| 1a | The

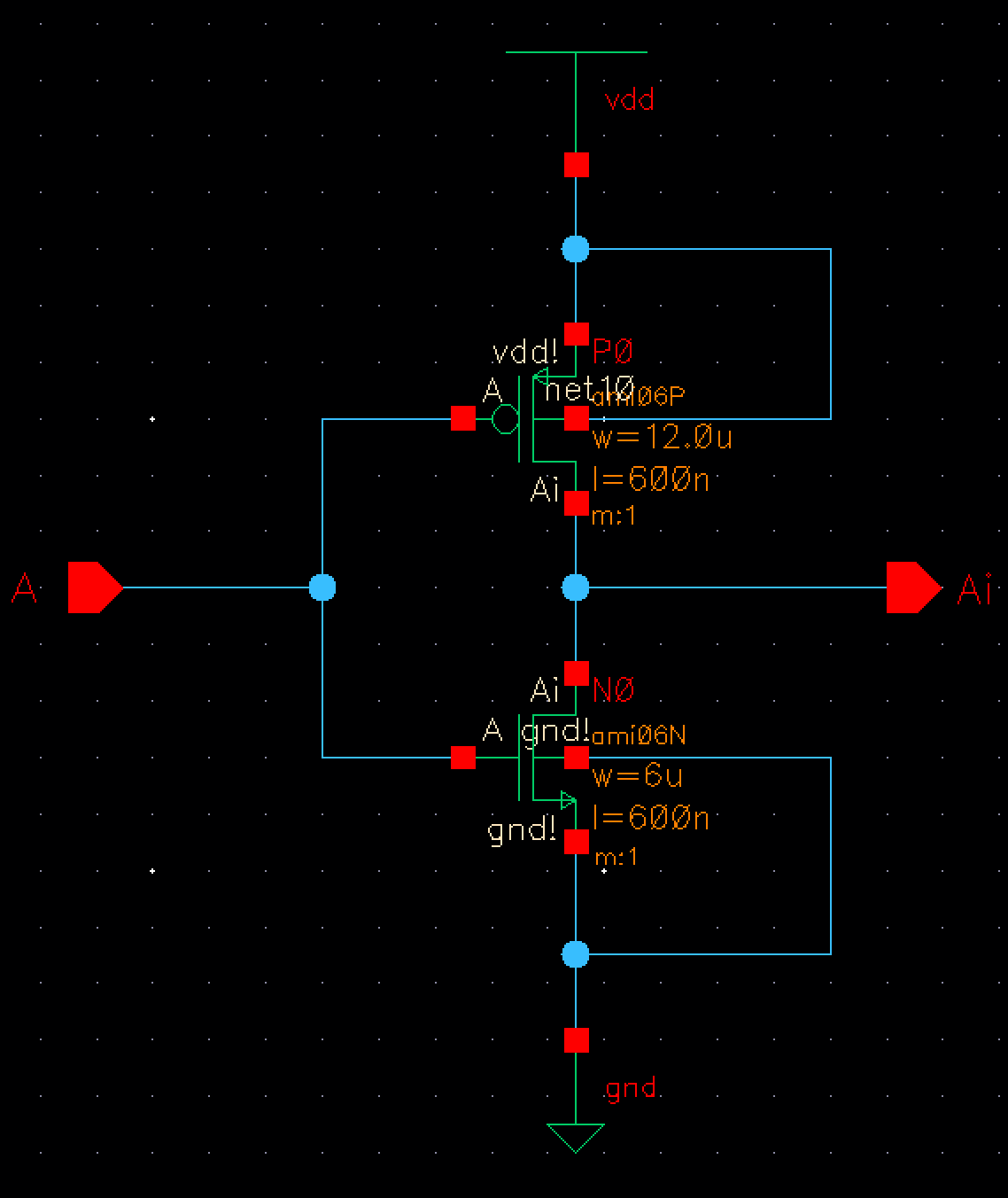

first step of this lab is to layout 2 CMOS inverters. For my first CMOS

it is the same as the tutorial 3. A 12u/6u CMOS with the lengths of .6u.

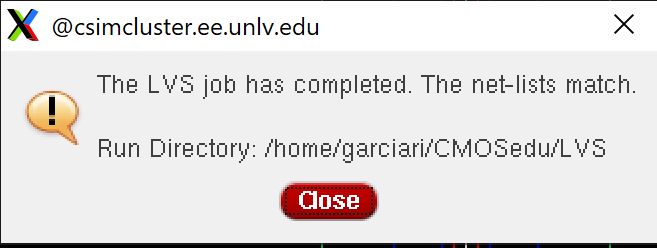

As in tutorial 3 we start by creating a schematic of our CMOS inverter consisting of a PMOS connected with an NMOS.

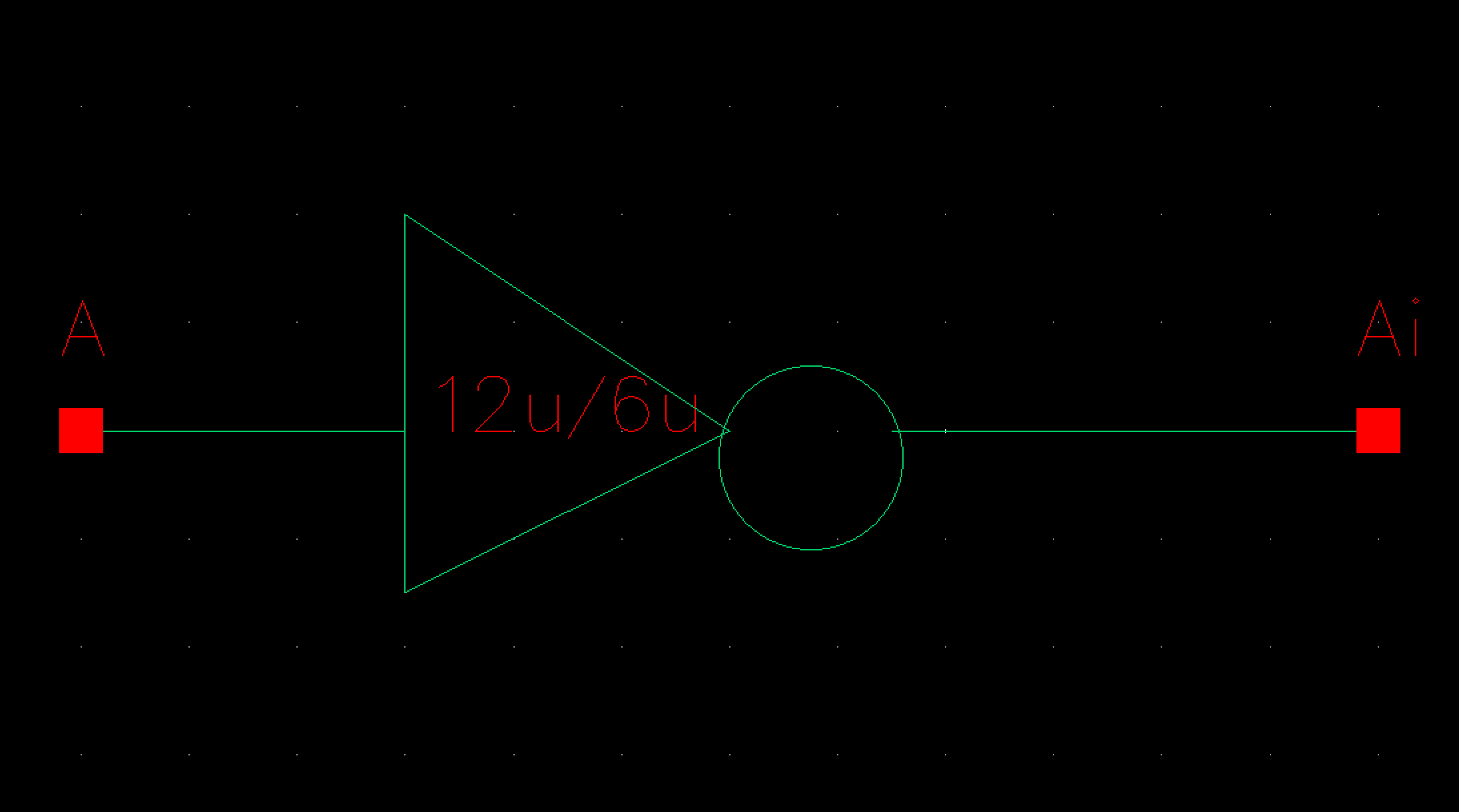

After

creating the schematic I next created a symbol. This followed the same

steps as the tutorial. I erased the premade symbol and create a more

appropriate symbol. This time however I added the text that tells me

which CMOS inverter I'm using to avoid confusion in the simulation

later on.

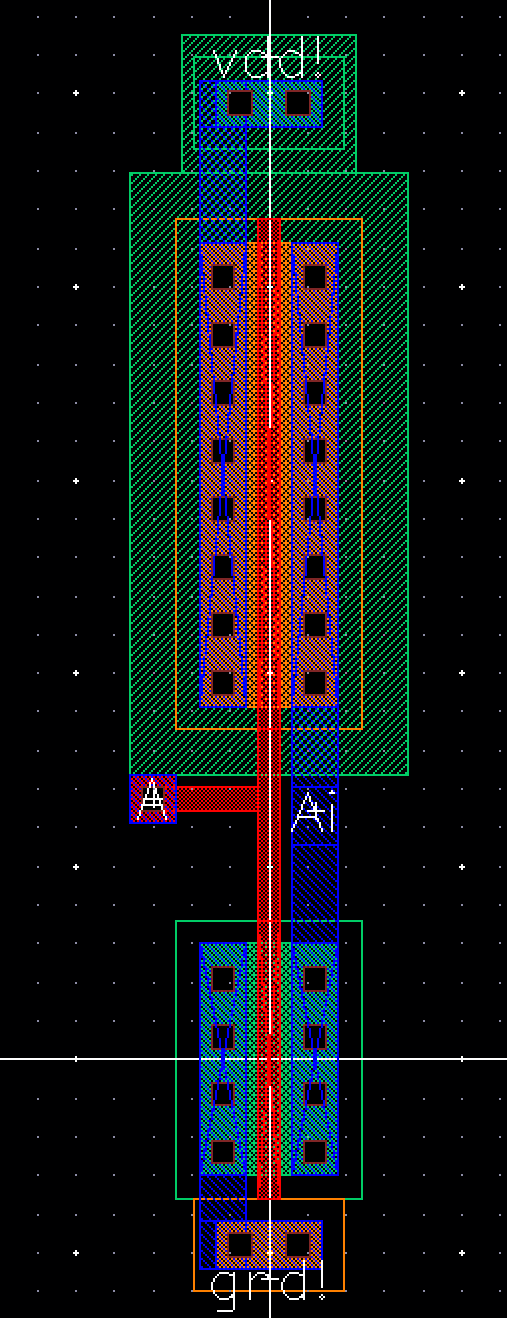

After creating my symobl I next created my layout which is the same as the tutorial since they're both 12u/6u CMOS inverters.

I drc'd my layout then proceeded to the next step which is extracting my layout.

