Designing a

Band-Gap Voltage Reference

EE 420L

Engineering Electronics II

Author:

Matthew Meza

Email:

mezam11@unlv.nevada.edu

May

8th, 2015

Project Guidelines and Requirements

Using

as many diodes, resistors, and capacitors as needed, along with two

CD4007 chips from the same production

lot

(see date code on the top of chip) to ensure current mirrors are

possible, design and build a bandgap voltage

reference

(BGR). Your report, in html, should detail your design considerations,

simulation results (using the models

you

generated in lab 8), and measured results showing the BGR's

performance (how the reference voltage changes

with

VDD). It

would be good, but it's not required, if you could also characterize

the BGR performance with

temperature.

Your report is due

at the end of lab on Friday, May 8. Access to your CMOSedu.com

accounts

will

be removed at this time.

Introduction to Voltage References

A voltage refernce is a

circuit used to generate a fixed voltage which

is often referred to as 'Vref'. The fixed

voltage 'Vref' is independent

of the power supply voltage (VDD),

temperature, and process variations. More

specifically, a bandgap

reference is a type of voltage reference which

uses both a proportional

to absolute

temperature (PTAT) quality and

a complementary

to ablsole

termparture (CTAT)

quality. When a voltage

reference has a PTAT quality

it means that the reference voltage

increases with increasing temperature; while

a voltage reference that has

a CTAT quality means that the refernece

voltage decreases with increasing

temperature. Since the

bandgap voltage reference incorporates both

qualities, the net change in the voltage

reference with increasing

temperature is ideally zero! Shown below is

figure 23.1 from "CMOS

Circuit

Design,

Layout,

and Simulation", by R.

Jacob Baker, which illustrates PTAT and

CTAT voltage references.

Design Considerations

For the Band-Gap Reference

(BGR) design, a diode-referenced

self-biasing circuit will be used for the CTAT

quality and thermal

voltage-referenced self biasing circuit will be

used for the PTAT quality. Ideally, a cascode

structure should be used

(higher output resistance) to force the same

current through each branch of of the

reference as seen below!

Unfortunately, only two

CD4007 chips can be used which significantly

limits the design since the BGR with the

cascode structure, shown

above, cannot be implemented! For this project

a regular current mirror must be used to

design the BGR which will

have reduced performance as compared to the

previously shown design. Shown below is the

BGR using a regular current

mirror where K = 8 which is the number of

diodes used in parallel. The two left most

branches (current mirror) is

referred to as a Thermal

Voltage-Referenced Self Biasing circuit which provides the

PTAT quality. Using K diodes

in parallel in the middle branch increases

the current flowing in the branch such that

the current flowing through

the reference is non-zero. The same effect

could be realized by increasing the

MOSFETS size on the leftmost

branch. The PTAT current generated from

the current mirror is then driven into

a resistive load R*L (PTAT

quality) and a diode (CTAT quality) to

create a voltage reference which ideally does

not change with temperature,

VDD variations, or process variations!

The hand calculations to find

the appropriate resistance value (R) and

length (L) can be seen below:

In our build and

simuluations, we used PNP BJT's which were grounded at

the base and collector instead of a diode.

