EE 421L –

Digital IC Design Lab - Project

Authored by Chris Barr

Email: barrc1@unlv.nevada.edu

11/13/2019

Project

Goal:

Project (not a group effort, each student will turn in their own project)

– design a circuit that takes a 9-11 MHz clock signal and generates a 36-44 MHz

clock signal. In other words, design x4 clock multiplier. The input clock is

multiplied by 4 and output. Assume the input clock signal has a 50% duty cycle.

Project

Requirements:

First half of the project (schematics and design discussions) of your

design and an html report detailing operation (including simulations), is due

at the beginning of lab on Nov. 13.

·

Your design report in html should show various input clock frequencies

and VDD voltages to show it works.

·

Put your report (proj.htm) in a folder called /proj

in your directory at CMOSedu and link to your

index.htm page.

·

Dr. Baker will go over your design with you (in person), including

running simulations, when lab meets on Nov. 13.

Second half of the project, a verified layout and documentation (in

html), is due at the beginning of lab on Nov. 20.

·

Dr. Baker will meet with you on Nov. 20 to go over your layout

·

Put your report in the /proj folder in your

directory at CMOSedu.

·

Ensure that there is a link on your project report webpage to your zipped

design directory.

Table of

Contents

First Half of Project (Schematic/Discussion)

-

1.) Design Planning/Sketching

-

2.) Component

Schematics/Symbols

-

3.) Final Design

Schematic/Simulations

Second Half of Project (Layout/Documentation)

-

4.) Component Layouts/Extracts

-

5.) Final Design

Layouts/Extracts

-

6.) Zipped Project

Folder (Download Link)

First Half

of Project (Schematic/Discussion):

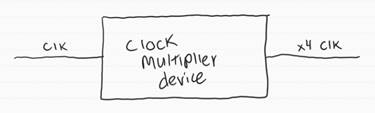

The goal is to quadruple the clock signal input. What we have is one

input (9-11 MHz clock signal), and one output (36-44 MHz clock signal).

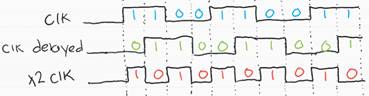

In order to multiply a 9-11 MHz clock signal, the use of digital logic

design can be implemented. Here’s an example of how we can multiply a clock

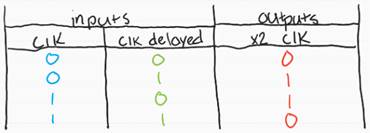

signal by utilizing an XOR gate.

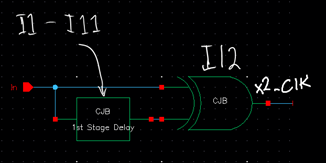

In this diagram, its

input will be a standard clock signal, and its output the doubled clock signal.

In this diagram, its

input will be a standard clock signal, and its output the doubled clock signal.

This technique is called edge detection and is what we will be using to

quadruple the clock signal.

If we can manage to

push back the “clk delayed” by half of the duty

cycle, our result for “x2 clk”

If we can manage to

push back the “clk delayed” by half of the duty

cycle, our result for “x2 clk”

would appear as shown in the drawn-out waveform.

Here are the characteristics

of an XOR gate to prove that the waveform should act as drawn above.

Here are the characteristics

of an XOR gate to prove that the waveform should act as drawn above.