After extrating my layout I next LVS'd my extracted layout to make sure I had successfully layed out my 12u/6u CMOS Inverter.

|

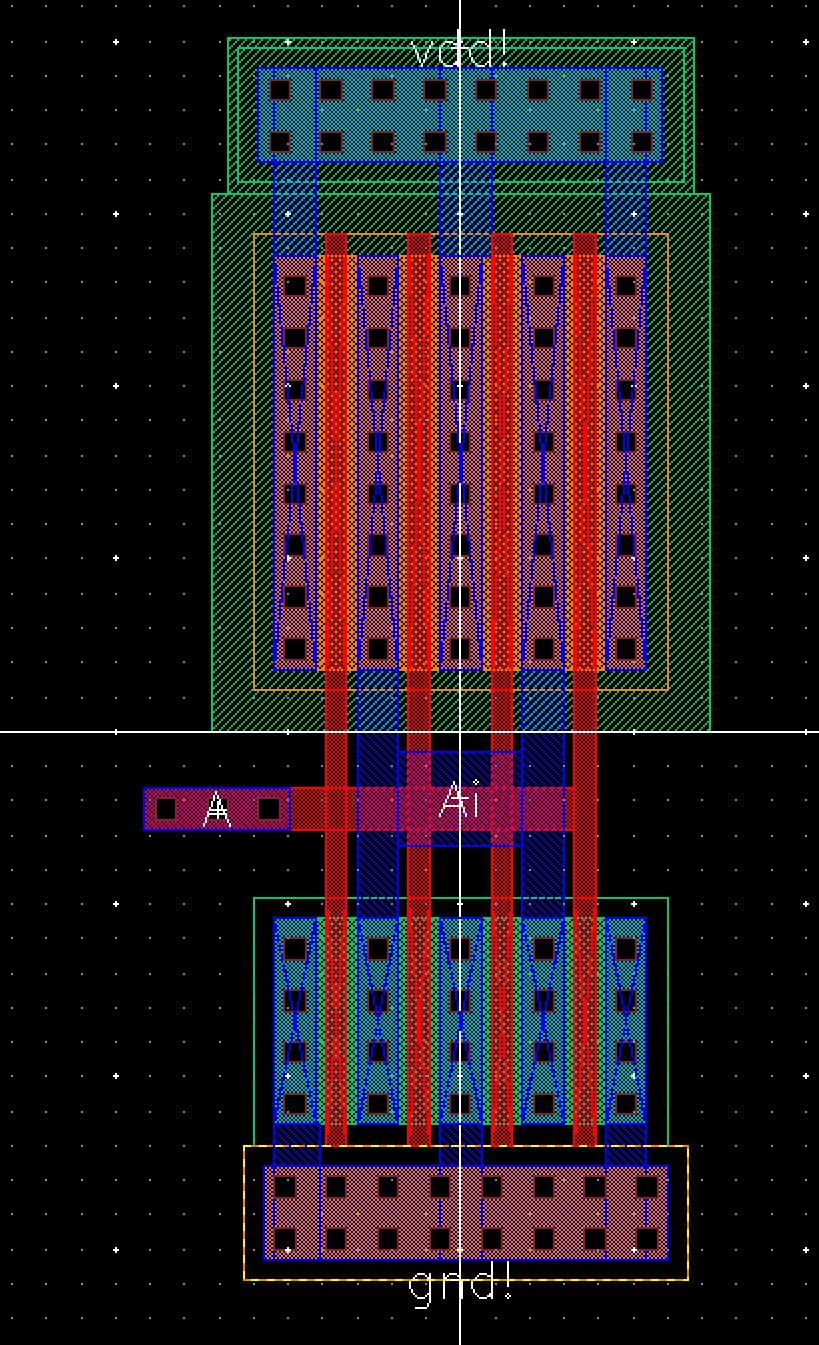

| 1b | For

the step 1b I next proceeded to layout a 48u/24u CMOS inverter. This

step is the similar to the 1a step and tutorial 3 except for the

inclusion of fingers. For this CMOS we're laying out using 4 fingers

which means we're laying out at a single 48u/24u CMOS that consists of 4 12u PMOSs and 4 6u NMOSs.

Again

I first start my layout by creating a schematic. This is the same as in

tutorial and step 1a however this time I must include 4 fingers in my

MOSs. I did this by inputting 4 into the mulitpiler fiield which tells

cadance that my MOSs will have 4 fingers or 4 MOSs next to each other.

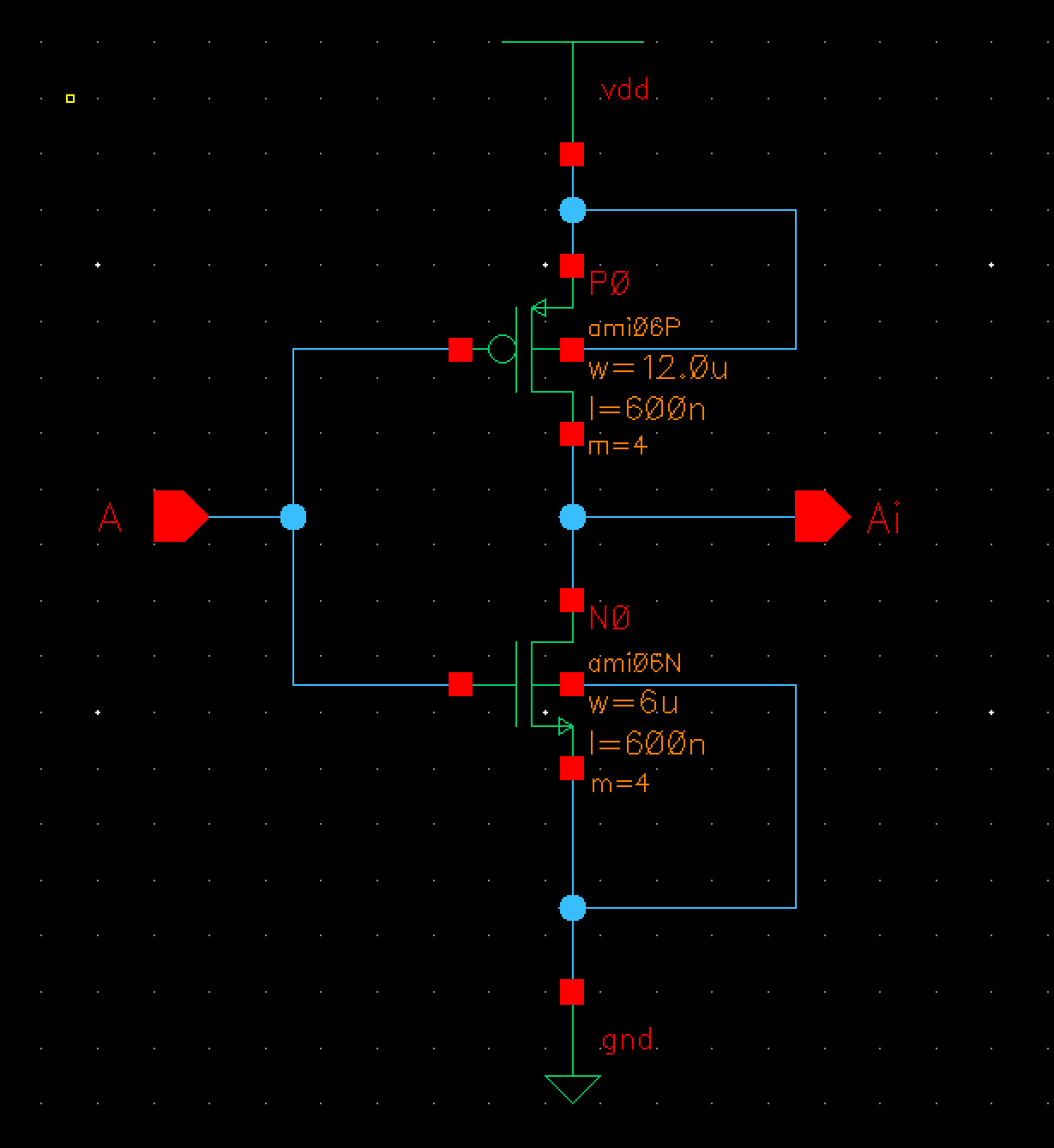

I

next created a symbol of my schematic this step is exactly the same as

in step 1a and tutorial 3. I added text specifying that this CMOS

inverter is a 48u/24u to avoid confusion later on.