Simulations

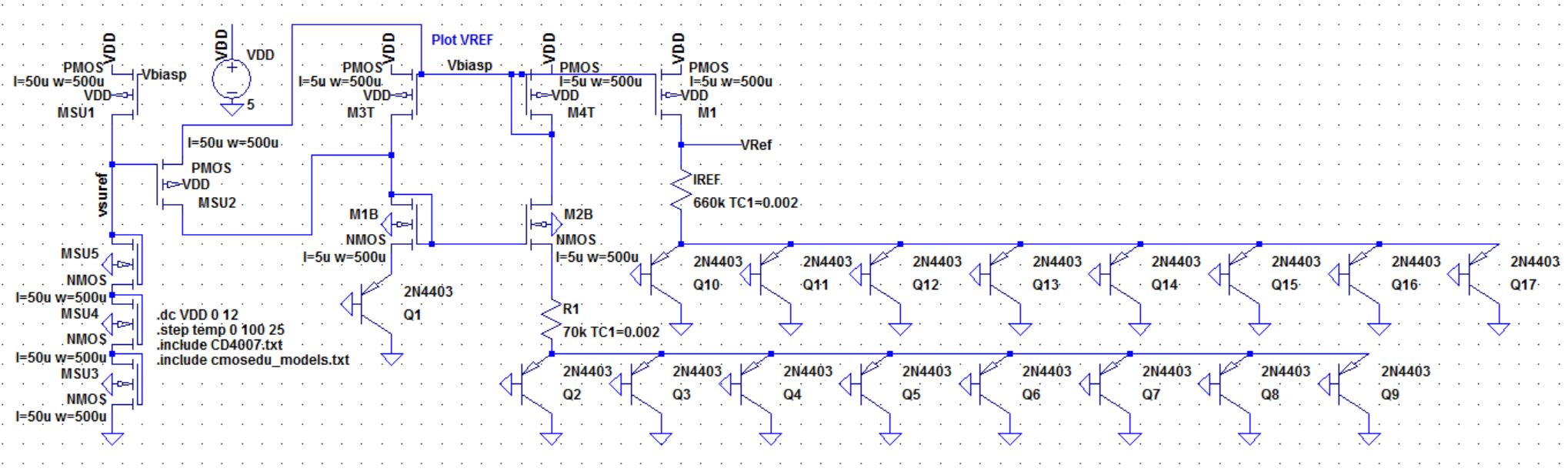

Below is our circuit in

LT-Spice along with simulations!

Click on this picture for the

full image!