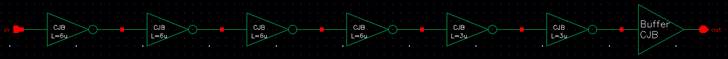

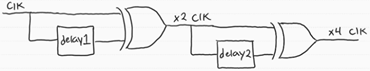

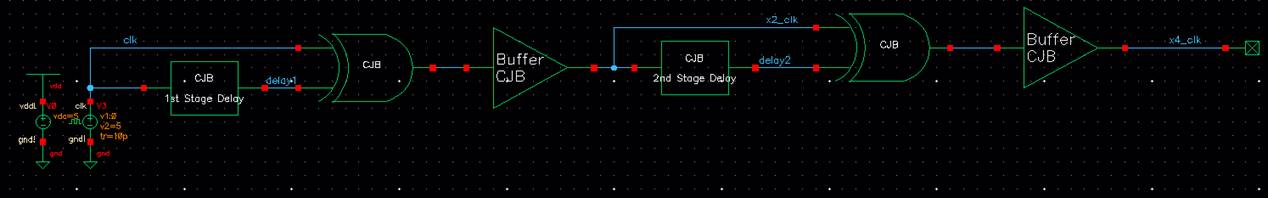

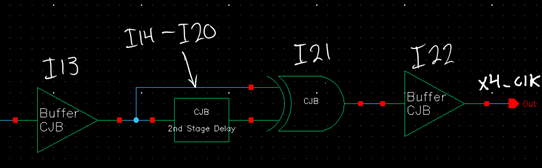

To quadruple our clock signal we’ll need two

different delay boxes, so our design will look like this:

Each delay box will

have its own amount of time to delay because it will handle two different

frequencies.

Each delay box will

have its own amount of time to delay because it will handle two different

frequencies.

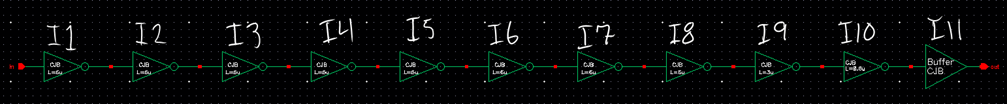

And to make these delay boxes, we will need inverters.

So, to finalize our design, we will need two different kinds of

components: XOR gates, and Inverters.

2.) Component

Schematics/Symbols

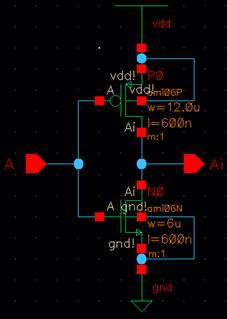

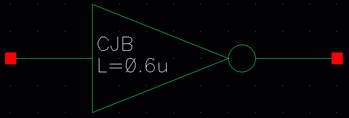

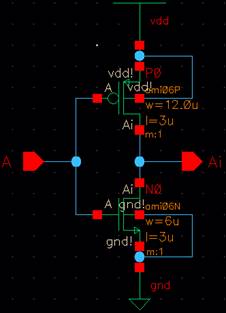

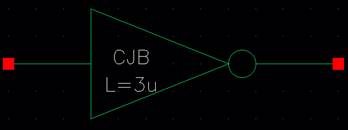

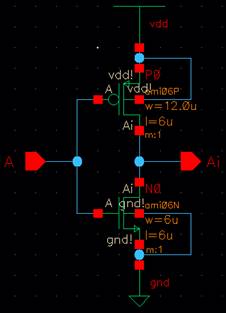

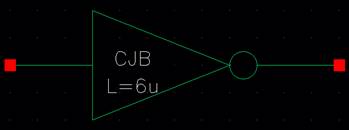

We need two components; XOR gate, and an inverter. But because we want to

create a longer delay, we want to increase the lengths of these inverters.

So, we’ll be making 3 kinds of inverters that are all 12u/6u with varying lengths.

We’ll have inverters with lengths of 6u, 3u, and the minimum length of 0.6u

(600n).

|

|

Schematic |

Symbol |

|

Inverter (Length = 0.6u) |

|

|

|

Inverter (Length = 3u) |

|

|

|

Inverter (Length = 6u) |

|

|

|

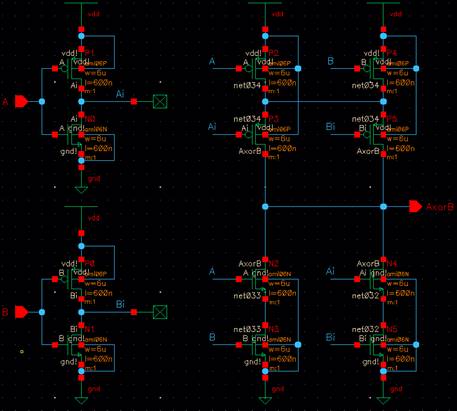

XOR Gate |

|

|

Inverter (Length = 6u), Inverter (Length = 3u), and Inverter (Length =

0.6u):

·

These components are used in the delay boxes.