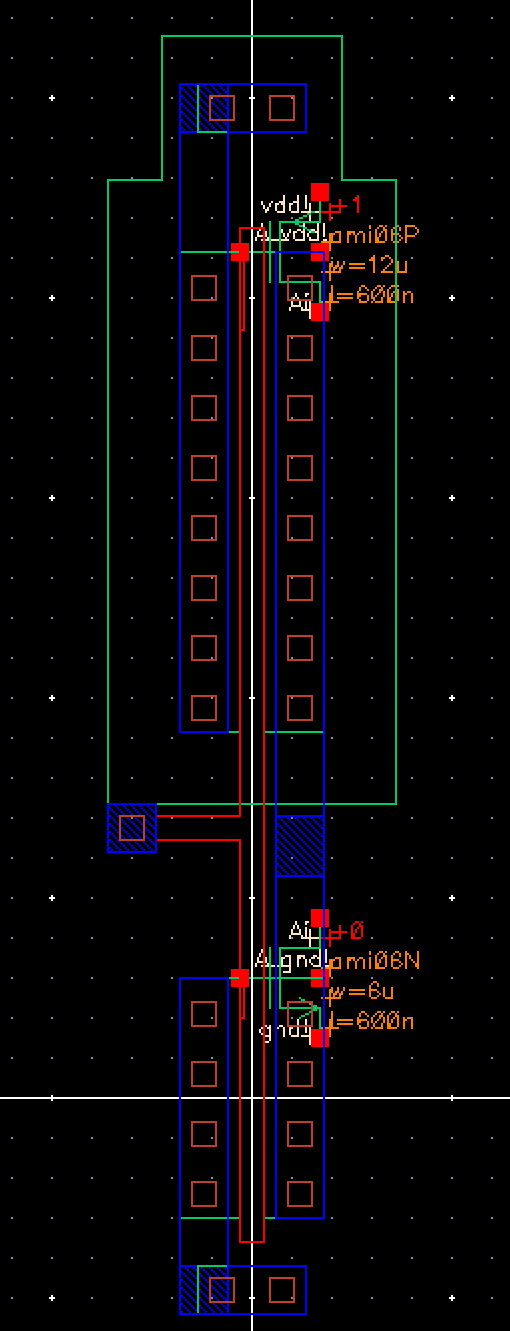

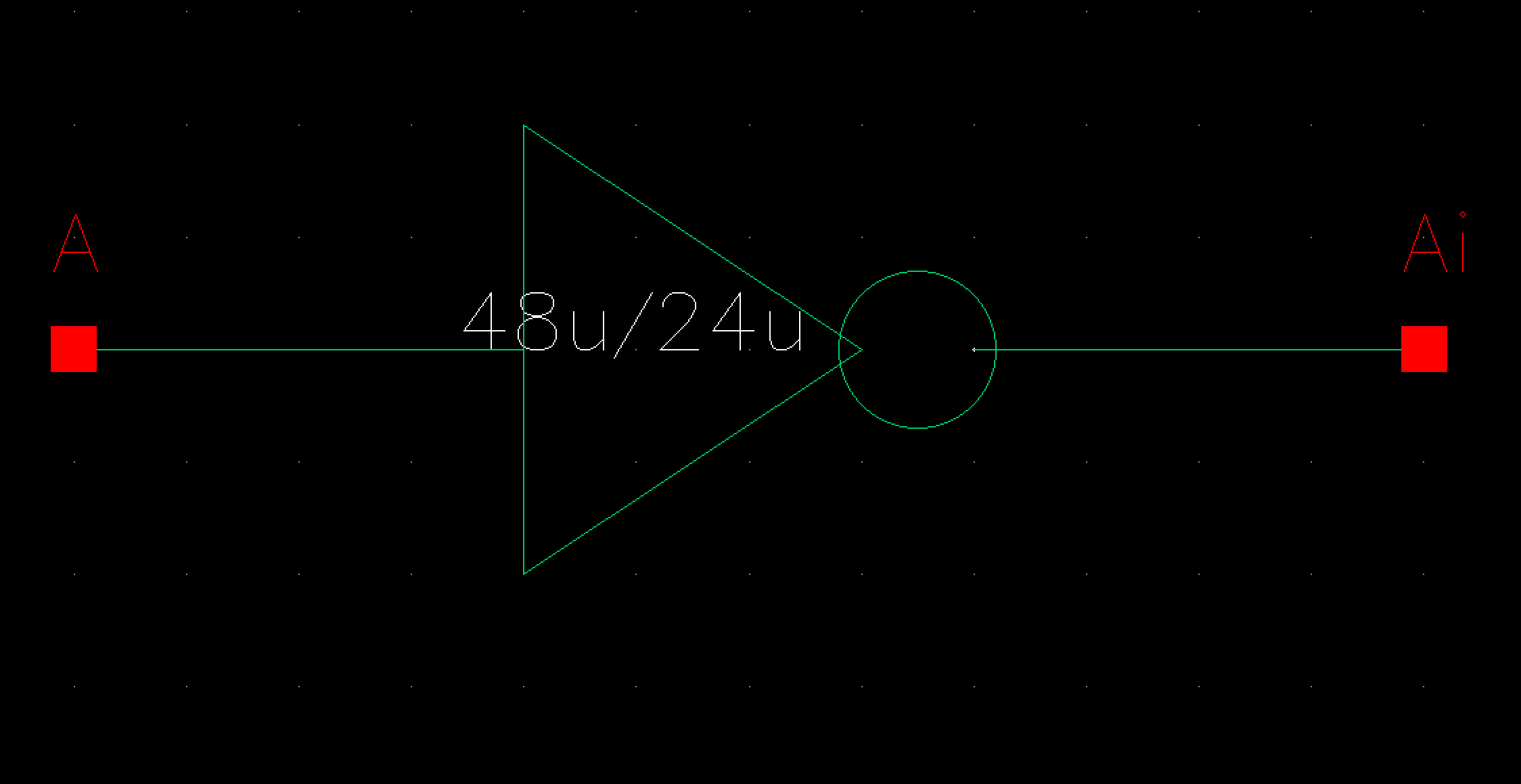

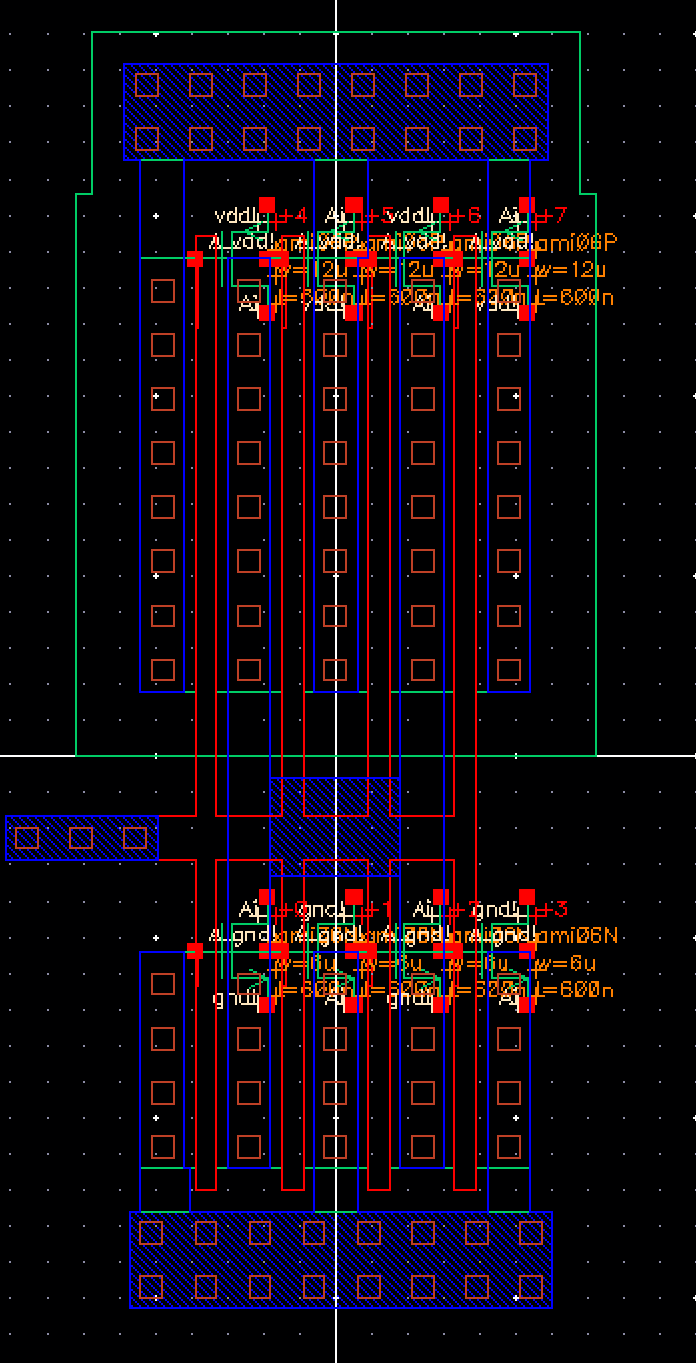

The

next step is to layout my schematic. My layout lets us see exactly what

4 fingers means. 4 fingers refers to the addition of 4 poly lines going

down our MOSs this results in the creation of more MOSs without

having to increase length. In this case we we're able to create 4 12u

PMOS and 4 6u NMOS. Despite the radical difference in this layout

compared to the layout in step 1a and tutorial 3 we still follow the

same steps. I interconnect our Poly's and connect these polys to our

m1_poly. After this I interconnect our PMOS Source with our NMOS Drain.

I next connected my PMOS drain to VDD and my NMOS source to GND. All

that was left after this was add pins to specify our inputs

,inputoutputs and outputs.

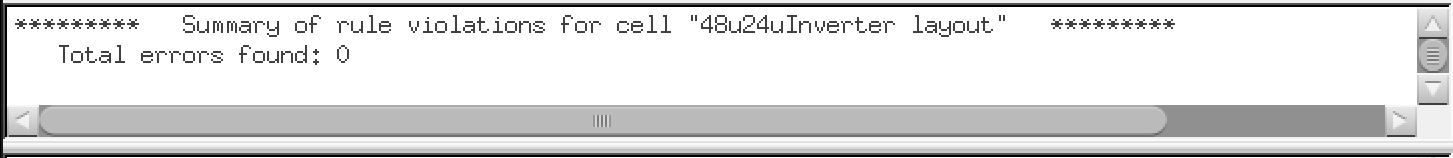

After completing my layout I drc'd my layout. As seen above it successfully drc'd. I next extracted my layout.

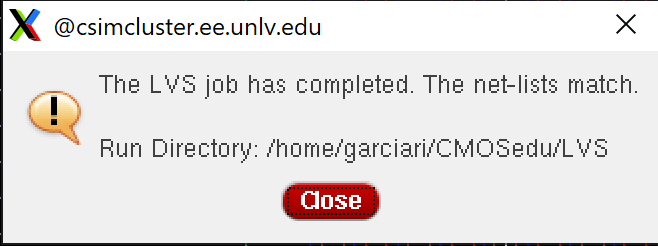

After extracting my layout I next run an LVS to make sure I successfully layed out my 48u/24u CMOS Inverter.

I have successfully layed out my 48u/24u CMOS inverter. |

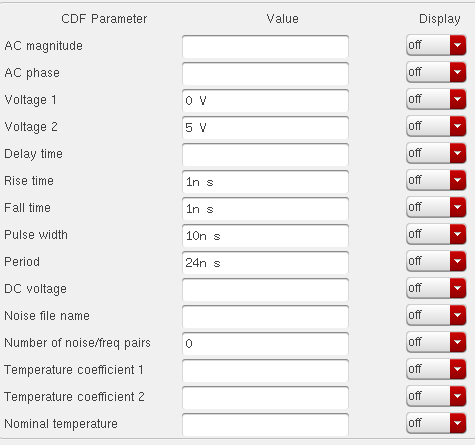

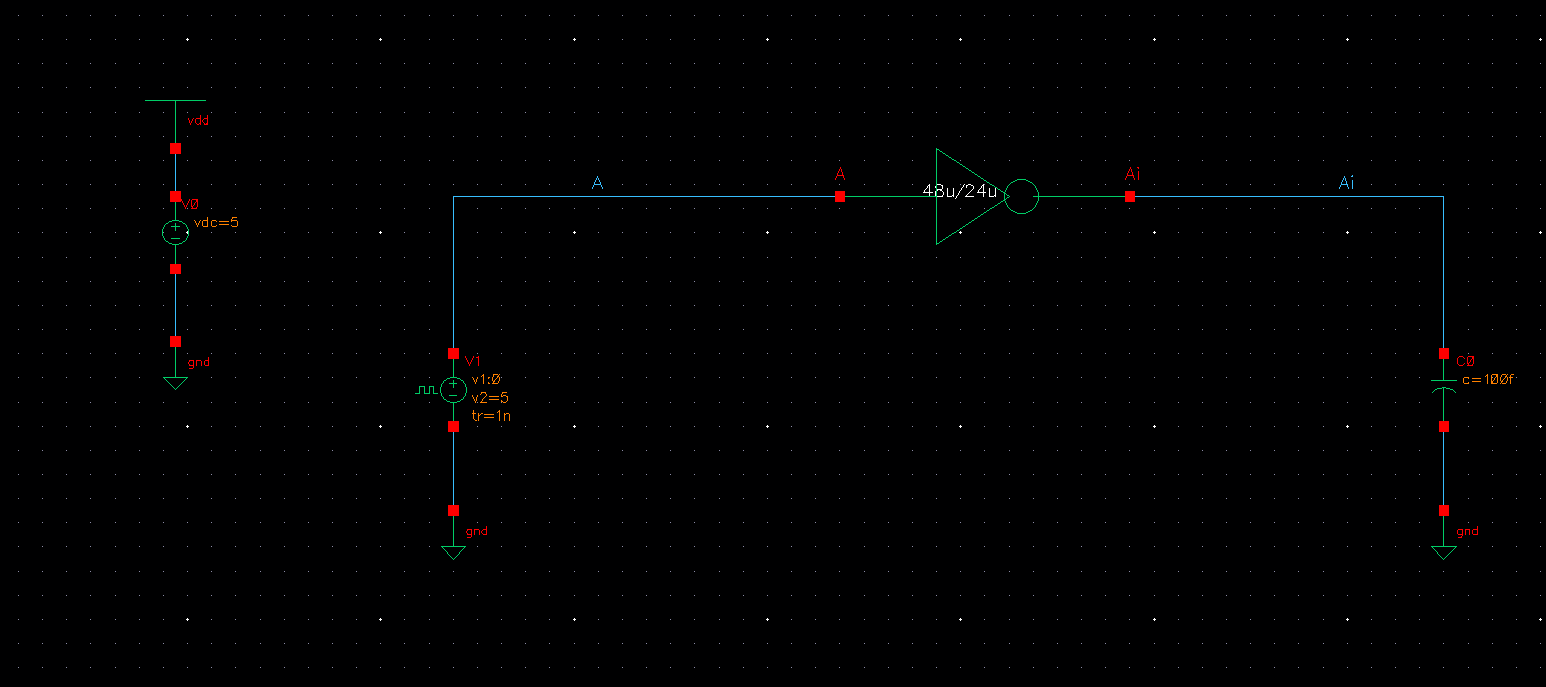

| 2a | I next ran simulations using my 12u/6u CMOS Inverter.