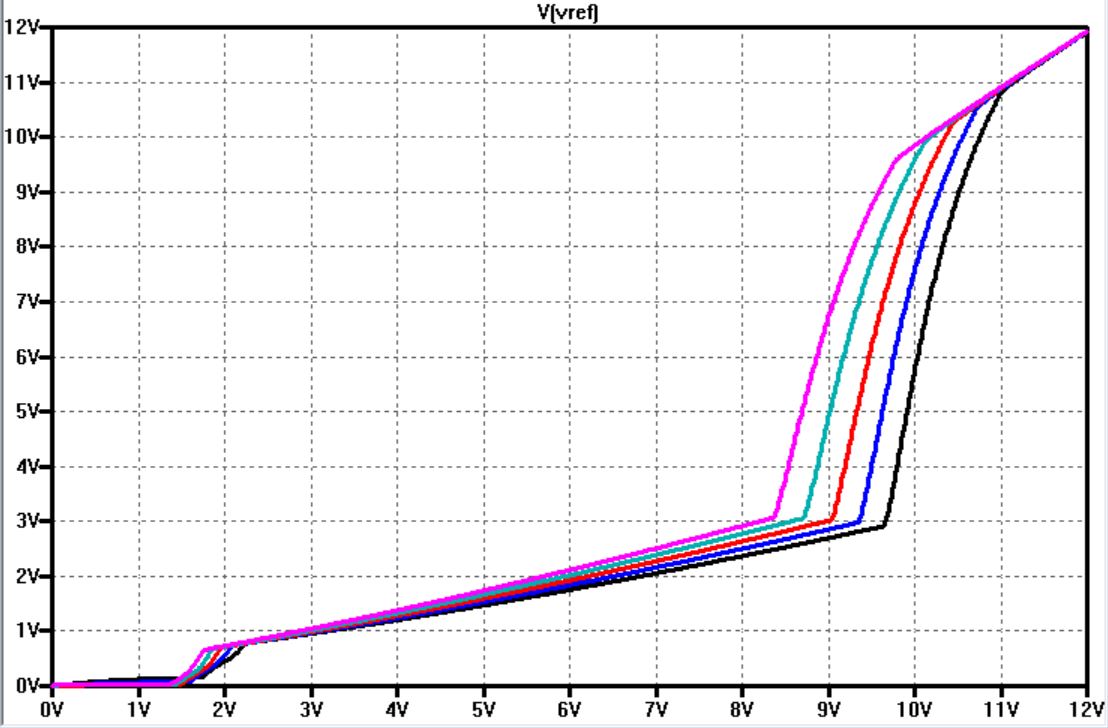

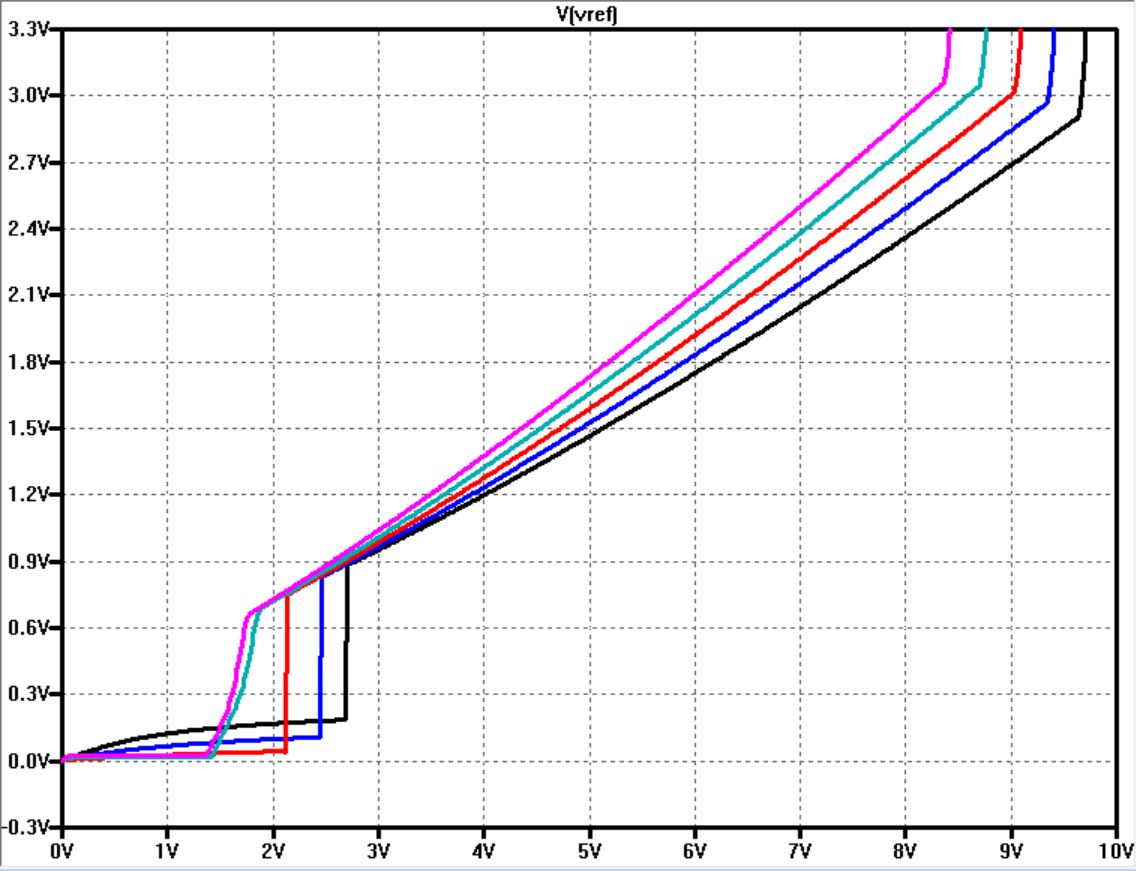

VREF

VS VDD

with variations in temperature

(click on pictures for full size)