·

The Inverter (Length = 0.6u) main purpose was used for the Buffer.

XOR Gate:

·

This is the main component that will help double the frequency.

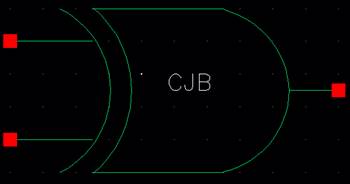

Now that we have the smaller components created, we can condense them to

create the delay boxes and a buffer.

|

|

Schematic |

Symbol |

|

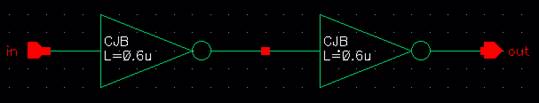

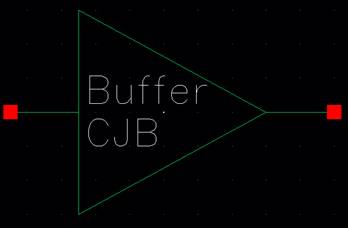

Buffer |

|

|

|

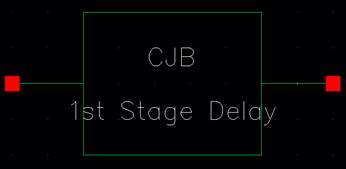

1st Stage Delay |

|

|

|

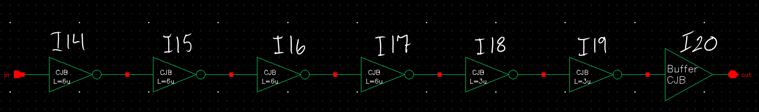

2nd Stage Delay |

(Click image to enlarge) |

|

Buffer:

·

We use two of the Inverters (Length = 0.6u) to square up the output

waveforms.

1st Stage Delay:

·

Using a clock input signal of 10 MHz (100ns period) as an example, this

delay box will delay the signal by roughly 25ns.

2nd Stage Delay:

·

Using a clock input signal of 10 MHz (100ns period) as an example, this

delay box will delay the signal by roughly 12.5ns.

3.) Final Design

Schematic/Simulations

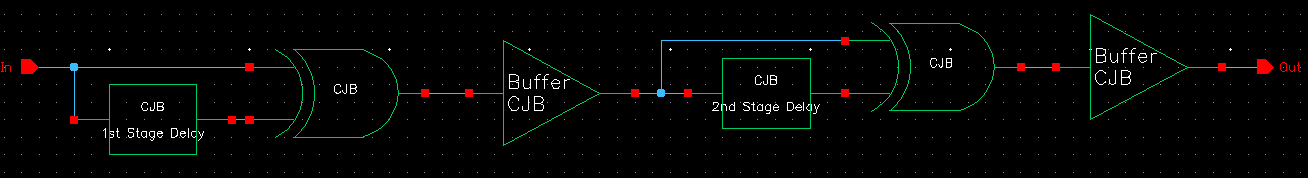

Putting all the components together as planned, this is what our final

schematic and symbol looks like.