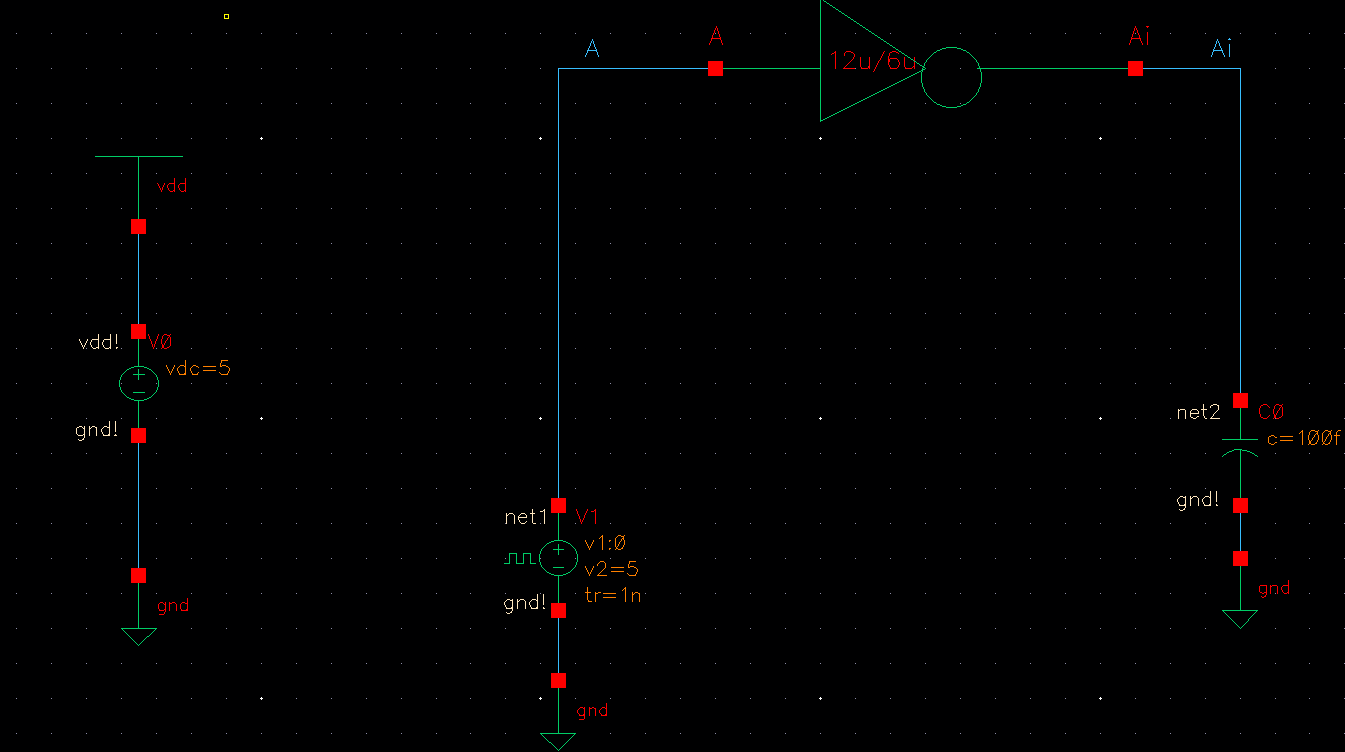

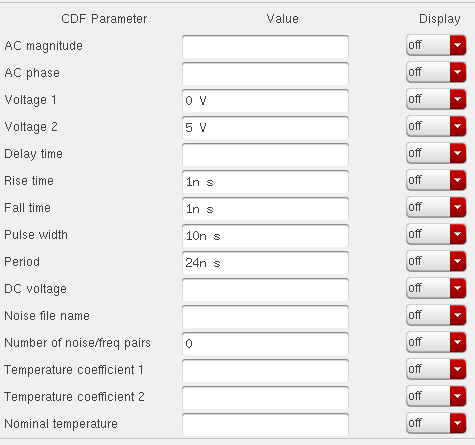

First

I created a schematic which consisted of VDD connected to a 5V DC

voltage source. A pulse voltage signal connected to our 12u/6u CMOS

Inverter, then a capacitor connected to the output of our Inverter.

Above is the settings used for our voltage pulse signal.

After

setting up my schematic I ran transisent analysis for different

capacitors. Our capacitors consisted of 100fF, 1pF, 10pF and 100pF.

