todo: redo pmos/nmos layout far

Lab 4 - EE 421L

Prelab: Go through Tutorial 2

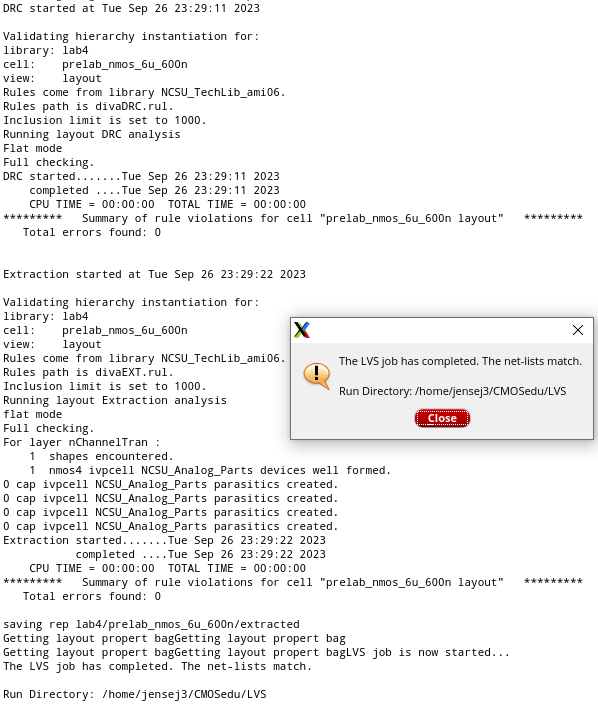

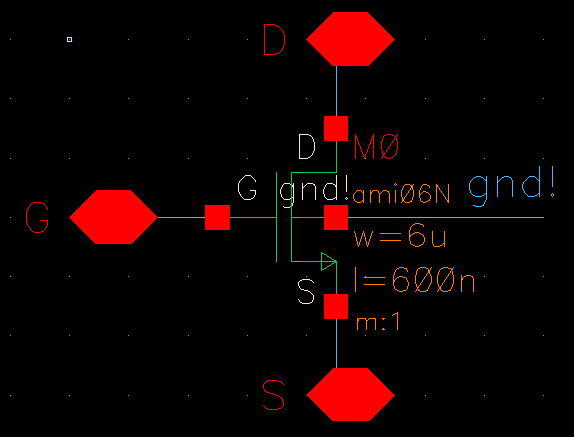

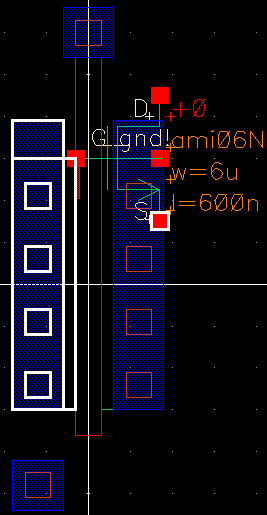

First, we were instructed to make an NMOS transistor with dimensions of

6um width and 6nm length.

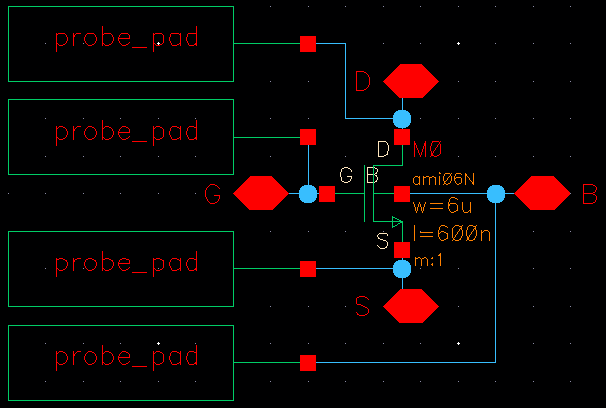

This is the schematic. Note that the body is tied to the gnd! net, as we want

the bulk of our NMOS devices to be tied to ground.

