![]() Wire Bonding

Wire Bonding

Technician

Craft

Produced by Daniel Senda

†

Page Information

∑

This page is intended to

demonstrate some wire bonding jobs that Daniel has done while working in the

Dr. Baker Research Group.

∑

Wire bonding is the process

of connecting a chip to a package using thin gold wire. Before the process can

begin, the chip must be adhered to the package, which is usually done by gluing

the chip to the package. At times, it is easier to solder the package to the

PCB before adhering the chip to the package. Also, there are some occasions

when the chip is adhered directly to the PCB (chip-on-board setup).

∑

The wire bonding machine

that the group uses is the K&S 4500 Series manual wire bonder (Model 4526).

∑

The next step is to secure

the chip and package to a work-holder and set it up on the wire bonding machine.

Also, the wire bonding machine needs to be adjusted to the correct parameters.

Once the adjustments are completed, the wire bonding can begin.

∑

Below are a few pictures

that show some finished jobs.

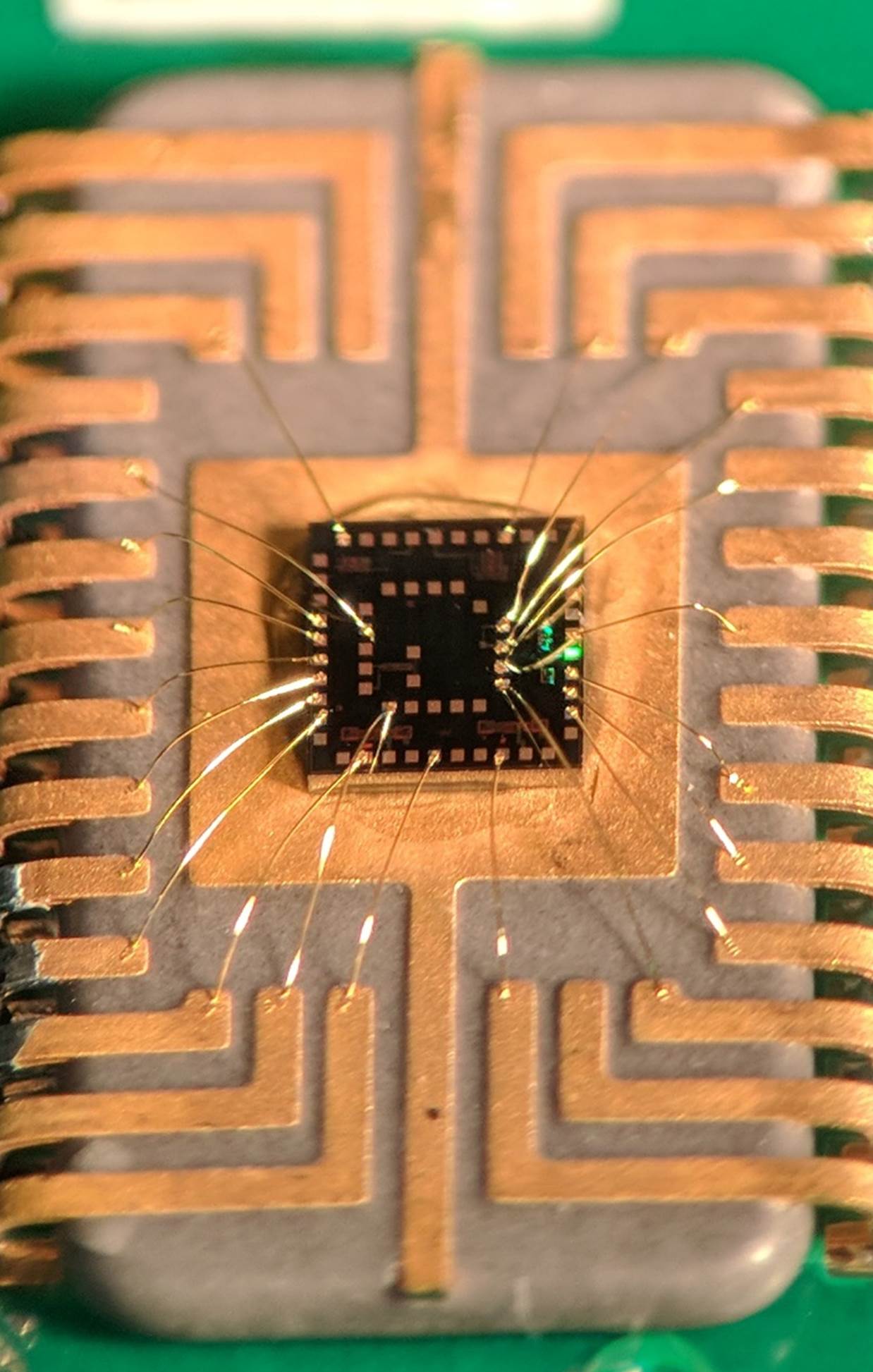

SSOP-28 Package Wire-bonded Chip

(First Official Wire-bonding Task)

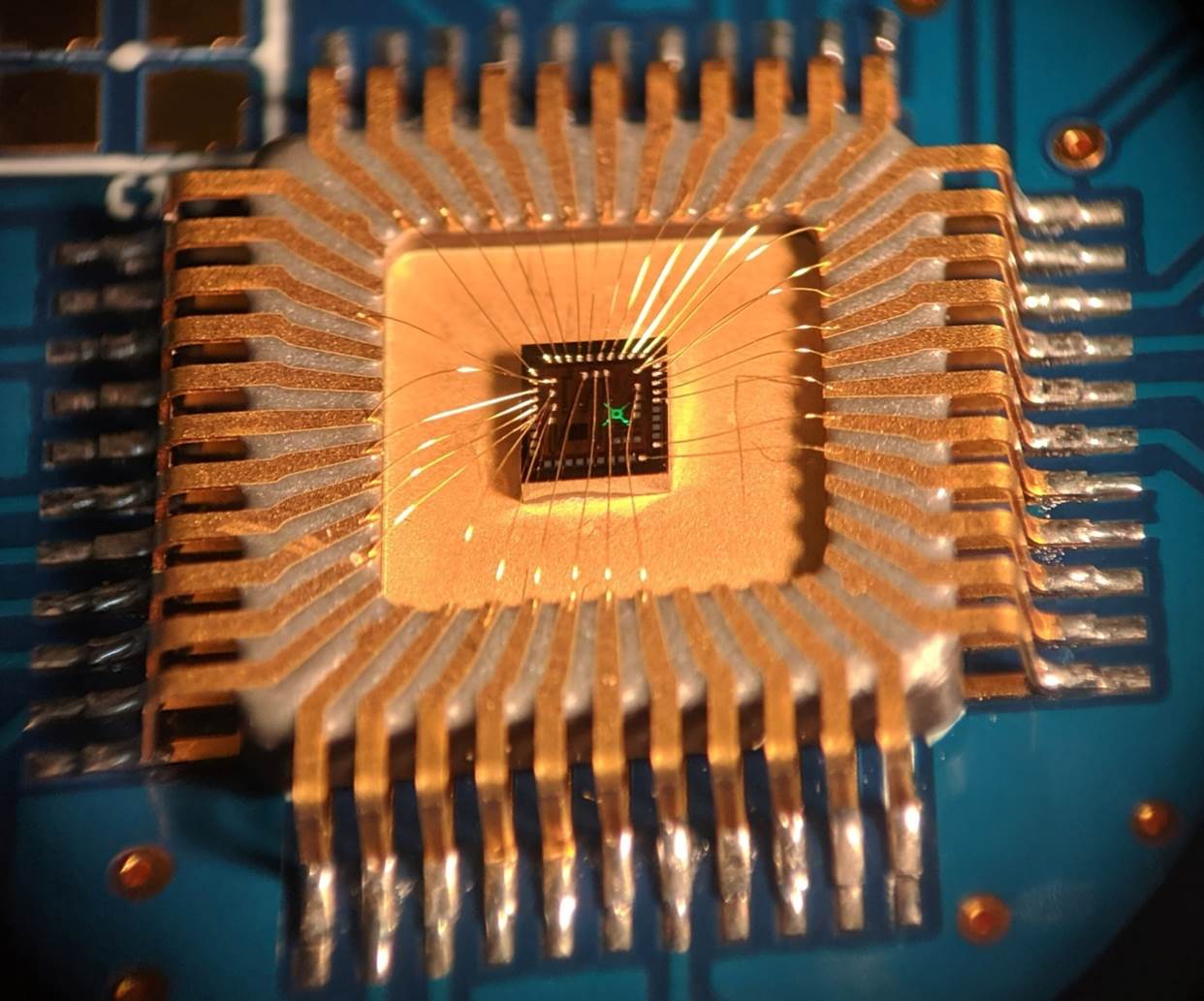

44-Pin Package Wire-bonded Chip

(Voyager VDDN)