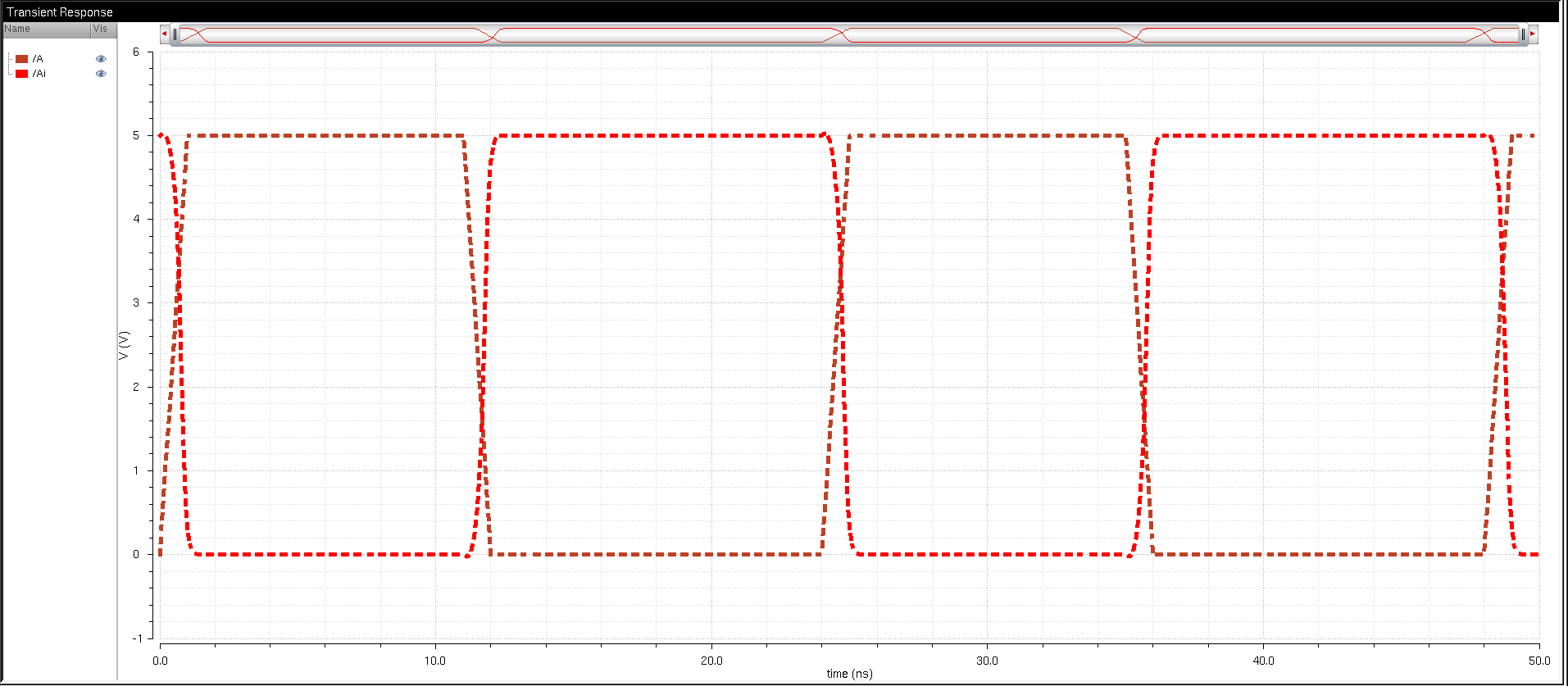

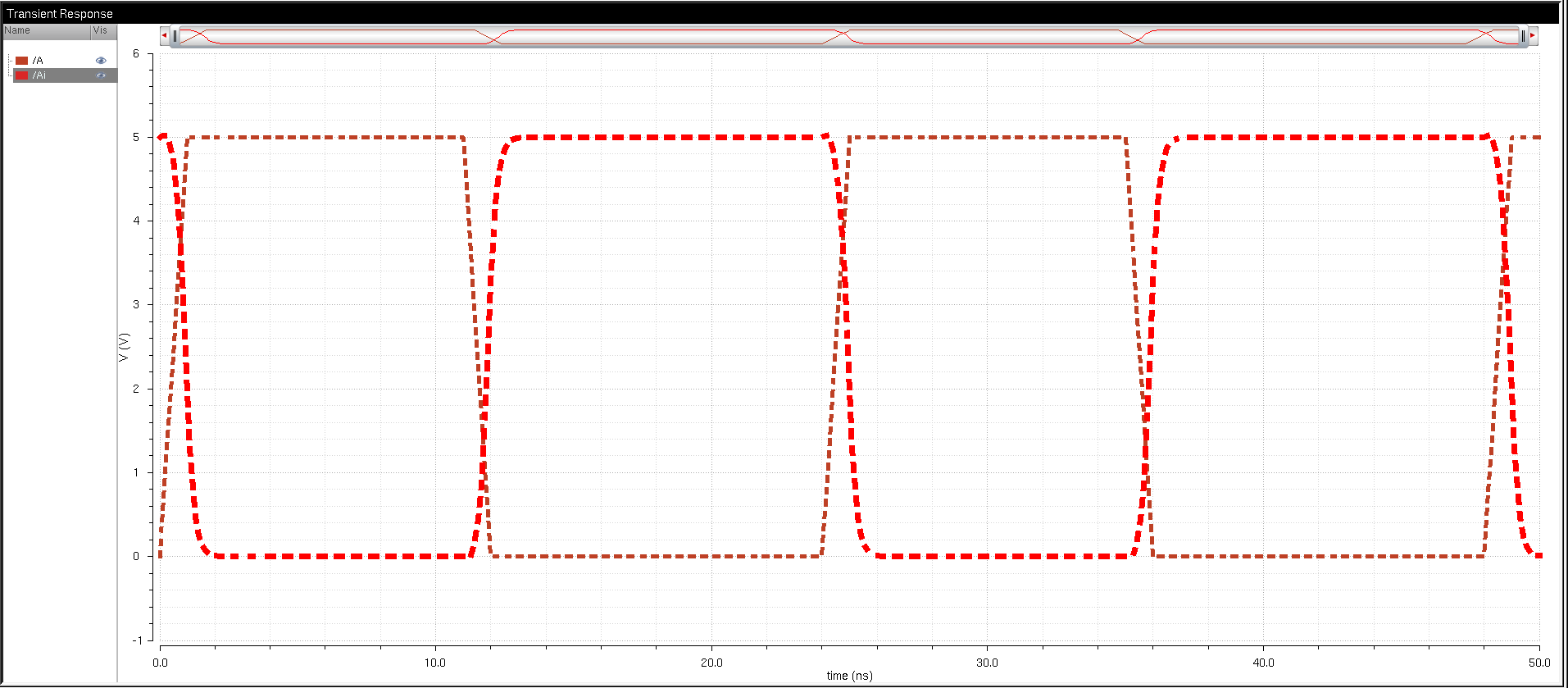

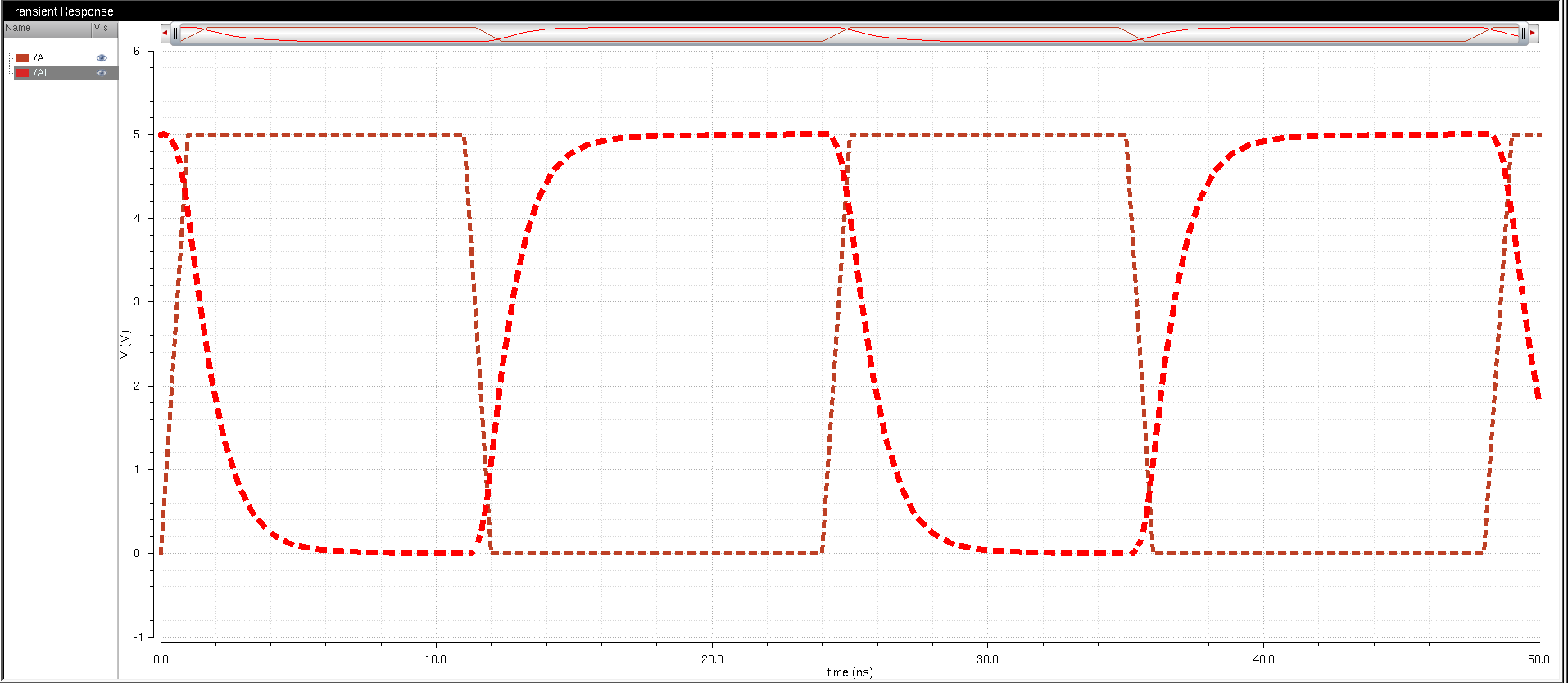

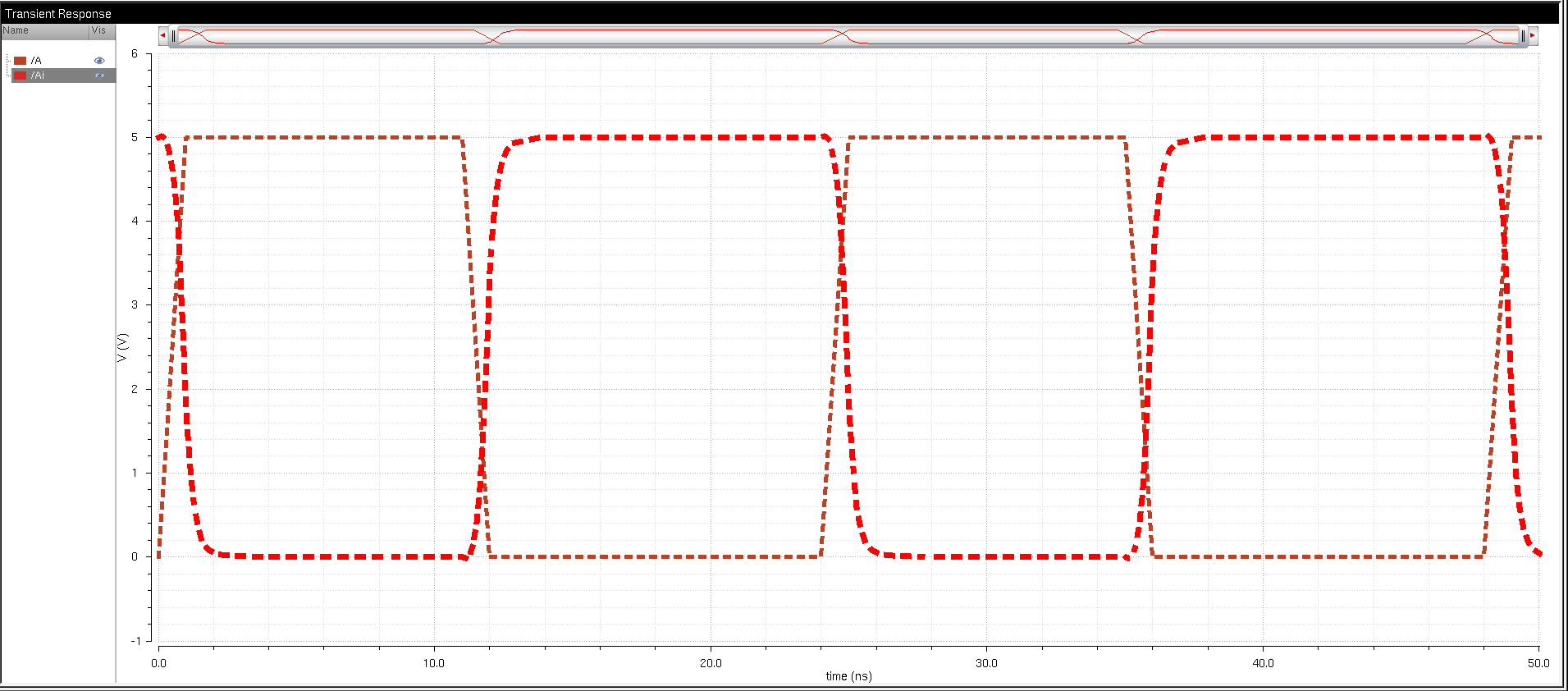

100fF

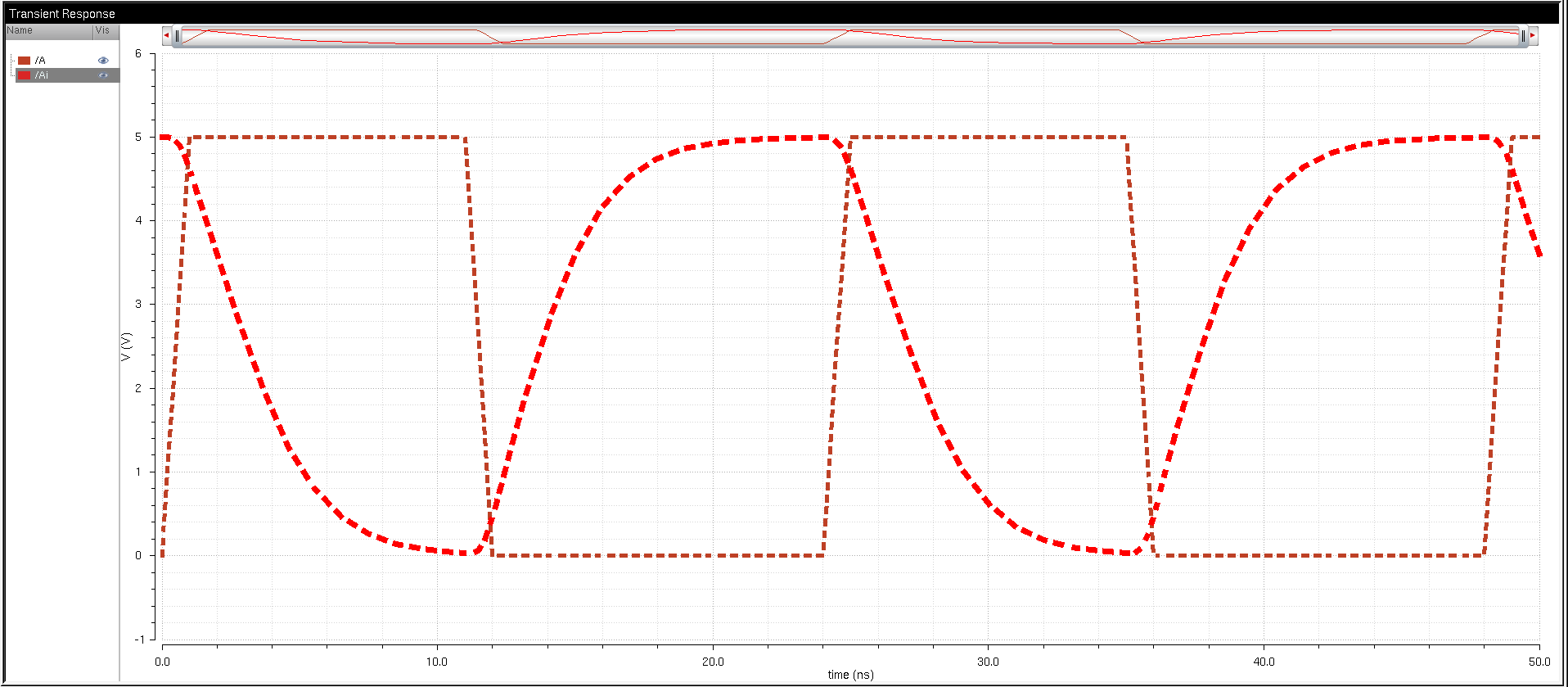

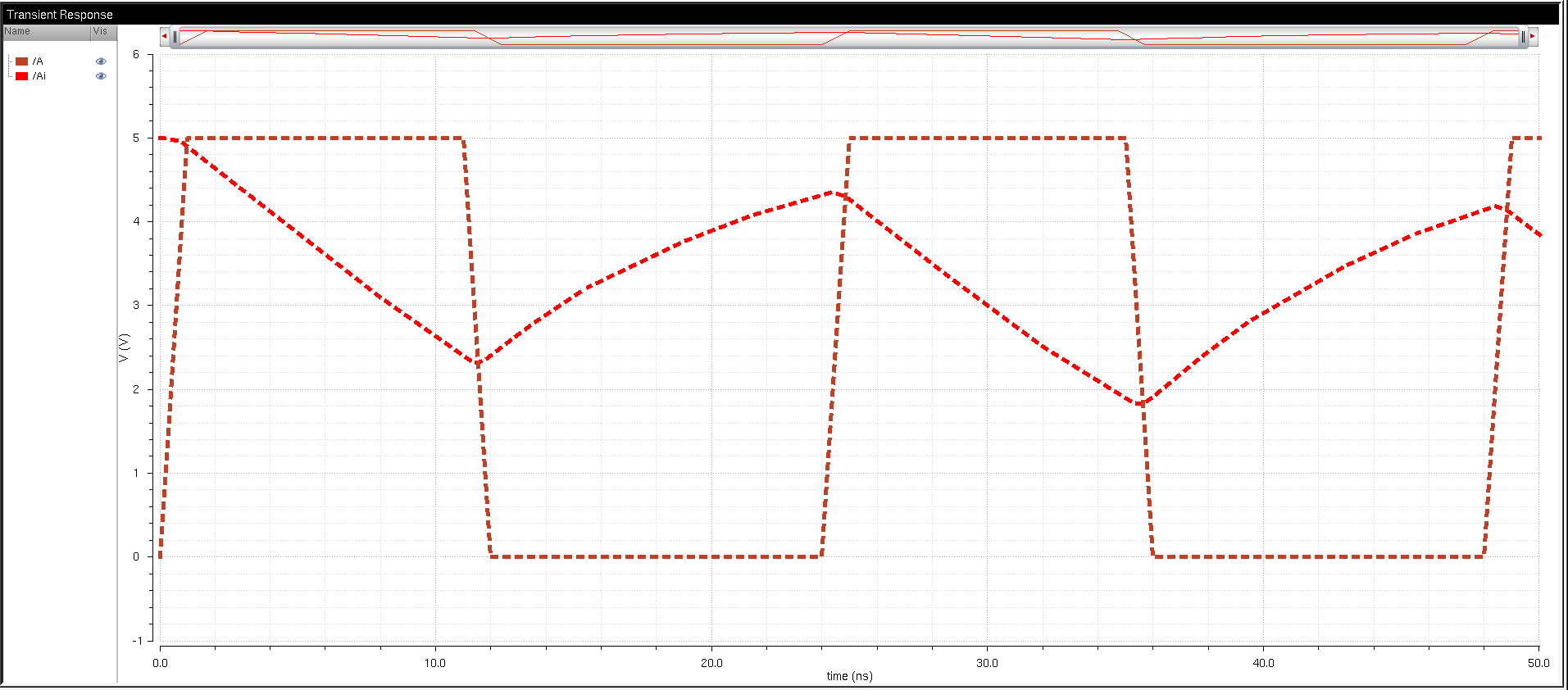

1pF

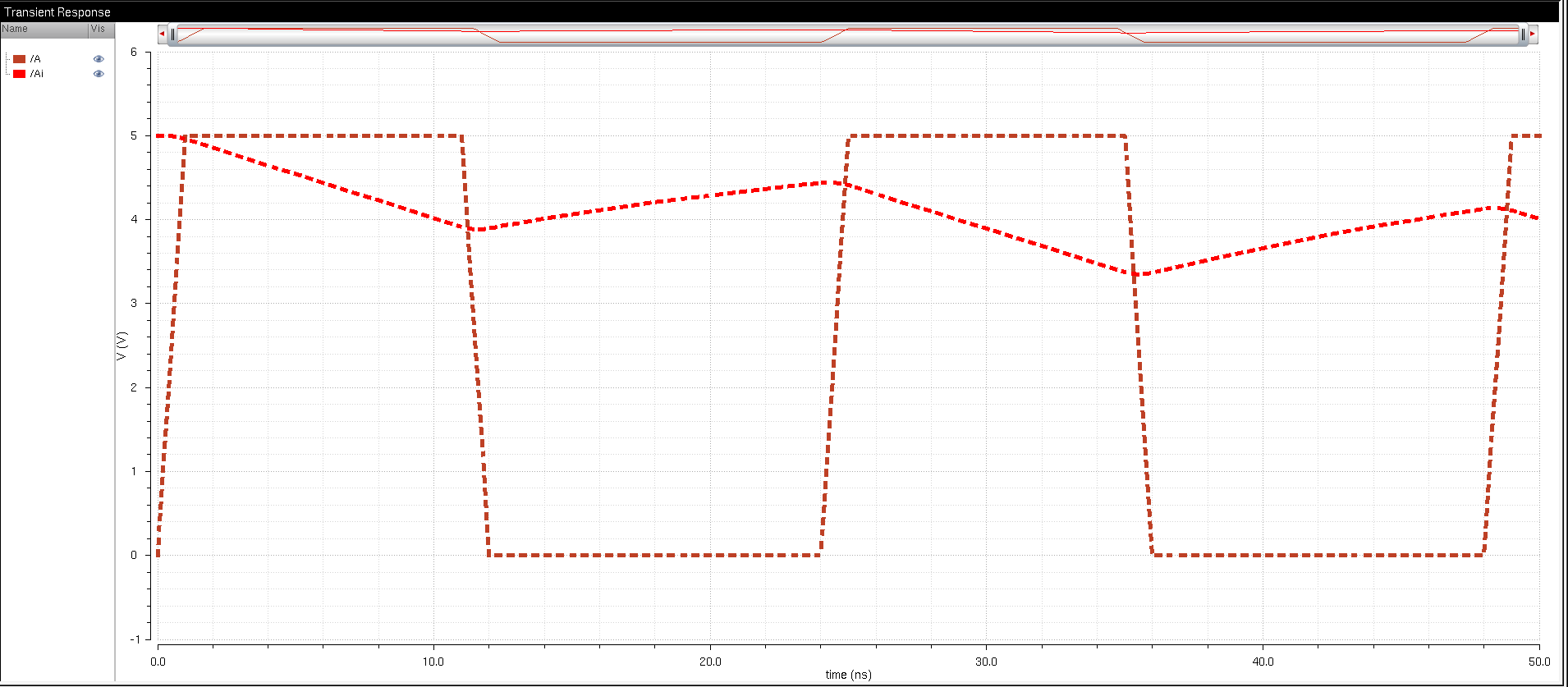

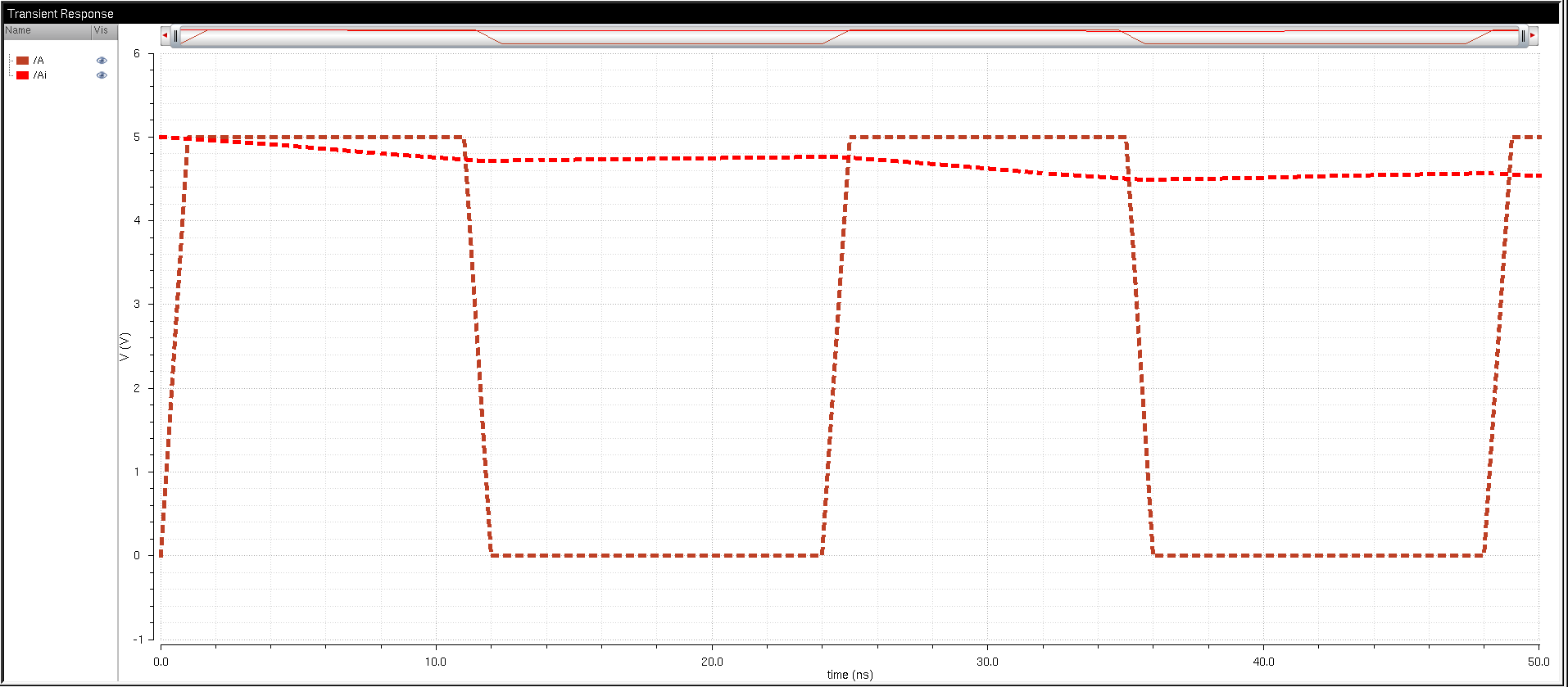

10pF

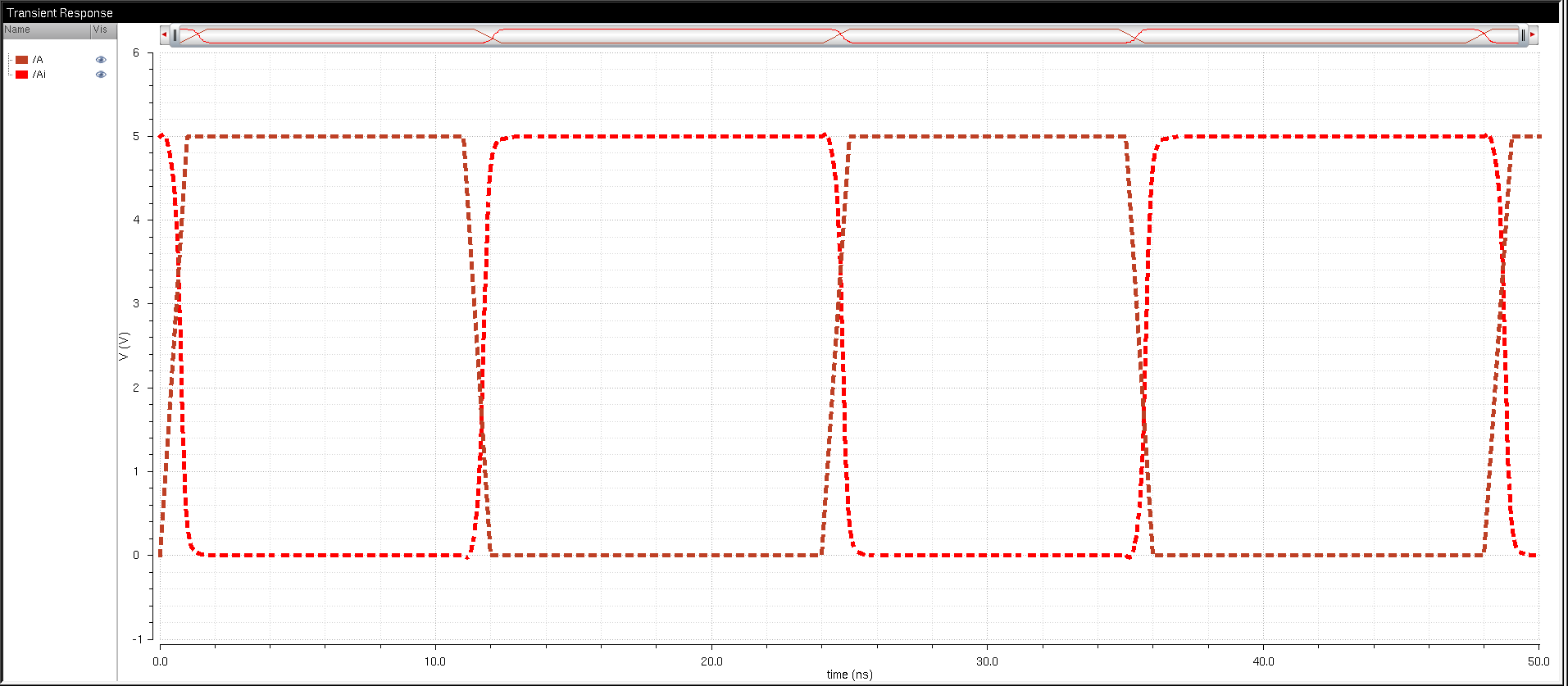

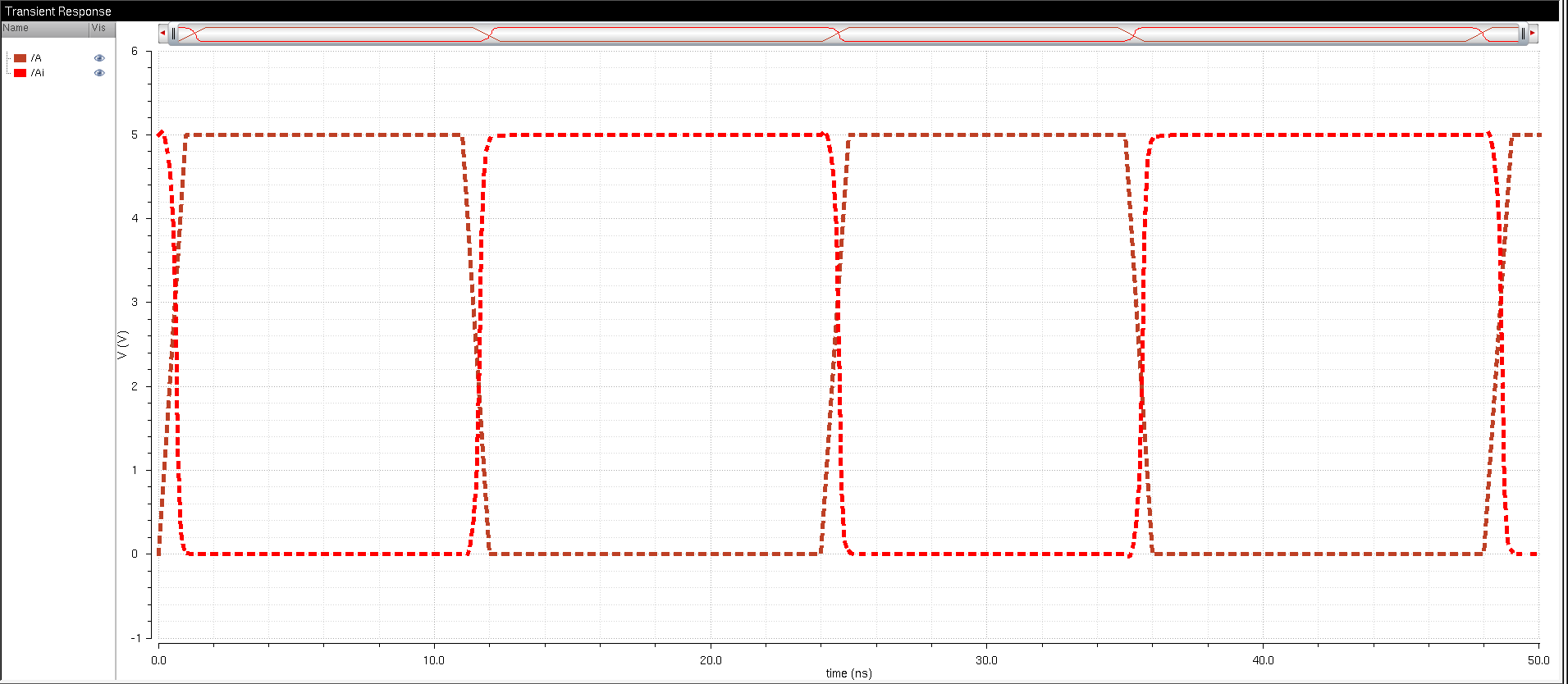

100pF