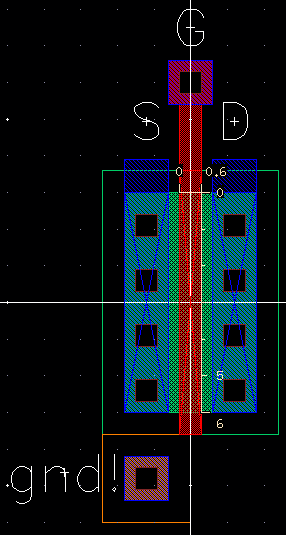

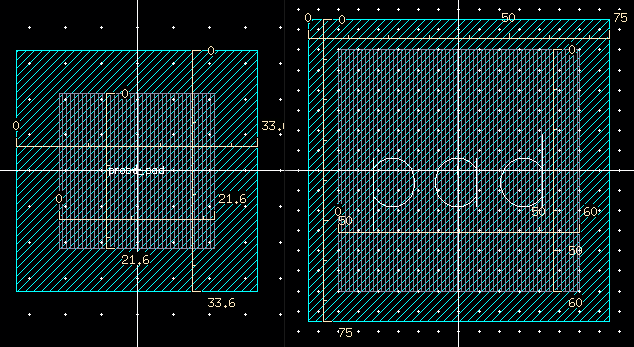

This is the layout of the device. I've placed rulers to show that the correct

dimensions were used, and how they are measured on the transistor.

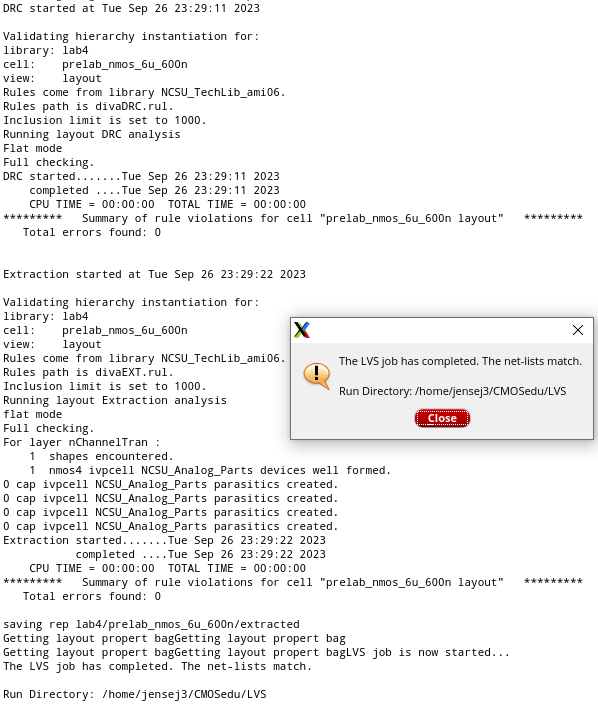

Next, I ran my DRC, Extraction, and LVS checks to make sure this design was good.

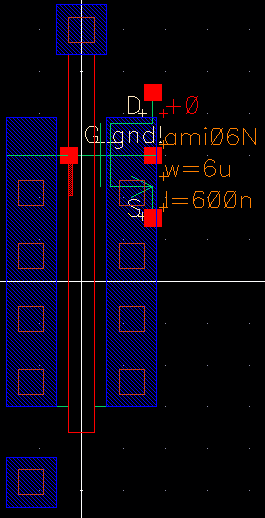

To verify one more time, we can look at the extracted view to see that the

software recognized the device I wanted to implement.

If we click on either the nodes of the schematic shown here or the metal/poly

layers shown in the background, the corresponding element is highlighted. For

example, I can click on the top left portion of metal1 to highlight the S node

in the schematic, or vice-versa. This confirms that that piece of metal1 was

indeed interpreted as the source node of the transistor.