|

VREF

VS VDD

ZOOM

|

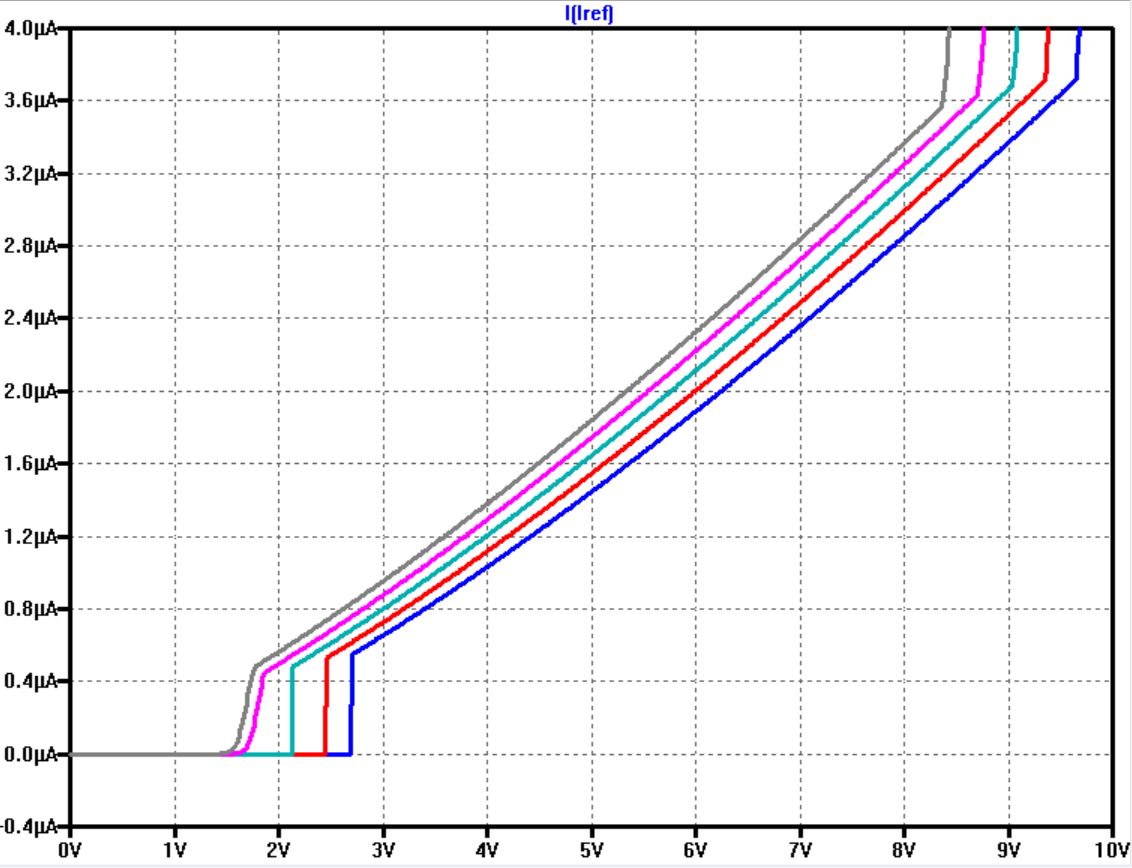

IREF

VS VDD

with variations in temperature

|

IREF

VS VDD

ZOOM

|

Note: The simulation models

must have a lambda value to be accurate. A

lambda value of 0.5 was used in the model.

From our simulation results

we see the voltage reference changes

approximately 282mV per 1V increase in VDD!

In addition, from simulations

we see that the current changes

approximately 442nA per 1V increas in VDD!

Experimental

Shown below is a picture of

the built BGR circuit. Notice the big blue

resistor on the top right; it is used as a

start up circuit by leaking a

small amount of current into the NMOS

gates so that the BGR circuit is in operation.