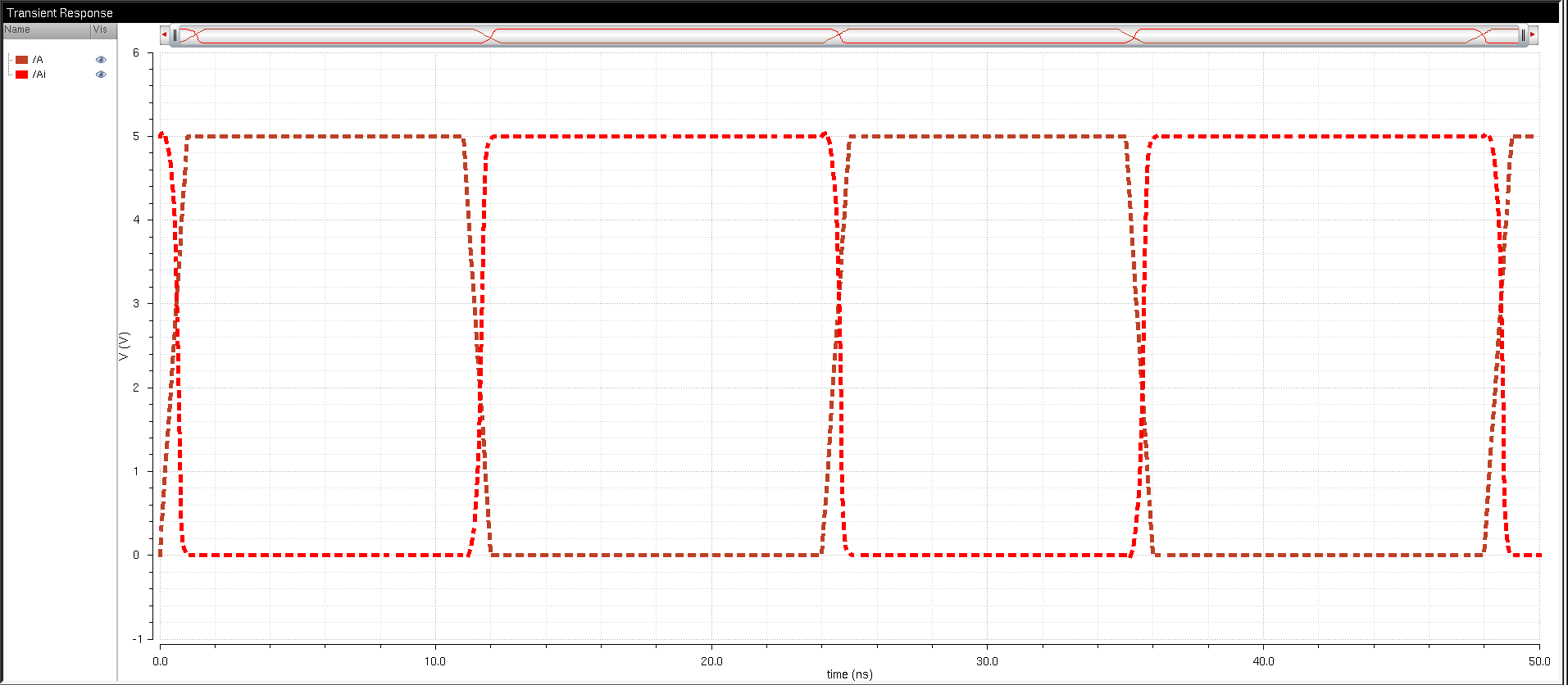

The

first thing I noticed is that my CMOS Inverter is in fact working, when

our input is high our output is low and when input is low our output is

high. This is very evident in the 100fF capacitor transisent response

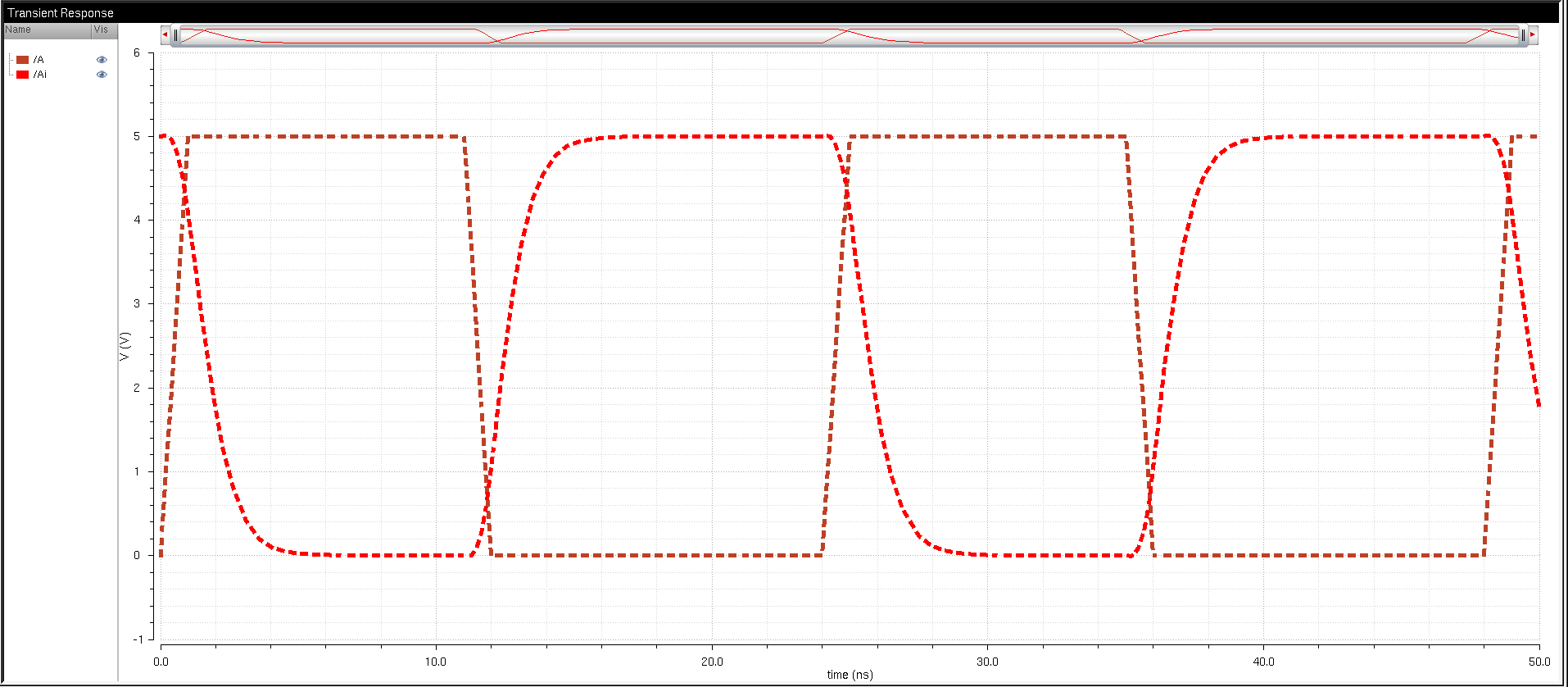

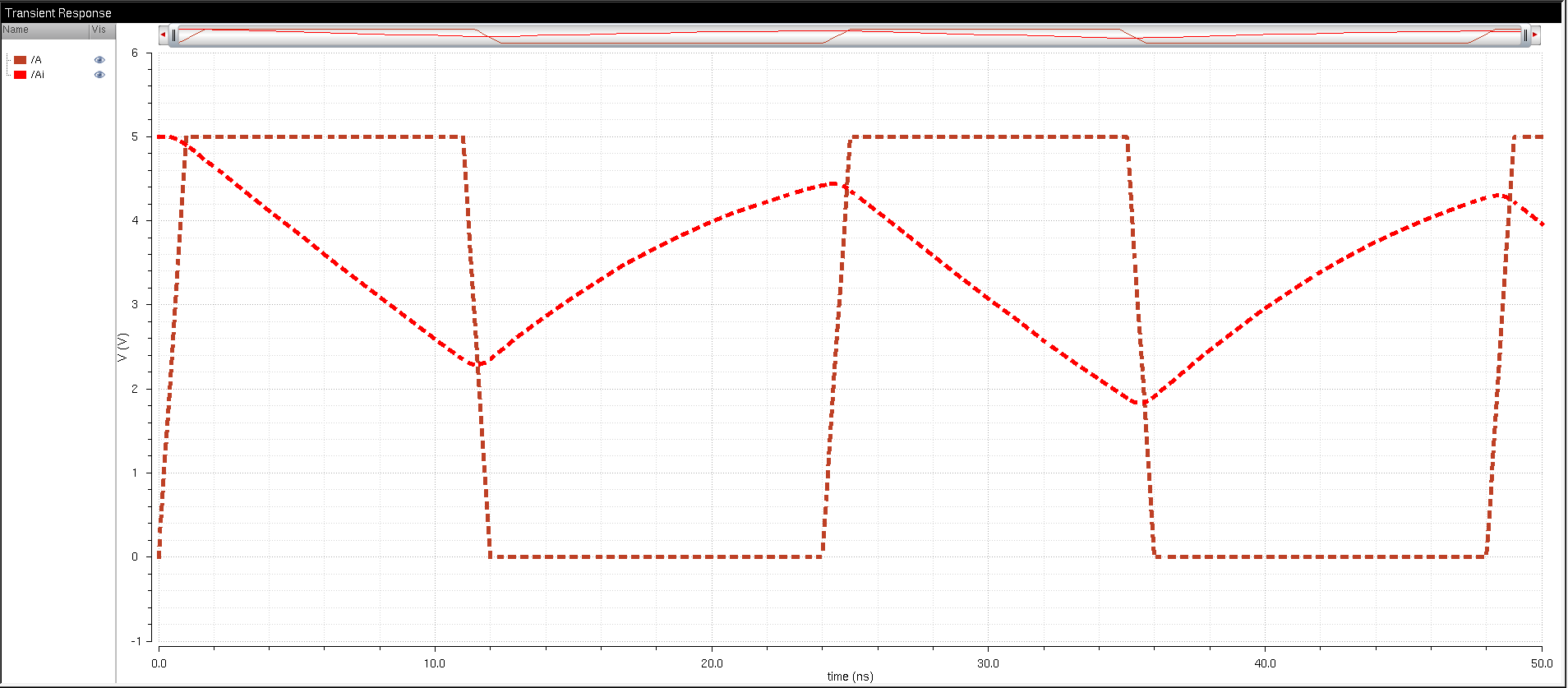

graph. The second thing I noticed is that as we increased the capacitor

size our graphs began to not be inversely related to our input. This is

due to the fact that our capacitors increased in value thus they were

able to hold more charge before dissapating. This is very evident in

the 100pF capacitor transisent reponse graph in which we see that we

are close to achieving a constant output. |

| 2b | For step 2b we follow the exact same steps as steps 2a except this time we are simulating using our 48u/24u CMOS inverter. We start by first creating a schematic.