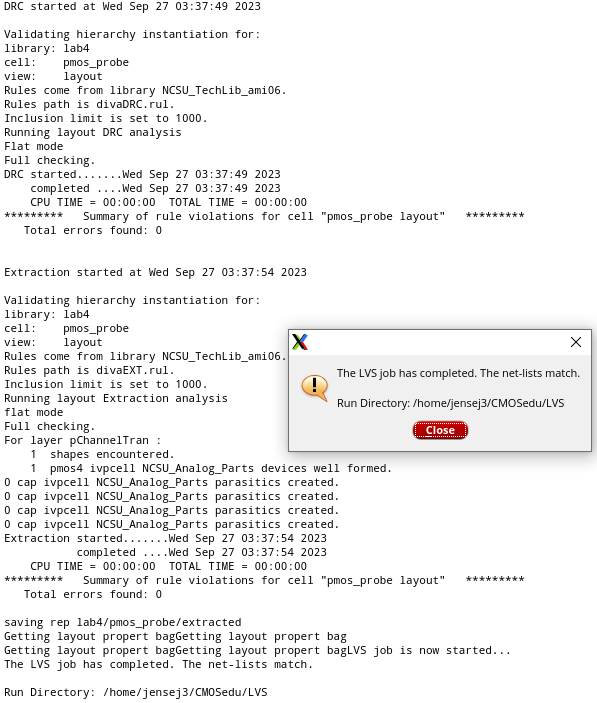

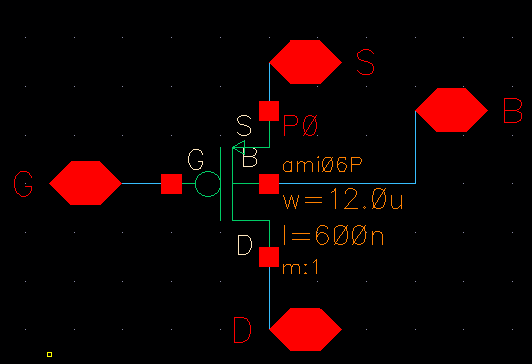

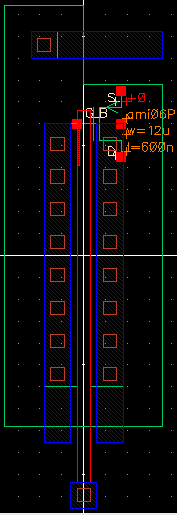

Next, we followed the tutorial to create a PMOS. The given dimensions were

12um by 600nm, and this time, we were to connect a B pin to the body instead

of tying it to a net. Here is the schematic.

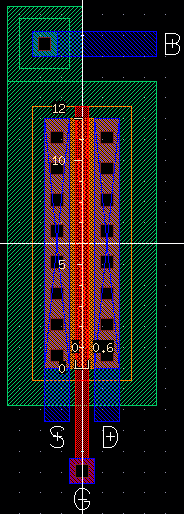

Next up is the layout, with dimensions shown.

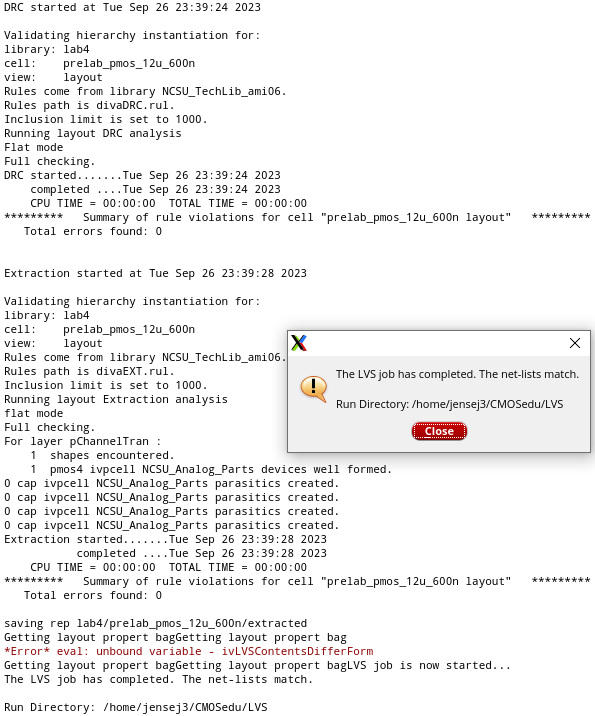

Here are the DRC, Extraction, and LVS checks, all passed.