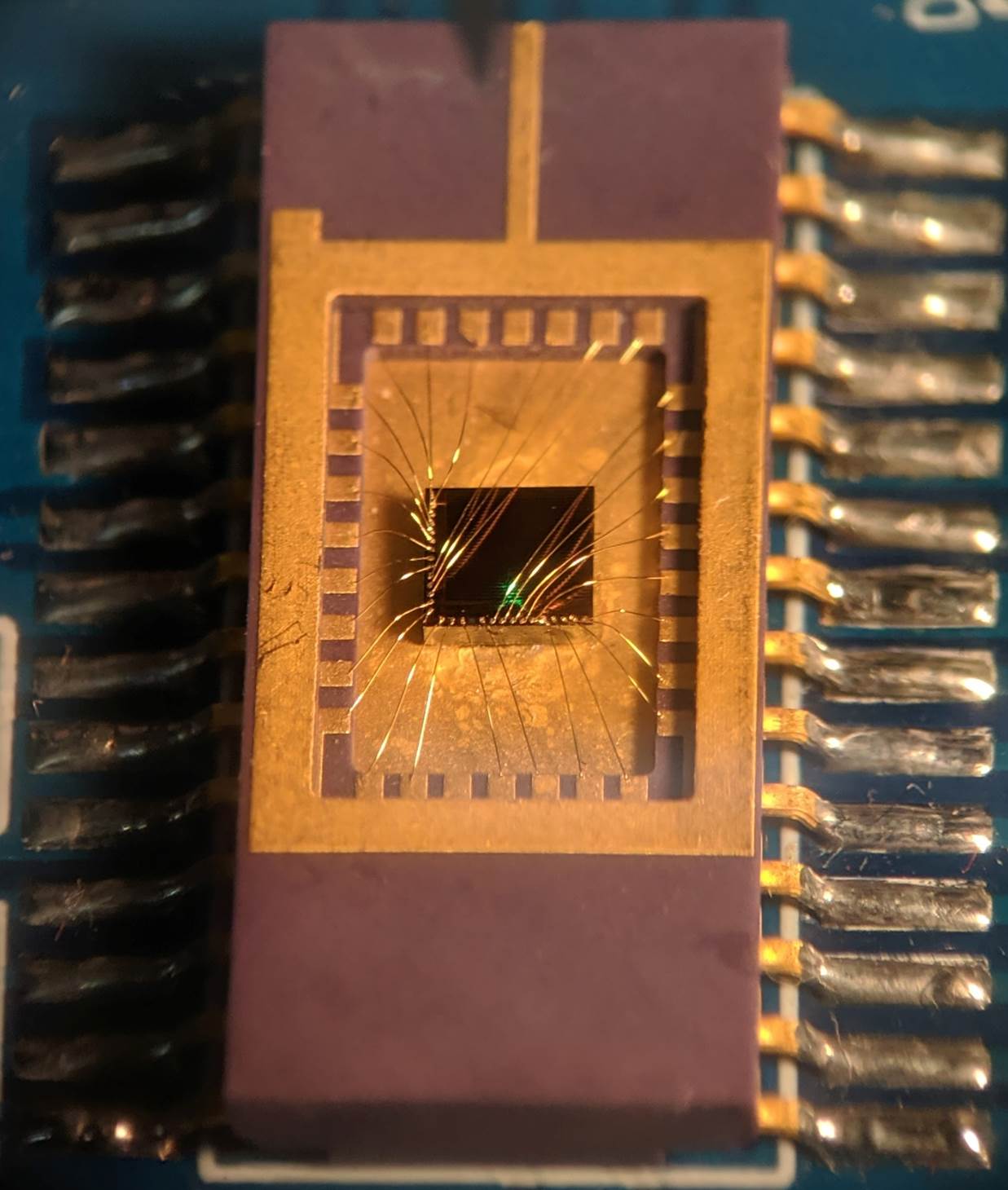

SOIC-28

Package Wire-bonded Chip

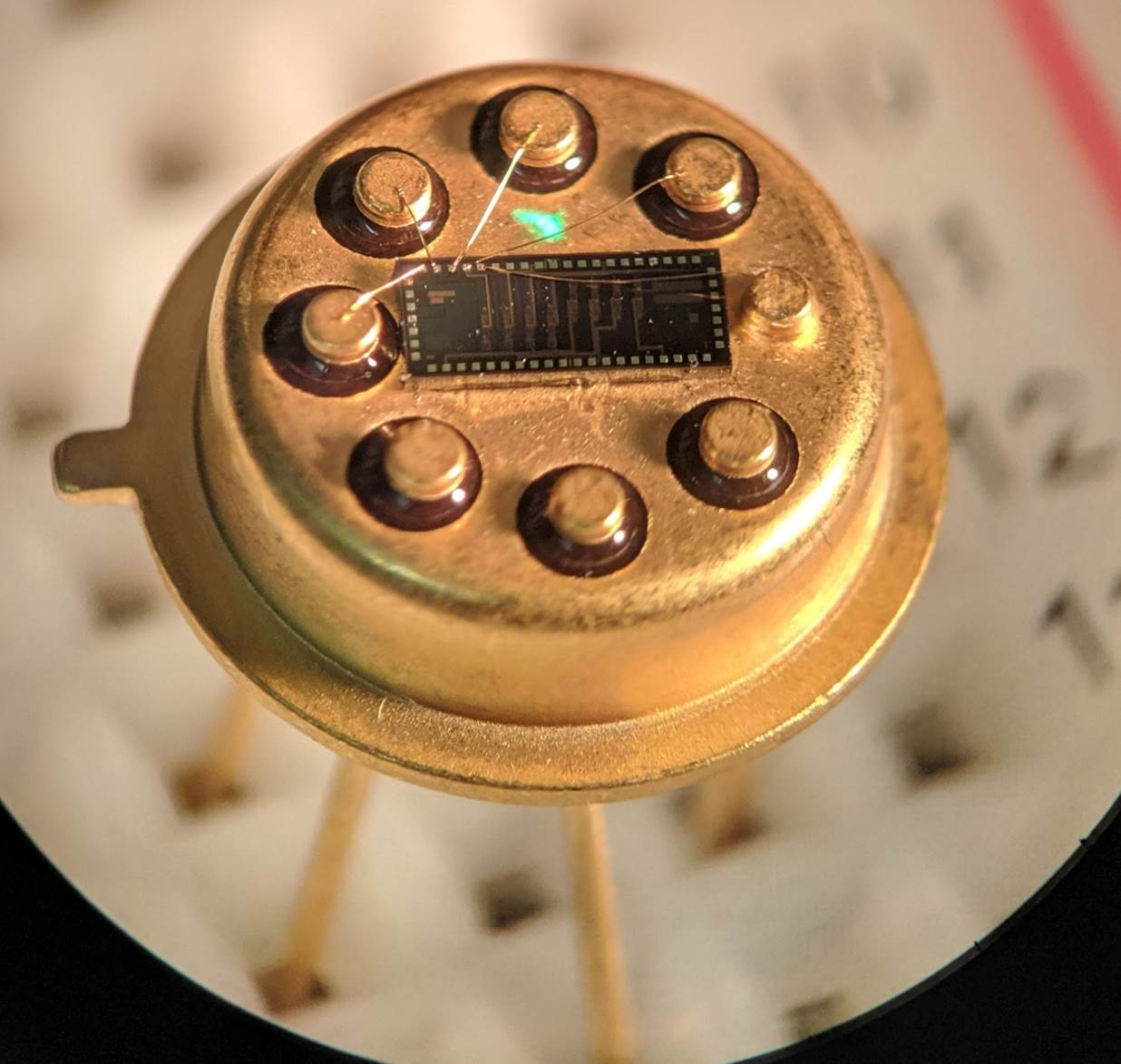

TO8

Package Wire-bonded Chip

Additional Links

††††††††††† →

Return to Danielís main page