Our schematic is exactly the same as the 12u/6u CMOS inverter except for the fact we are simulating a 48u/24u CMOS Inverter.

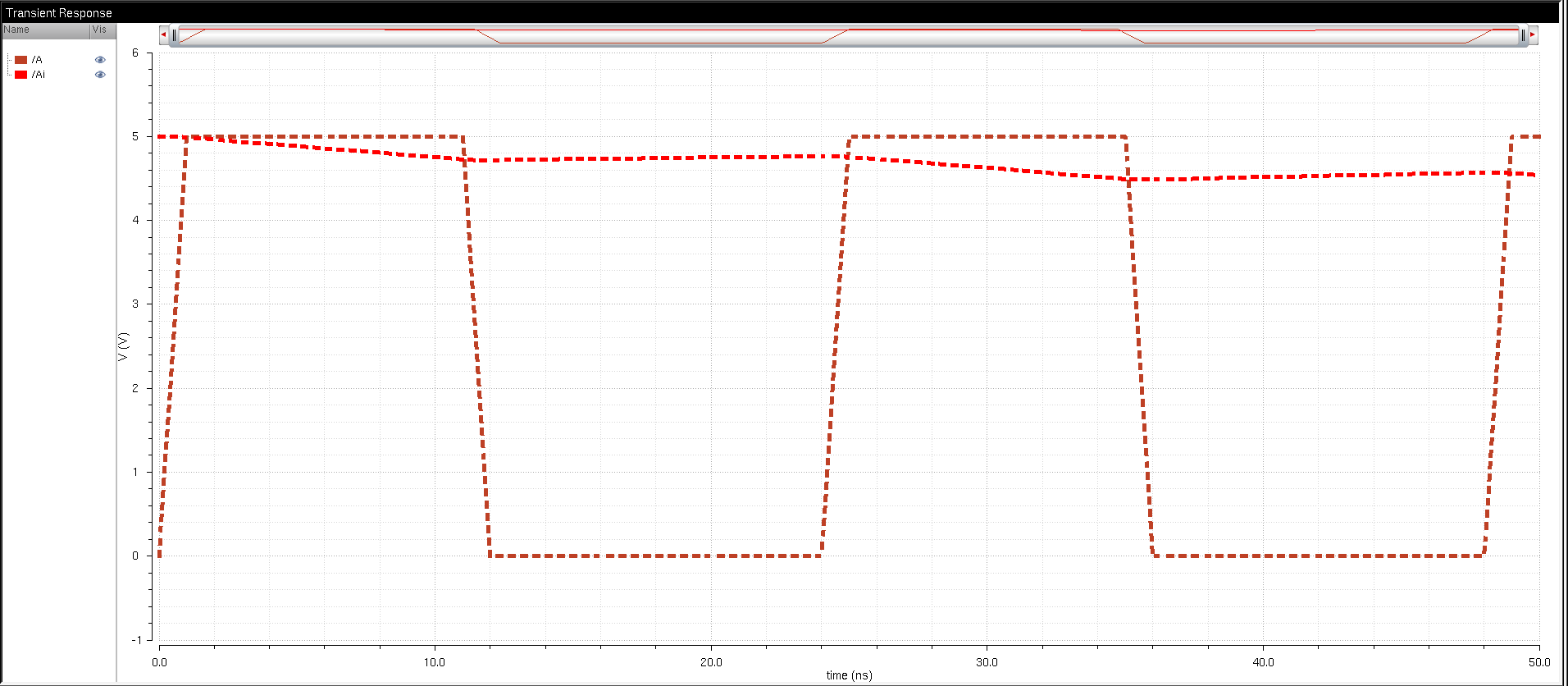

Our

VPulse settings are exactly the same. After completing my schematic I

ran transisent analysis for 100fF, 1pF, 10pF, and 100pF capacitor loads.

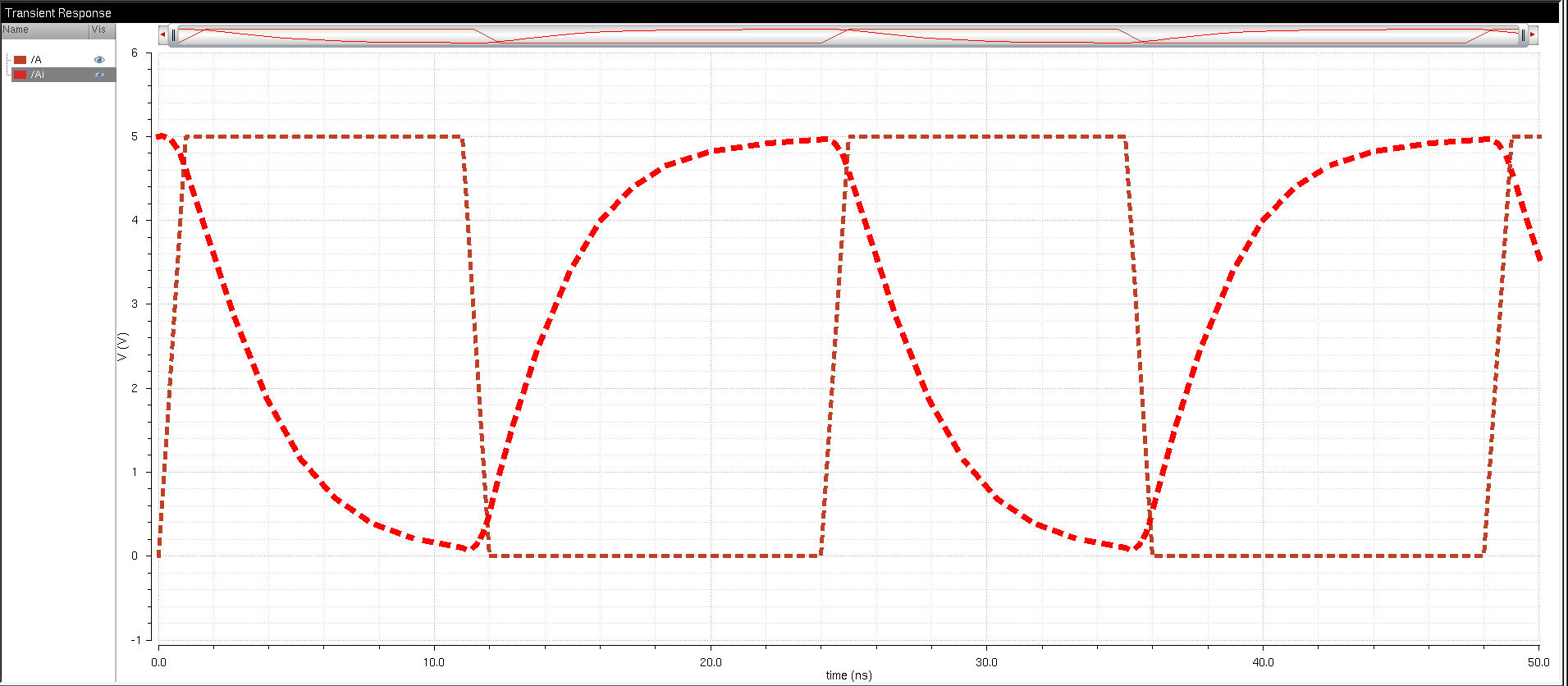

100fF

1pF

10pF

100pF

Our

48u/24u CMOS inverter outputs share the common theme that the 12u/6u

had, as I increased the capacitve load my outputs began to get more

straightened out. However, for my 48u/24u CMOS inverter this occured

slower compared to 12u/6u. This can be seen by comparing th 100pF load,

our 12u/6u CMOS inverter output is more straight/constant than our

48u/24u CMOS inverter output. |

| 3a | For

the final step 3a, I simulated the same schematic as in step 2a with

the same loads 100fF, 1pF, 10pF and 100pF. However this time I used the

ultra simSPICE simulator instead of Spectre.

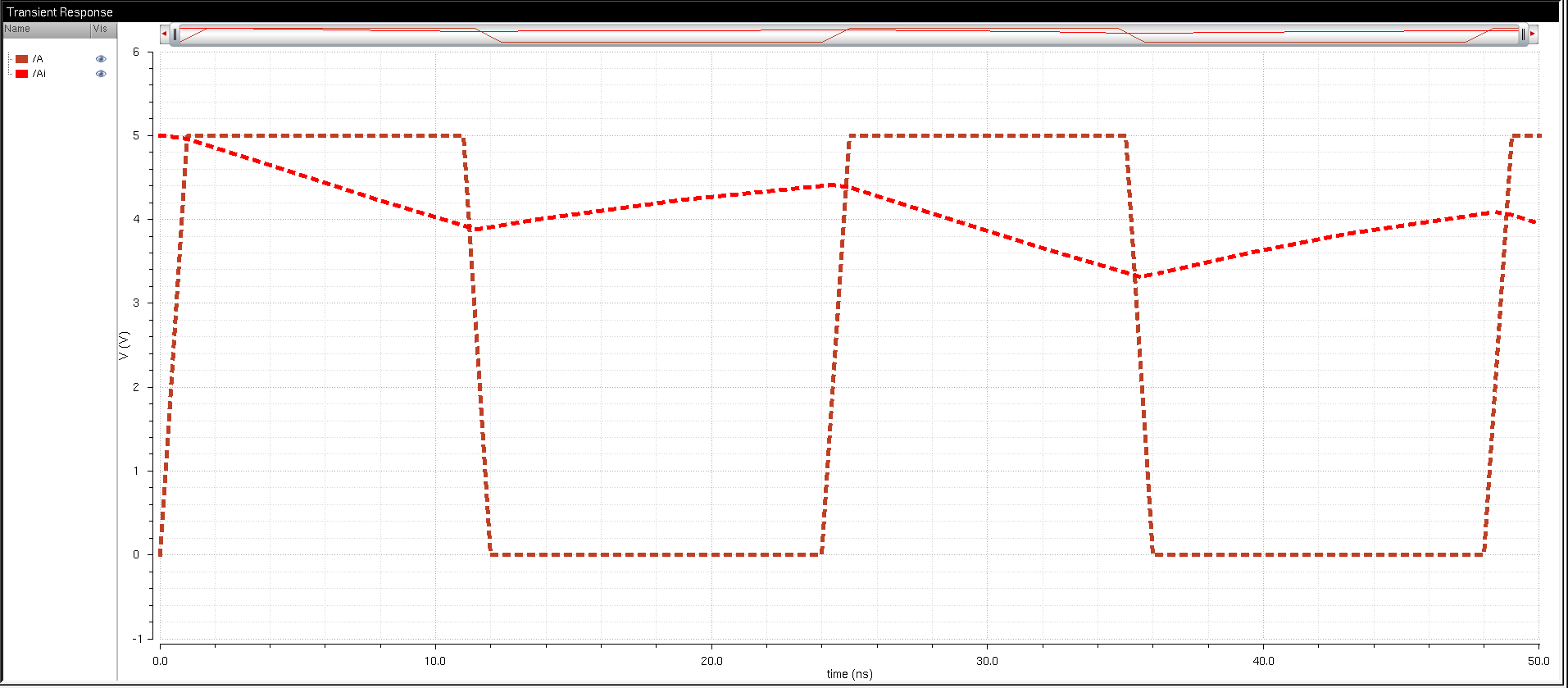

100fF

1pF

10pF

100pF

In

this case, when comparing my ultrasim transisent graphs to my spectre

graphs I really couldn't see any difference between the two. In the

future I will continue to use spectre since the time to create the

netlists and simualtions hasn't to been too bad and because I'd have

accurate results. However, this could possibly change as we simulate

more complex schematics and the speed difference between ultrasim and

spectre becomes noticeable. |

| 3b | As in step 3a, we repeat the simulations that I did in step 2b however this time simulating using ultra sim instead of spectre.

100fF

1pF

10pF

100pF

As

stated in step 3a, I didn't see any noticeable difference when using

Ultra Sim compared to Spectre but as I gain more experience with

cadance I could possibly develop a use case in which Ultra sim is more

appropriate than spectre. For now spectre should suffice. |