And as before, here is the extracted view.

Lab:

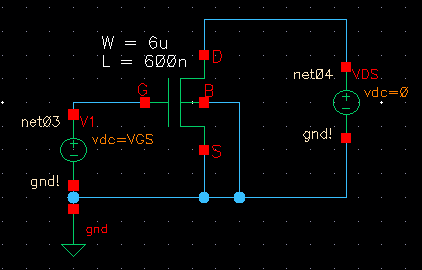

First, we ran some simulations. The NMOS devices are 6u/0.6u and the

PMOS devices are 12u/0.6u.

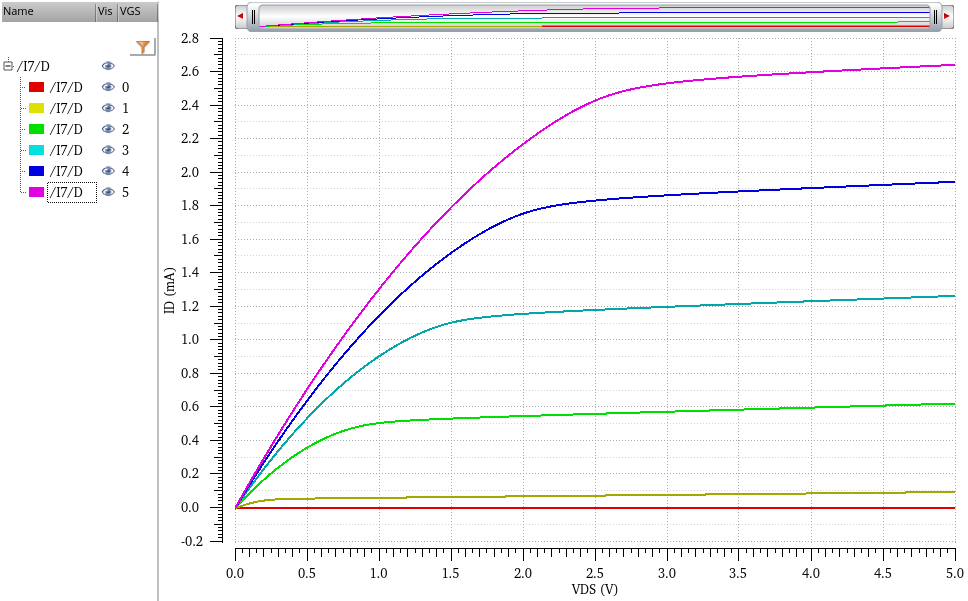

Simulation 1: I_D vs. V_DS of an NMOS.

V_GS will be tested from 0 to 5V in steps of 1V

V_DS will be tested from 0 to 5V in steps of 1mV

Here is the pertinent schematic.

For this first simulation, I'll briefly summarize the steps of setting up

the simulation.

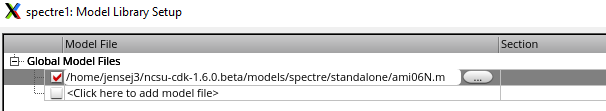

First, we need to make sure we include the models for the transistors we are

using. In this simulation we are only using an NMOS, so we include that model.

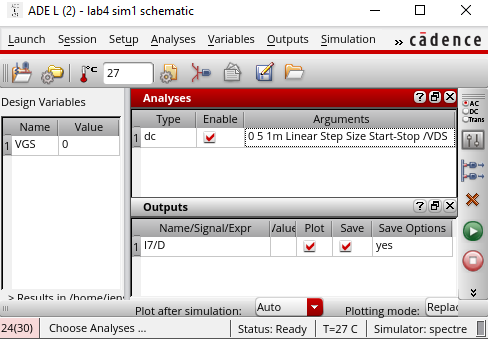

Next, we set the V_GS to 0V in the design variables. This is just an arbitrary

value for now and will be changed in the parametric analysis window. The dc

analysis here allows us to do the 0-5V variation of V_DS.