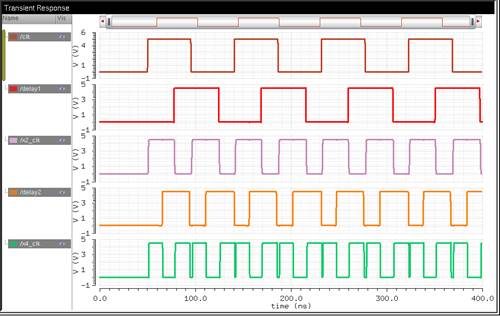

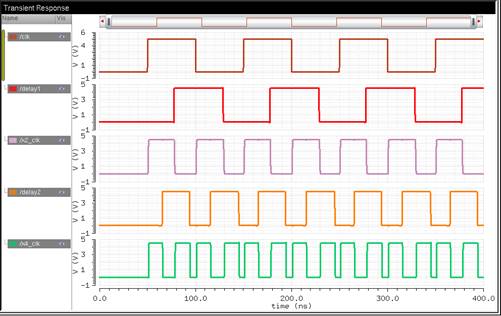

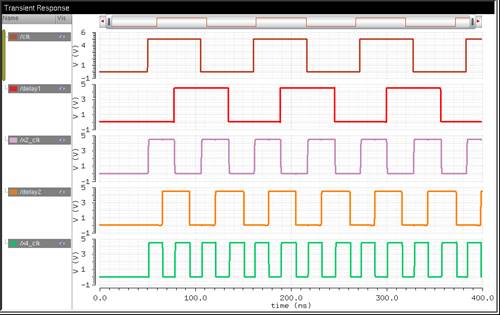

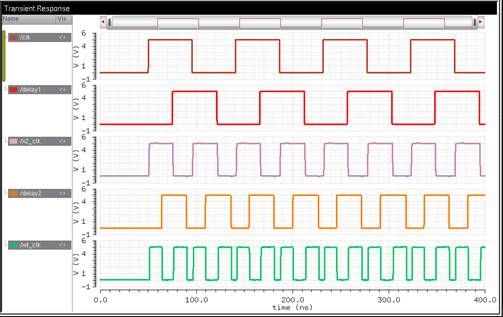

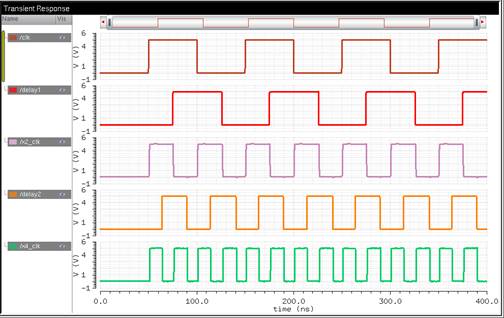

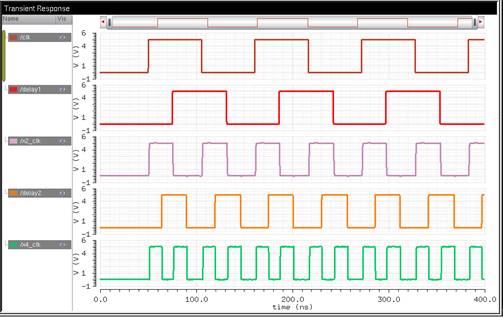

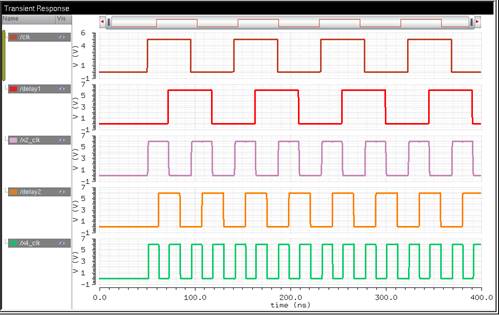

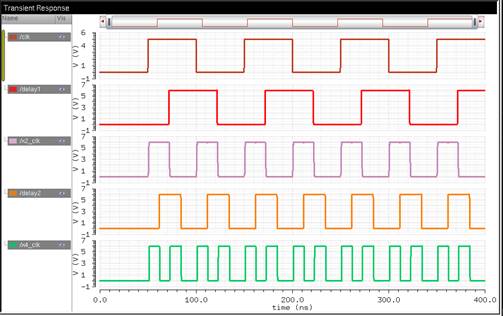

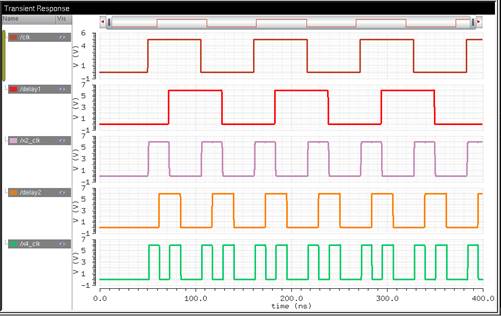

Proceeding to the detailed simulation of the x4 Clock Multiplier. This is

the setup that will test every point in the schematic.