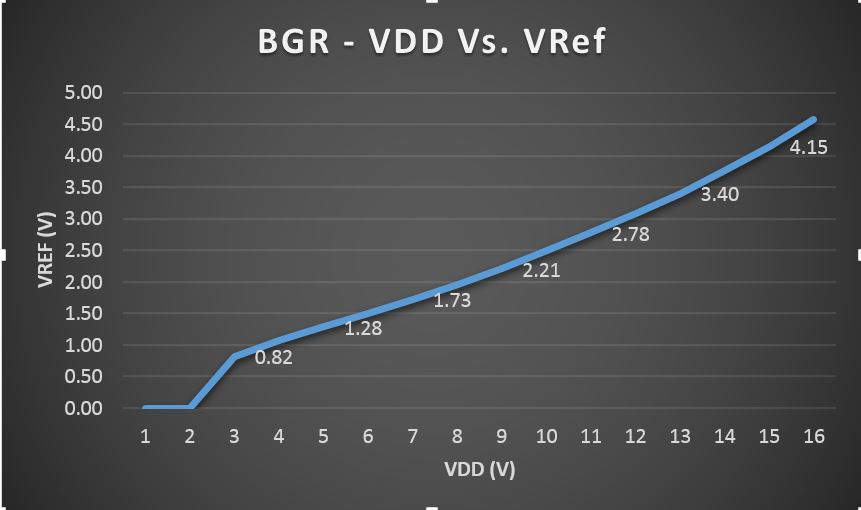

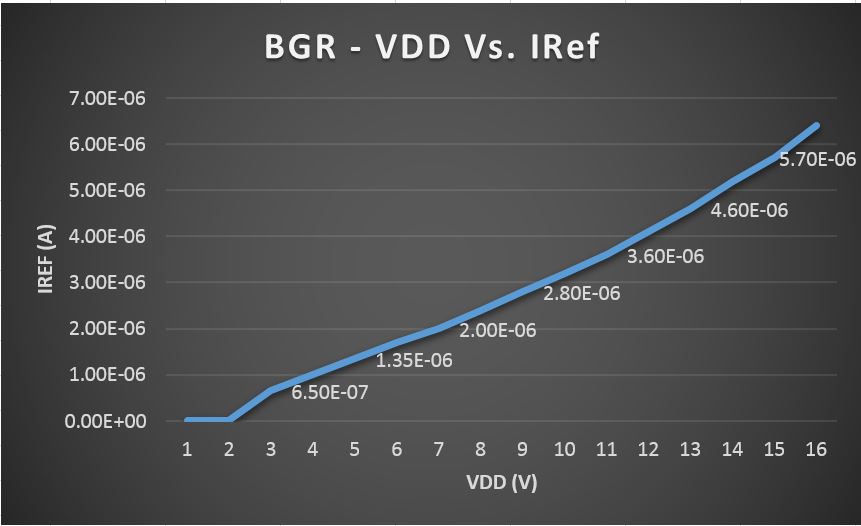

After measuring the voltage

and current for several VDD, we graphed the

data in Excel.

The graph below plots the

changes in Vref with varying VDD. From our

experimental data, Vref increases

approximately 220mV per 1V in

VDD. This is better than our simulation

value!

The graph below plots the

changes in Iref with varying VDD. From our

experimental data, Iref increases

approximately 350nA per 1V in

VDD. This is also better than our

simulation value!

Conclusion

Although the changes in VRef

and Iref are not as small as we would

like, we can see first hand that the BGR does

work. Being limited to only 2

CD4007 chips definitly inhibits the

possible performance of the BGR. As stated

above, it would be ideal to

have a cascoded current mirror for a higher

output resistance. Nonetheless, the project

proved to be helpful in

seeing how process variations can also change

the performance of a BGR. Overall I score

this Lab-Project a 10/10.

Return

to EE 420 Labs