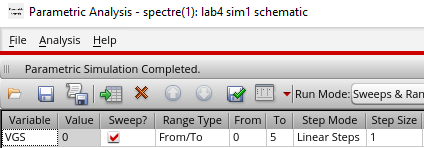

Next, we set up the parametric analysis to allow us to plot separate curves

for each of the V_GS values (0, 1, 2, 3, 4, and 5V).

Finally, here are the resulting I-V curves.

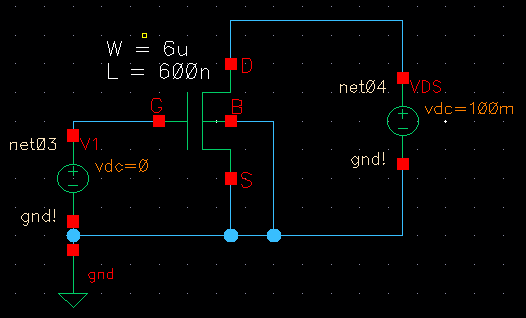

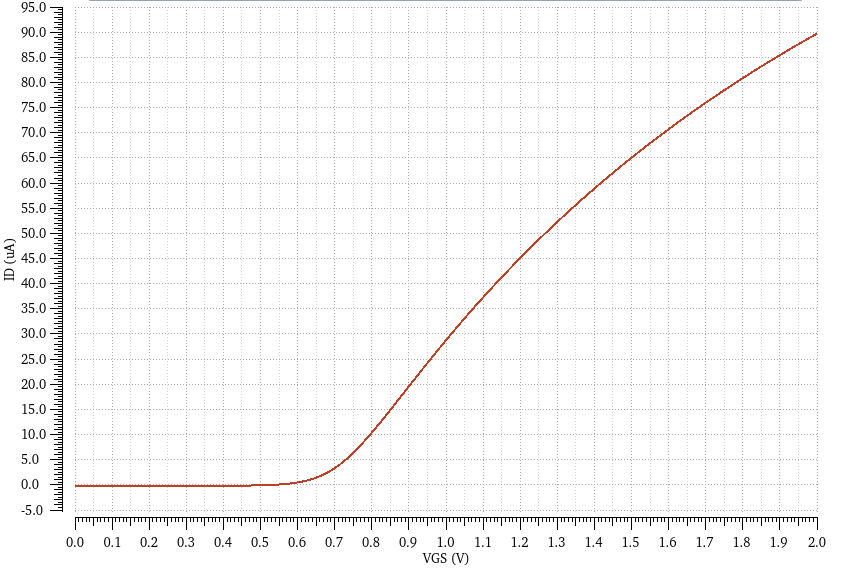

Simulation 2: I_D vs. V_GS of an NMOS. This is the same as simulation 1,

but V_DS will be kept constant at 100mV while V_GS is swept from 0 to 2V,

in steps of 1mV. Here is the schematic I used.

Here is the resulting curve.