Tabulated Results of the Simulations:

Note: Click image to enlarge

|

|

Frequency = 9 MHz |

Frequency = 10 MHz |

Frequency = 11 MHz |

|

VDD = 4.5V |

|

|

|

|

VDD = 5V |

|

|

|

|

VDD = 6V |

|

|

|

What we can notice is that at different Frequency values, we will get an

offset on our x4 clock signal and narrow the periods.

When we raise or decrease VDD it will raise or decrease the

amplitude of our x4 clock signal.

Notice that the further away the frequency and VDD get from 10

MHz and 5V (respectively), the output of the ‘x4_clk’ will cause a major

glitch. This is shown on the image of VDD = 4.5V and Frequency = 9 MHz.

Second Half

of Project (Layout/Documentation):

4.) Component Layouts/Extracts

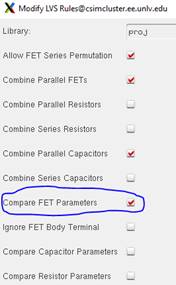

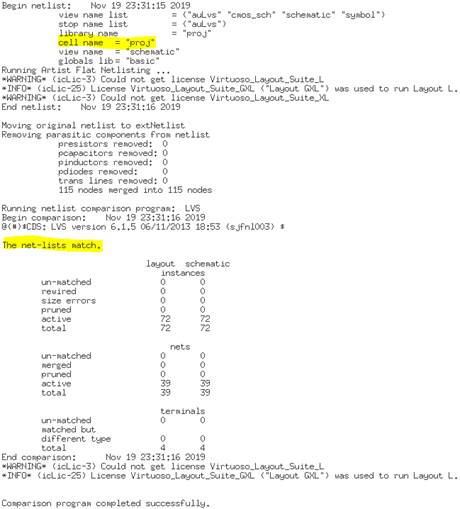

To ensure that our layouts match our schematics, we will be modifying the

default LVS rules:

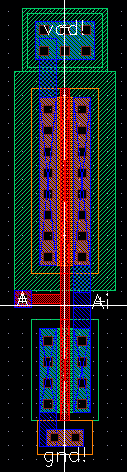

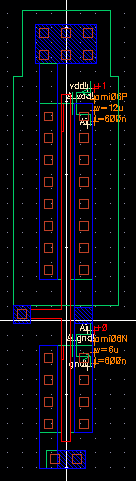

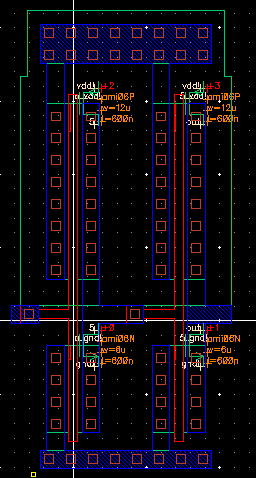

Tabulated Components Layout and Extracted views with DRC/LVS

Verification:

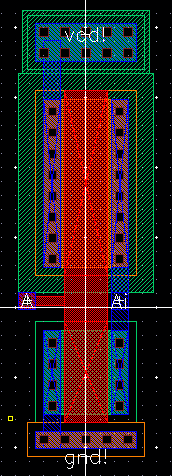

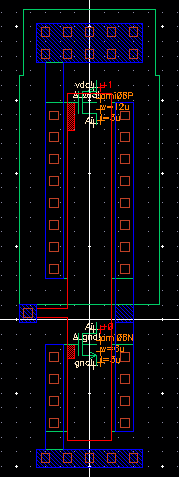

|

|

Layout |

Extracted |

DRC Verified |

LVS Verified |

|

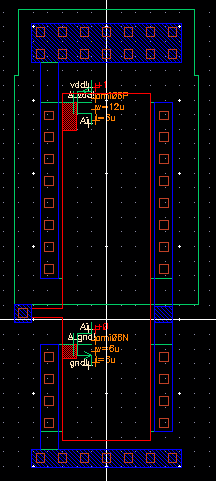

Inverter (Length =

0.6u) |

|

|

|

|

|

Inverter (Length =

3u) |

|

|

|

|

|

Inverter (Length =

6u) |

|

|

|

|

|

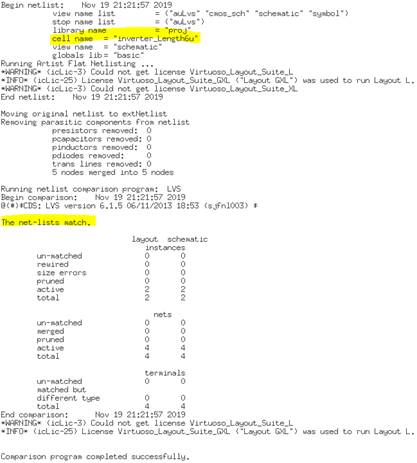

XOR Gate |

(Click image to

enlarge) |

(Click image to

enlarge) |

|

|

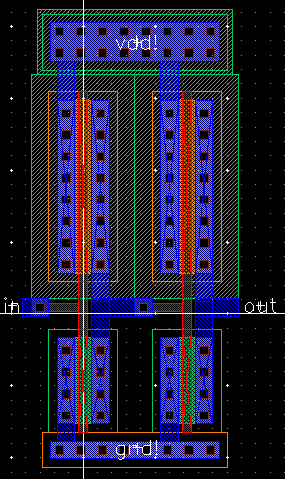

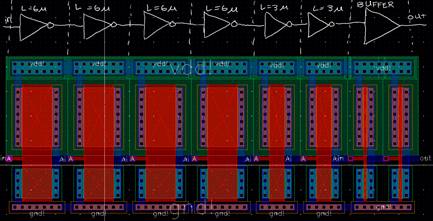

Tabulated Large Components Layout and Extracted:

|

|

Layout |

Extracted |

|

Buffer |

|

|

|

1st

Stage Delay |

|

|

|

2nd

Stage Delay |

(Click image to

enlarge) |

|

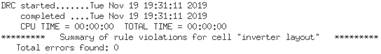

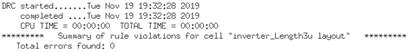

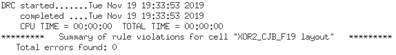

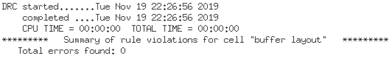

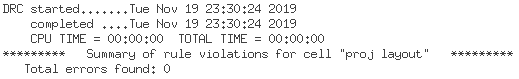

Tabulated Large Components DRC/LVS Verification:

|

|

DRC Verified |

LVS Verified |

|

Buffer |

|

|

|

1st

Stage Delay |

|

|

|

2nd

Stage Delay |

|

|

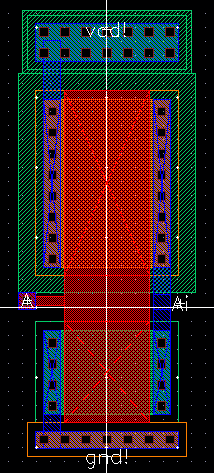

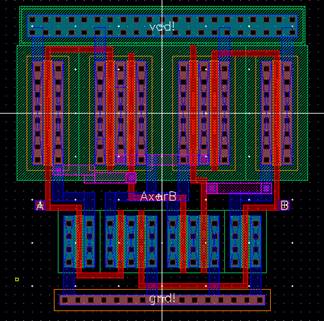

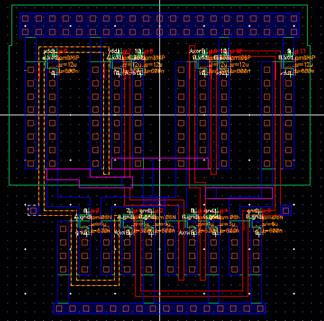

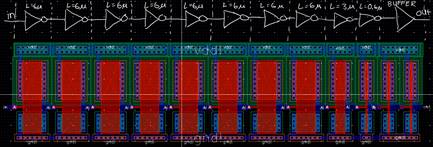

5.) Final Design

Layouts/Extracts

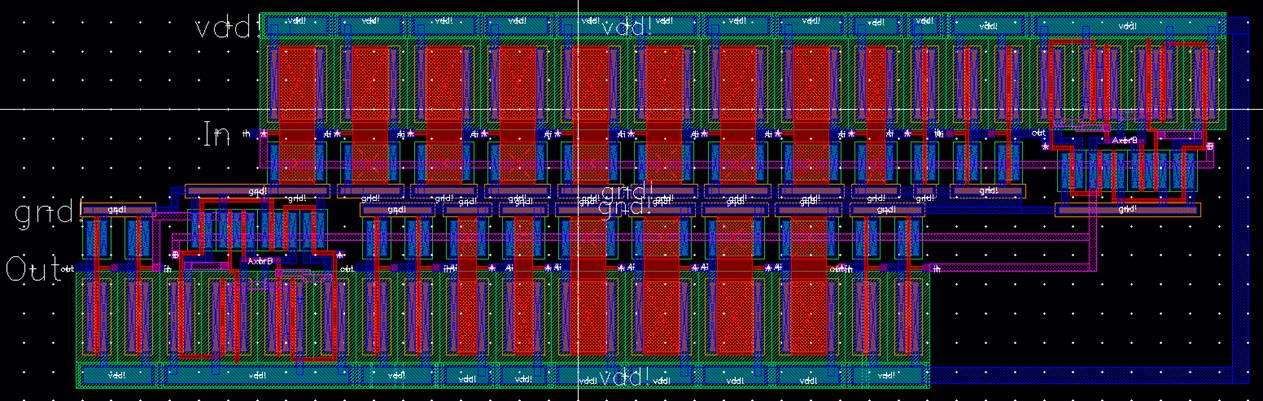

Now that all the designs are modulated and verified, the final design can

easily come together.

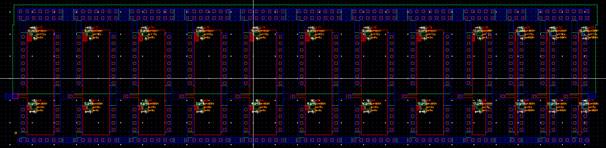

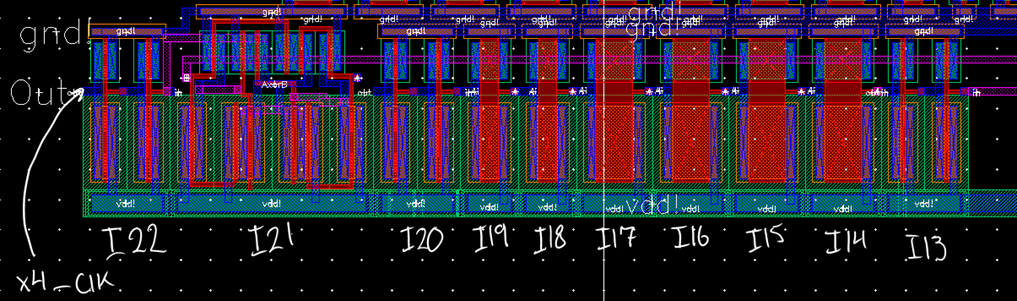

Layout view:

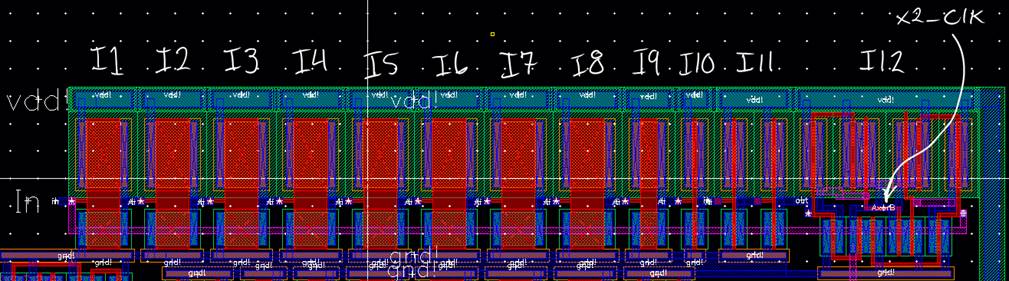

The top half of the layout represents the ‘x2_clk’.

Below is a labeled schematic of the instantiations within the ‘1st

Stage Delay’ box.

Below is a labeled schematic of the first half of the final design

schematic.

Below is a labeled layout of the top half of the final design layout to

make clarity of the matching schematic.

The bottom half of the layout represents the ‘x4_clk’.

Below is a labeled schematic of the instantiations within the ‘2nd

Stage Delay’ box.

Below is a labeled schematic of the second half of the final design

schematic.

Below is a labeled layout of the top half of the final design layout to

make clarity of the matching schematic.

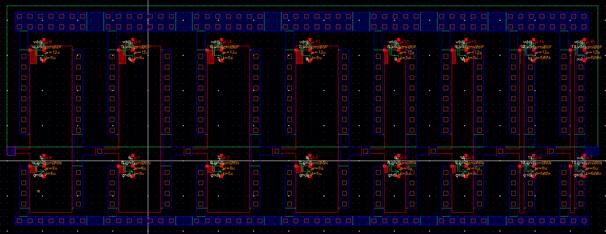

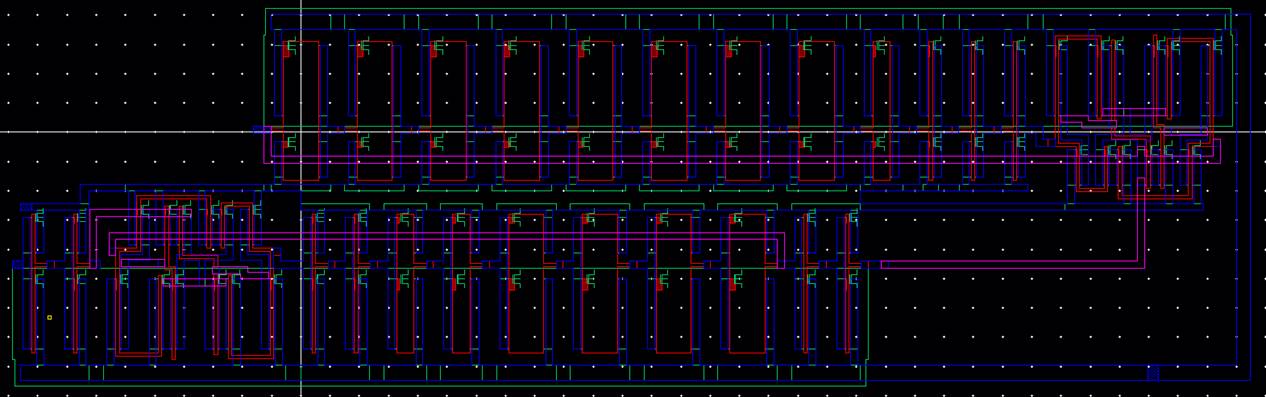

Extracted view:

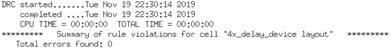

DRC Verified:

LVS Verified:

6.) Zipped Project Folder

(Download Link)

Left-click image to download the FULL .zip of this project.