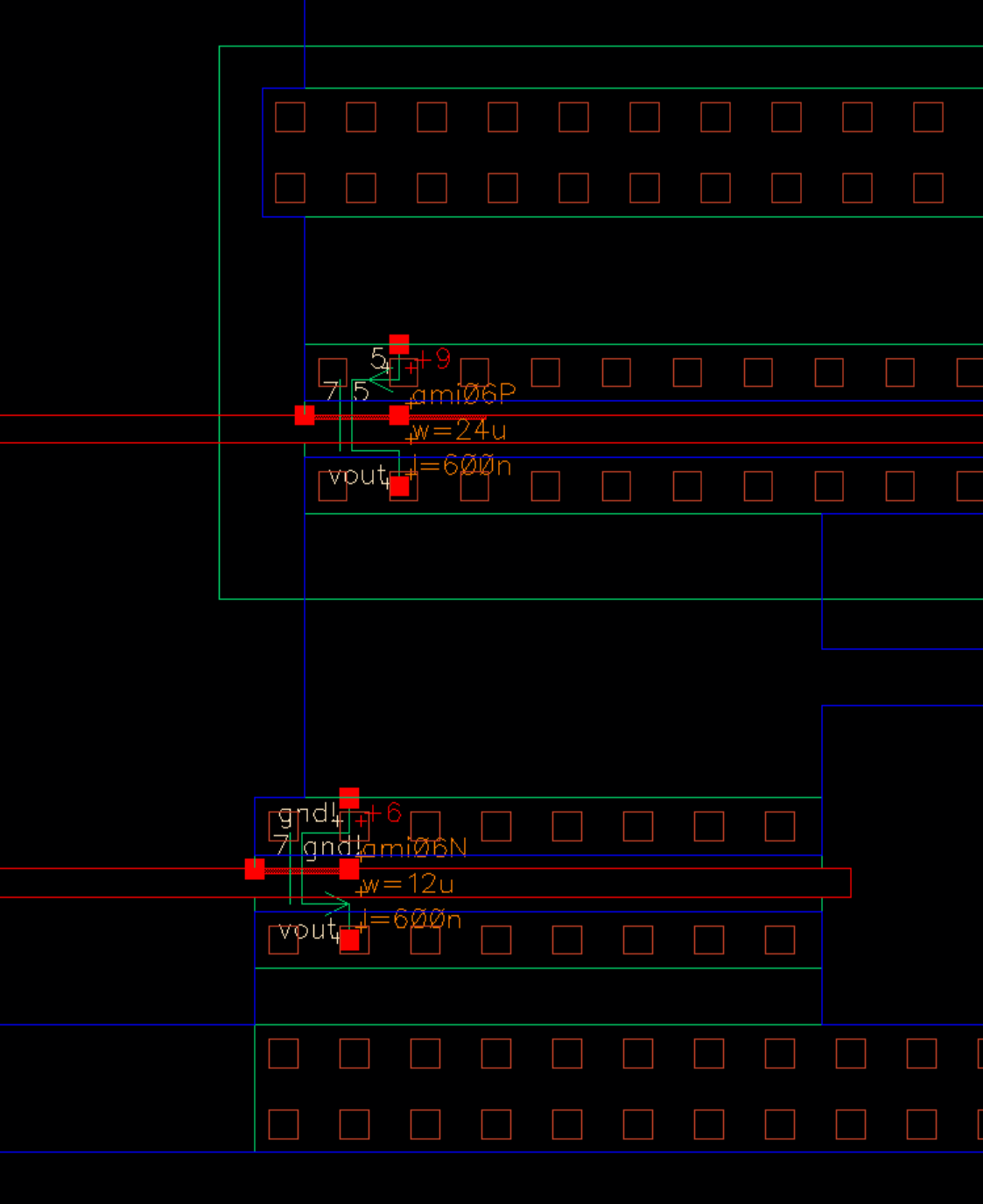

Close up View:

Inverters:

VDD Connected Transistors:

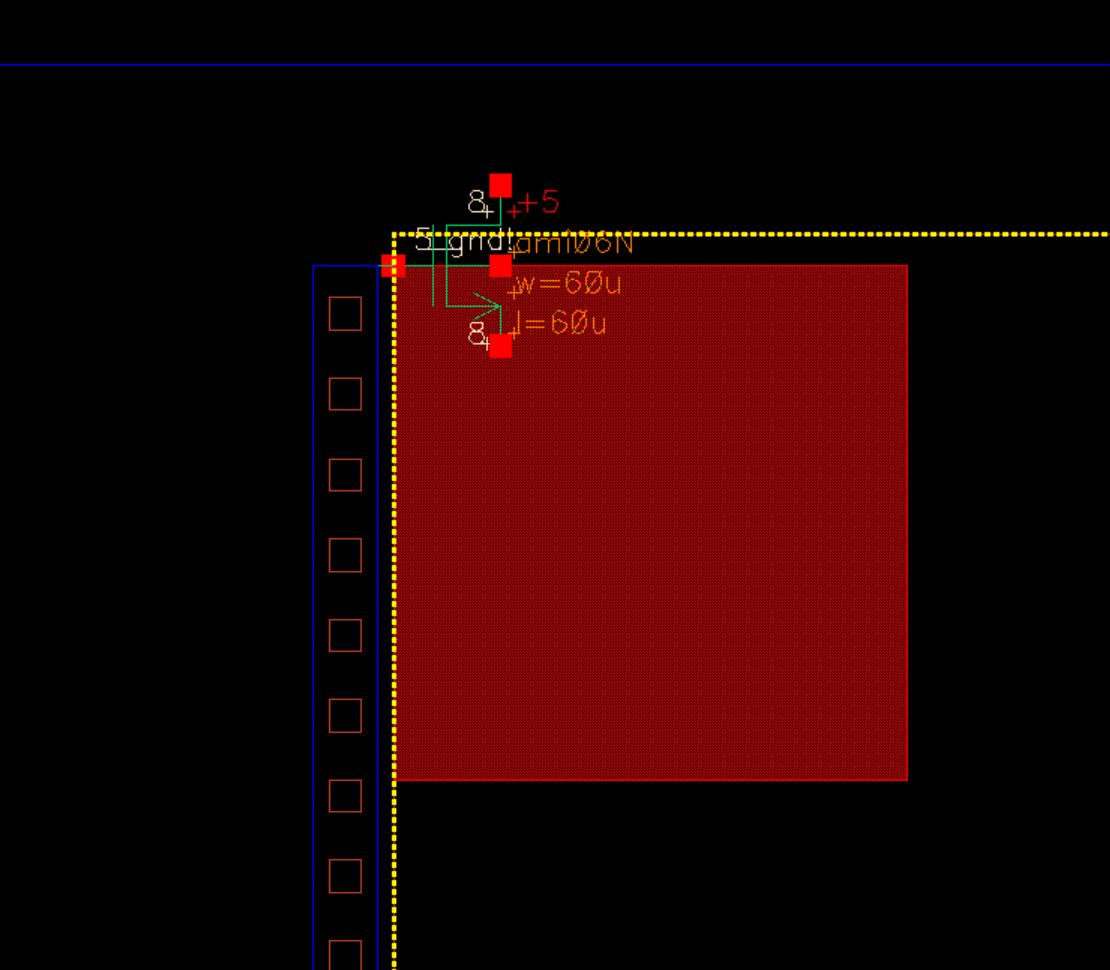

Strong Inversion NMOS Cap: 21u x 21u for 1.1pF and 60u * 60u for 9pF

Extracted Views:

Large and Small Cap, N1 and N0 transistors, inverters.

|  |

|  |

|  |

Output Inverter:

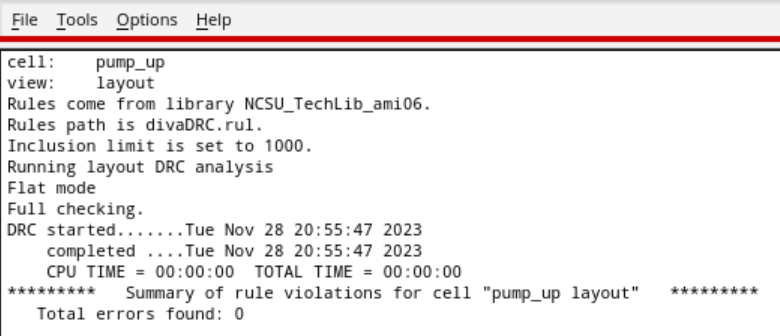

DRC:

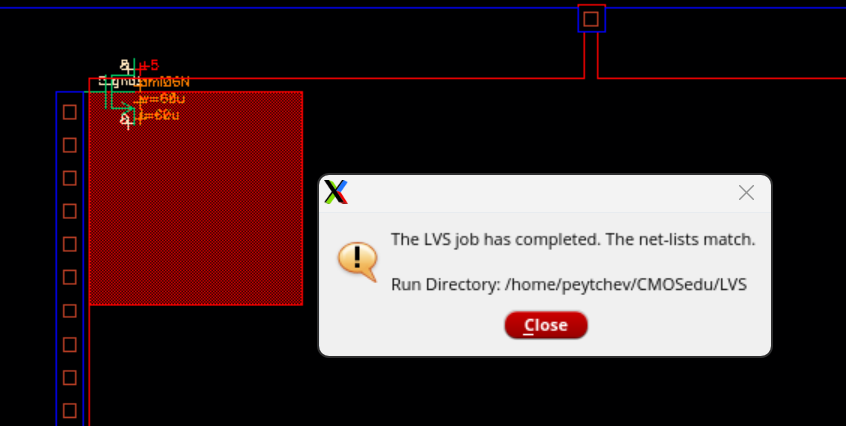

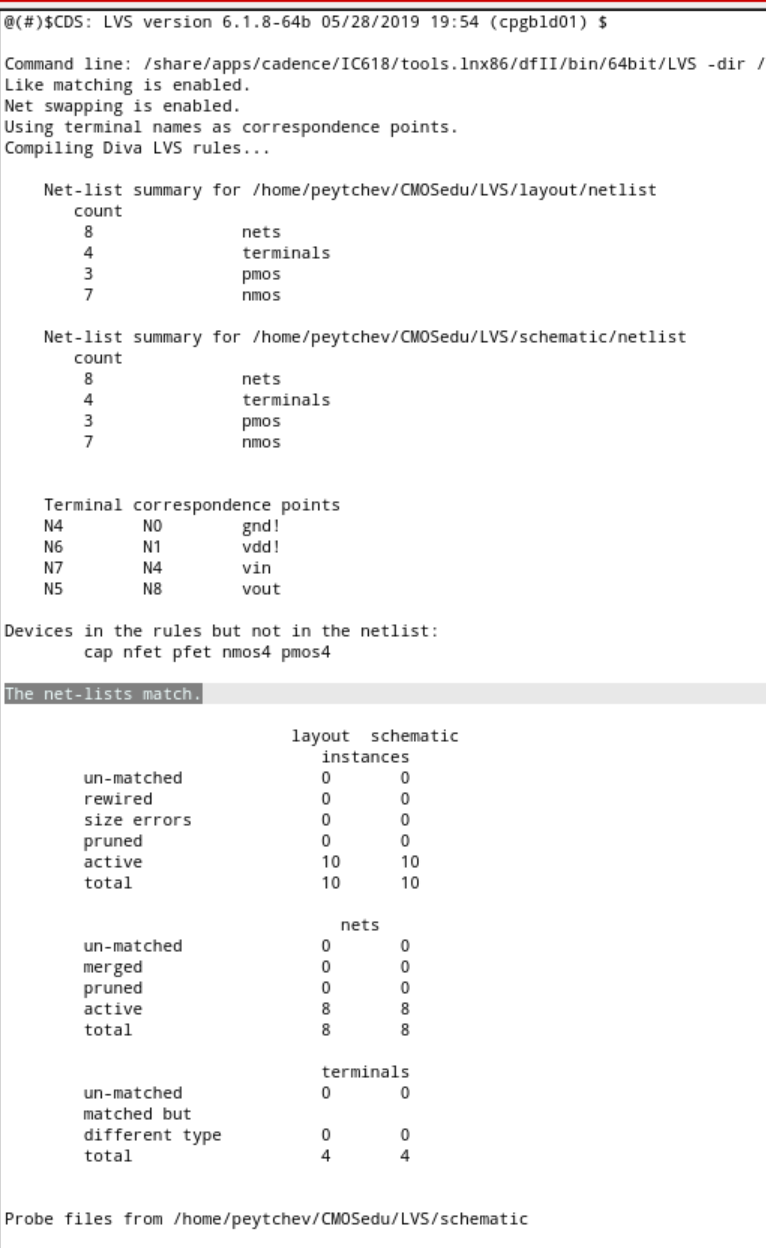

LVS:

Output:

As we see here the layout DRCs and LVSs and is suitable to function like the schematic sims.