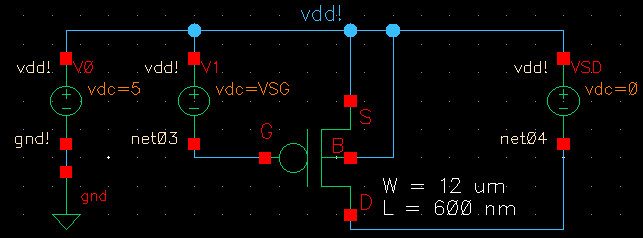

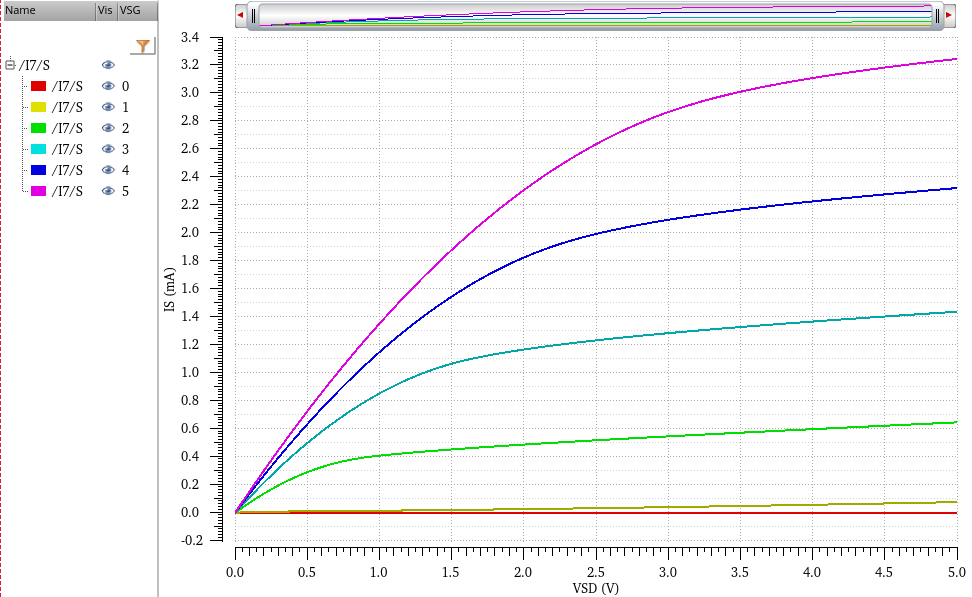

Simulation 3: I_D vs. V_SD of a PMOS.

V_SG will be tested from 0 to 5V in steps of 1V

V_SD will be tested from 0 to 5V in steps of 1mV

Here is the schematic.

Here is the simulation plot. I labelled the current I_S instead of I_D because that

is the node I used to plot it, and it looks nicer because the values are positive.

I_D would have the same magnitude, but the values would be negative as the sim

would measure it in the opposite direction.

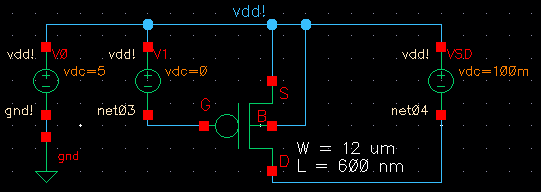

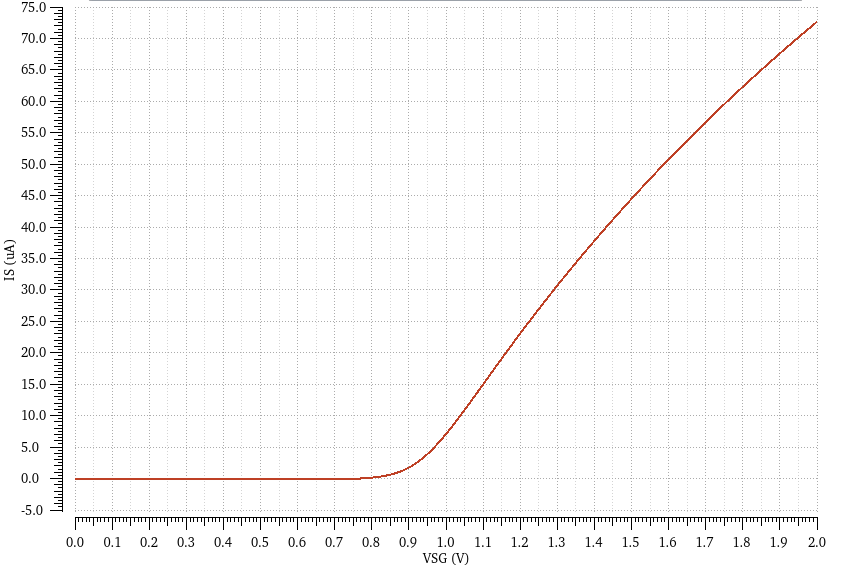

Simulation 4: I_D vs. V_SG of a PMOS. This is the same as simulation 3,

but V_SD will be kept constant at 100mV while V_SG is swept from 0 to 2V,

in steps of 1mV. Here is the schematic I used.

Here is the resulting curve, plotted as I_S against V_SG.

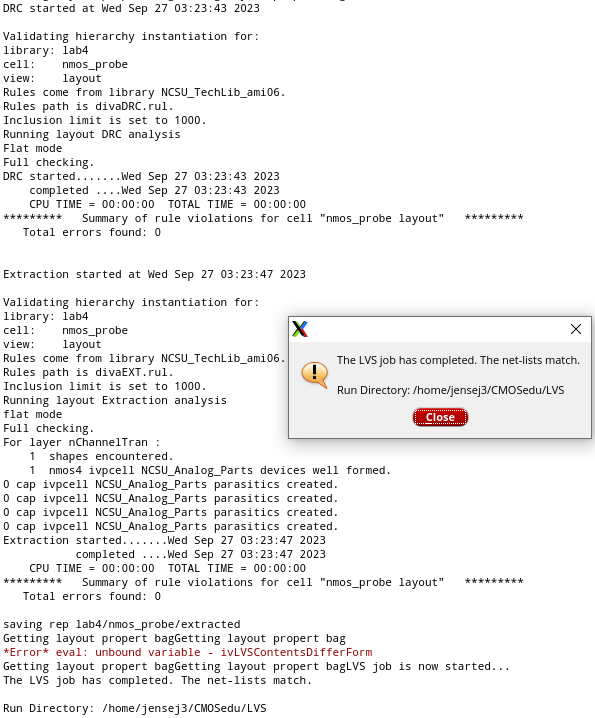

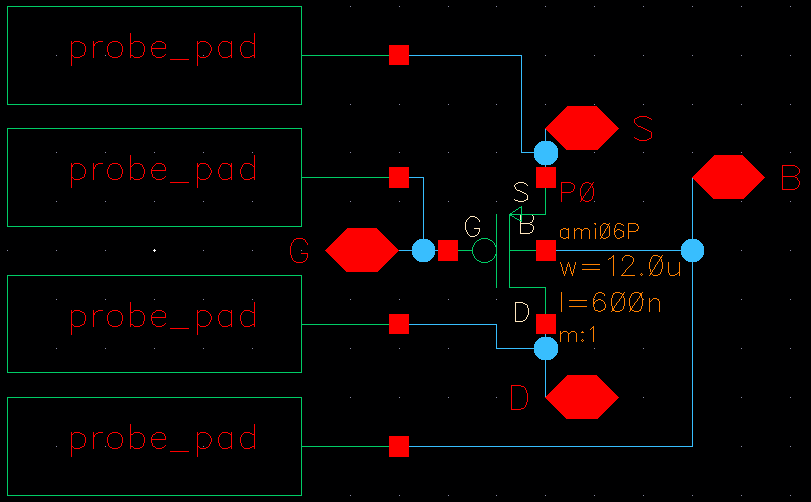

Next, we did a layout for a 6u/0.6u (W/L) NMOS with all four terminals

connected to probe pads. The cell for these probe pads was given in the

provided lab4 directory. We've used bonding pads before in the lecture

section, but these new probe pads are significantly smaller.

Here is a comparison of their relative sizes, with the probe pad on the left

and the bonding pad on the right. Aside from the size difference, they use

the same layers- metal3, (over)glass, and of course the text labels.

First, I created my NMOS schematic, with probe pads.

Next, I attached the probe pads to the layout I created before, also making

sure to connect the body ptap to a pin B instead of just to the gnd! net.

Here is the zoomed out version, showing the entire pads.

Of course, I performed all the necessary verification checks.

Of course, I performed all the necessary verification checks.